Used HELLER 1913 MK III #9394322 for sale

URL successfully copied!

Tap to zoom

ID: 9394322

Vintage: 2017

Reflow oven

N2 Type

Left to right

Front fix

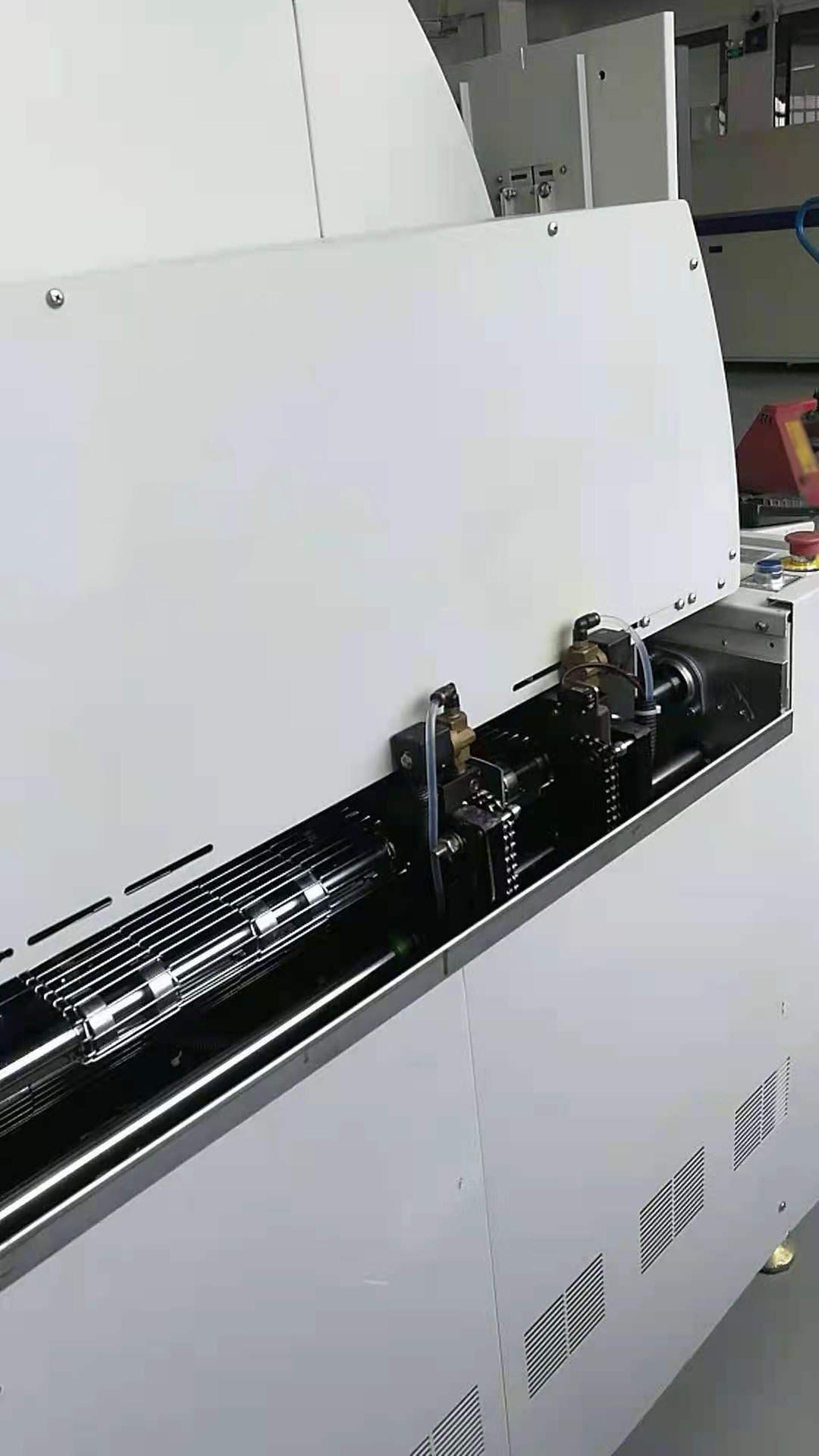

Chain and mesh belt

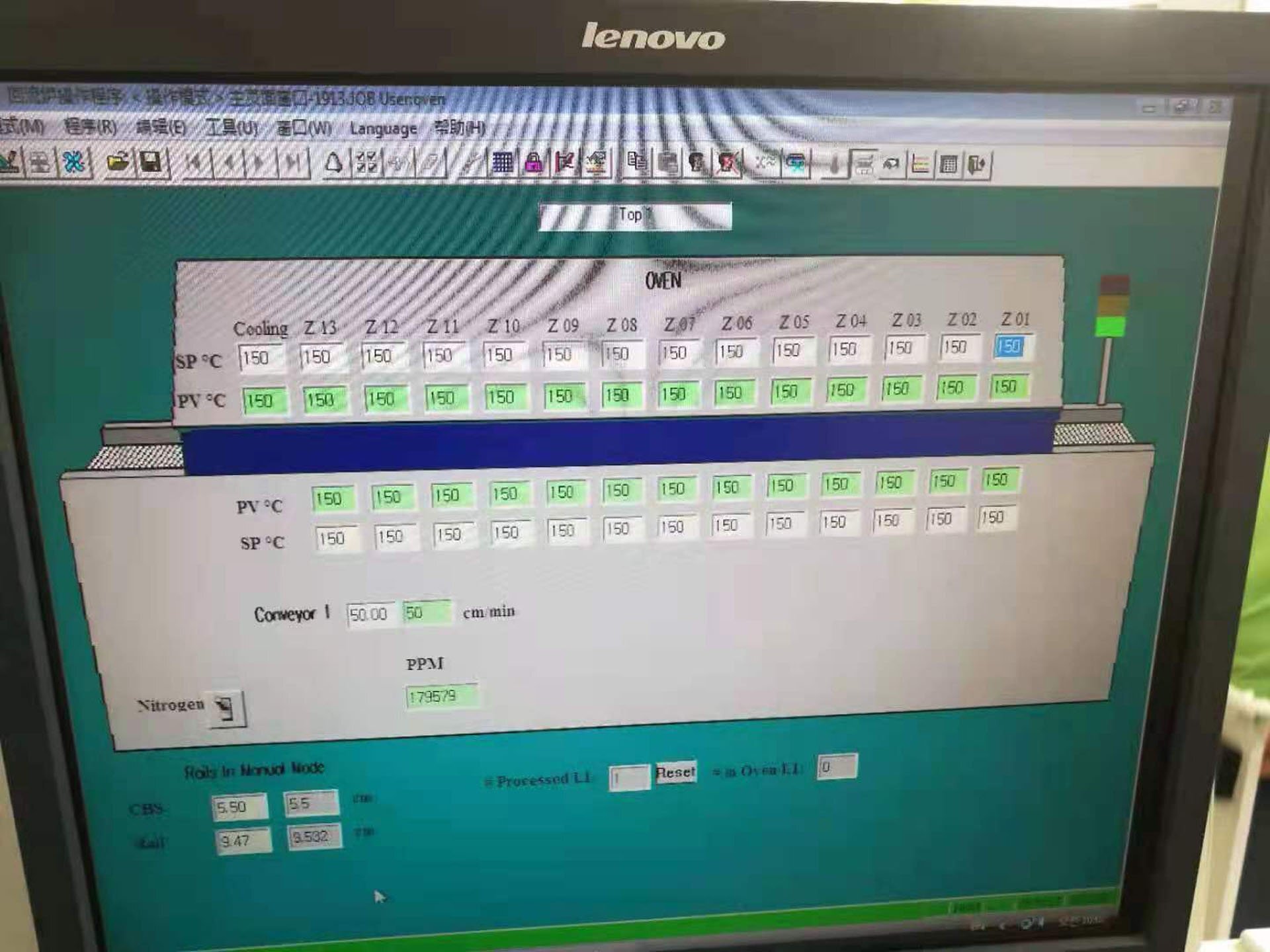

N2 Analyzer

O2 Level: <1000 PPM

Chiller

UPS Battery backup

Operating system: Windows 7

Wooden packing with vacuum included

2017 vintage.

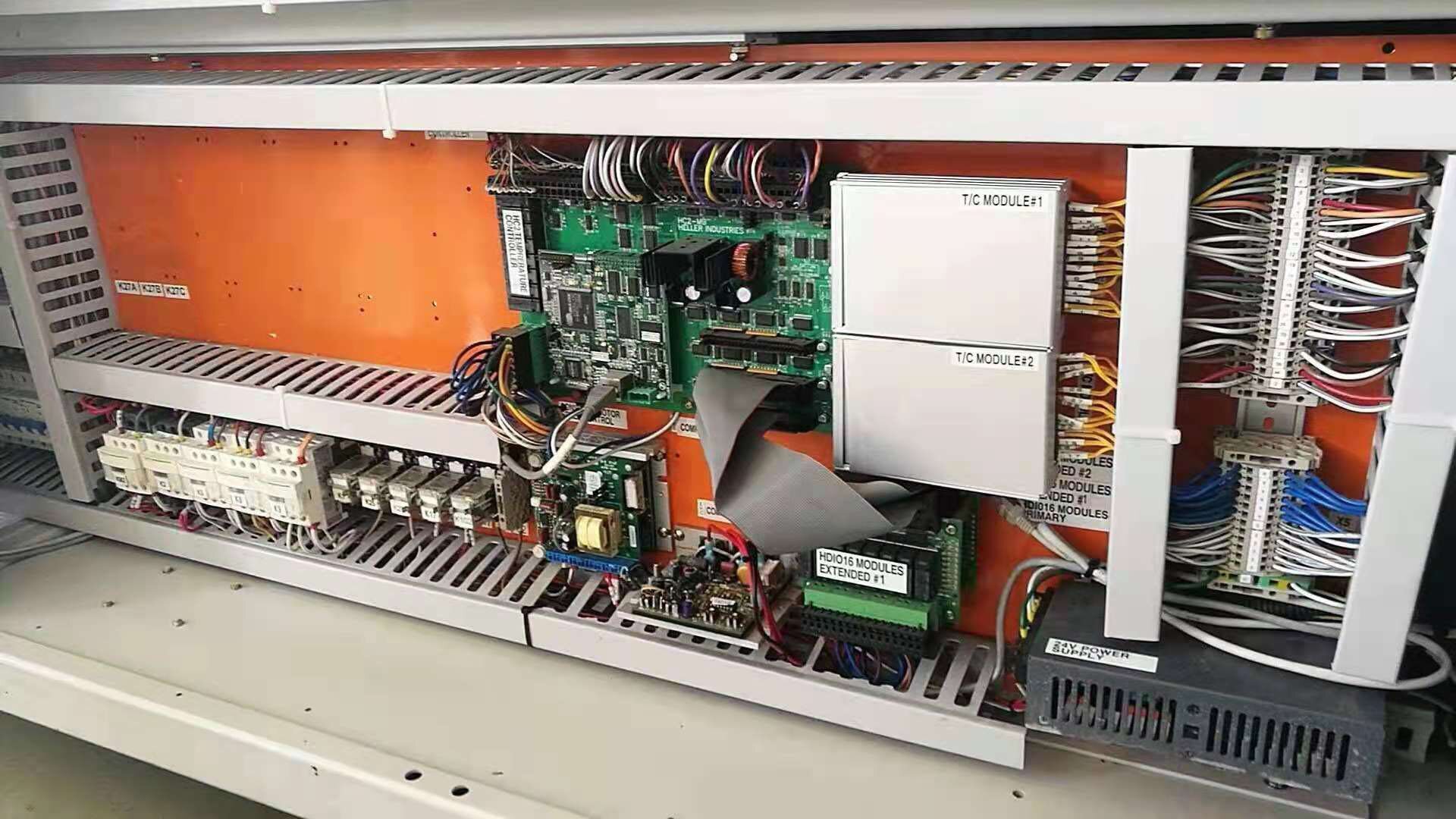

HELLER 1913 MK III is a reflow oven designed for high throughput of electronic assemblies, while providing precise, low impact profiles. The oven is equipped with a multi-zone 3 zone convection system with an advanced air flow technology for optimizing temperature during the drying and reflow process. It also utilizes a thermal compression wave technology for providing uniform heat across the length of the tunnel. HELLER 1913MKIII features advanced temperature and air flow control, designed to preserve components during the reflow process. The oven uses closed-loop process control to maintain a preconfigured thermal profile throughout the entire process. Advanced diagnostic software provides real-time monitoring of temperature, air flow, and system performance. The injector ports and fan speed allows for precise temperature adjustment. The oven is also capable of saving multiple thermal profiles in its memory. The oven is 99" long and has a 24" wide work chamber, built using stainless steel and other proprietary materials. The interior of the work chamber is lined with a special coating to ensure even linear heating. It contains several independent heating zones capable of reaching temperatures of up to 450°C (842°F). 1913 MKIII can process components of any dimension, from 0.020" (0.5 mm) to 0.100" (2.5 mm). It provides individual board-by-board temperature control and fast cool-down times for quick turnaround. The conveyor belt speed ranges from 3.0 ft/min (1.0 m/min) to 7.0 ft/min (2.1 m/min). A separate, dedicated clean-room cabinet is also included to meet any applicable cleanliness requirements. 1913 MK III is a reliable and safe reflow oven designed for high throughput of PCBA's that require precise, low impact profiles. Its advanced temperature and airflow control system, combined with the thermal compression wave technology, ensures uniform heat across the length of the tunnel. With its high-quality construction, robust diagnostic software, and multiple thermal profiles, the oven is ideal for any reflow application.

There are no reviews yet