Used HELLER 1809 MKIII #293670436 for sale

URL successfully copied!

Tap to zoom

ID: 293670436

Vintage: 2009

Reflow oven

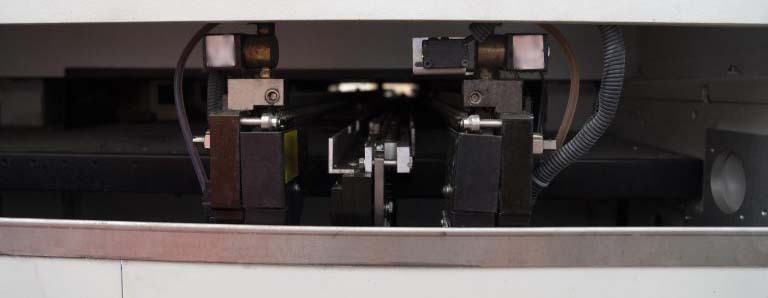

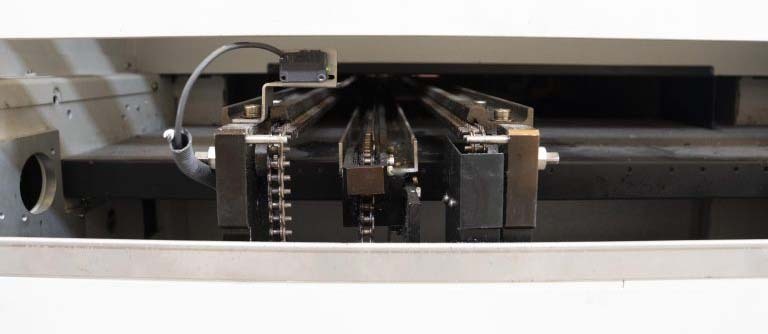

PCB Chain transport

Central support system

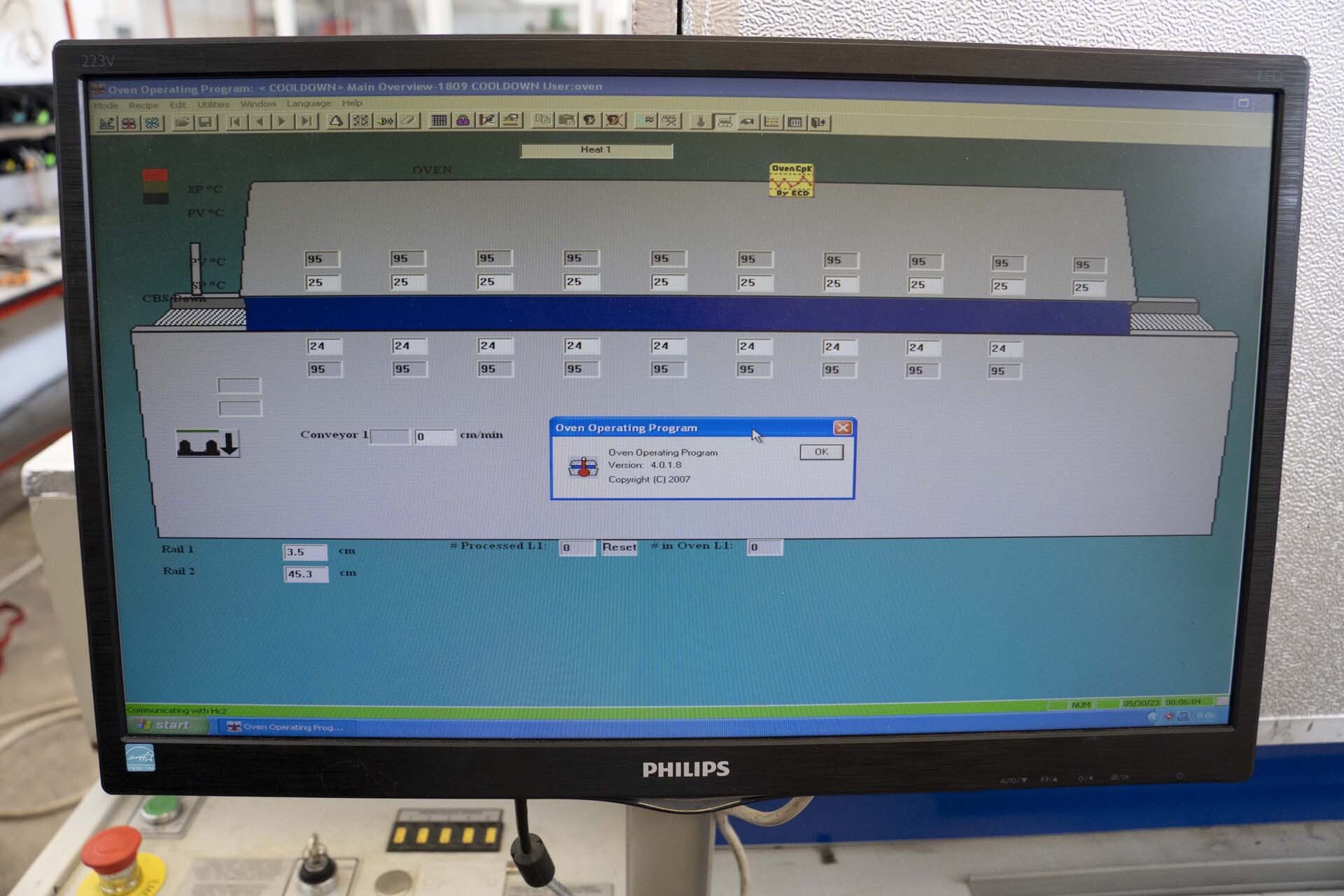

Heating system: Top / Bottom

Heating zone 9: Top / Bottom

Cooling zone: Top

Power supply:

Power input standard 480 Volts (3 Phase)

Breaker size 100 Amps at 480 V

Continuous: 7.5- 16 kW

Typical run current 30-35 Amps at 480 V

Sequential zone turn on dimensions 50 /60 Hz

2009 vintage.

HELLER 1809 MKIII Reflow Oven is an upgraded version of the original HELLER 1809 Reflow Oven. It is designed for batch reflow soldering of PCBs (Printed Circuit Boards). It has a temperature accuracy of ±2°C with an increased thermal homogeneity of ±2°C over some of its predecessors. The MKIII is also capable of heating in 25°C steps up to 450°C and can hold a steady high temperature for an extended period of time. The MKIII is designed for a production environment, providing superior process time consistency and repeatability. HELLER 1809 MK III Reflow Oven is a dual zone reflow oven. It features a separate preheat zone that delivers a consistent preheat temperature profile, enabling quick entry to the reflow zone. This zone is designed to reduce oxidation and soak time while also decreasing cummulative energy consumption. A powerful air delivery equipment generates a three-dimensional vertical convection of air throughout the oven chamber. This ensures uniform heat transfer throughout the entire space while also helping to minimize temperature gradients. The air delivery system also powers multiple cooling options, allowing the option of a quiescent airflow, jet fan cooling, or a combination of both. 1809 MKIII's process control unit features Auto-Tune Plus technology, which automatically configures the oven parameters based on the data gathered during the machine setup. This provides a quick and easy way to customize the reflow profile with consistent performance. The tool includes real time monitoring of temperature and other data points for improved process visibility. 1809 MK III includes multiple safety features, such as an O 2 monitor and halogen gas leak detection. The O 2 monitor ensures proper balance of O 2 and N 2 to protect components from oxidation, while the halogen gas leak detector monitors for CHFINE and prevents any gas exposure to the components or electronics. The conveyor asset also features multiple automatic safety interlocks and a wide range of adjustable conveyor speeds. HELLER 1809 MKIII is an impressive reflow oven and is ideal for PCB production. Its advanced design ensures reliable and repeatable solder reflow with consistent performance, while its safety features ensure that no components are damaged by gas or oxidation. The Auto-Tune Plus model ensures quick setup process times, and its powerful air delivery equipment ensures consistent heating and cooling rates. Together, HELLER 1809 MK III provides a highly accurate and efficient reflow solution.

There are no reviews yet