Used HELLER 1936 MK 5 #9229444 for sale

URL successfully copied!

Tap to zoom

ID: 9229444

Reflow oven

Conveyor direction: Left to right

Conveyor speed control: Closed loop

Signal light tower

Powered hood lift

Mesh belt conveyor:

Height from floor: 35.5" + 2.0" (90 cm & 5 cm)

Maximum PCB width: Standard 20" (56 cm), Option 24" (61 cm) / 26" (66 cm)

Space required between PCB's: 0.0" (0.0 cm)

Conveyor length:

On-load: 18" (46 cm)

Off-load: 18" (46 cm)

Heated tunnel length: 135" (343 cm)

Process clearance above mesh belt: 2.3" (5.8 cm)

Mesh belt pitch: 0.5" (1.27 cm)

Maximum conveyor speed: 74" / Min (188 cm/min)

Edge hold conveyor system option:

Height from floor standard: 37.0" + 2.0" (94 cm + 5 cm)

Clearance above & Below conveyor pins: 1.15" (2.9 cm)

Length of PCB support Pins: 0.187" (4.75 mm)

Minimum / Maximum board width: 2.0" to 24" (5 – 61 cm)

Option 24" (61 cm) / 26" (66 cm)

Power width adjustment

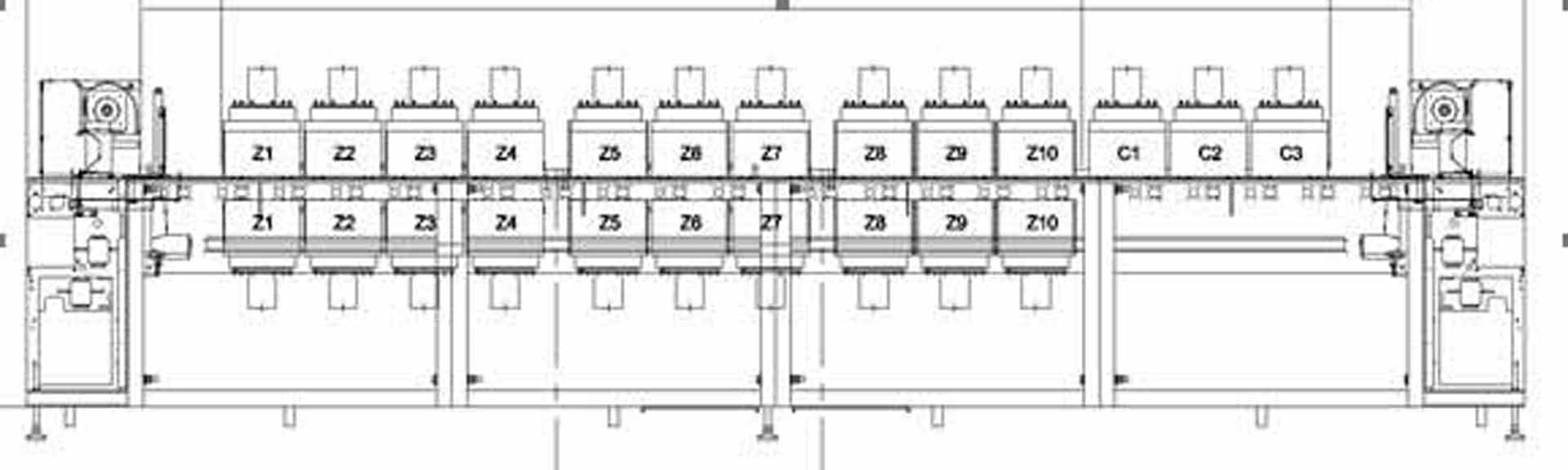

Forced convection zones:

Top & Bottom: 10

Heater type: Instant response open coil

Heater material: Nichrome

Profile change time: 5 to 15 Minutes

Cooling systems:

(3) Cooling zones: Standard

No water cooling

Temperature control:

Accuracy of temperature controller: + 0.1°C

Cross-belt temperature tolerance: + 2.0°C

Heater wattage per zone: 6000 W

Temperature range standard: 60° C to 350° C

Computer control:

AMD / Intel based computer

Flat screen monitor with mount

Operating system: Windows

Data logging

Password protection

Electric supply:

Power input (3-Phase) standard: 480 V

Breaker size: 100 Amps @ 480 V

(9) Continuous kW

Typical run current: 25 - 35 Amps @ 480 V

Sequential zone turn on

Frequency: 50/60 Hz.

HELLER 1936 MK 5 Reflow Oven is a precision reflow oven designed to ensure repeatable and consistent results in printed circuit board (PCB) assembly utilizing Lead Free or traditional Lead Based solder. This machine is capable of rapidly heating up substrates to extreme temperatures while accurately controlling the rate of heating and cooling with negligible thermal gradients. This controlled thermal environment provides outstanding solder joint integrity through peak temperature control that is vital in meeting IPC and NASA requirements. HELLER 1936MK5 allows its user to set time/temperature profiles for each soldering application, minimizing process setup time and maximizing reliable results. It also has embedded adaptive learning AI which can be used to optimize cycle times for maximum throughput and efficiency, regardless of assembly complexity or board size. The oven is built using the latest in advanced technology, including integrated industrial-grade temperature sensors and programmable control systems. When it comes to convenience, 1936 MK5 reflow oven is user-friendly and durable enough to withstand heavy use. Its control panel is intuitive, allowing for precise temperature control, and its user-friendly touchscreen interface ensures that the process settings are precise and easy to navigate. Additionally, the oven is designed to stay cool to the touch, preventing potential user burn hazards. Performance-wise, 1936 MK 5 is designed to meet the highest standards in industrial reflow ovens. It can handle extreme temperatures to 700°C, achieving a peak temperature which is maintained for a precisely-defined time, allowing complete oxidation and effectively dissipating surface flux residues. It also features an advanced closed-loop air circulation, providing superior process optimization with minimal energy consumption. Built with quality materials, HELLER 1936 MK5 is designed to ensure durability and reliability. The robotic thermal insulation and stainless steel chambers are designed to deliver safety, reliability, and temperature repeatability over the long term. With its full access insulation lined top and integrated out-feed ramp, 1936MK5 offers the best in industrial-level reflow oven engineering. In conclusion, HELLER 1936 MK 5 is a reliable and precise reflow oven that is built to deliver on demands for uniform solder joint integrity. With its intuitive touchscreen interface, reliable adaptive AI, precise temperature control, and cutting-edge safety features, this oven is ideal for repeatable use and delivering optimal results in industry standard or extreme PCB assemblies.

There are no reviews yet