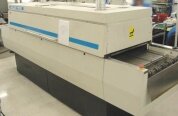

Used HELLER 1500S #159404 for sale

URL successfully copied!

Tap to zoom

ID: 159404

Reflow oven

Mesh belt conveyor:

Conyevor height from floor: 35" + 3/-2"

Maximum PCB width: 22"

Conveyor length on-load: 18"

Conveyor length off-load: 18"

Heated tunnel length: 72"

Conveyor speed control: closed loop

Process clearance above mesh belt: 2.3"

Edge Hold Conveyor:

Power width adjustment: S

Computer width adjustment: O

Clearance above conveyor pins: 1.2"

Clearance below conveyor pins: 1.2"

Length of board support pin: 0.15"

Minimum / Maximum board width: 2.21"

Forced convection zones:

Top: 5

Bottom: 5

Heater type: Instant response open coil

Warm up time from cold start: 15 minutes

Profile change time: <5 minutes

Temperature Control:

Accuracy of temperature: +/- 1°C

Cross-belt temperature tolerance: +/-1°C

Heater wattage per zone: 6000 W

Temperature range standard: 25-300°C

High temperature up to 350°C

UV Cure

Cooling system:

Number of internal cooling zones: 1

External cooling zone: 0

Water cooling: -

Electric Supply:

Power input (3 Phase) Standard: 208 or 240 volts

Warm up current: 100 amps @ 208 V

Run current: 45 Amps @ 208 V

Optional inputs available: 380/400/415/440/480V ac

Frequency: 50/60 Hz

Sequential zone turn on: S.

HELLER 1500S is a reflow oven designed for in-line production processes in the electronics assembly industry. It is an advanced SMT reflow oven that provides superior process control, accuracy, and repeatability over a variety of soldering applications. 1500S is a forced convection reflow oven that provides excellent heat transfer and uniform heating for any type of SMT solder paste. It has a maximum heat capacity of 1400 degrees C (2550 degrees F) with a temperature accuracy of +/- 2%, meaning that it is ideal for small batch production as well as large production runs. The oven comes equipped with 16 independent zones, each of which can be programmed for heating and cooling. This ensures that every component within a product is heated accurately and consistently, allowing for rapid reflow. HELLER 1500S utilizes a revolutionary Production management system (PMS) that provides insight into production costs, process data and equipment operations. The PMS allows users to monitor the progress of the oven throughout the production process, enabling operators to adjust parameters, if needed, in order to ensure the highest levels of quality. 1500S also features an intuitive user interface, advanced data logging, and customized process settings that allow operators to optimize the reflow process. HELLER 1500S reflow oven also offers a nitrogen reflow capability, which reduces the risk of oxidation and provides a clean and consistent working environment. It is equipped with a semi-automated conveyor system, allowing for quick and safe product handling. In addition, 1500S incorporates an advanced cooling system, designed to minimize thermal stress and maximize the reliability of mechanized assemblies. Overall, HELLER 1500S is an ideal choice for any application that requires precise and repeatable soldering. It is designed for maximum efficiency and safety and provides consistent and reliable thermal results. With its state of the art technology, 1500S offers enhanced productivity and cost-efficiency, making it the perfect solution for any SMT production line.

There are no reviews yet