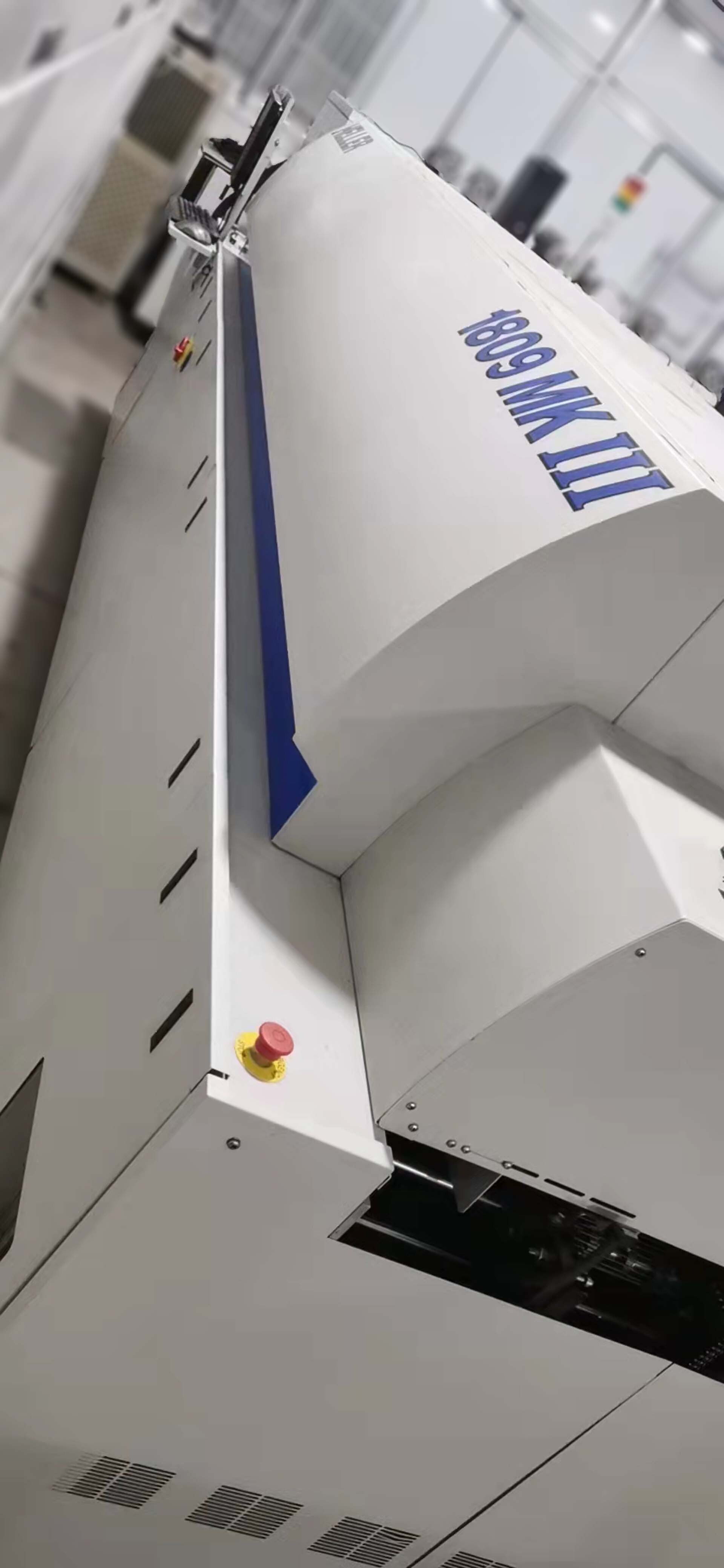

Used HELLER 1809 MKIII #9412374 for sale

URL successfully copied!

Tap to zoom

HELLER 1809 MKIII Reflow Oven is a high performance reflow oven designed for electronic assembly and soldering. This precision oven offers precise temperature control and quality assurance during manufacturing. It features an internal conveyor belt which moves printed circuit boards (PCBs) along the full-length of the oven while they undergo the reflow process. HELLER 1809 MK III Reflow Oven's advanced micro-processor control equipment allows precise temperature settings and a range of pre-programmed reflow profiles to suit any product assembly. It is easy to setup and maintain with a user-friendly colour touch screen interface, while the 5-zone mechanical convection air flow system ensures consistent distribution of hot air across the boards. The flexible air-flow control unit can be set to meet specific needs, i.e. top or bottom heating, as well as heavy or light product loading and varying types of printed circuit boards. This high-performance reflow oven is capable of reaching temperatures of up to 300°C with a temperature uniformity and stability of +-1 to 2°C. It is powered by 208V and has a power input of 24 kW. 1809 MKIII Reflow Oven also includes both manual lock and auto shut-off safety features. The manual lock prevents the oven from opening while it is in operation, while the auto shut-off feature automatically powers down the oven once the reflow process is completed. Other features include a built-in self-diagnosis machine, which allows operators to identify and correct common problems. 1809 MK III Reflow Oven is suitable for a wide range of printed circuit boards and applications. Its extended temperature range and advanced profile control capabilities make this oven ideal for both prototyping and mass production. It is fast and efficient, reducing cycle time and allowing for a greater throughput of products. Additionally, this oven includes patented low-emission design and no-clean capabilities, ensuring a clean and safe operation environment.

There are no reviews yet