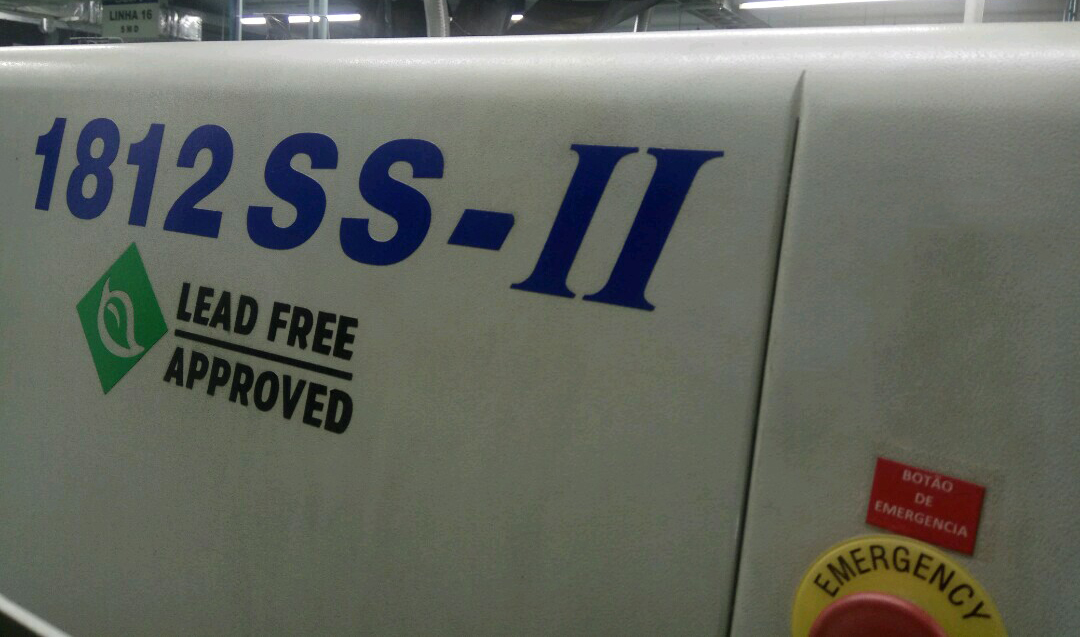

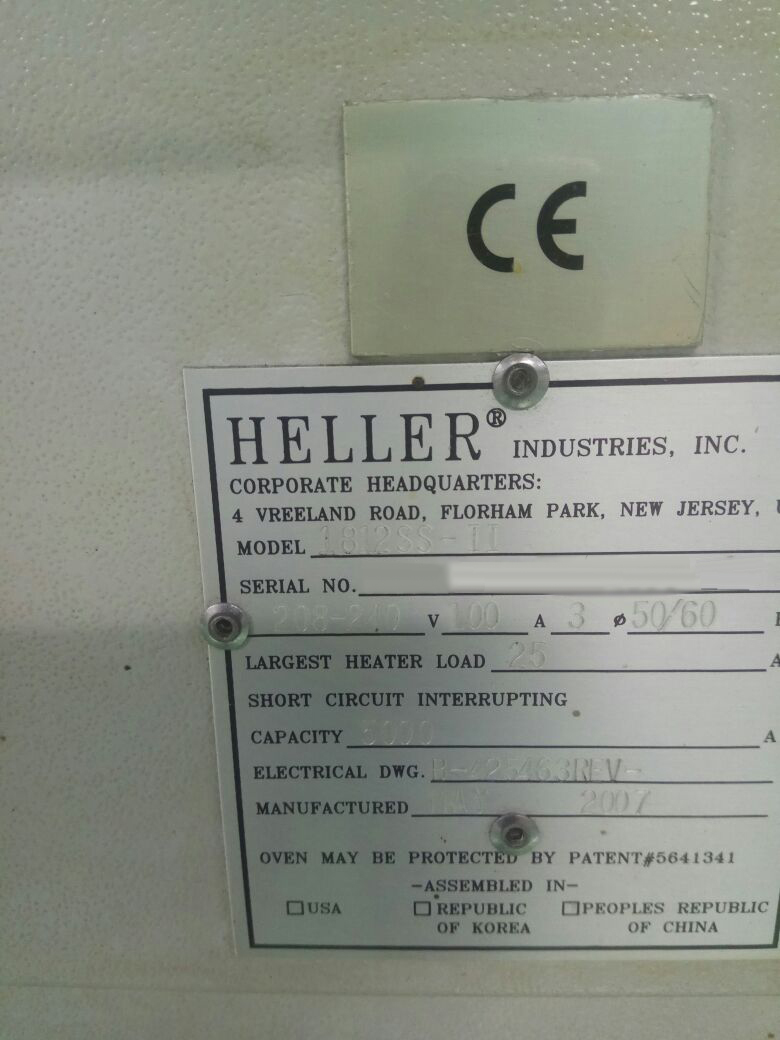

Used HELLER 1812SS-II #9174296 for sale

URL successfully copied!

Tap to zoom

HELLER 1812SS-II is a state of the art precision reflow oven designed for production of printed circuit board assemblies (PCBA). The industrial oven is suitable for low to medium-volume manufacturing of PCBA with the use of Lead-free or Leaded solder paste. It has a large capacity of 142 standard PCBs of 50x50mm size. HELLER reflow oven is designed with integral convection based on a stainless steel air impingement equipment which allows for consistent thermal profiles in the reflow zone. This ensures that boards of top quality are consistently produced. It provides the highest heat transfer rate to the board and simplifies maintenance and cleaning. Its control panel allows for programming of up to 64 programs and recipes to completely automate the process. The intensive graphical display of all parameters simplifies the setup and maintenance of the reflow oven. Its control legs and feet with adjustment screws made of metal ensure a stable platform. The interlocked door keeps the operator away from the oven during the welding process. Its 14-zone temperature profiling provides the highest level of accuracy and precision during the reflow process. The innovative RealHeat™ Oven Optimization System™ ensures that consistent quality is maintained and consistent temperatures are achieved across all zones at all times. The machine's 15-second heater cycle allows for quick process setup and changeovers. 1812SS-II reflow oven is also designed with an efficient temperature control unit that utilizes hot air jets to maintain a consistent temperature even when there is an imbalance in the board loading. The machine also features an open-profile thermal efficient infrared heater and its vacuum exhaust machine allows for quick heat cleaning and degas of the reflow cavity. It offers precise control of the reflow through accurate temperature ramps, times and temperatures for superior PCB assemblies.

There are no reviews yet