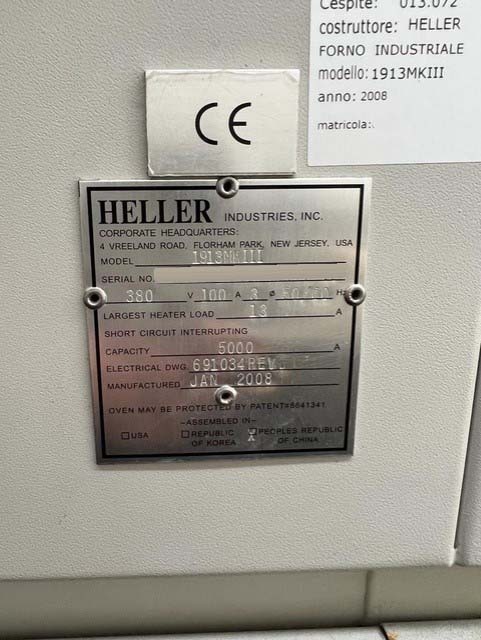

Used HELLER 1913 MK III #293670435 for sale

URL successfully copied!

Tap to zoom

HELLER 1913 MK III is a four-zone convection reflow oven. It is designed for use in both leaded and lead-free assembly soldering processes for a wide range of PCB assemblies. HELLER 1913MKIII reflow oven features four independently programmable top-down/bottom-up heating zones for reliable soldering of even the most complex assemblies. Programmable inter-process notches provide additional profile flexibility. It also offers manual external control for temperature ramp up/down rate in each zone as well as manual external control for the conveyor speed. 1913 MKIII features a high-efficiency forced-air convection equipment and independently adjustable temperature set-points for each heating zone to ensure all components reach solder temperature uniformly and reliably. The conveyor length is adjustable to support different PCB sizes up to 500mm x 500mm. The oven's power requirements include 3-phase AC power with 415VAC/50Hz input voltage for the oven chamber and optional Natural Gas or Liquid Propane Gas (LPG) for Element Protection System to ensure overload protection. Safety features on HELLER 1913 MKIII include a cool-down exhaust unit with two-stage pump to ensure the chamber is cooled before the operator can enter the oven chamber. It also includes a Gas Leak Detector which monitors and warns the user when any gas leaks occur, as well as a Program Lockout Machine to prevent any unauthorised personnel from making changes to the oven's cook sequence. 1913 MK III also offers 24 hour time-temperature graphs, manual or automatic setpoints and cook cycles, as well as digital display of both chamber temperature and conveyor speed. Overall, 1913MKIII is an efficient, reliable, and safe solution for leaded and lead-free assembly PCB manufacturing. It is an ideal choice for those who require precise temperature control for production of complex electronic products.

There are no reviews yet