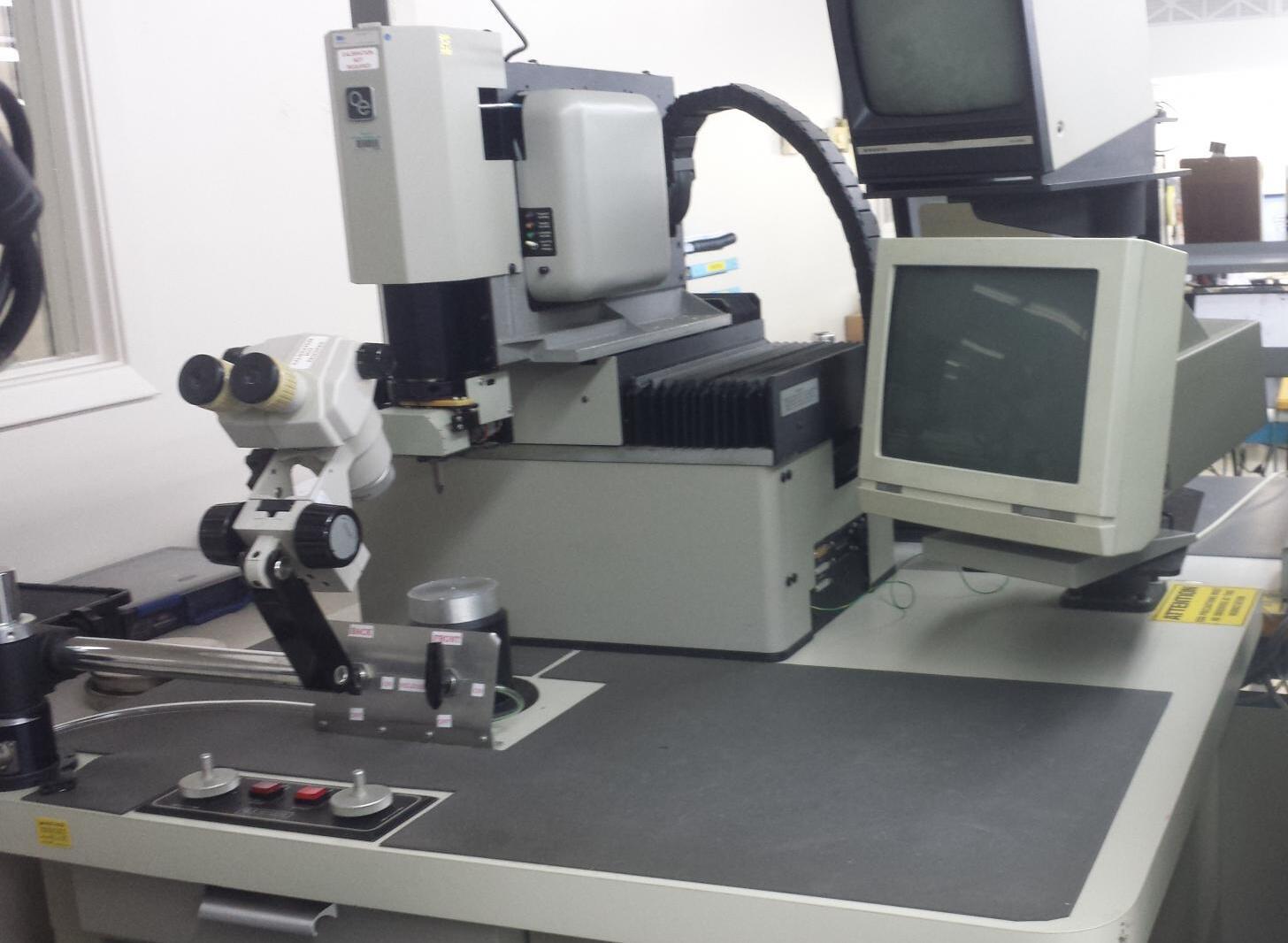

Used QUAD ZCR #9095722 for sale

URL successfully copied!

Tap to zoom

ID: 9095722

Convection reflow oven

4-Zones

Preheat zone

Forced air convection heating

Closed loop transport system

4-channel PCB profiling

Active cooling zone

Power hood lift

Integrated real time PC control system

Graphic display

Zone to zone temperature separators

Internal powered exhaust

Zonal power up software

Data logging

Computer controlled rail.

QUAD ZCR is a reflow oven designed to suit the needs of higher volume production with one of the most efficient ways of reflow soldering. It has a high-efficiency, interlocks-protection chamber that can reach temperatures of up to 350°C (661°F) and a preheat zone of up to 220°C (428°F). The reflow oven has an innovative design where the heating sources are spaced very closely to the board, allowing for a fast and even heat transfer that results in a uniform, consistent temperature throughout the board. The oven is equipped with four infrared (IR) heat sources and two natural convection heat sources for accurate and precise temperature control. The Infrared heaters provide a strong and consistent temperature, while the convection sources provide more flexibility and aid in the optimization of each process. This design ensures that each layer of the board is heated uniformly with the correct temperature. Furthermore, the oven has an advanced touch-screen control panel that allows for intricate programming and access to the last ten recipes used. ZCR comes with a robust safety equipment, which includes an interlock, fire suppression nozzle, and temperature control. The interlock is designed prevent insertion of the board until the preheat zone has reached its set point. The fire suppression system uses a compressed air nozzle to cool the oven chamber in the event of a smoke or fire due to spilled flux or other sources. The temperature control unit monitors oven temperature, pressure, and humidity to ensure an optimal operating environment. QUAD ZCR can optimize its recipes with the integrated real-time feedback machine. This allows for constant feedback from the reflow process on how the temperature is distributed throughout the board. This is especially useful for accurately targeting any hotspots for reflow problems. The oven also contains a diagnostic tool with a fault detection asset that is capable of identifying any errors in the reflow process. In conclusion, ZCR is a powerful, reliable reflow oven that is designed to meet the needs of high-volume production. Its efficient design, advanced safety features, and complete control model make it a great choice for any electronic assembly production line.

There are no reviews yet