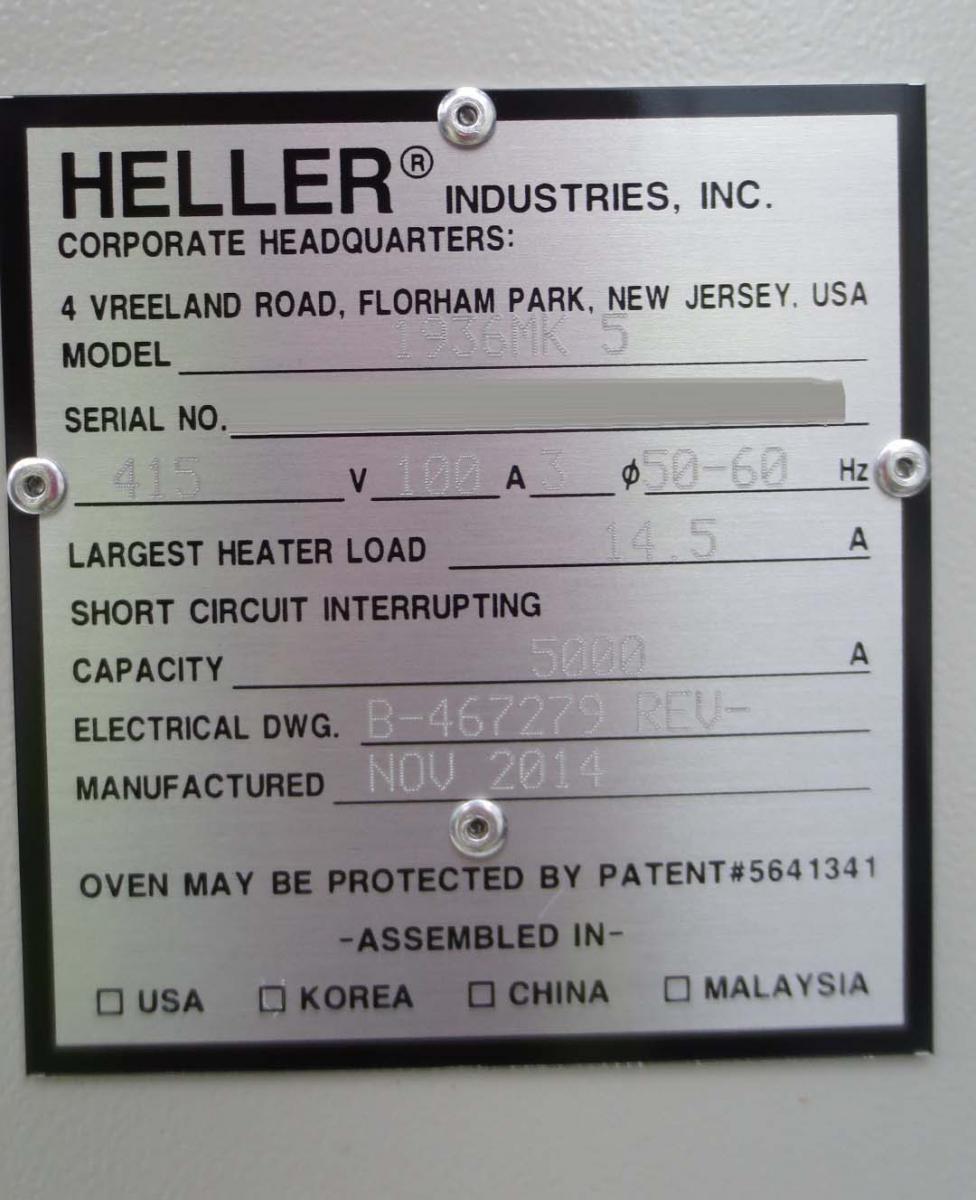

Used HELLER 1936 MK 5 #9177360 for sale

URL successfully copied!

Tap to zoom

HELLER 1936 MK 5 is an industrial-grade reflow oven, designed to create components for use in electronic assemblies. It consists of a massive, double-shelled steel chamber with sealed doors for user access. Inside the chamber is a halide lamp for thermal heating, as well as a rotating mechanism that evenly distributes the heat to the desired areas within the oven. With the help of state-of-the-art temperature controllers, it's possible to accurately adjust and maintain the temperature inside the oven. HELLER 1936MK5 uses a forced convection process to ensure that the epoxy resin component is heated evenly throughout. The entire process starts with a preheat stage that sets the section board before reflowing. Dependant on the type of boards and components that are being reflowed, the user can alter the temperature of the pre-heat stage for optimal results. Once the pre-heat stage is complete, the core reflow process begins. To maintain a homogeneous heat cycle, the convey where the components are placed is powered by independent variable speed motors. As the case is moved forward, the temperature is ramped up slowly and then held steady at the reflow temperature. During this process, heat is distributed from the top and bottom of the chamber. The temperature then begins its cooling cycle, to solidify the reflow. To ensure the most thorough cooling, 1936 MK5 is outfitted with a high-speed fan that circulates cold air inside the chamber. This helps to reduce stress on the components during the solidification process. The cooling process can also be managed manually, to adjust for component type. Overall, HELLER 1936 MK5 is a reliable and user-friendly reflow oven, capable of producing high-quality results. It provides an excellent means of putting together boards, without the need for tedious manual processes. Plus, the oven's intuitive controls make it a joy to work with.

There are no reviews yet