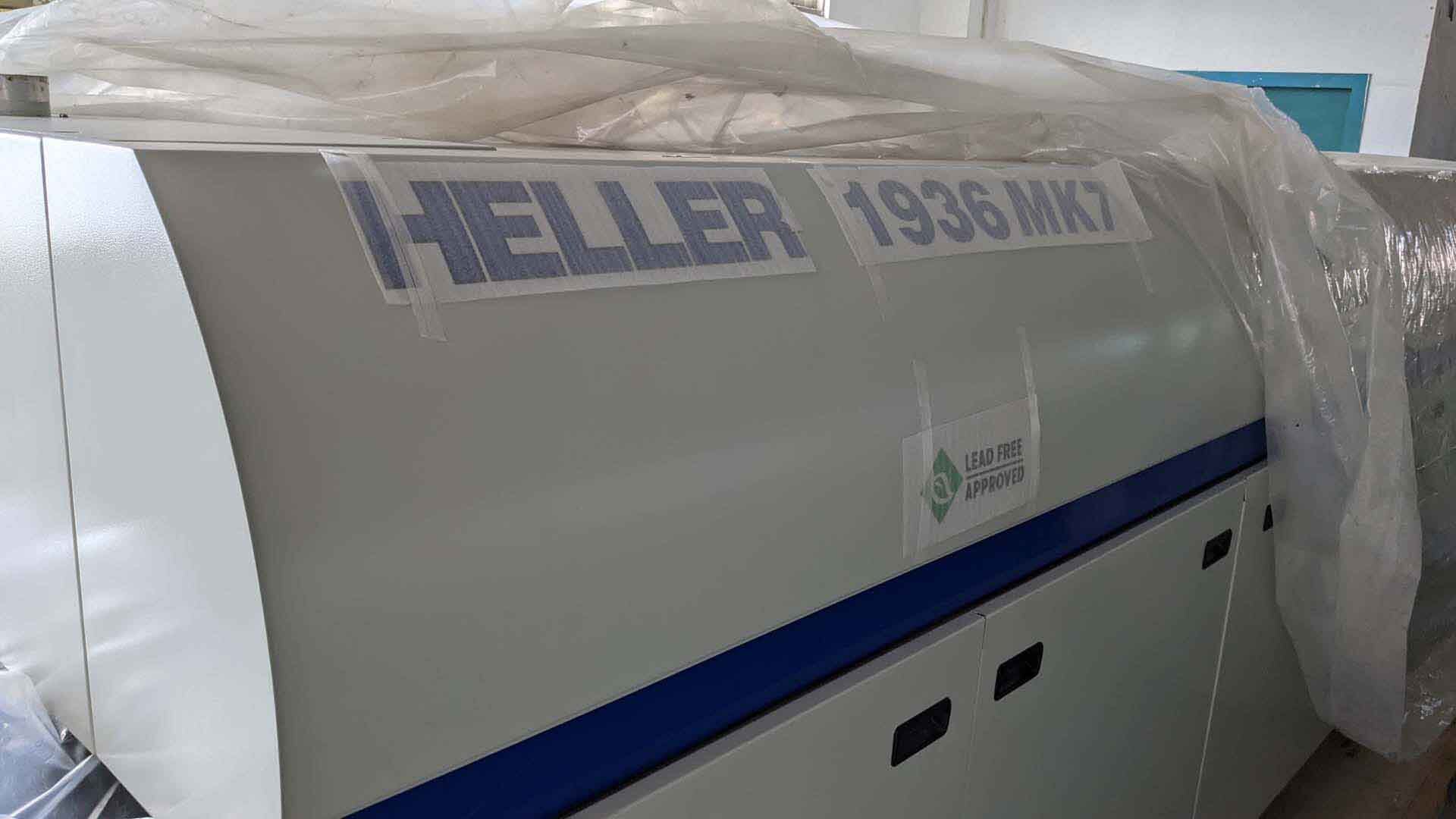

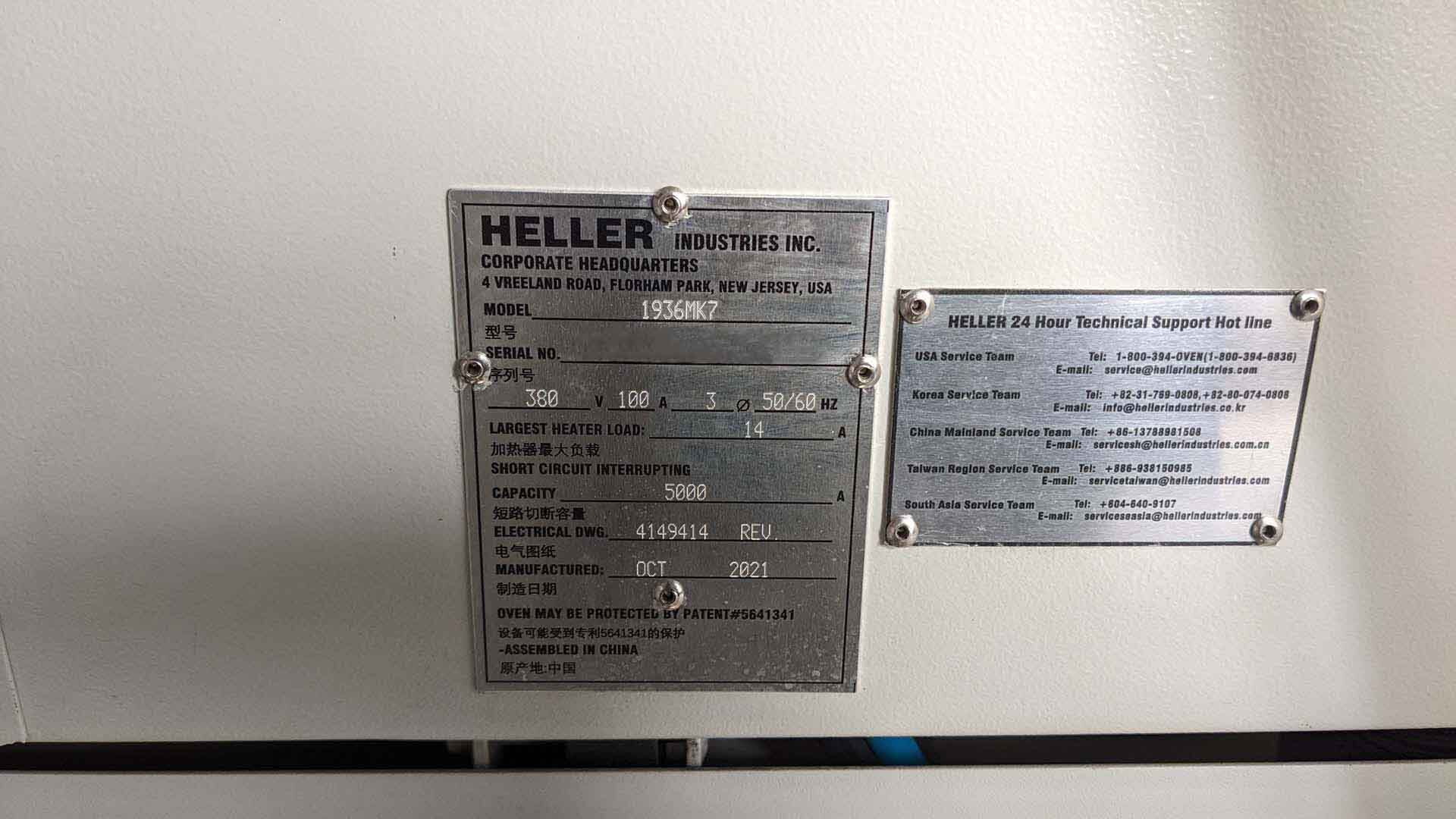

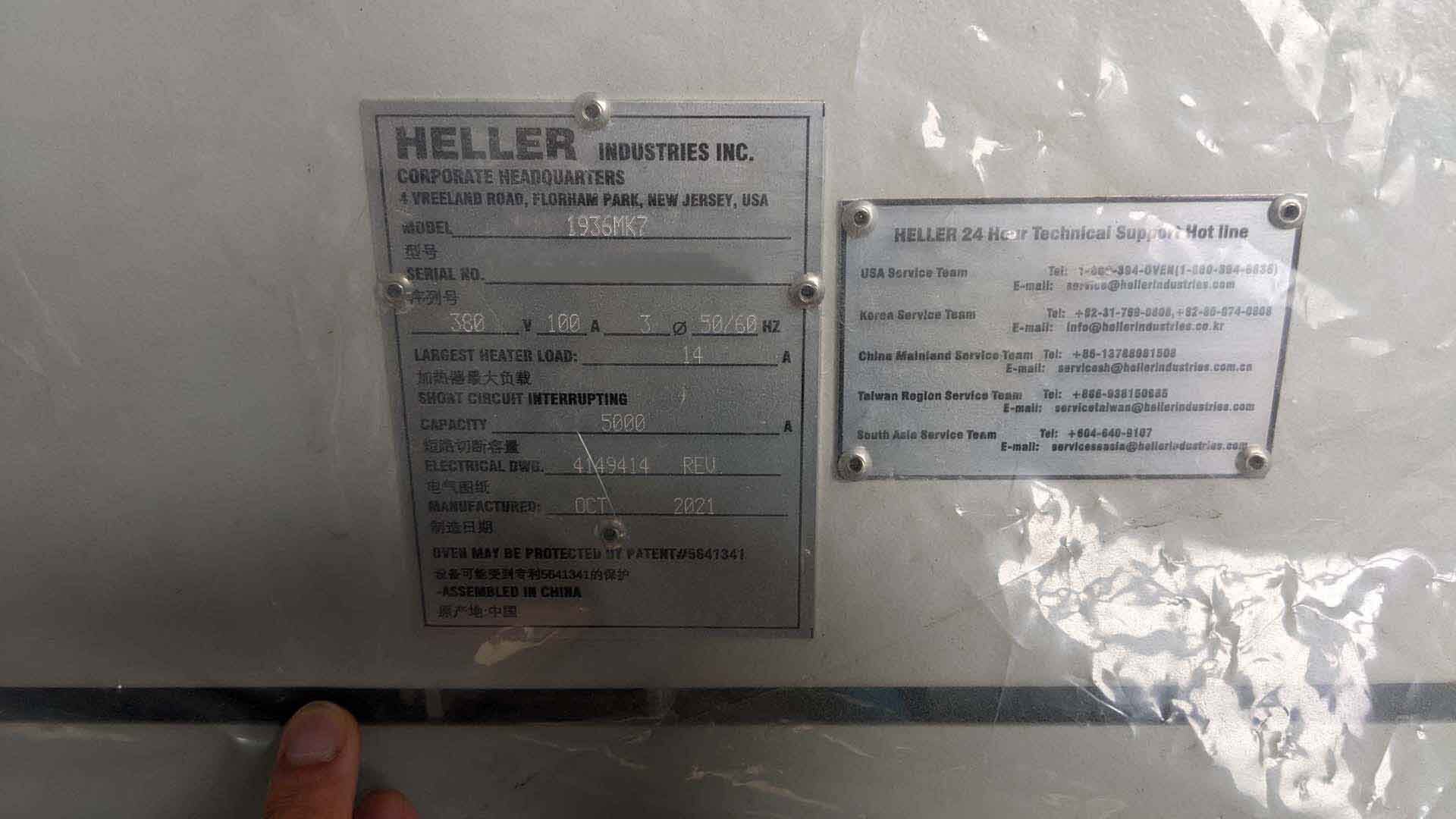

Used HELLER 1936 MK 7 #293641799 for sale

URL successfully copied!

Tap to zoom

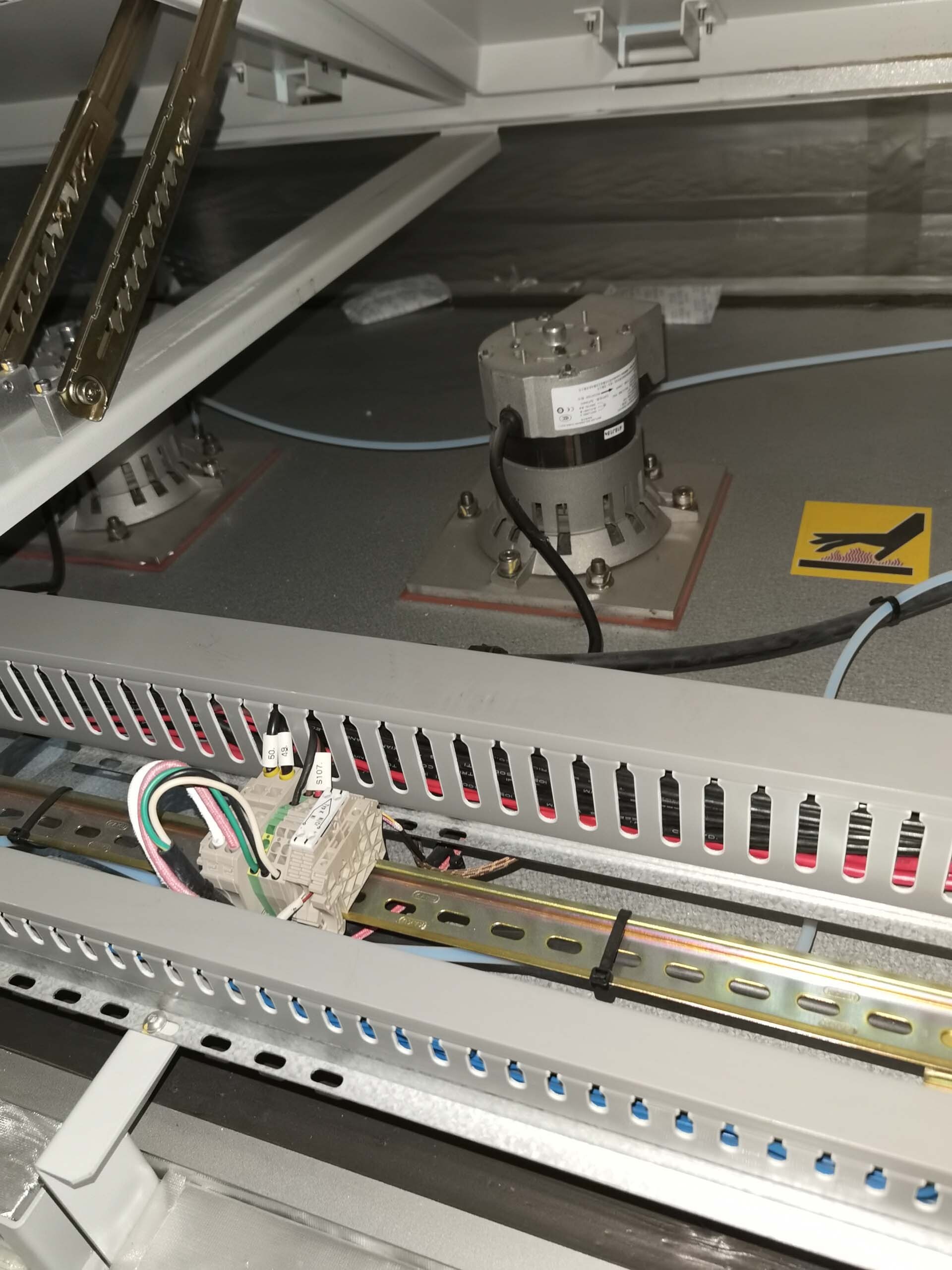

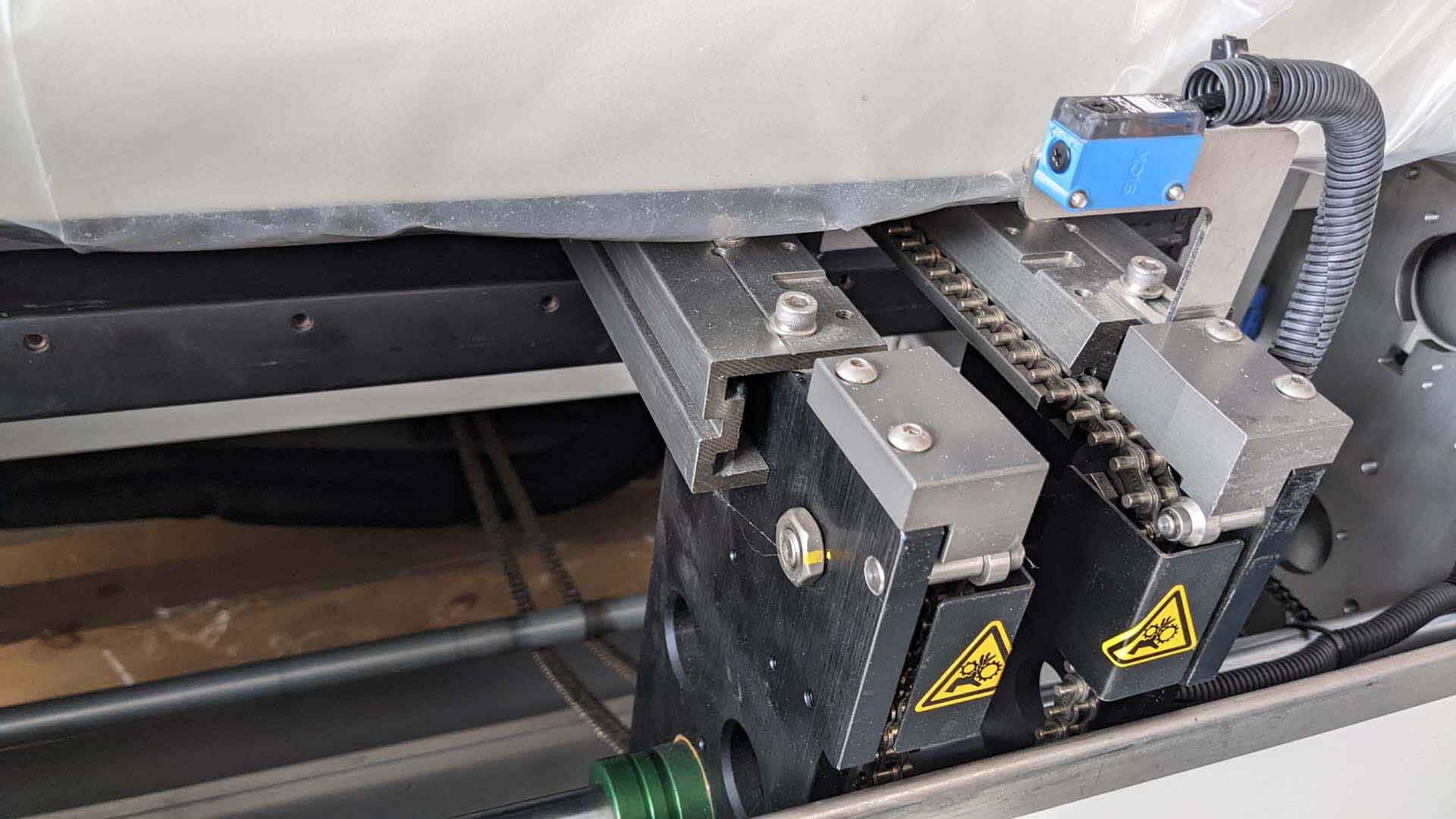

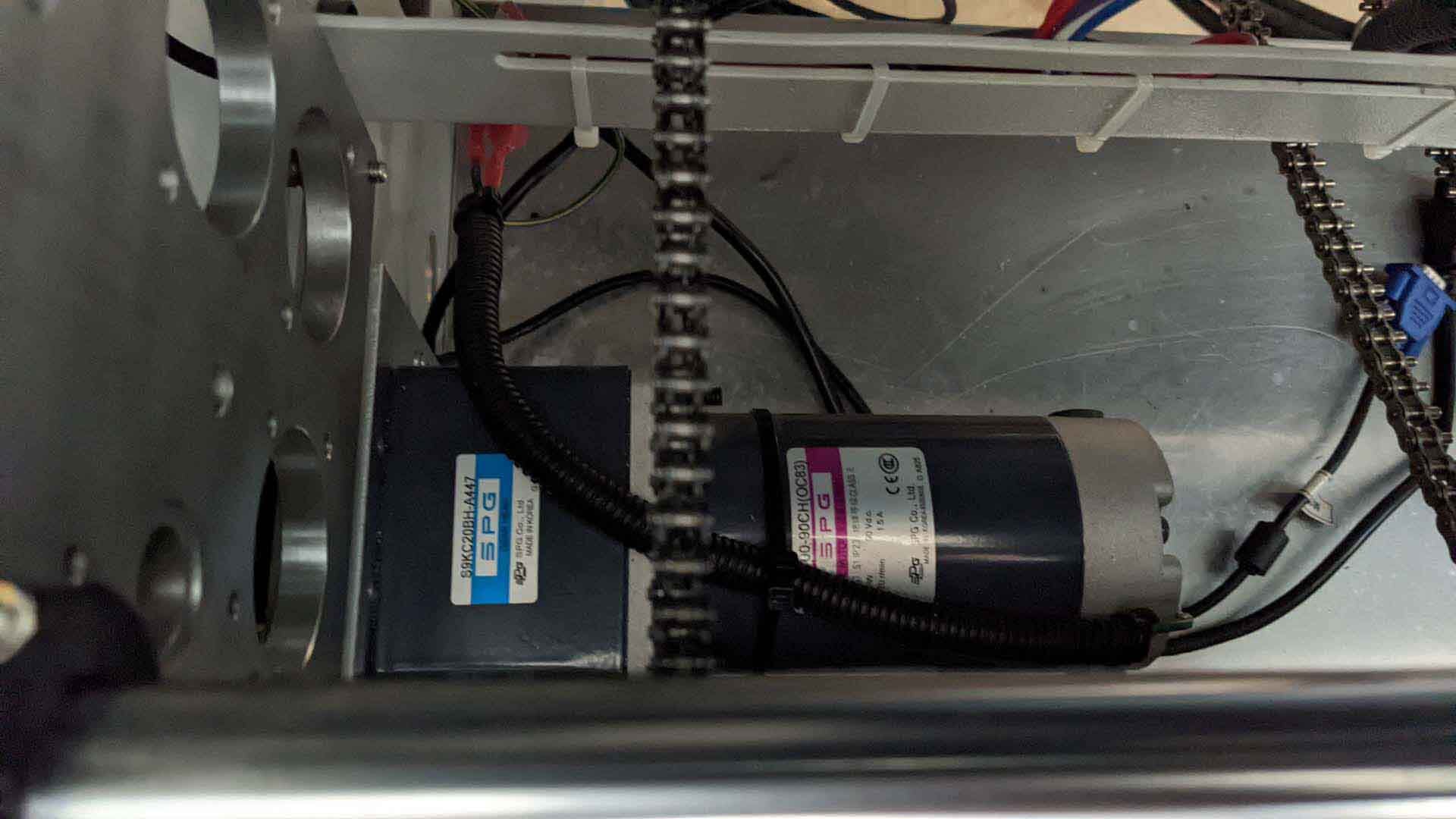

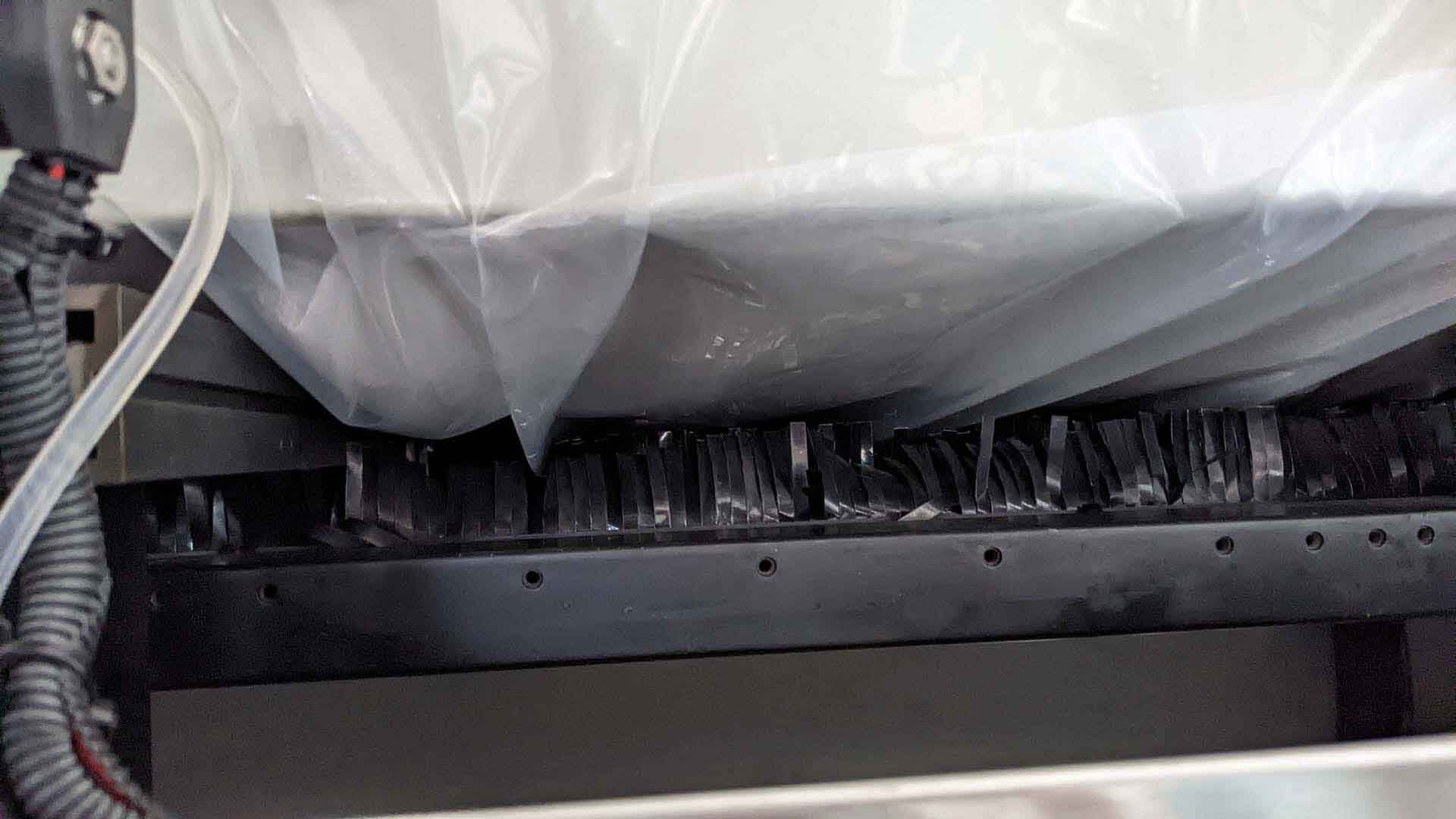

HELLER 1936 MK 7 Reflow Oven is a highly-advanced equipment used to join soldered components to a printed circuit board (PCB). It uses high temperatures to soften the solder so that the components are securely bonded to the PCB. The result is a reliable, heat-resistant and environmentally friendly connection. 1936 MK 7 is a vertically arranged reflow oven that can accommodate PCBs up to 12" x 12" in size. It has five heating zones, each with its own independently-programmable temperature setting and a maximum temperature of 450°C. The oven also has advanced temperature uniformity control, ensuring that the warmest part of the tunnel never deviates more than +/- 2°C. In addition, it provides three operating modes—slow, fast, and low cost—to suit different processes and recipes. To further improve performance, it's equipped with advanced bypass control, which adjusts the time in the preheating oven according to the PCB's characteristics. HELLER 1936 MK 7 also has a built-in software for data collection and analysis. Operators can use the data logging capabilities to generate accurate production reports. The software is also capable of storing up to 1000 recipes and supports up to four different recipe types, allowing operators to quickly switch between products without recalibrating the oven. Moreover, the oven's user-friendly LCD display allows operators to quickly and accurately select the desired temperatures and operating modes. 1936 MK 7 is a reliable and highly efficient reflow oven. It boasts robust construction, accurate temperature control, advanced bypass control, and data logging. All these features make HELLER 1936 MK 7 an ideal choice for a variety of printed circuit board assembly processes.

There are no reviews yet