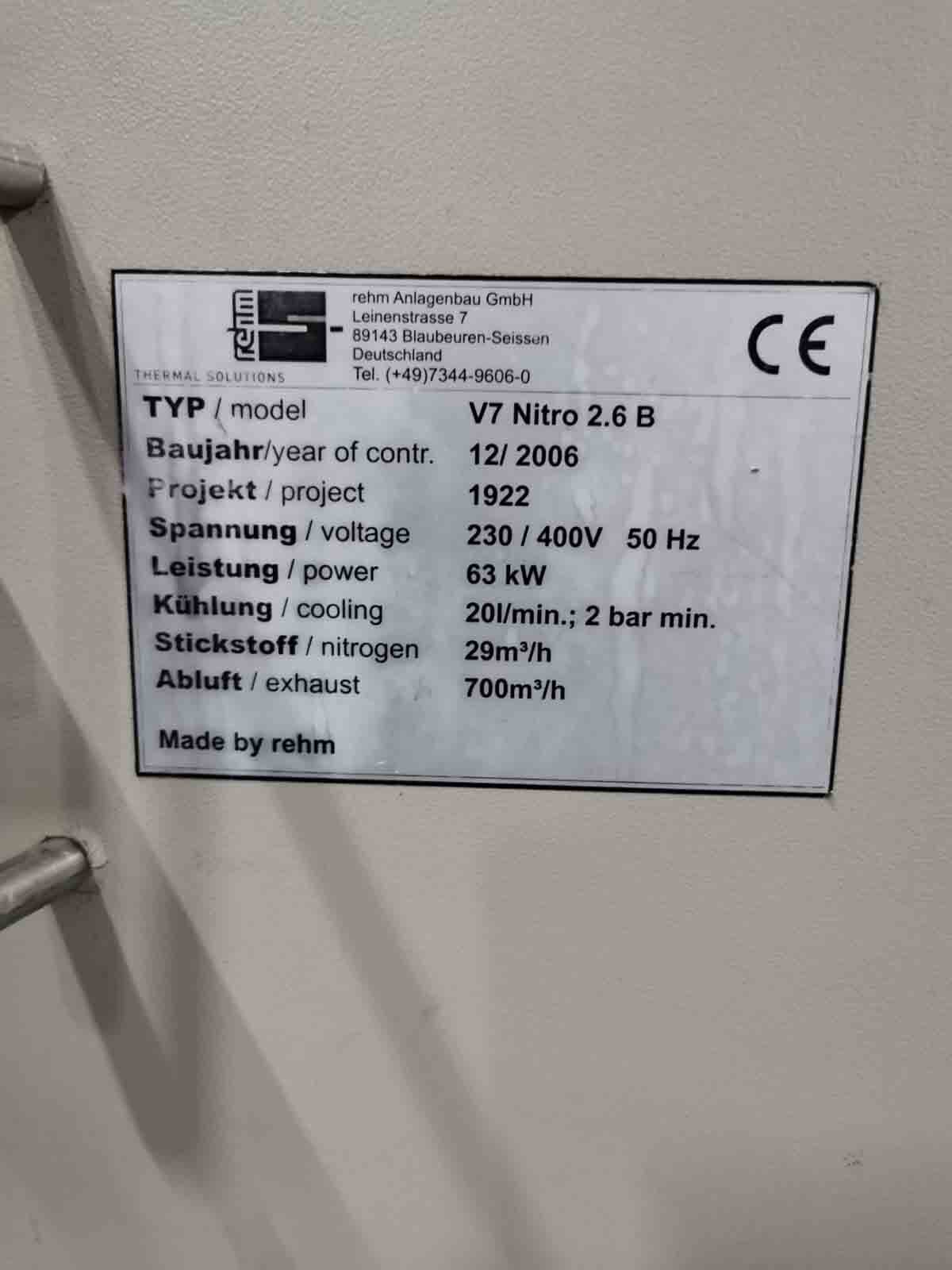

Used REHM V7 Nitro 2.6B #9235989 for sale

URL successfully copied!

Tap to zoom

ID: 9235989

Vintage: 2006

Reflow oven

(6) Heating zones

Cooling zone

Nitrogen / Air operation

Height with open hoods, 86.61"

Required area: 7.7 m²

Load per unit area: 400 kg/m²

Voltage supply

Nitrogen

Length of inlet table, 9.84"

Length of outlet table, 9.84"

Length: 102.36"

Pin chain conveyor:

Conveyor system height: 900 mm ±75 mm / 35.43", ±2.95"

Width:

Single conveyor ±0.5mm:

Min 3.15" (MU-lowest position) / 3.94" (MU-highest position) - Max 15.75" (option 18.11")

Dual conveyor ±0.5mm:

Min 3.15" (MU-lowest position) / 3.94" (MU-highest position) - Max 8.5"

Clearance above conveyor, 1.18"

Clearance below conveyor, 0.78"

Adjustable conveyor speed: 7.09" - 70.87" per minute

Tolerance conveyor speed: <= 0.354" per minute

Conveyor system height: 35.43" ±2.95"

Mesh belt conveyor:

Width mesh belt conveyor: 15.77"

Adjustable conveyor speed: 7.09" - 70.87" per minute

Tolerance conveyor speed: < 1%

Cooling water at external cooling:

Connection: M 28 x 1.5 (0.87" Cu tube)

Cooling water flow: between 10-20 l/min/158.5-317 gal/hr

Operating pressure: 2 bar / 29 psi - 5 bar /145 psi

Differential pressure: 0.5 bar / 72.52 psi

Voltage supply consumption:

Type of power system: 5-wire system (L1, L2, L3, N, PE)

Voltage supply: 230/400 VAC ± 5%, 50 Hz

Connected load without bottom heating V7 nitro: 44 kW

Connected load with bottom heating V7 nitro: 53 kW

Connected load +5kW, with internal cooling

Operating capacity without bottom heating V7 nitro: 11.0 kW

Operating capacity with bottom heating V7 nitro: 13.3 kW

Operating capacity +2 kW, with internal cooling

Nitrogen supply:

Connection: M16x1 (10.472" Cu tube)

Nitrogen supply pressure: 6 bar/87 psi - 10 bar /145 psi

Operating pressure: 5 bar/72.52 psi

Nitrogen consumption (single conveyor at <100 ppm in peak):

25 - 29 m³/h 14.71 -17.06 ft³/min

Exhaust:

Exhaust socket diameter: 5.91"

Exhaust at min 3 mbar under pressure V7 nitro: 600 m³/h/353.36 ft³/min

Exhaust temperature: < 50°C / 122°F

Exhaust external cooling / warm + clean air:

Exhaust socket dimensions: 28.15" x 11.82"

Exhaust surrounding temperature: 2400 m³/h /1413 ft³/min

Exhaust temperature: < 50°C / 122°F

Heating:

(4) Preheating zones

(2) Peak zones

Length of zones: 15.75"

Cross profile (Delta T:Tmax thin): ±2.5 Kelvin

Permissible soldering temperature

Preheating zones, 300°C / 572°F

Peak zones, 350°C / 662°F

Heat transfer through forced convection

Gas circulation per heating zone: 600m³/h / 353.15 ft³/min

Cooling zone: Length: 49.21"

Warm up time: 30 minutes

Specification: 5K / 4 sigma

Maximum noise level without internal cooling: 72dBA

Maximum noise level with internal cooling: 75dBA

Room temperature: between 15°C and 32°C / 59°F and 89.6°F

Humidity: between 30% and 75%

Oxygen: < 100 ppm in peak zone

Center support:

Center support V7: link chain, 20mm

Center support position: 1.97" - 3.78" (Option 16.14"/18.03")

2006 vintage.

REHM V7 Nitro 2.6B reflow oven is an industrial tool for soldering electronic components on printed circuit boards or similar circuit substrates. It is powered by a Propane/Butane gas heater, which provides up to 12 stages of temperature control for accurate soldering results. The oven has a working area of 890 x 420 mm, allowing for boards up to 25 cm in length and width. The V7 Nitro 2.6B oven uses infrared radiation to evenly heat all areas of the board, providing an even, uniform solder melting temperature. It also uses forced convection air for cooling the solder joint to ensure a reliable and consistent temperature is reached. The oven is equipped with a variety of built-in features to ensure reliable results. It has an automatic dual-timer, adjustable from 0-60 minutes, to ensure accurate soldering timing. It also has a 200 program memory, so that various board types can be stored and recalled as needed. The integrated vacuum system is used to ensure the board remains flat and prevents any contact disruption during the heating and cooling process. Other features include a window for inspection of the process, heavy-duty stainless steel insulated double-wall chamber, and a robust industrial strength roller conveyor for easy board loading and unloading. The oven has a variety of safety features that ensure operator and equipment safety. The automated door locking system, with adjustable delay timer, prevents any accidental opening or closing of the chamber which could interrupt the process. Additionally, a safety sensor is installed to ensure that the chamber is not opened in the middle of a process. The built-in fire suppression system uses an inert gas for fire prevention and has the ability to automatically shut down the oven in case of a fire. REHM V7 Nitro 2.6B reflow oven is a robust and reliable tool for enhancing the soldering of electronic components. Its features ensure uniform heating and cooling processes and its safety features guarantee the safety of workers and equipment.

There are no reviews yet