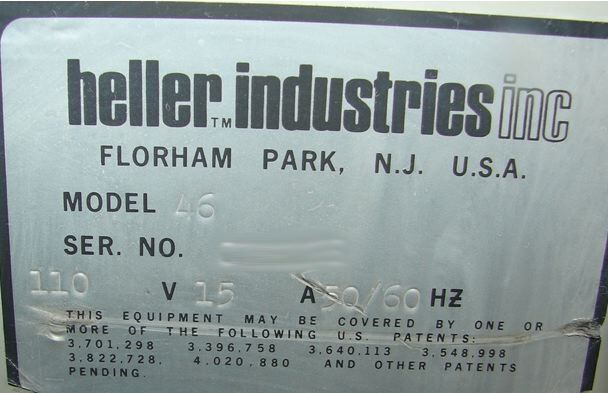

Used HELLER 46 #113302 for sale

URL successfully copied!

Tap to zoom

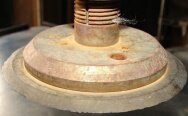

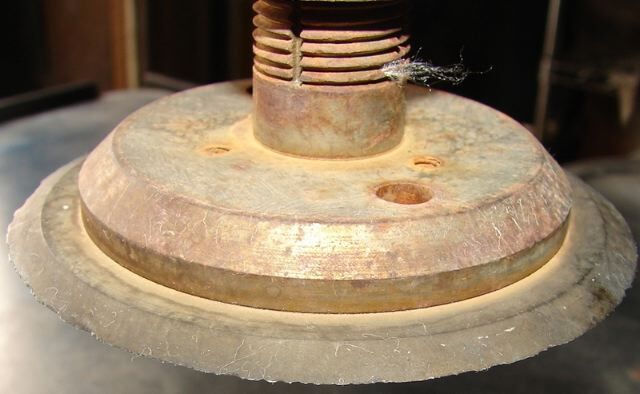

HELLER 46 is a reflow oven designed by HELLER CORPORATION. It is a medium-sized reflow oven with a maximum processing size of 350 x 460 mm and peak temperature up to 300C. It is designed to perform rapid, high-precision reflow soldering processes on printed circuit boards and die attach. 46 utilizes a dual zone convection heating system and three types of temperature profiling to ensure reliable soldering results. It consists of two zones - the preheating zone and the reflow zone. The preheat zone consists of six heating elements that provide a more even heating profile for circuit boards. The reflow zone utilizes IR and convection heaters to produce a more uniform temperature profile for reflow soldering. These heating elements can be configured for different temperature ranges to accommodate various types of PCB designs. HELLER 46 also employs three types of temperature profiling - linear, step and multi-step. With linear temperature profiling, the oven increases or decreases the temperature at a constant rate throughout the heating cycle. In a step profiling, the oven will heat the board to a specific temperature before decreasing the temperature or maintaining it at the same level. Multi-step profiling gives the user the flexibility to customize the temperature profile to meet the specific needs of their particular board design. 46 reflow oven also features advanced reflow management options such as preheating, cooling and post-soak capabilities. The preheating option stabilizes the temperature of the board before the reflow process, while the hot and cold spots detection ensures that all components are accurately soldered to their pads. Finally, the post-soak feature maintains constant temperatures for an extended period of time and produces a homogeneous surface temperature on the board. HELLER 46 reflow oven is exceptionally durable and reliable, ensuring that boards are soldered with the highest accuracy and quality. It is easy to operate, with a user-friendly controller that provides information and adjustments in real-time. The optional nitrogen gas Purge Upgrade is available to minimize oxidation and reduce operating costs. Finally, the automatic conveyor system is adjustable, so that components of different sizes and shapes can be processed and soldered on the same board.

There are no reviews yet