Used SMT 2.8 PC N2 #9407167 for sale

URL successfully copied!

Tap to zoom

ID: 9407167

Vintage: 2005

Reflow ovens

(3) Heating modules (Preheat zones)

Peak zone with (2) heating modules

(12) SMT Slot nozzle units

Heated tunnel length: 2700 mm

Active convection zone: 2405 mm

Cooling zone length (Stage 1): 1370 mm

Temperature measurement: NiCr-Ni Sensors

Warm up time: 30 mins (Approximately)

Air circulation: 1600 m³/h

Air circulation for (5) Heating modules: 8000 m³/h

Process temperature: 300°C (Preheat zone), 350°C (Peak)

Transport chain conveyor:

Working width: 10-460 mm

Working width with PCB support: 60-460 mm

Working height PCB support PIN level: -15mm

Pass-through height (Top / Bottom): 30/30 mm

Transport mesh belt conveyor:

Working width: 500 mm

Pass-through height (Top): 30 mm

Conveyor speed: 0.2 to 2.0 m/min

Average conveyor speed 0.6 to 0.9 m/min

Extraction 3:

Suction nozzles 2 x Æ150 mm

Required exhaust air per nozzle (Inlet / Outlet): 300 to 400 m3/h

Temperature of exhaust air at nozzle temperature: < 50°C

Continuous sound pressure: < 70 dB(A)

Control unit PC

Power supply:

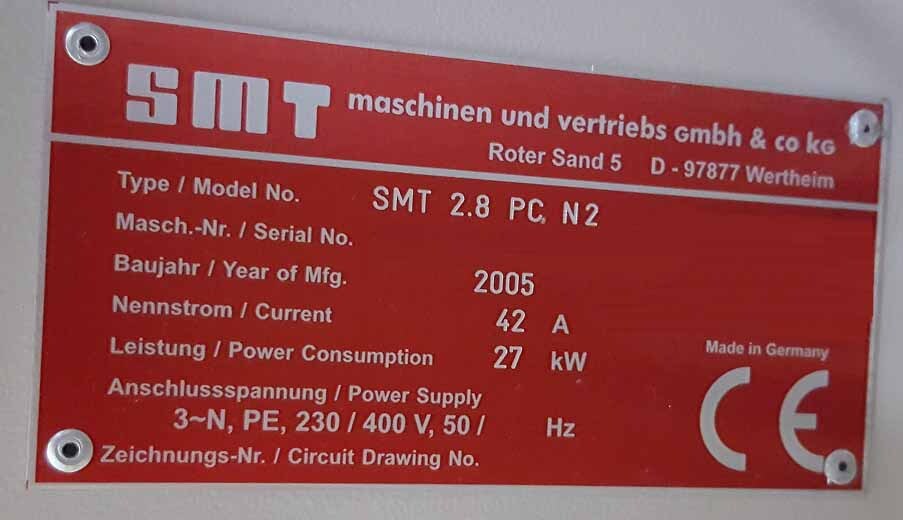

Connecting power supply: PE 230 / 400 V, 3~N, 50/60 Hz

Maximum current consumption per phase (5) Heating modules: 42 A

Power consumption during heat-up: 27 kW

Power consumption steady-state: ~4 kW

2005 vintage.

SMT 2.8 PC N2 Reflow oven is a high-efficiency and high-precision oven designed for reflow soldering machine applications. It comes equipped with an intelligent profile control equipment and a 3-zone hot air convection system. The oven utilizes a microprocessor-controlled unit and provides the most accurate temperature control and repeatability available. It is well-suited for medium to high volume reflow soldering of medium to high density printed circuit boards (PCBs). SMT 2.8 PC N2 features a wide-body design that accommodates larger boards within its 23.6" (600 mm) long x 13.4" (340 mm) wide interior chamber. It comes with three temperature zones that allow for accurately controlling temperature profiles. Each zone is independently temperature-controlled and uses a combination of convection and infrared/radiant heat to properly heat the board and ensure flat, uniform solder joint formation. The advanced profile controlling machine of the oven allows for up to 6 programmable temperature profiles and ensures uniform temperatures throughout the entire profile. The profile can be adjusted on-the-fly to suit the product process, eliminating the need for traditional PID tuning. It also has a user-friendly LCD display controller, allowing for easy set-up of parameters and for full visual management. The controller is designed with a datalogger to store historical data for review and analysis. As for safety, the oven has numerous built-in features to prevent over-heating, such as over-temperature protection shut down, as well as multiple alarms and warnings for various tool conditions. It features an external exhaust port for fume management and has a check-check function that provides continuous monitoring of temperature-setting accuracy and profile repeatability. Overall, SMT 2.8 PC N2 Reflow Oven is a reliable and efficient piece of equipment that offers precision temperature control with excellent uniformity and accuracy. It is suitable for medium to high-volume soldering and is an excellent choice for a variety of reflow soldering applications.

There are no reviews yet