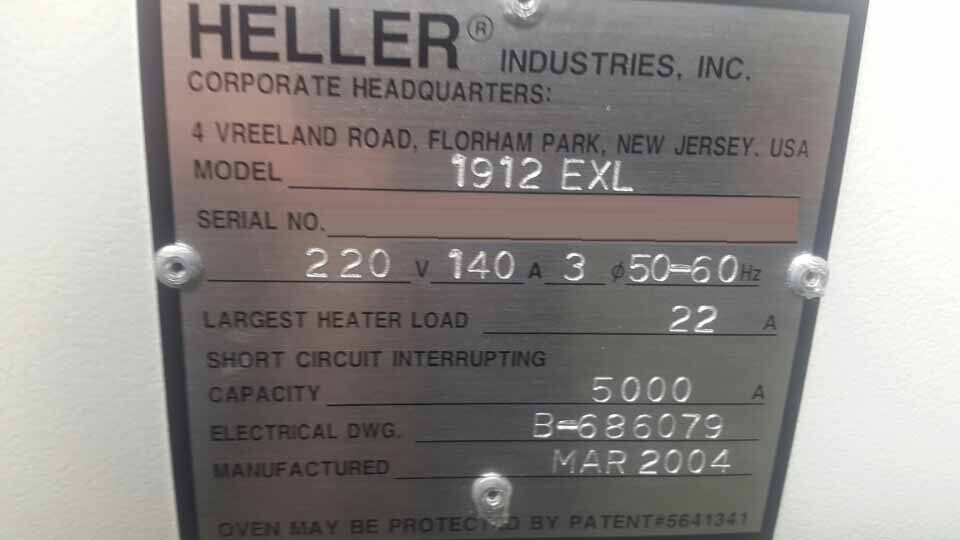

Used HELLER 1912EXL #9181383 for sale

URL successfully copied!

Tap to zoom

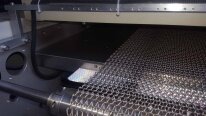

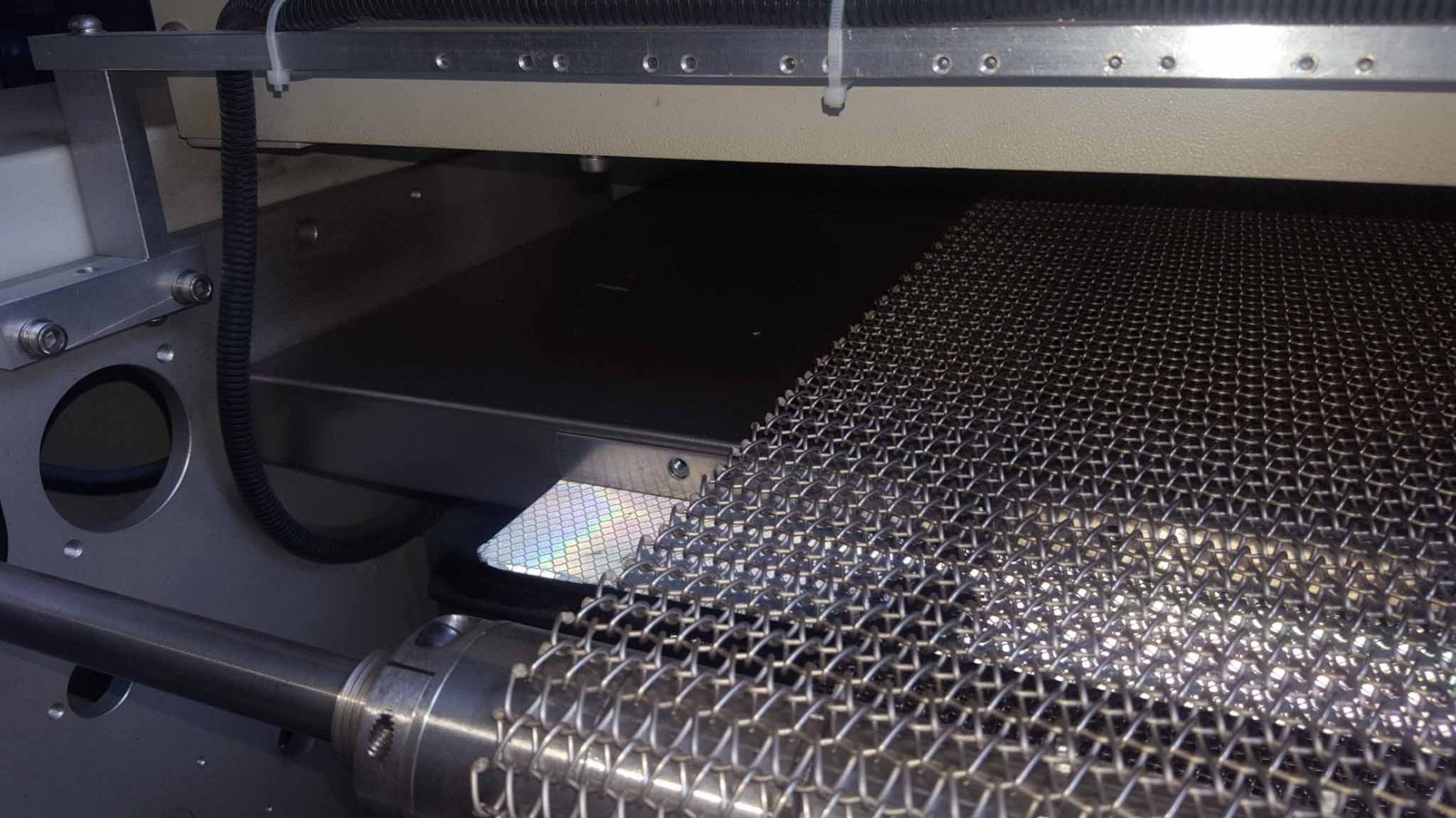

HELLER 1912EXL Reflow Oven is an industrial machine used in the manufacture of printed circuit boards (PCBs). It is designed for precision control of the entire PCB soldering process, from preheating and soldering to cooling, optimizing the PCB fabrication process and reducing production time. The machine is designed to handle large production runs with maximum precision, accuracy, and traceability. HELLER 1912-EXL Reflow Oven is a single-zone, five-zone convection unit with a maximum temperature of 480°C (900°F). The quality of the finished PCBs is largely dependent on the evenness of the temperature of the machine's energy sources. This machine features indirect heaters, adjustable forced-air convection, and bottom-up infrared heating to ensure a uniform temperature distribution across the entire board. The adjustable bottom-up infrared heating is especially important in controlling the temperature profile of the oven to ensure proper soldering. 1912 EXL Reflow Oven is designed for maximum control and accuracy, featuring PID (proportional-integral-derivative) temperature controllers with digital inputs for accuracy and repeatability of the machine settings. It also includes a digital display and an easy to use interface, allowing operators to control the process quickly and efficiently. The advanced software for the unit allows for remote monitoring and control, reducing downtime and maximizing efficiency. 1912EXL Reflow Oven has a large chamber for maximum throughput, as well as individual racks for efficient temperature control throughout multiple rounds of PCB fabrication. On-board diagnostic messages allow for troubleshooting and identifying any issues before the production cycle is complete. Additionally, it includes a patented "HELLERRAIN" system for controlling atmosphere and preventing oxidation, which ensures the longevity of the solder joints. For improved safety measures, HELLER 1912 EXL Reflow Oven includes several features such door limit switches and energy protection controlling the opening and closing of the door, as well as safety lockouts to protect personnel from operation when service is necessary. It also has an optional cooling chamber which allows for rapid cooling of the PCBs, thereby reducing production time and improving the quality and life of the final product. 1912-EXL Reflow Oven is designed for large-scale production runs as well as small to mid-sized production, providing maximum precision, accuracy, and traceability of the process for consistent and reliable results. It is an investment in quality and high performance, helping to reduce the PCB fabrication time, improve safety and quality standards, and maximize production efficiency.

There are no reviews yet