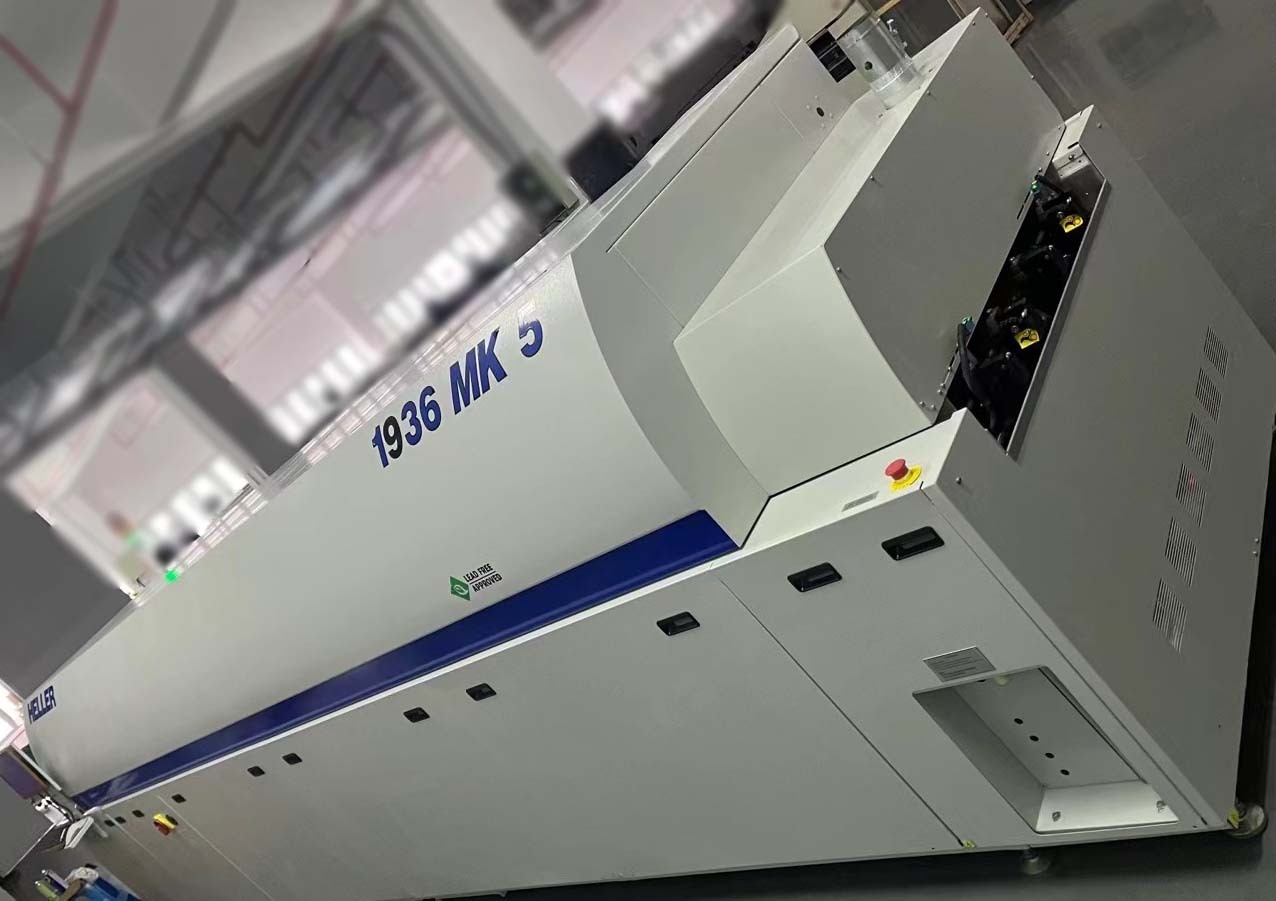

Used HELLER 1936 MK 5 #293656448 for sale

URL successfully copied!

Tap to zoom

HELLER 1936 MK 5 is a two-zone reflow oven - an electronic device commonly used in the manufacturing industry to attach components to a substrate through a soldering process. This type of industrial oven is a reliable and efficient solution for light board and large panel manufacturing that requires accurate and repeatable soldering results. HELLER 1936MK5 operates via a pair of heating zones and a cooling zone. A board is loaded onto a conveyor belt, that transports it through the heating zones where heat energy is applied and the solder is melted. The oven is then cooled by cold air in the cooling zone, causing the solder to return to a solid state and firmly attaching the components to the board. Uniquely, 1936 MK5 can be adapted to different production setups, either through a 'single-lane', where the board is sent through the oven in one pass, or a 'multi-lane' setup, when the board needs to go through the oven more than once. Additionally, it can also be equipped with a dual zone option, allowing for further control over the preheating characteristics of the boards. HELLER 1936 MK5 also ensures accurate temperature management and data-driven tracing of the workflow. It is equipped with an advanced profiling equipment and a 10" colour touchscreen display that offers direct access to different settings and profiles. The thermal management system allows a range of temperature profiles to be setup and stored in the oven's memory, allowing for quick and easy recall when needed. In addition, 1936 MK 5 is fitted with sophisticated safety features that enable it to safely and efficiently produce SMD/SMT boards. The oven is designed to produce 360 boards per hour, with a peak power consumption of 15 kW. It has an operating temperature range of 0 to 300°C, and is equipped with a self-cleaning air flow unit and a patented disolvent-free fume exhaust machine to provide a safe and efficient soldering environment. Overall, 1936MK5 is a reliable and efficient reflow oven that provides professional results for a wide range of light board and large panel manufacturing applications. It is an ideal solution for low- to mid-volume production scenarios and comes equipped with a range of features to ensure an accurate and consistent soldering process.

There are no reviews yet