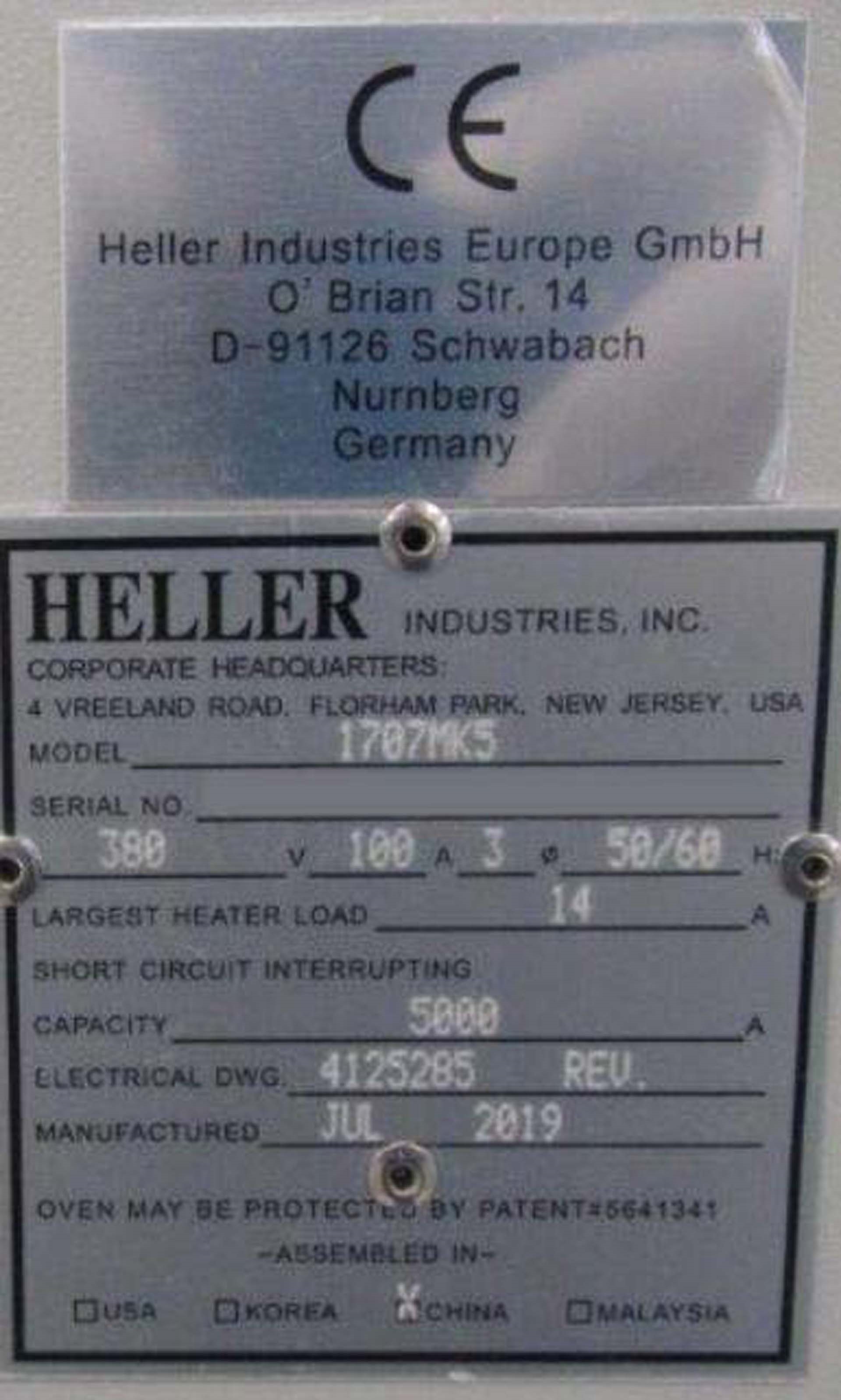

Used HELLER 1707 MK5 #9262614 for sale

URL successfully copied!

Tap to zoom

ID: 9262614

Vintage: 2019

Reflow ovens

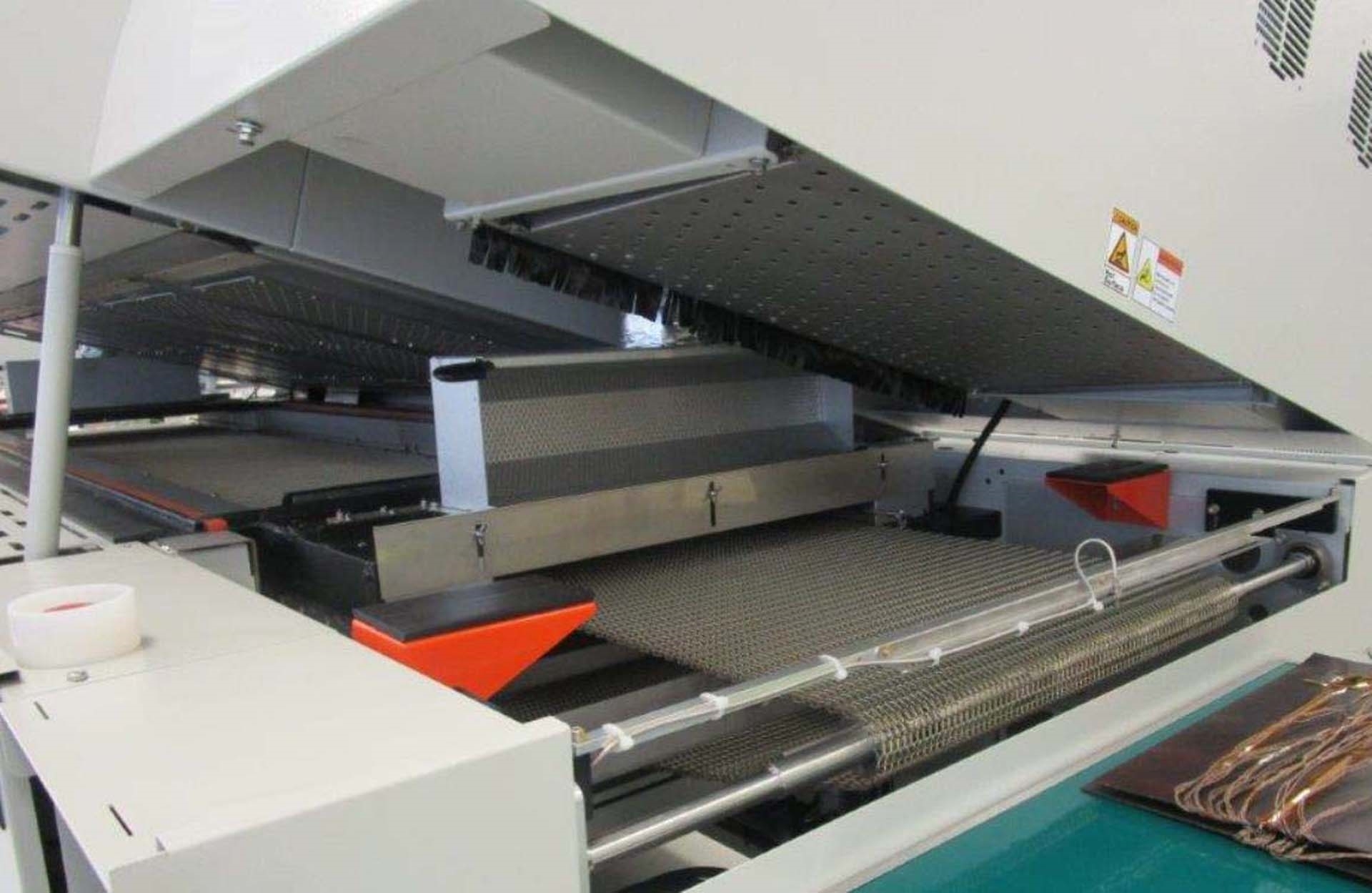

Forced hot air convection oven

N2

(7) Heating zones: Top and bottom

Cooling zone top

Top heated tunnel length, 70"

Battery backup with hood lift

SMEMA Interface

Audible alarm

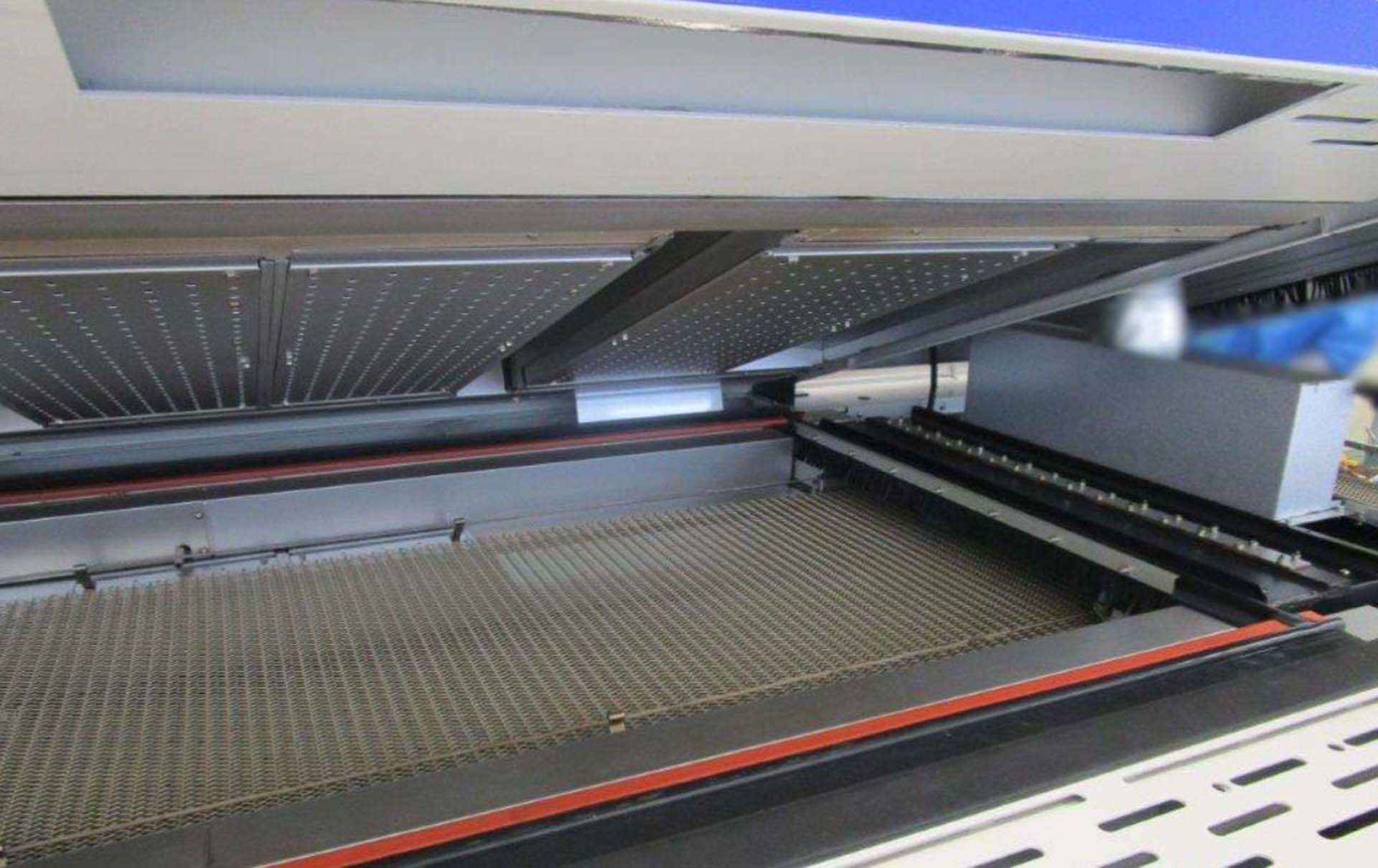

Mesh belt (Woven mesh belt selected)

Nitrogen inert operation

Low Nitrogen consumption kit

Water less cooling

Flux separation: Generation 5.2

Nitrogen On/Off switch: Computer control

Conveyor travel direction: Left to right

Blower and heater

Signal light tower: (3) Lights

No edge hold conveyor

Options:

FSC-H- Fan speed control of heated zones

FSC-C- Fan speed control of cooling zone

Nitrogen closed loop control without display

HELLER P/P Valve

Off-load, 12"

Energy Management System (EMS)

Exhaust monitoring

Woven mesh belt

GEM/SECS Host computer interface

Fan failure detection

KIC RPI System

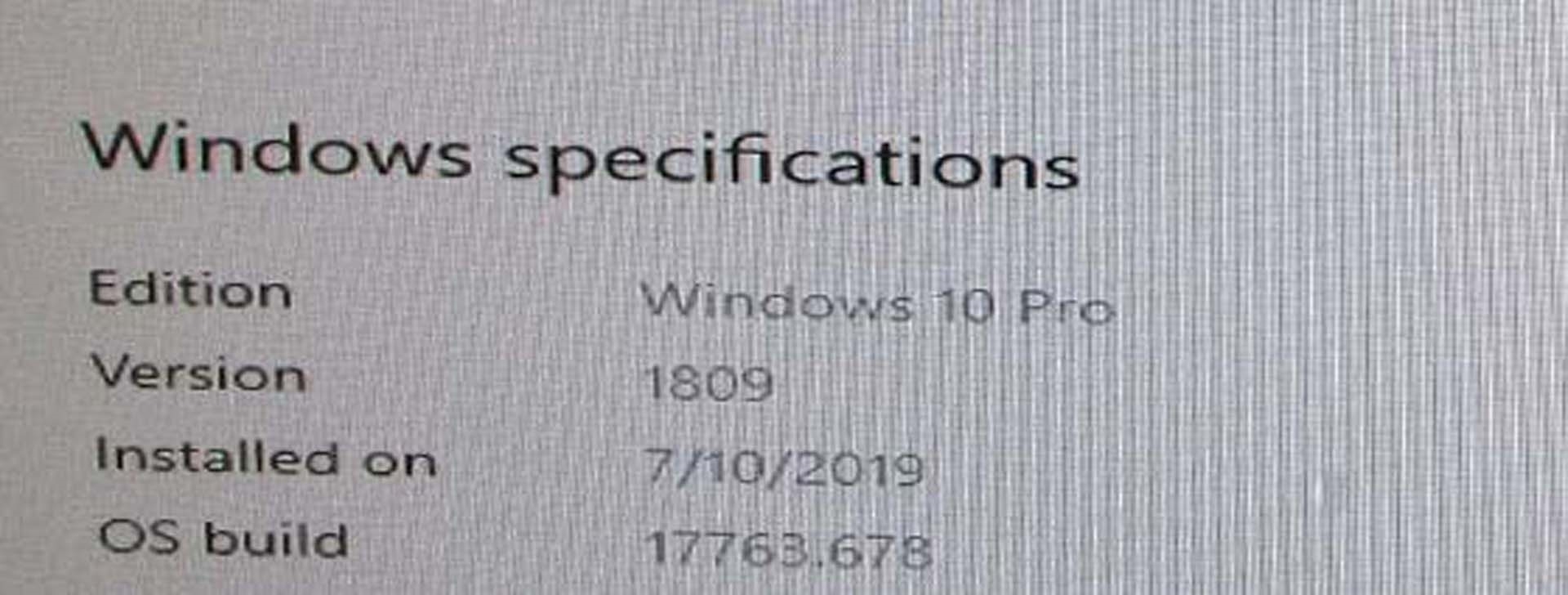

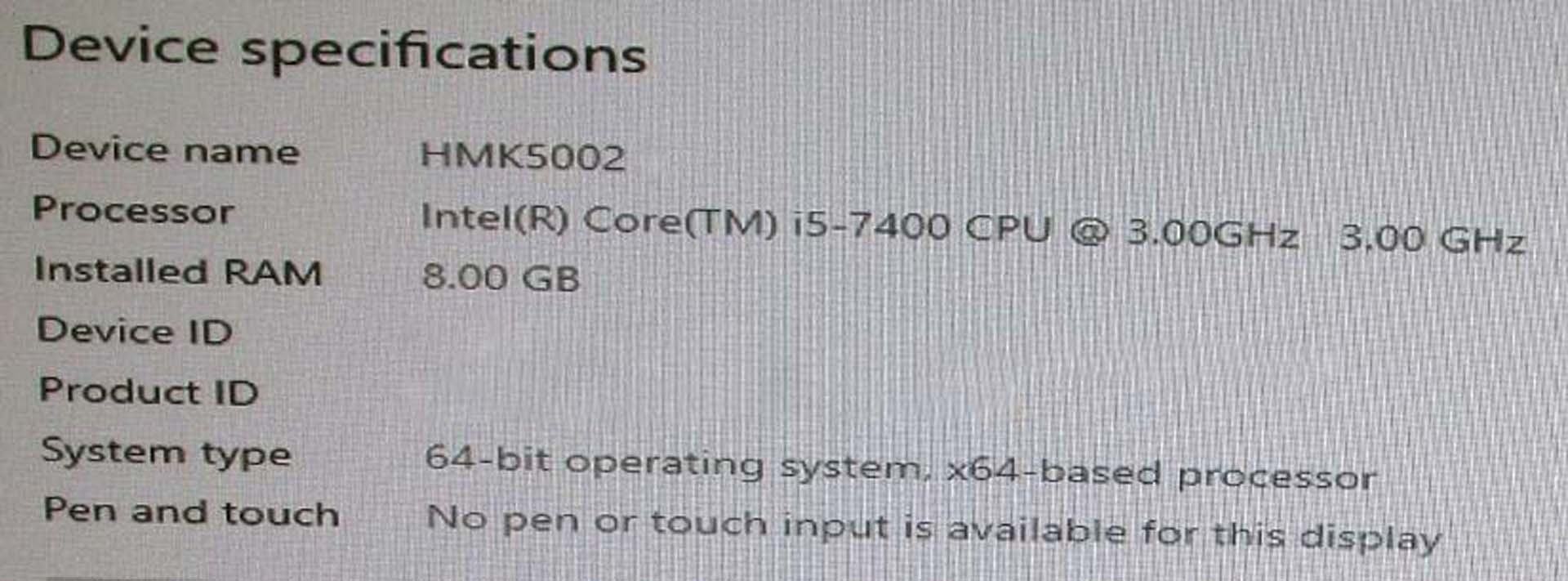

Operating system: Windows 10 Pro Edition

External Cooling Module (ECM)

CE Compliance

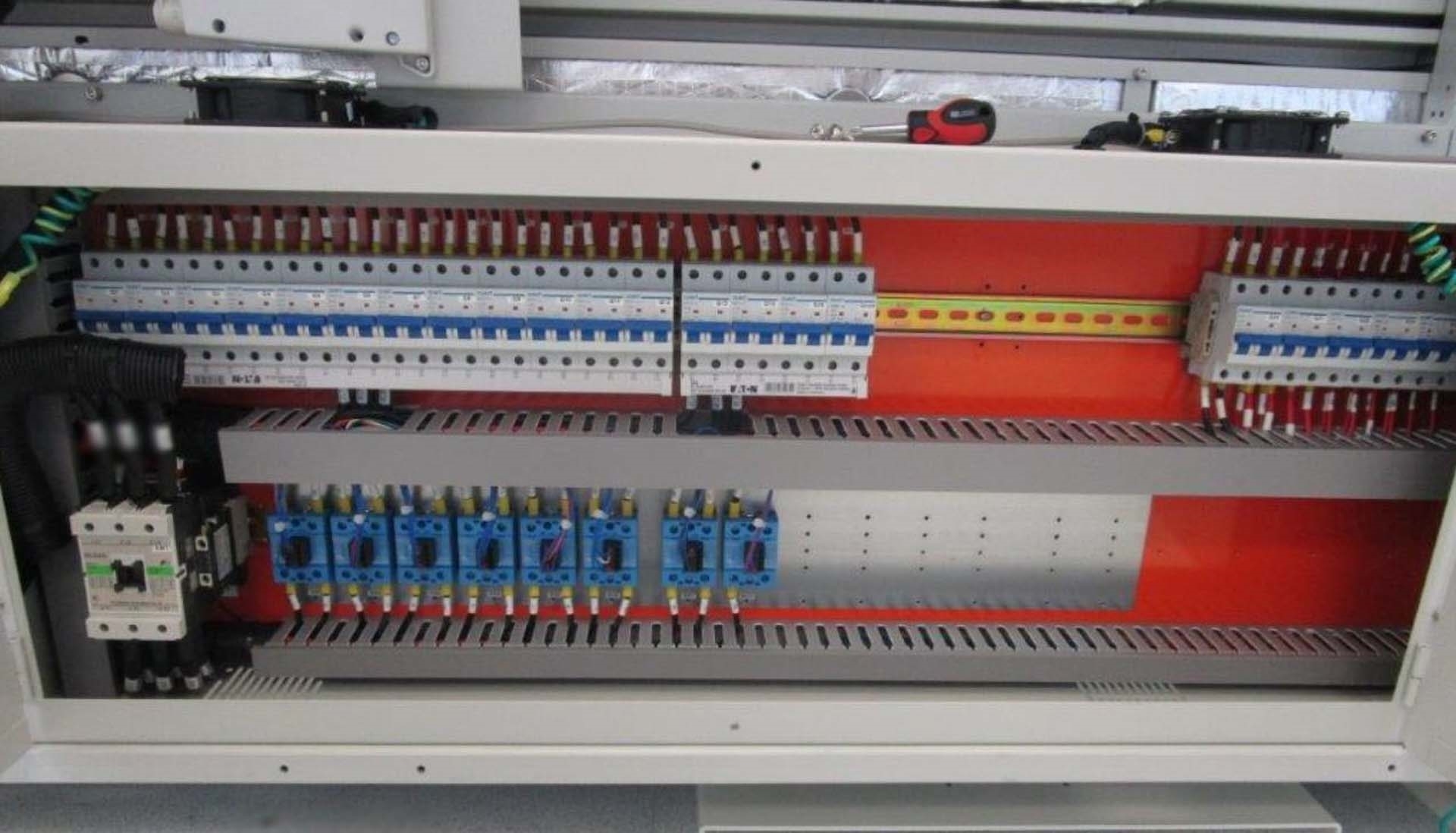

Power: 380 V, 3-Phase

2019 vintage.

HELLER 1707 MK5 Reflow Oven is a professional-grade convection thermal oven, designed for soldering components on PCBs in a wide range of production environments. It is suitable for use with standard lead-free and lead-containing alloy materials, including SAC alloys, Pb-free alloys, Sn-Ag alloys, and other low-temperature alloys. This reflow oven is easy to use and offers an intuitive operation system. The reflow oven is capable of working with peak temperatures of up to 300 °C and has a generous temperature range that allows for complete design flexibility and safe operation. The even temperature distribution of the system ensures an optimal reflow process for a wide variety of components. Additionally, the circulation design of the air bath ensures an even heat distribution through the entire machine, resulting in a more reliable and repeatable soldering process. Furthermore, the adjustable hot dust filter helps prevent contamination of the flux, ensuring precision and optimal soldering results. HELLER 1707MK5 also features a variety of convenient control options. The intuitive touchscreen allows users to access and adjust reflow parameters, including temperature curves, belt speed settings, temperature profiles, and other settings. The oven also features customizable profiles, memory storage, recipe management, data logging, remote monitoring, and much more. Additionally, with its third-party connectivity options, this reflow oven is compatible with PC or SCADA systems. For added safety, 1707 MK5 Reflow Oven is equipped with multiple safety systems to ensure optimal performance and protect operators from possible accidents. The built-in cool-down mode and temperature sensor alarms allow the operator to actively monitor the temperature while adjusting parameters. It also includes a door-interlock system and robust design features that prevent sparks or fire during operation. 1707MK5 Reflow Oven is ideal for high-volume production applications, offering advanced features and convenient design for optimal results and user protection. Its even temperature distribution and adjustable hot dust filter ensure precise soldering and safe operation, while its intuitive touchscreen and customizable profiles make it simple to operate and achieve consistent results each time.

There are no reviews yet