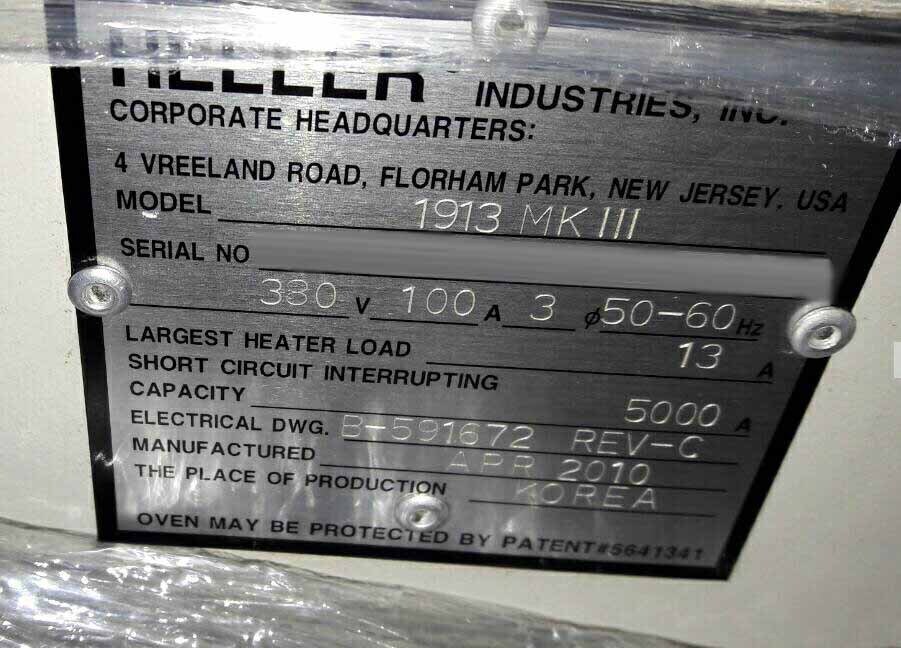

Used HELLER 1913 MK III #9166676 for sale

URL successfully copied!

Tap to zoom

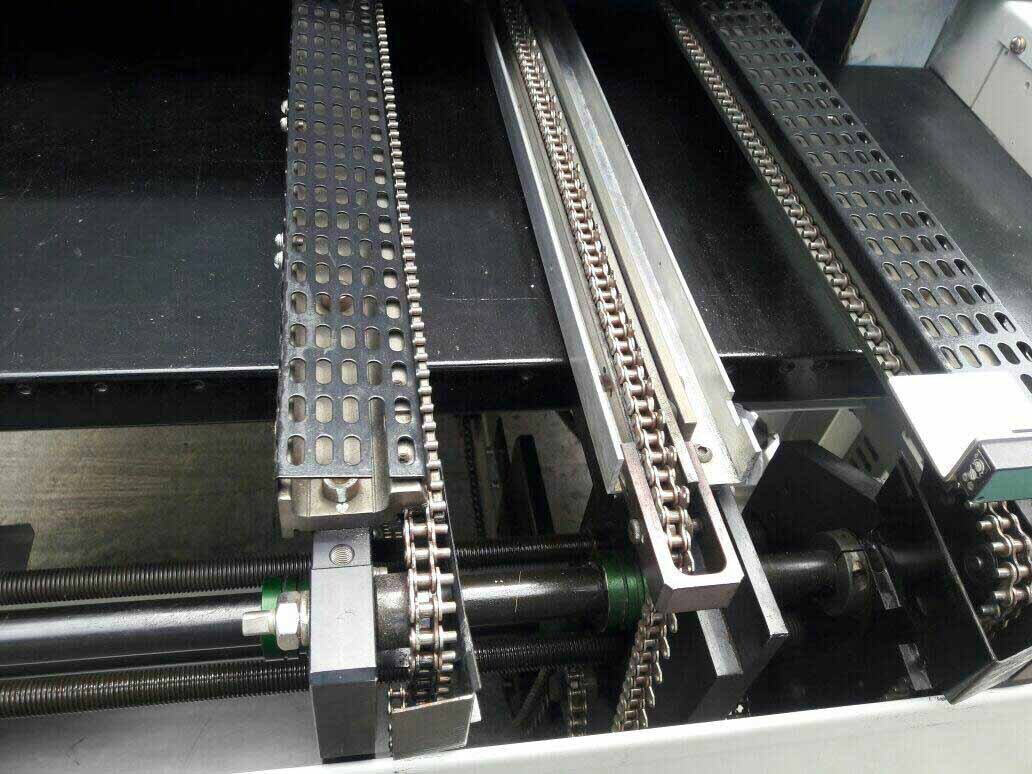

HELLER 1913 MK III Reflow Oven is a machine used to provide higher reliability soldering for advanced microprocessors and ICs. It is an advanced nitric oxide (NO) reflow oven designed with an advanced automatic NO injection equipment. The dynamic distribution system ensures uniform heating across the entire board with precise temperatures and nitrogen injection. HELLER 1913MKIII oven is built with a 12-zone design, each zone composed of four top and four bottom RSF heating elements. The machine also includes comprehensive cooling for full coverage in each zone, allowing for a controlled cooling rate and uniform temperature. The oven can sustain temperatures ranging from 100-350 degrees Celsius, giving the user pinpoint accuracy and precise temperature control. 1913 MKIII also offers advanced process control capabilities to ensure precision in wave soldering process. A user-programmable up to 4-step soldering profile with a wide-range of actual/simulated test points and sequencing allows the user to closely monitor the process and ensure accuracy. The oven also features a 20-chamber gas monitoring unit to analyze the nitrogen oxide (NOx) concentration to ensure stability in the soldering process. HELLER 1913 MKIII's pioneering design makes it an optimal choice for advanced soldering of integrated circuits, giving superior accuracy and providing a safe and reliable atmosphere for wave soldering. Additionally, its precise temperature control and 20-chamber gas monitoring machine makes it highly reliable, and its intuitive design makes it easy to use. Those looking to use advanced soldering techniques for modern ICs may find the 1913MKIII an ideal fit.

There are no reviews yet