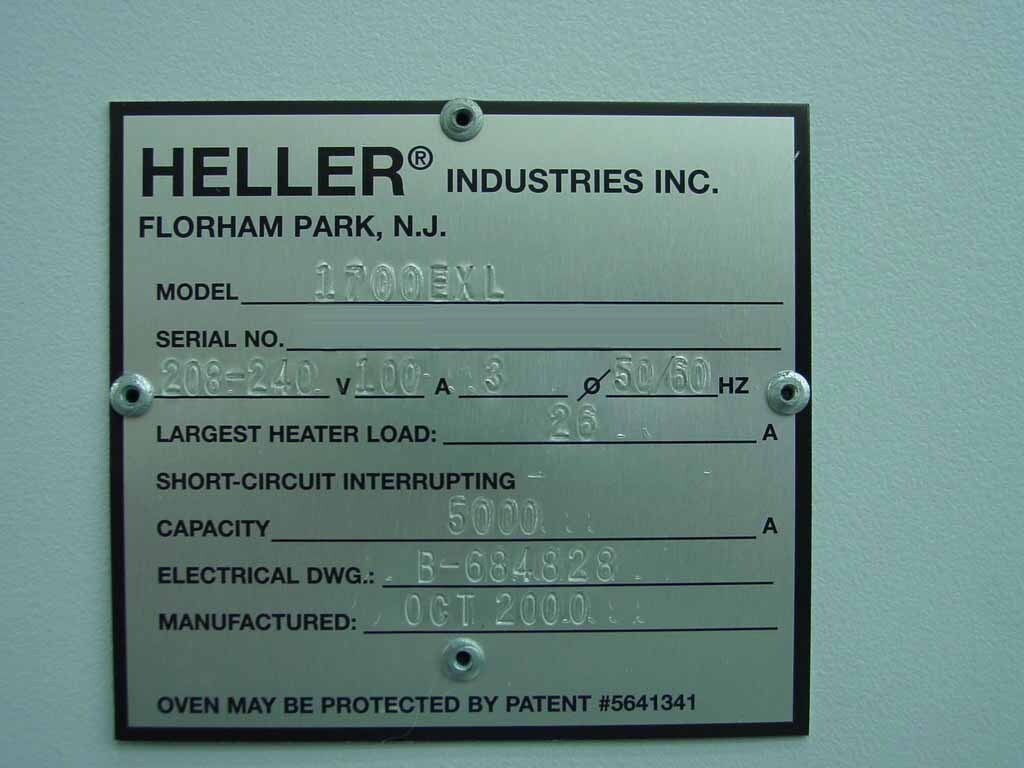

Used HELLER 1700EXL #9068802 for sale

URL successfully copied!

Tap to zoom

ID: 9068802

Vintage: 2000

Reflow oven

Edge rail with mesh belt

Air machine

Flow direction: Left to right

(14) Heating zones

Hours: ~23,100

Power supply: 440V, 60 Hz, 3 Phase

2000 vintage.

HELLER 1700EXL is a powerful, self-contained, precision reflow oven for use in high-volume production of a variety of products. This model oven has been designed to meet the needs of a demanding production environment with its many advanced features and reliable performance. This model oven has an overall peak power output of 3500 W with an average temperature range of 100°C to 400°C. The oven's well-defined thermal profile, along with the finely controlled thermal zones, allows for accurate and tight temperature control. This ensures uniformity and repeatability in the reflow process. HELLER 1700 EXL model features three independent heating zones and a programmable cooling zone, which allows manufacturers to fine-tune their thermal profile for maximum impact and repeatability. The machine's built-in programmable memory enables the user to store up to 100 individual process cycles. Also, HELLER oven's data log capabilities allow process-monitoring and will provide highly accurate records of how a specific process/cycle has been running. The operator can easily monitor both machine and process data via the full-color touch display which provides an easy to use interface to optimize parameters for the reflow process. 1700EXL oven also provides a wide choice of process temperature and timings that can be used to fine-tune the reflow process. The user is able to tailor the thermal profile to a particular process as well as repeat the same process multiple times. This particular machine can also be used in both manual as well as automated mode. The manual mode allows the user to adjust temperature and time per segment while the automated mode will allow the user to set the full process cycle and just entering a start time and end time. Additionally, 1700 EXL may be used with an optional nitrogen environmental control system which is capable of safely producing a 99.999% pure nitrogen atmosphere to minimize oxidation of the components and materials during the reflow process. Overall, HELLER 1700EXL model is a reliable and robust reflow oven designed to meet the need of high-volume production applications. It has been designed to deal with the toughest challenges that reflow processes present offering maximum repeatability and thermal uniformity within the oven. This precision oven provides a wide array of functions, including an advanced touch screen interface, adjustable temperature and timing parameters, and an advanced cooling system, all of which contribute to the efficient production of superior quality products.

There are no reviews yet