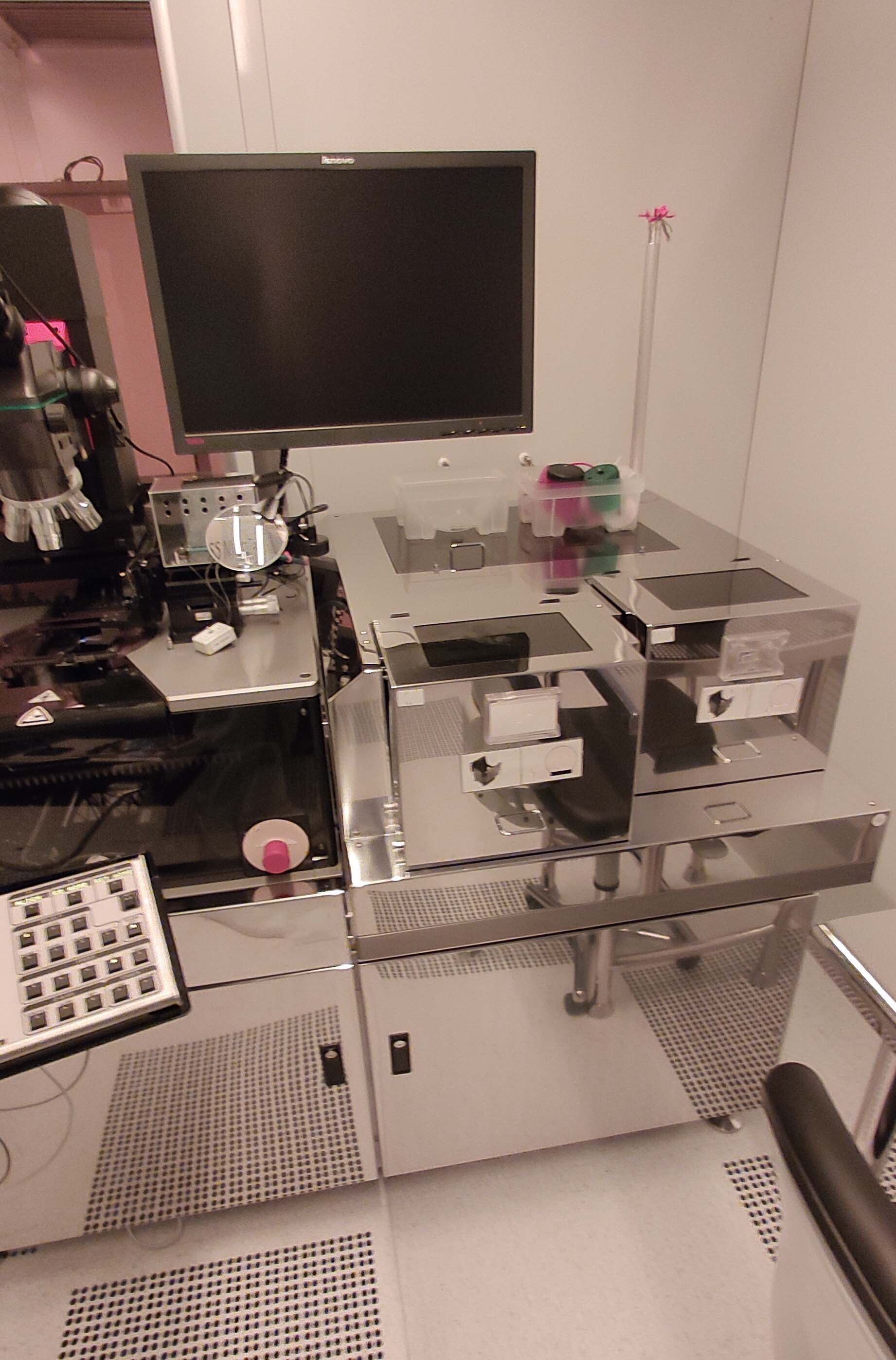

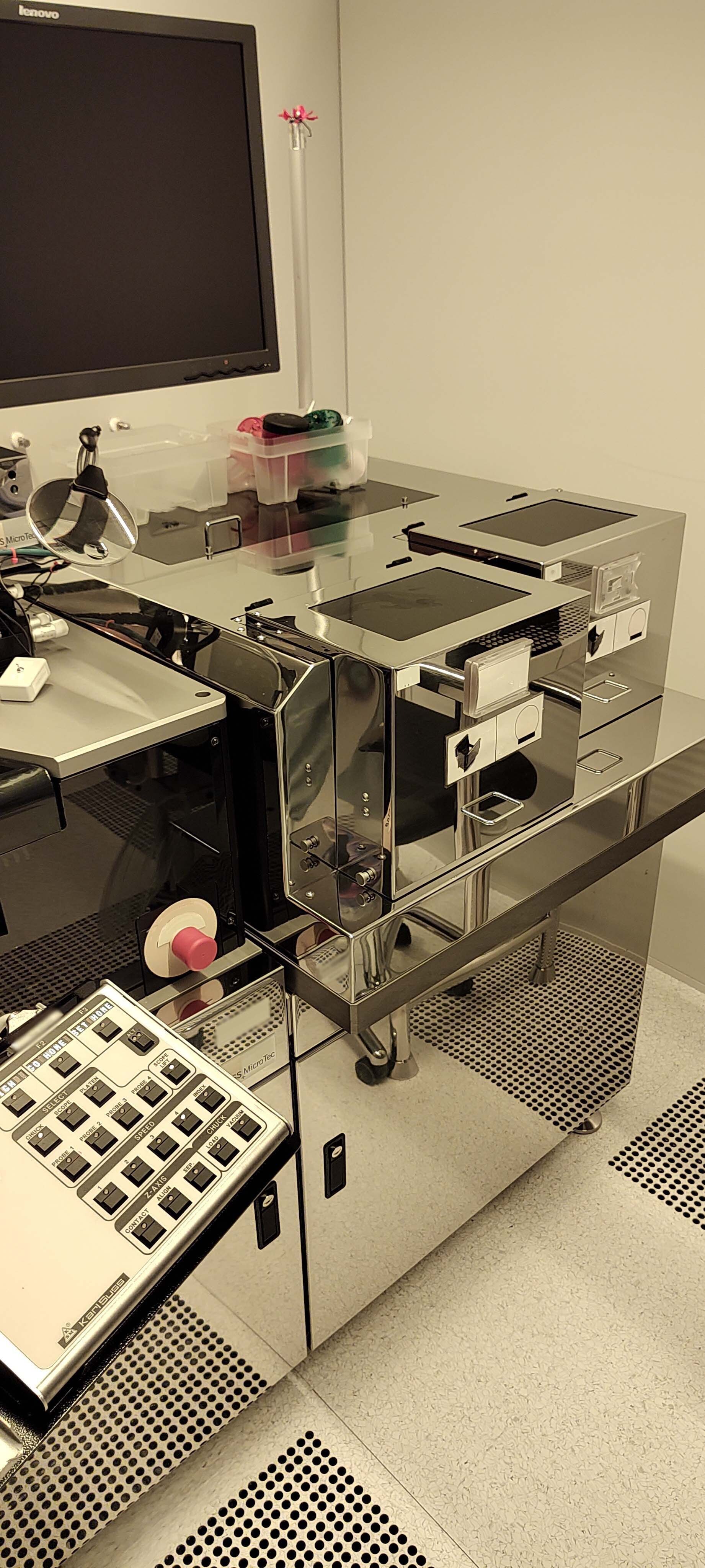

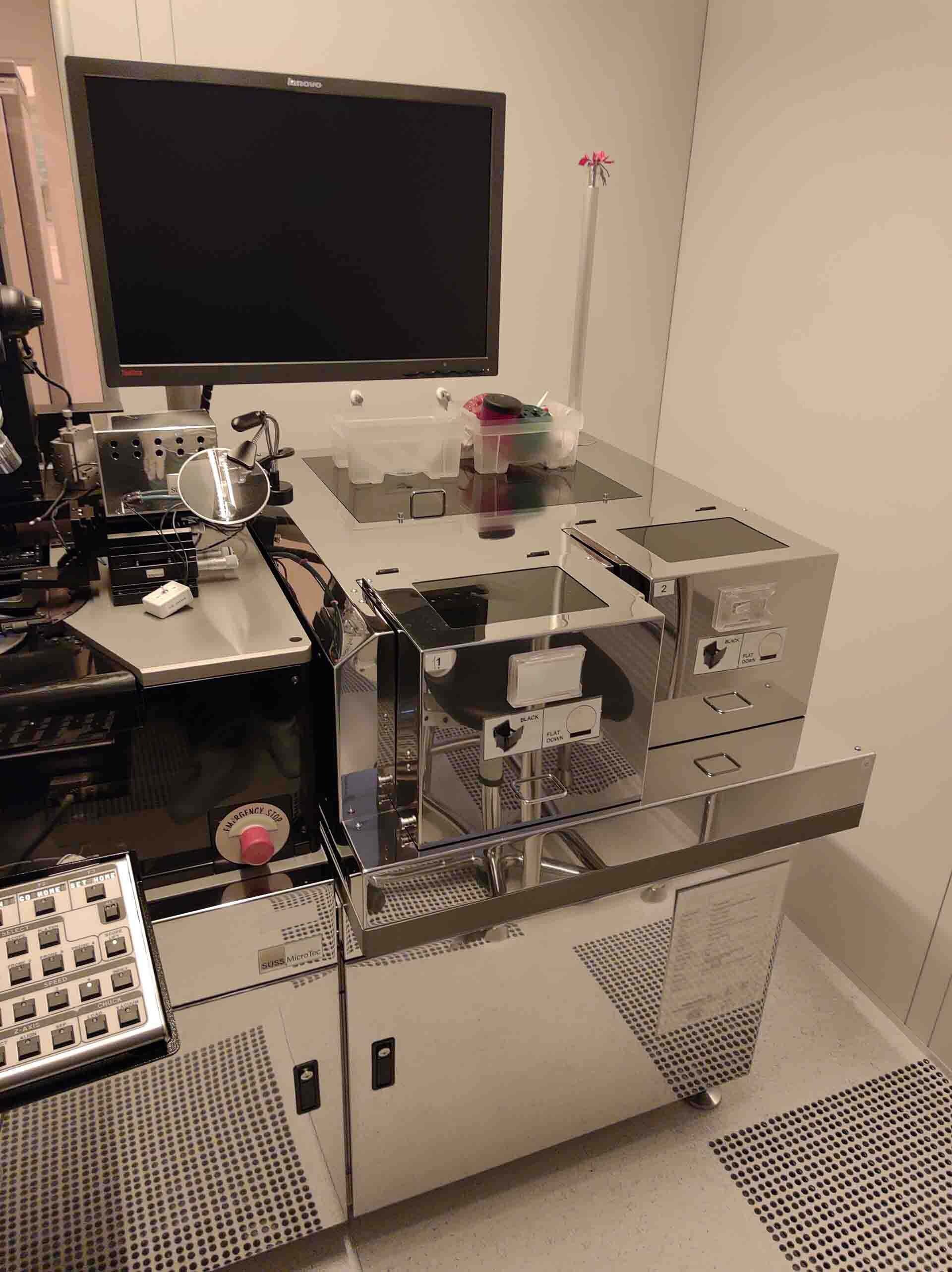

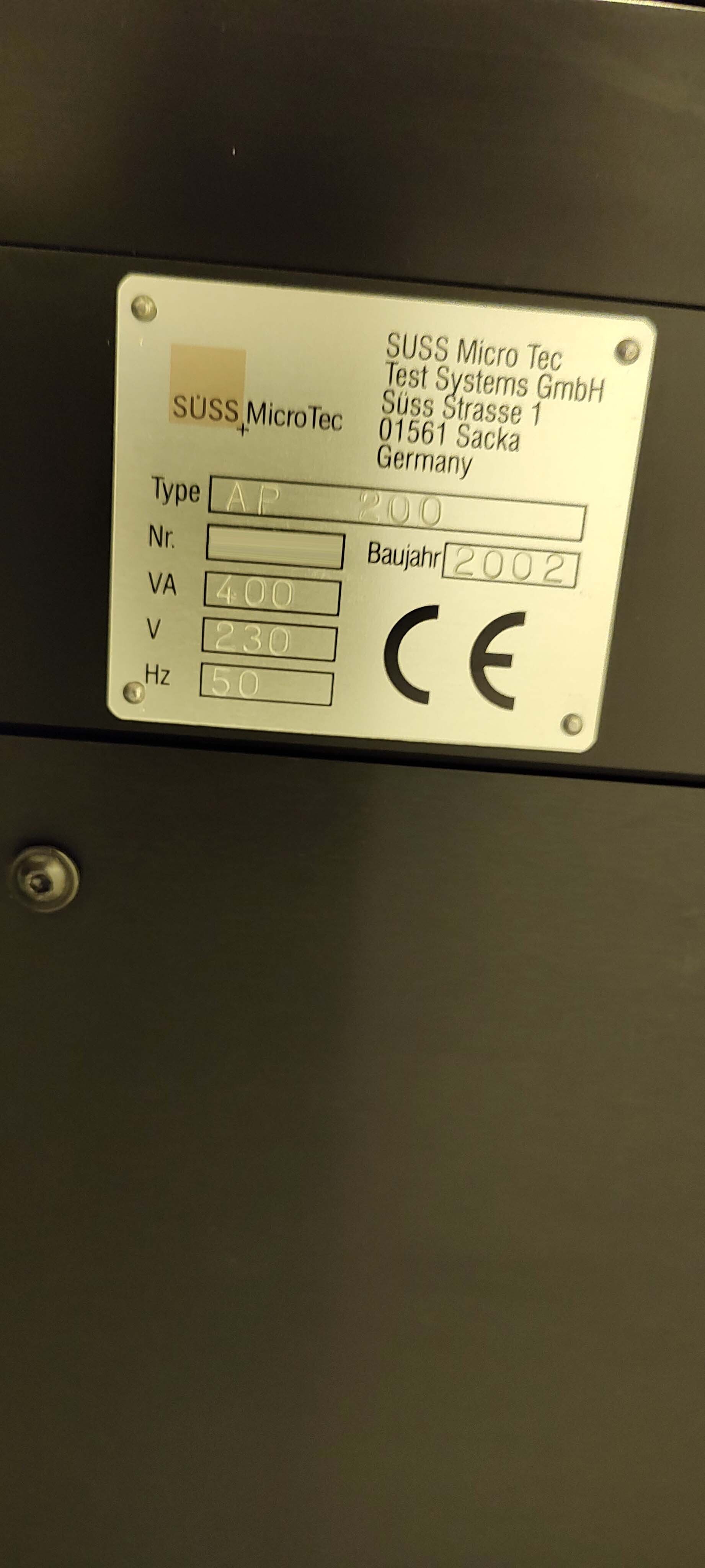

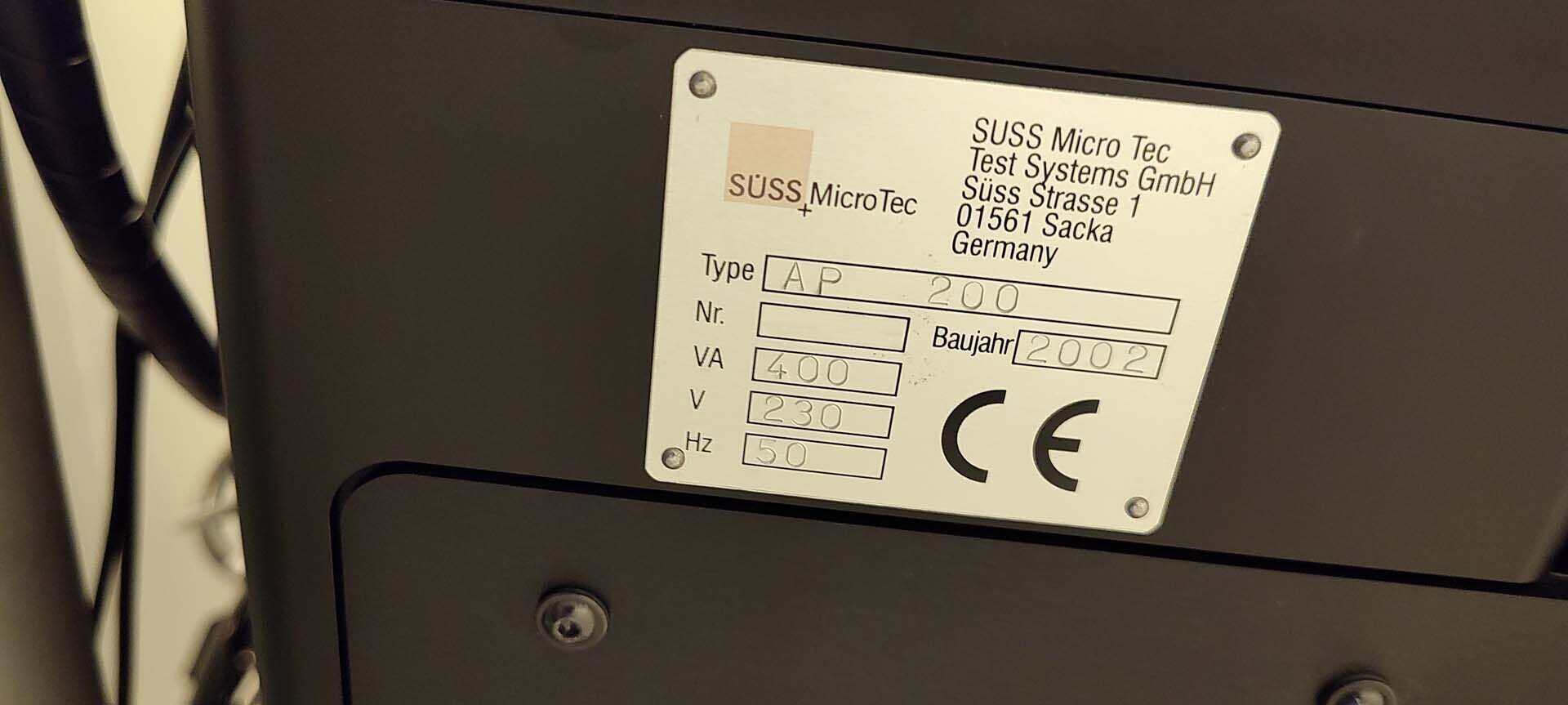

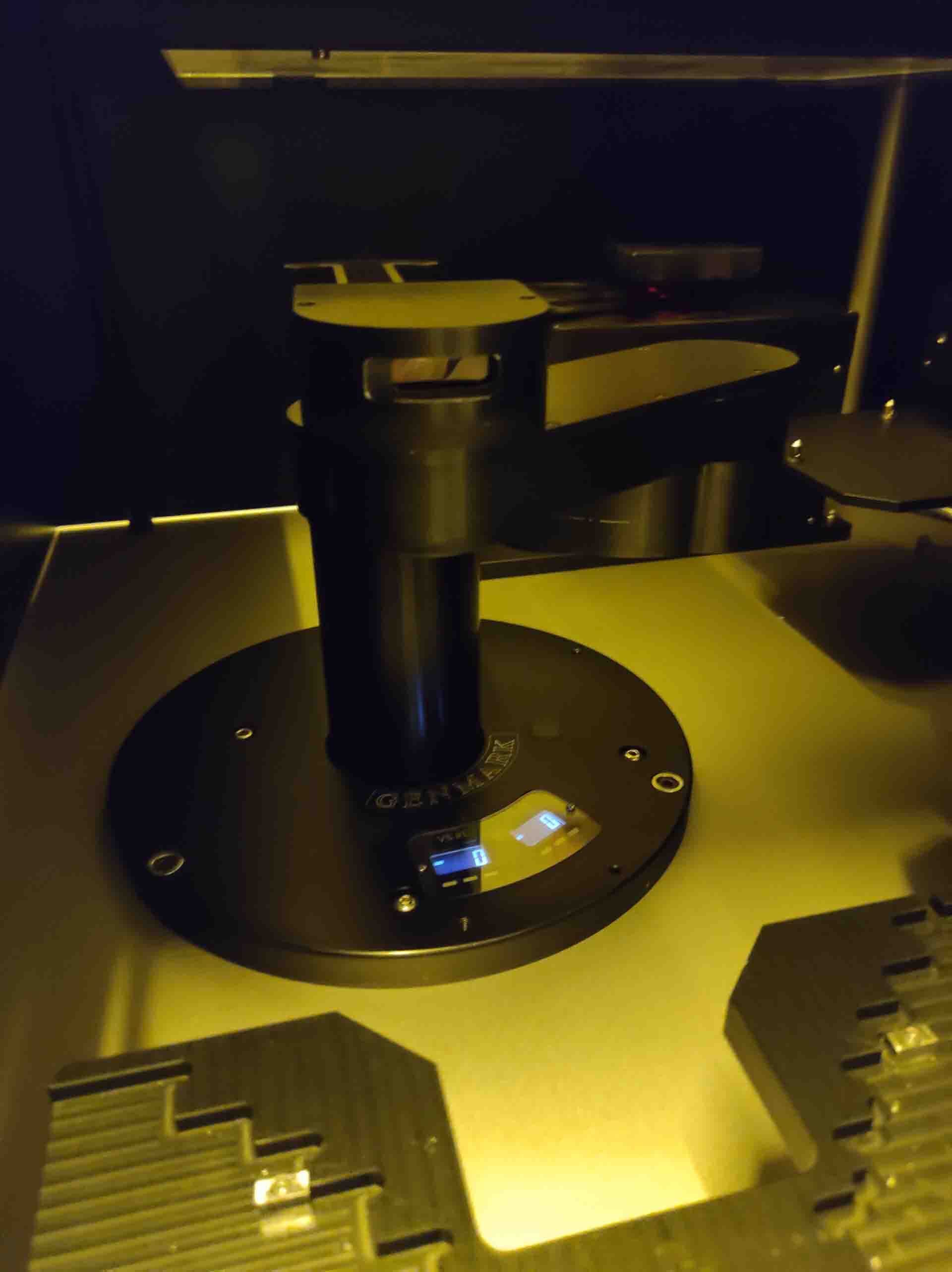

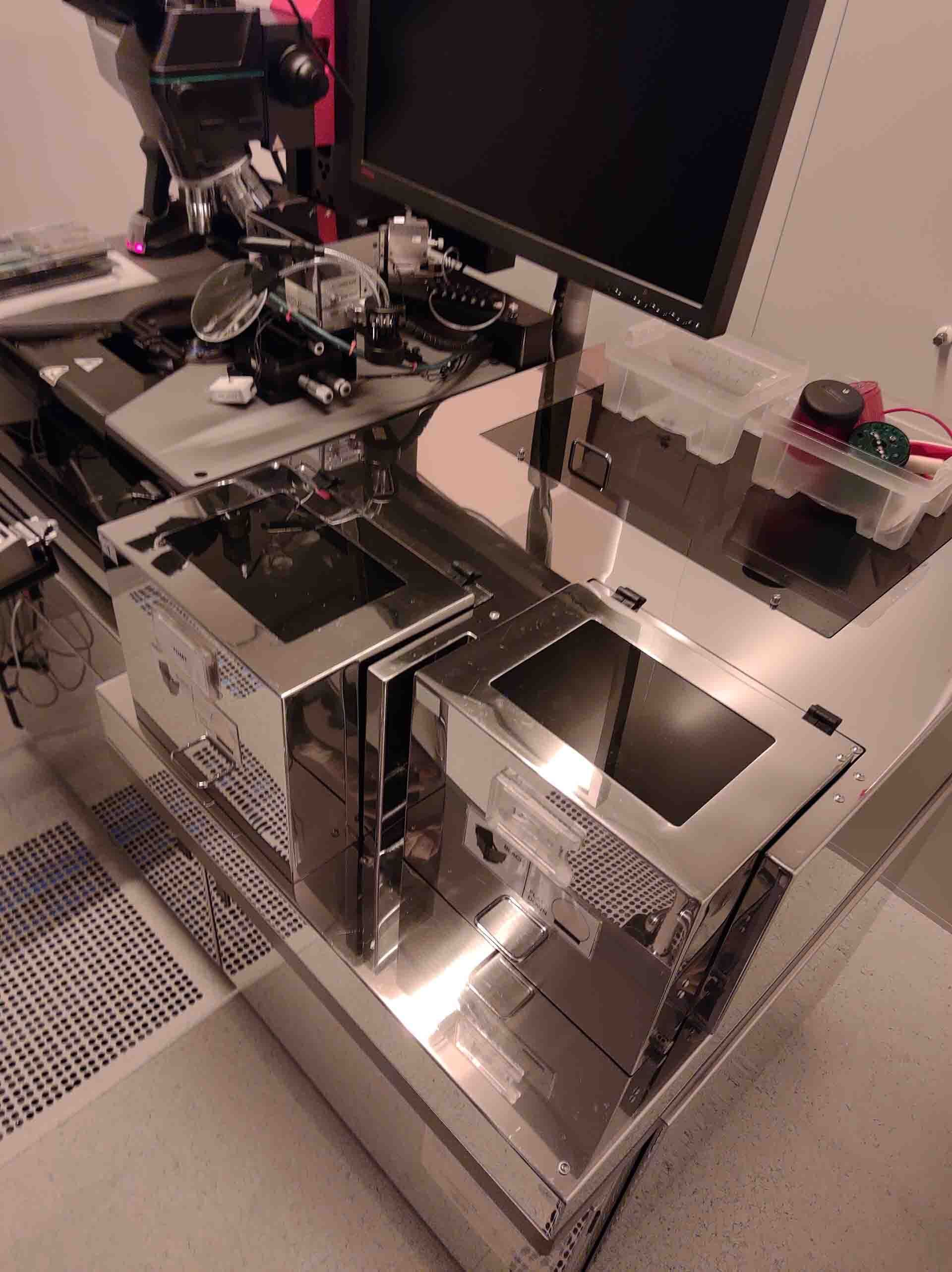

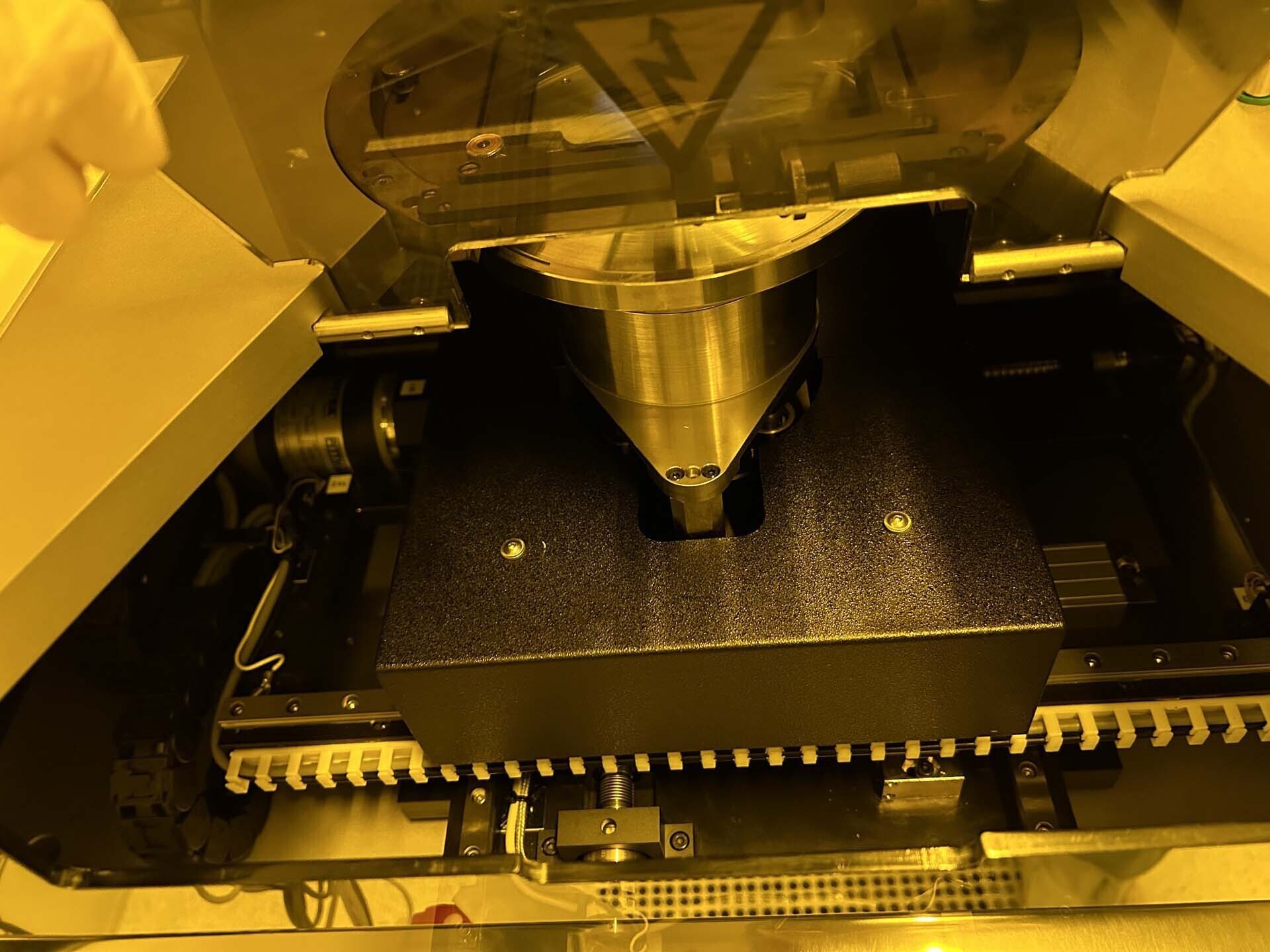

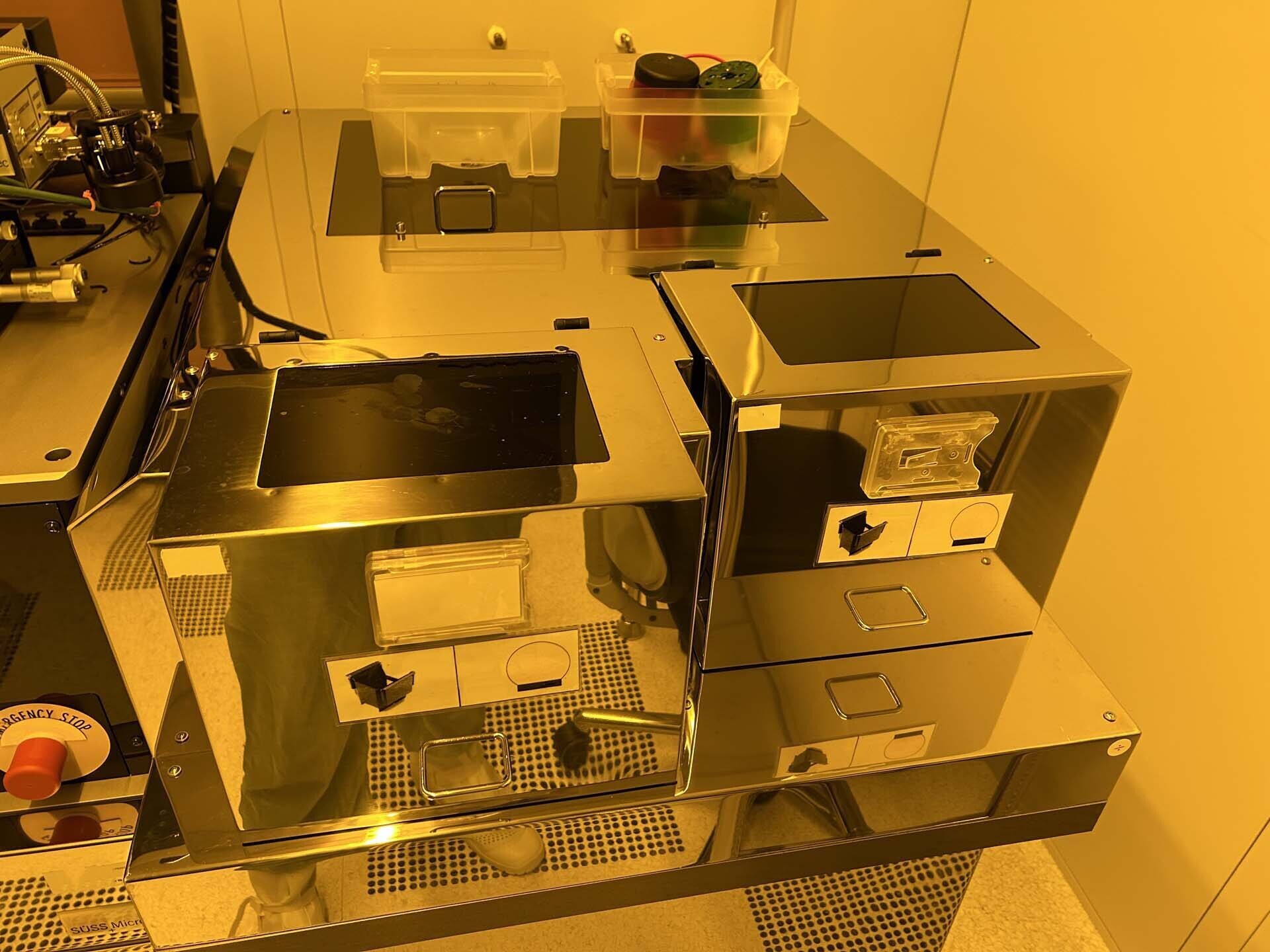

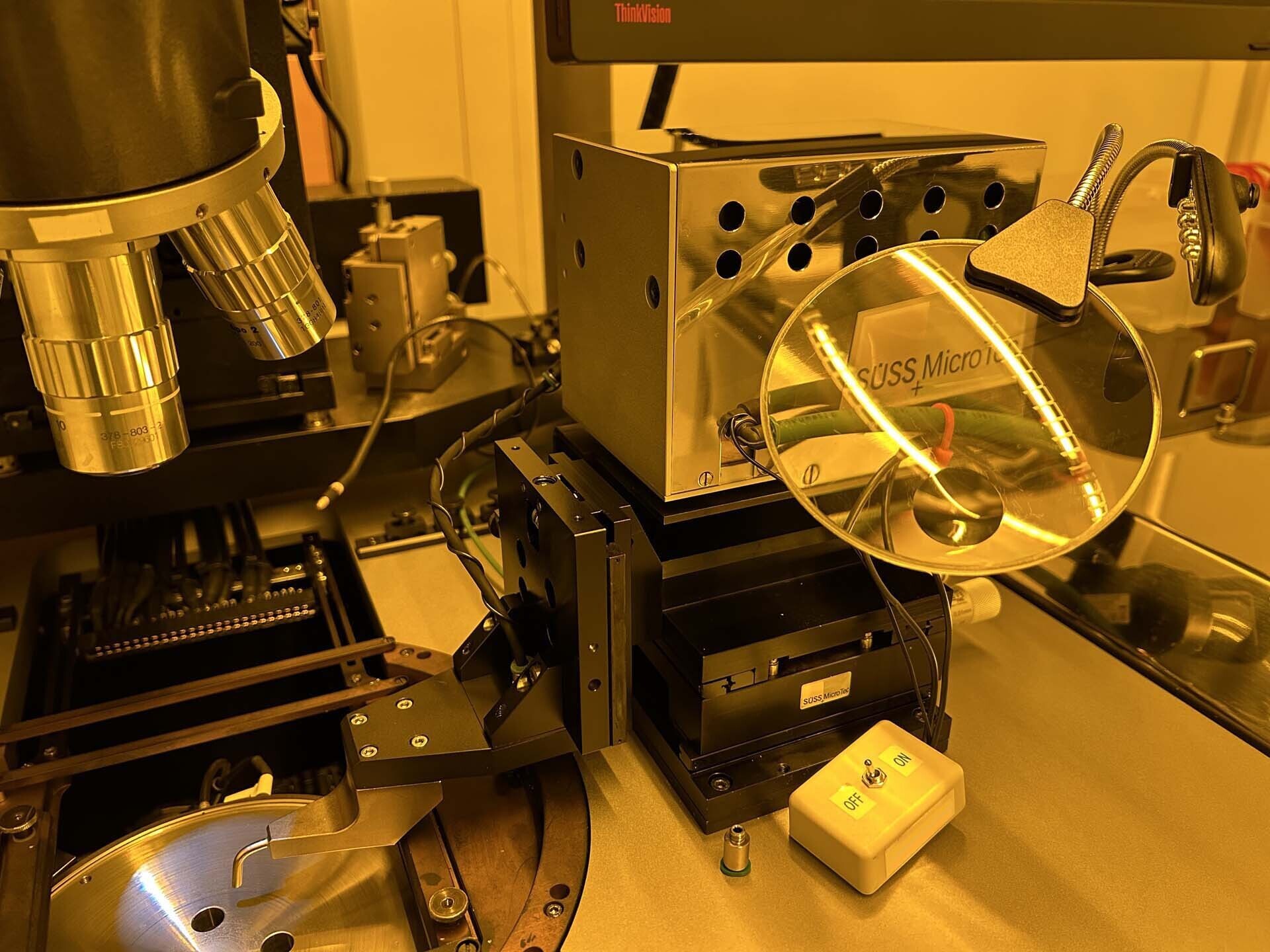

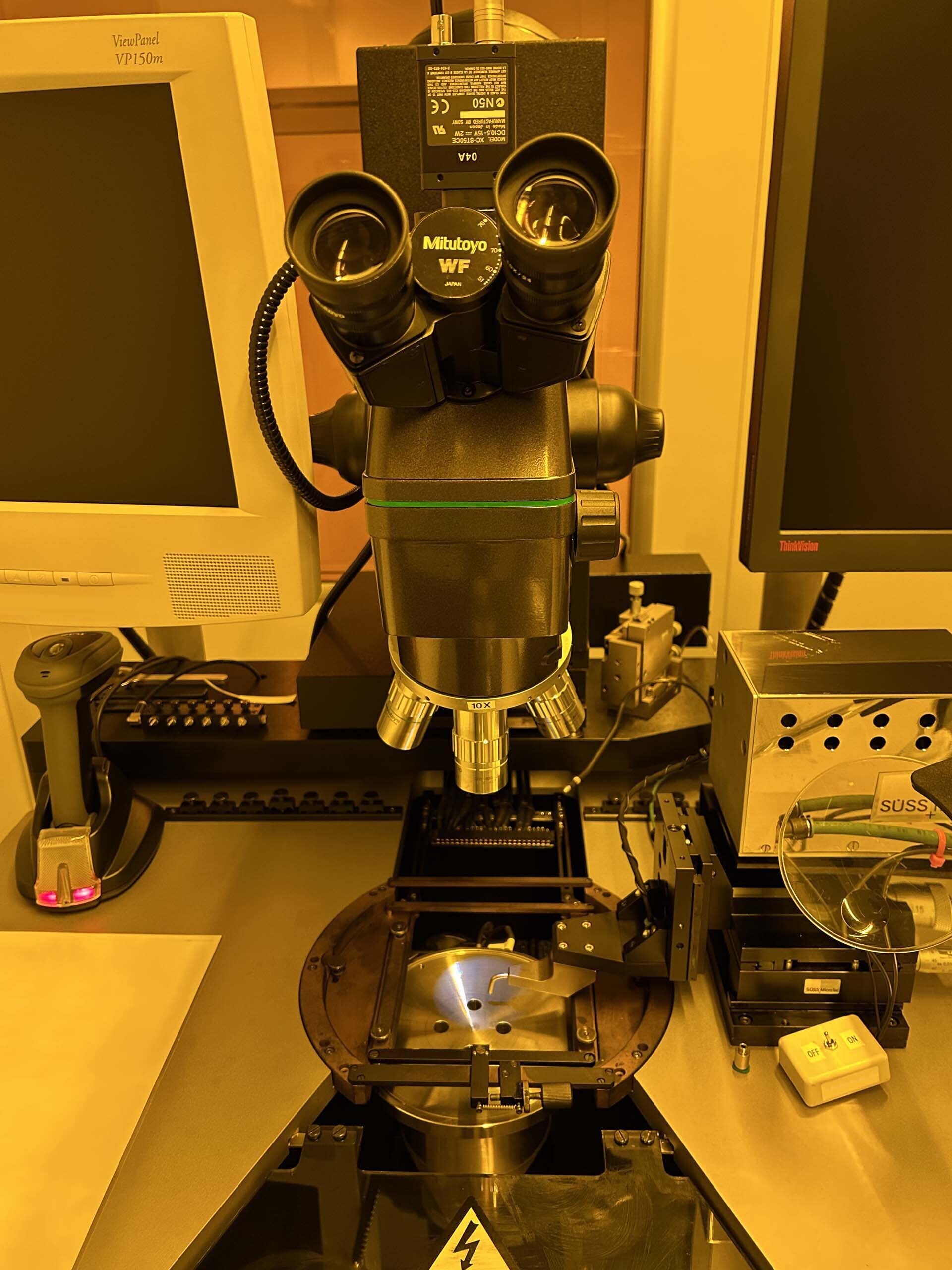

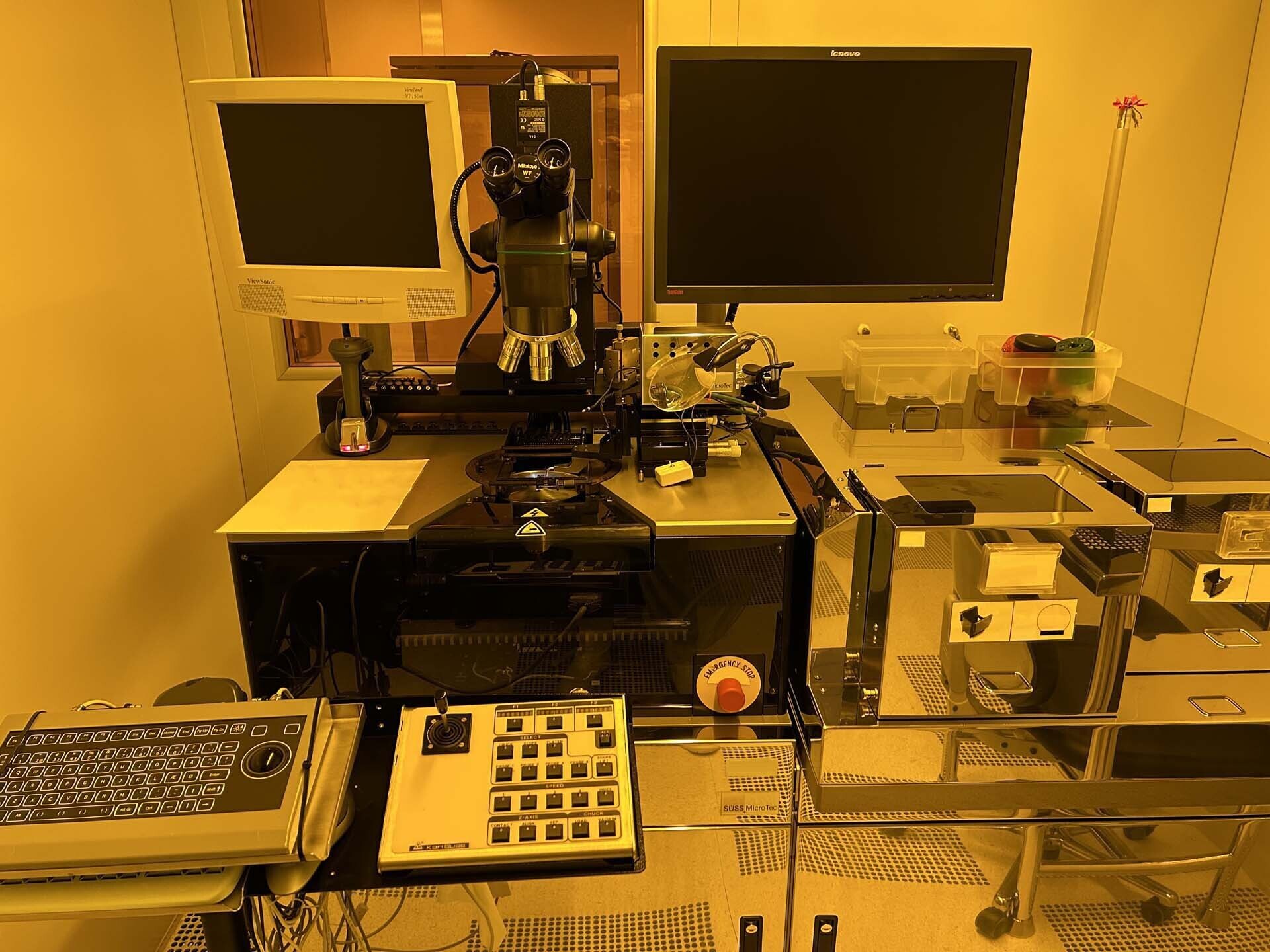

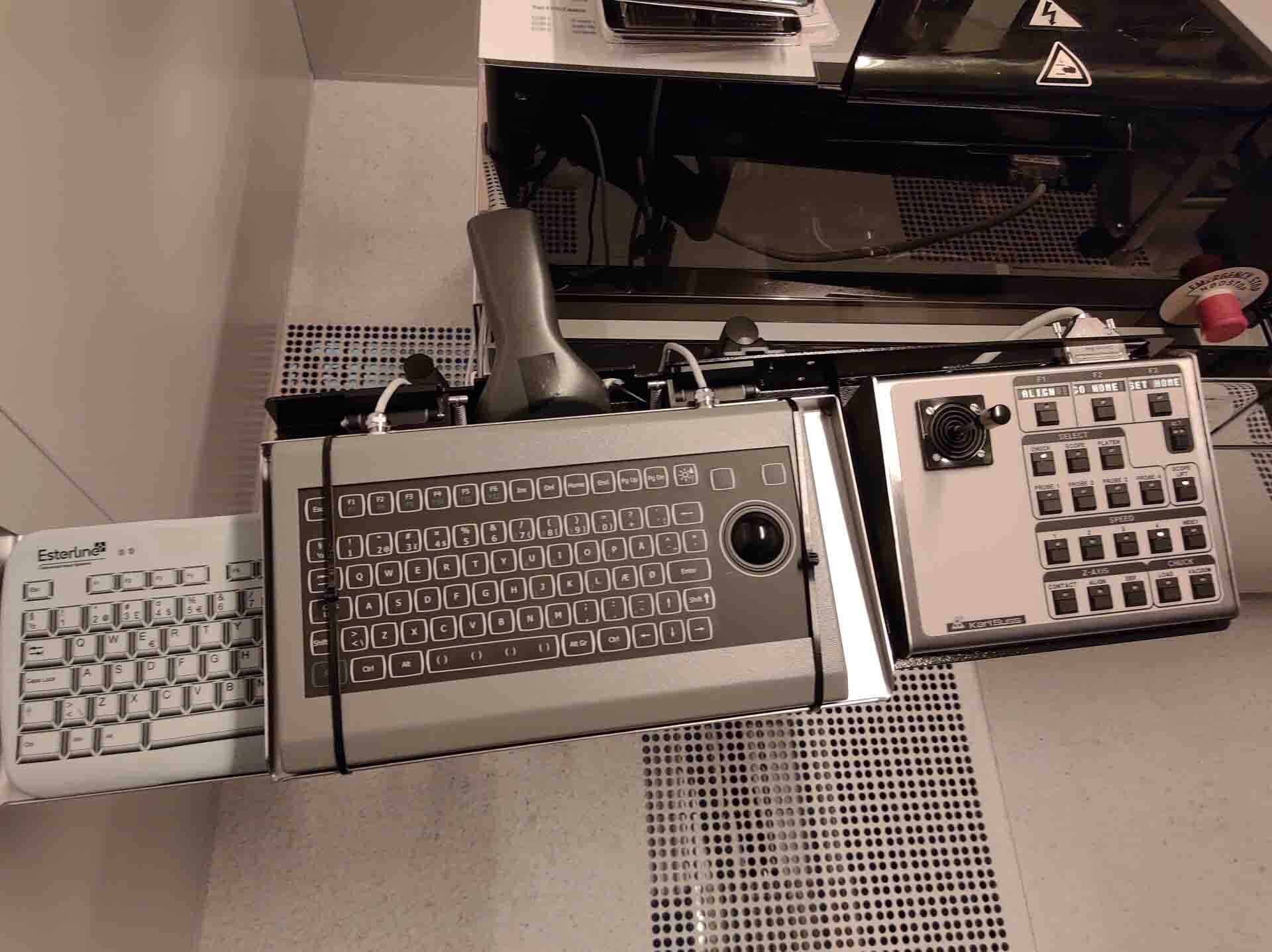

Used KARL SUSS / MICROTEC AP 200 #293629348 for sale

URL successfully copied!

Tap to zoom

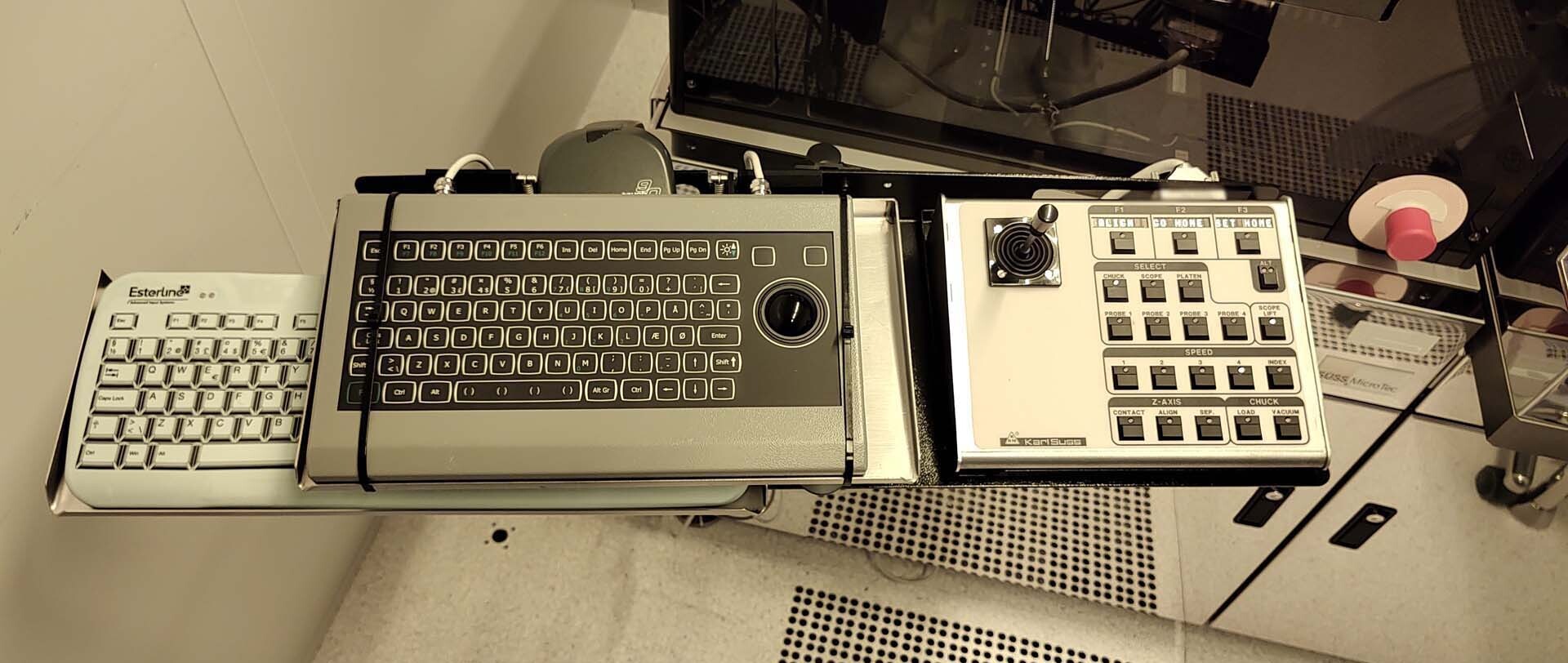

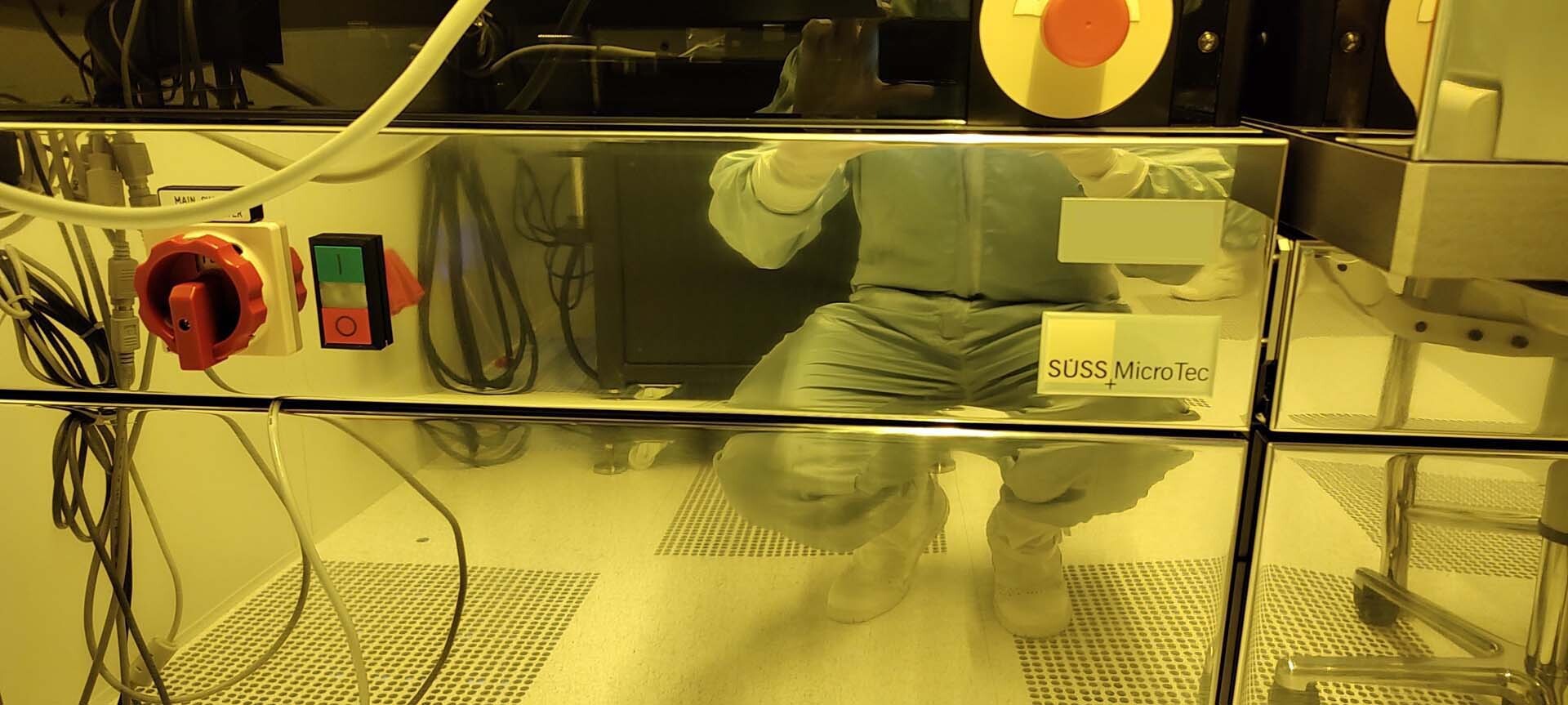

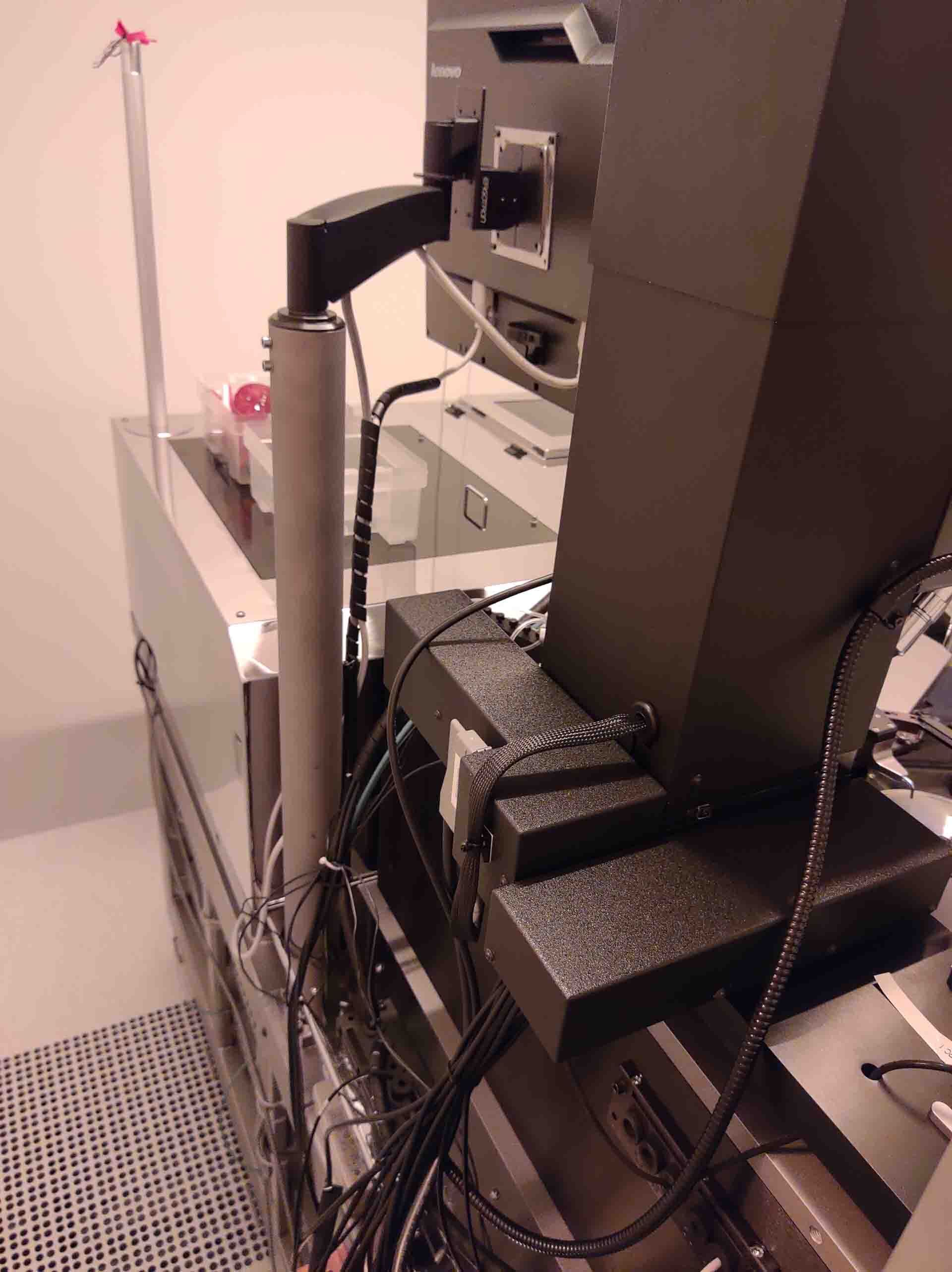

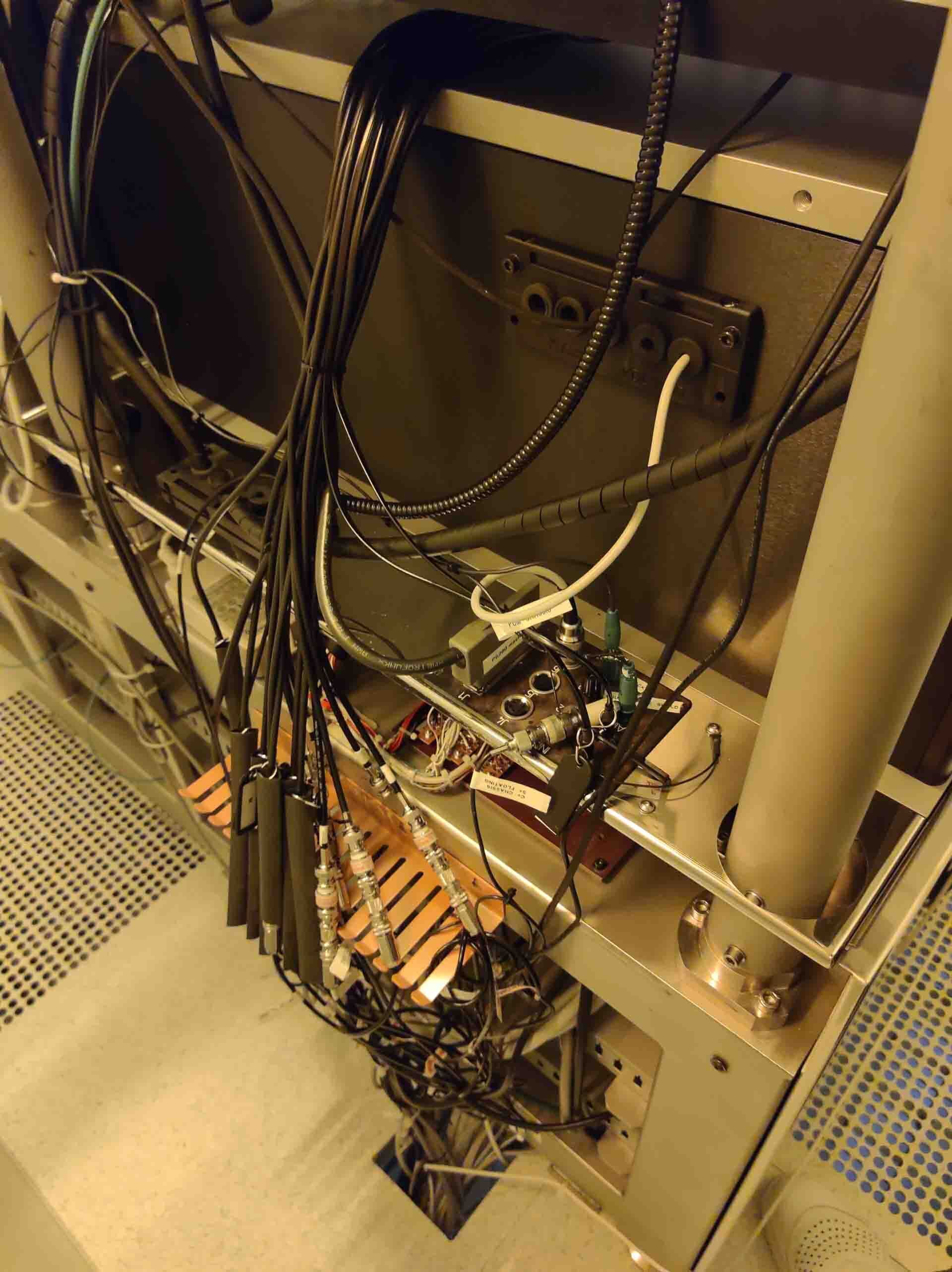

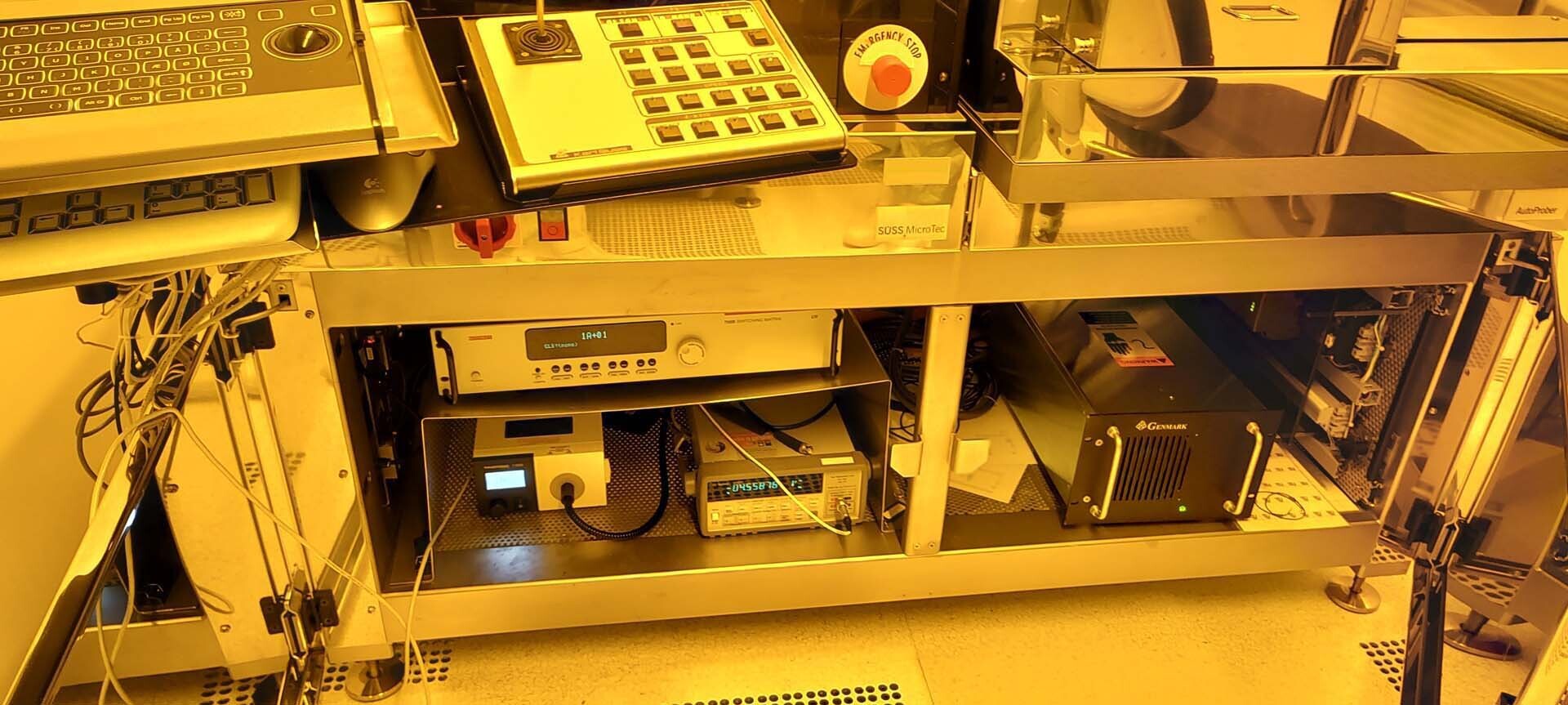

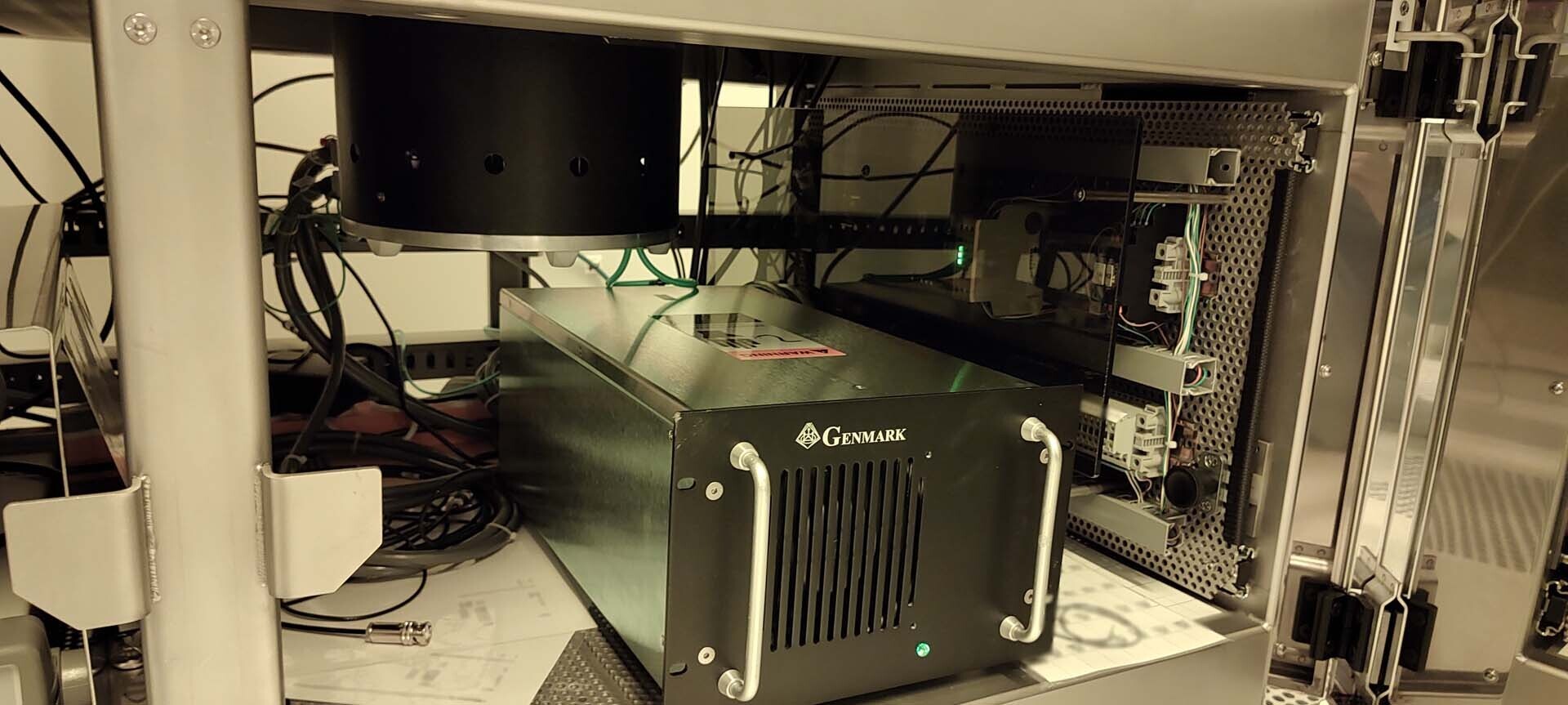

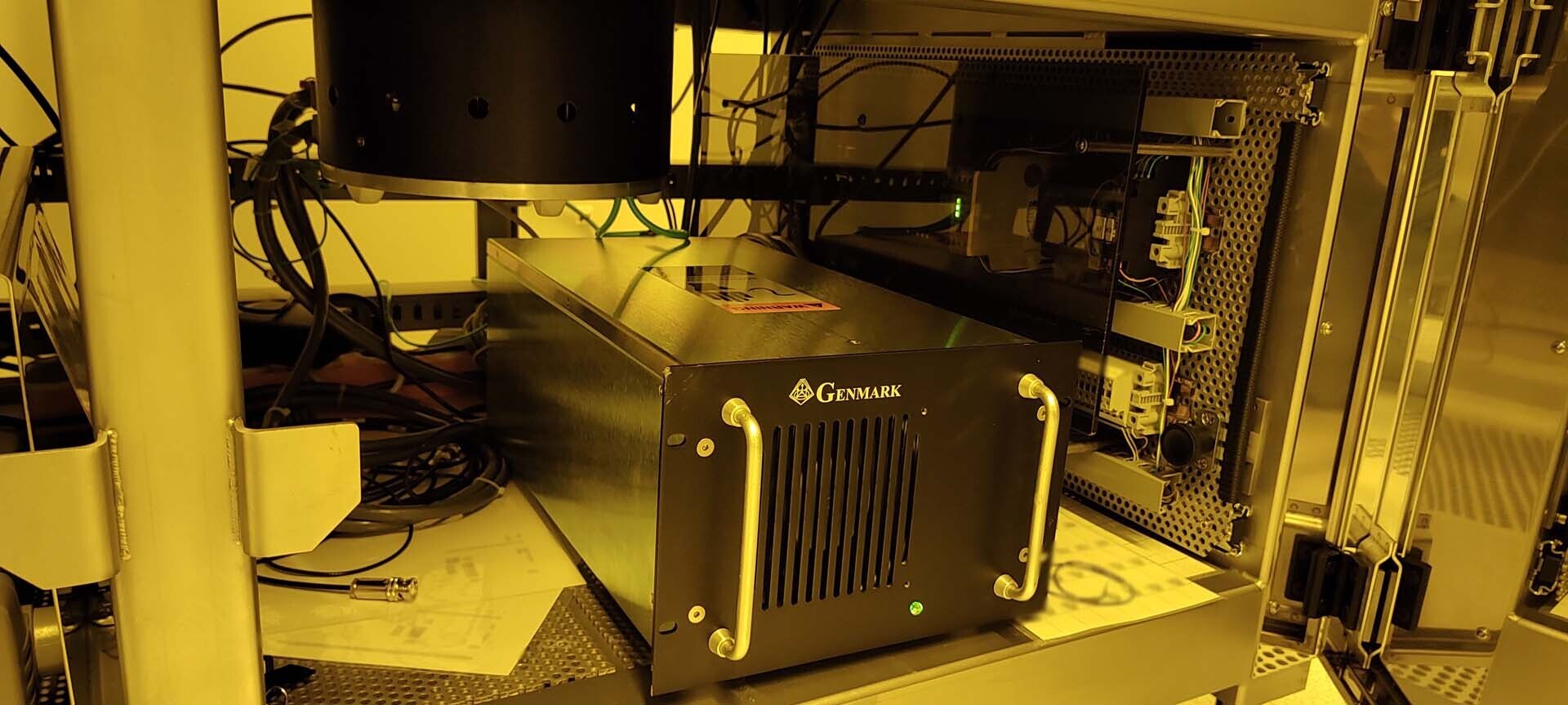

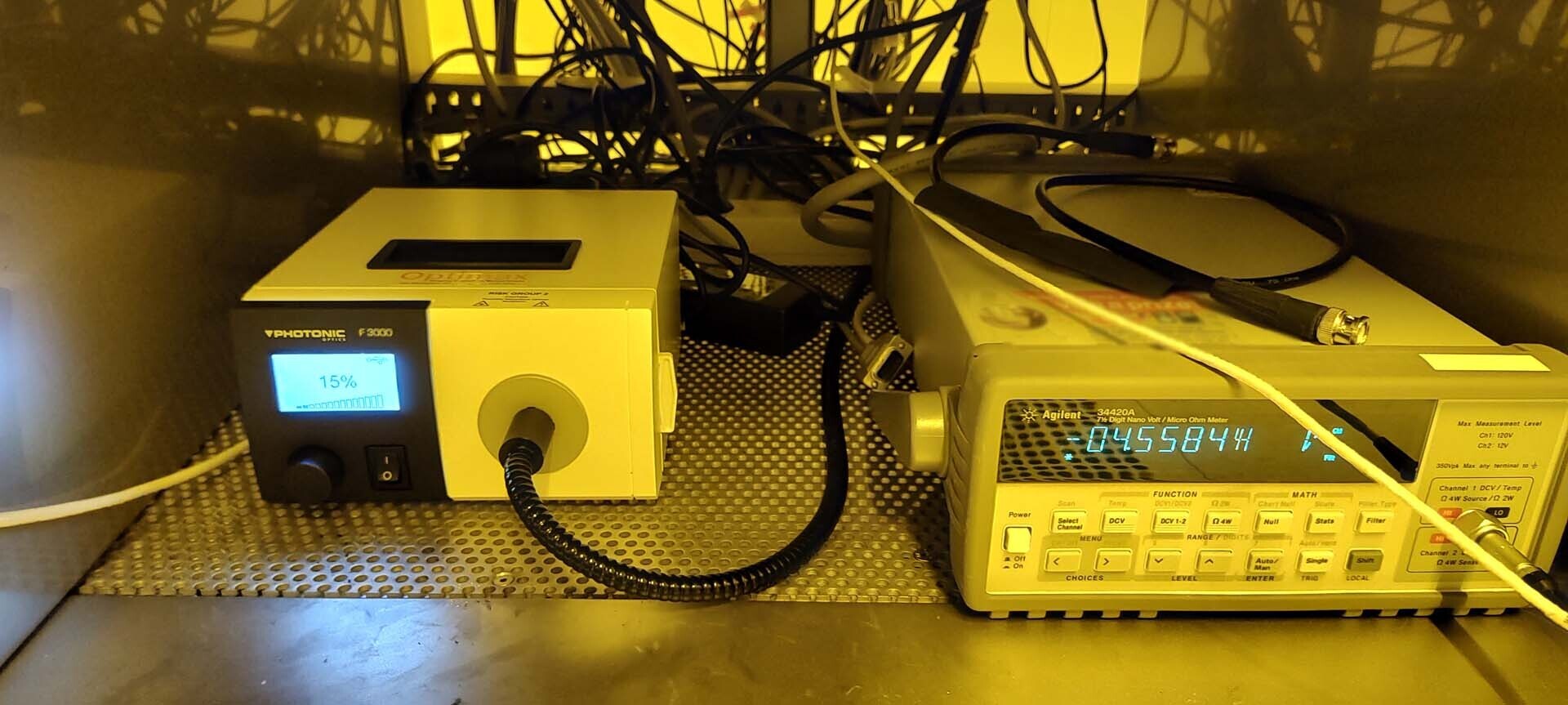

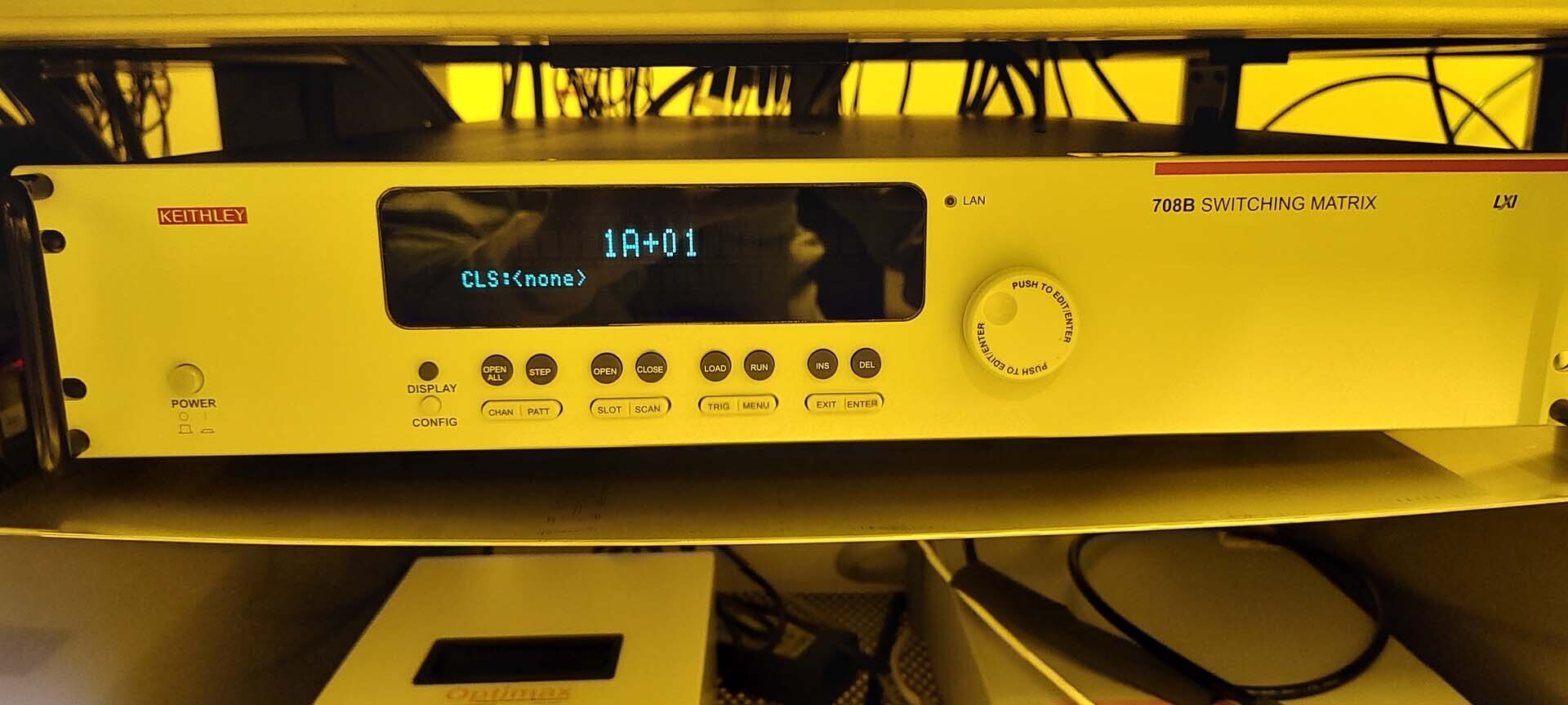

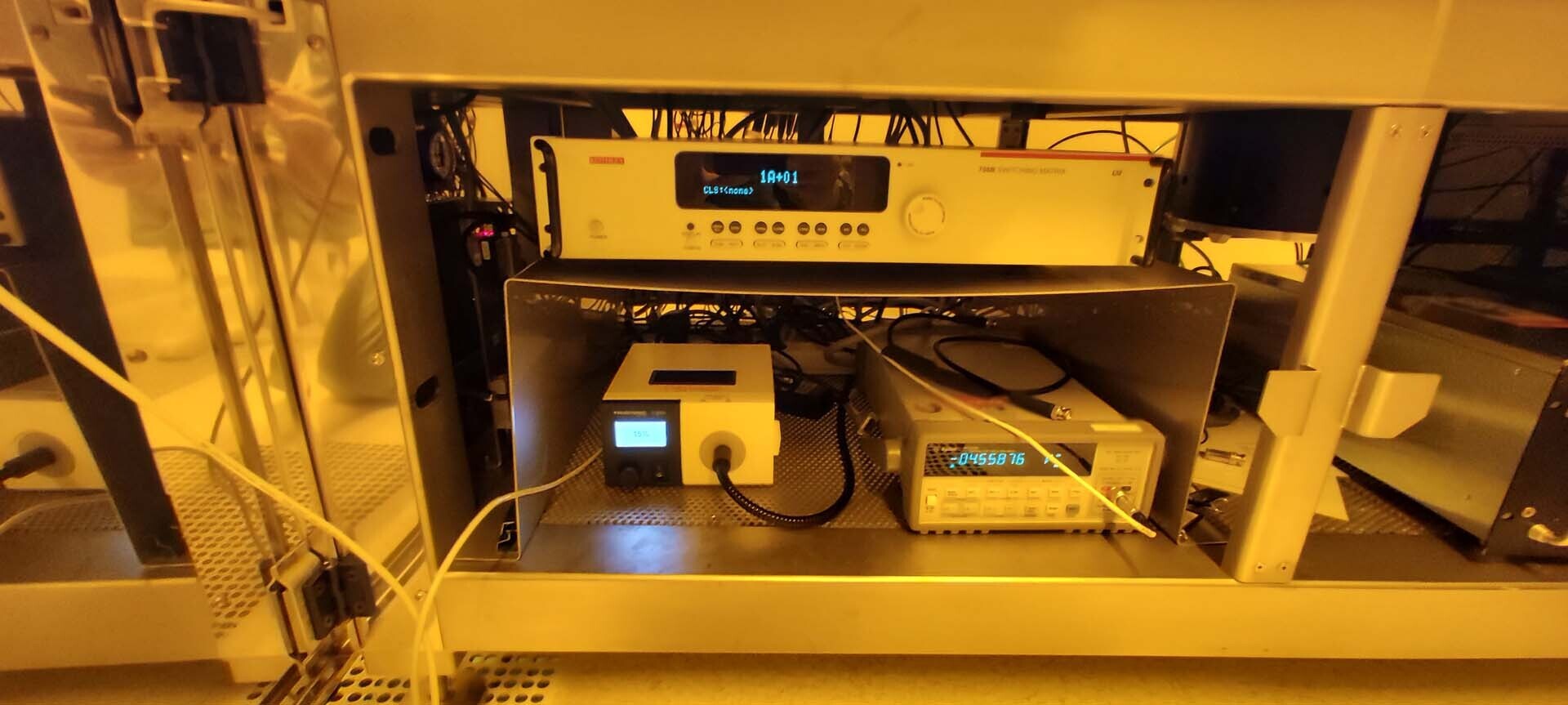

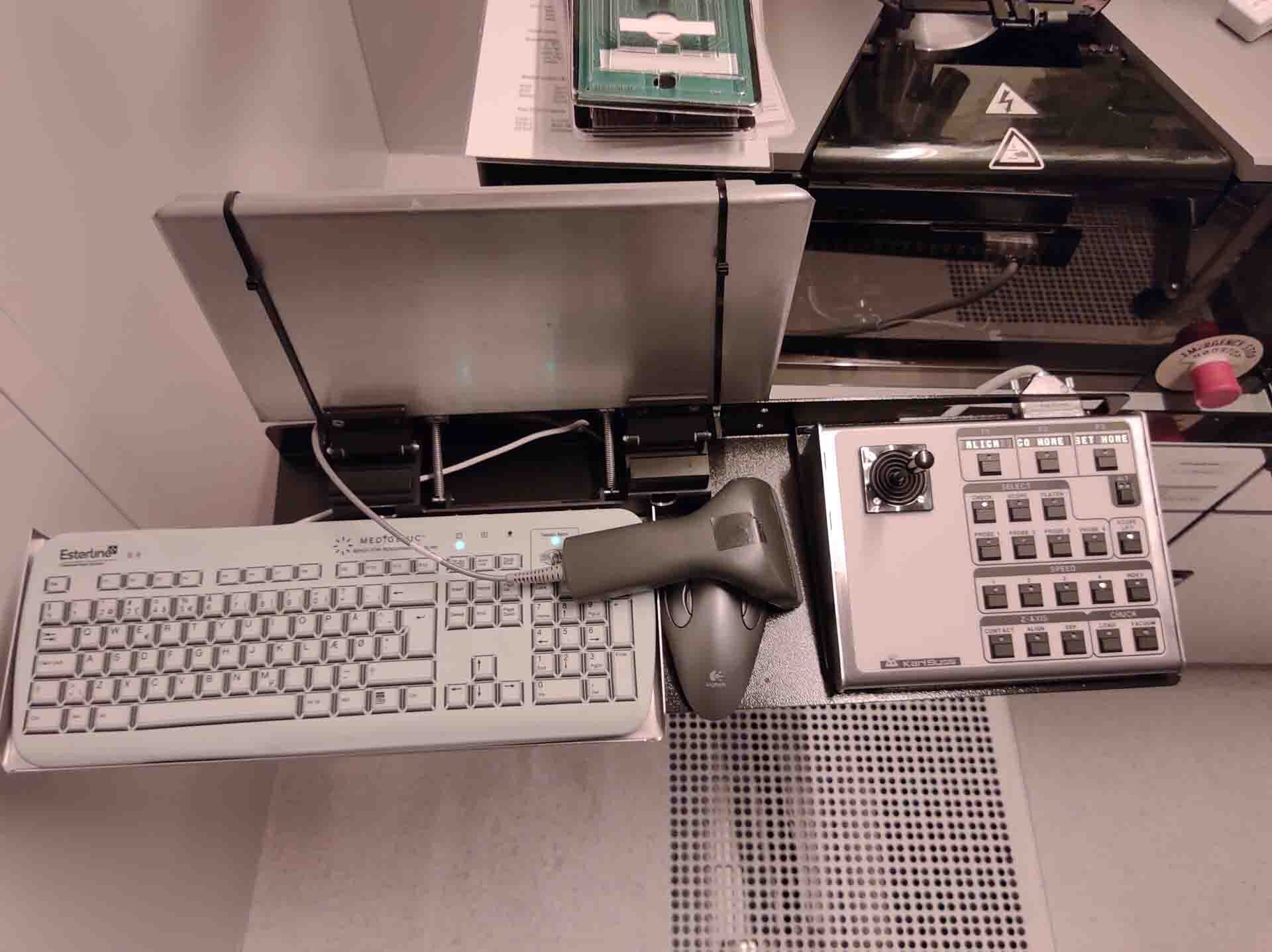

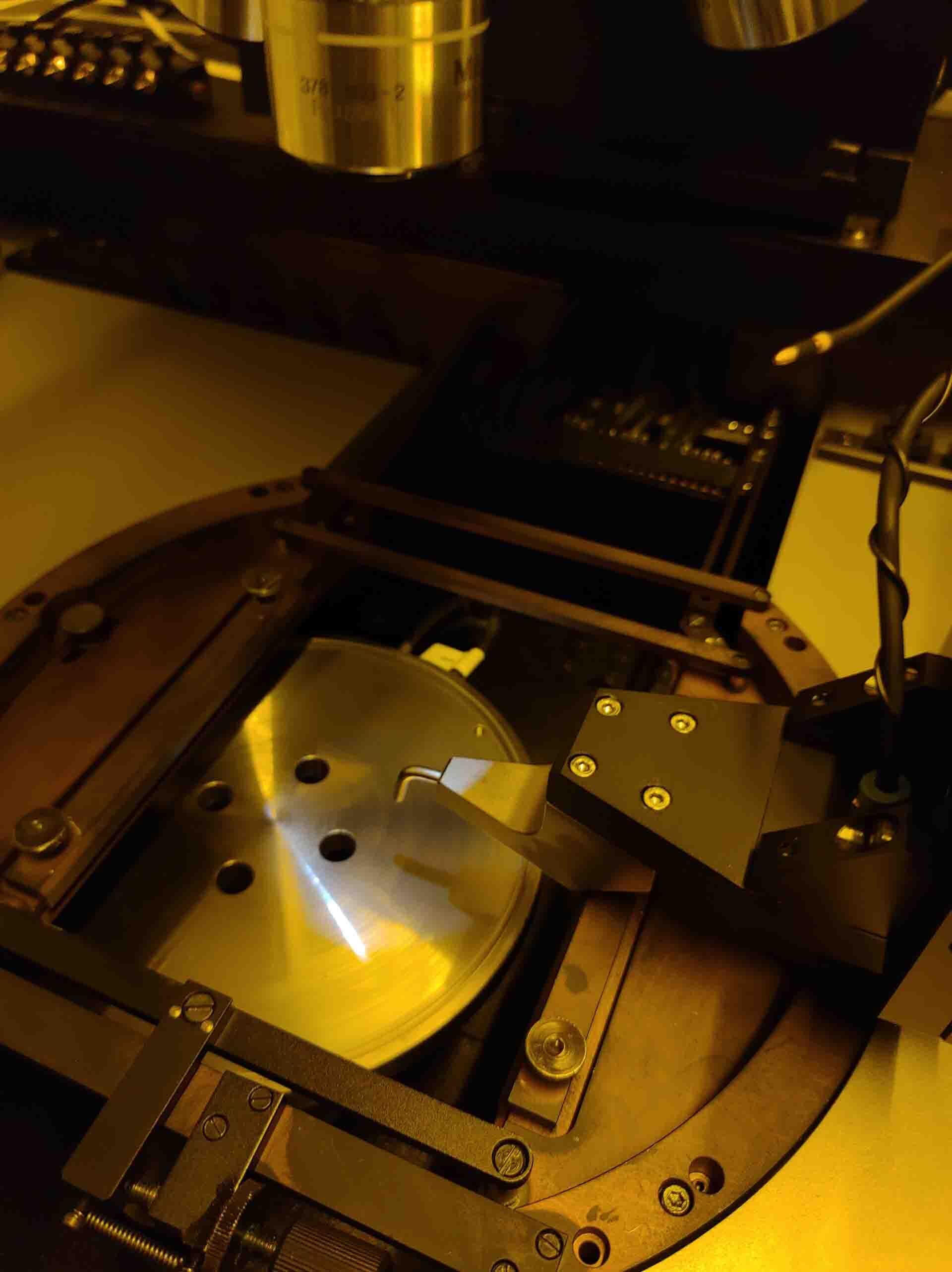

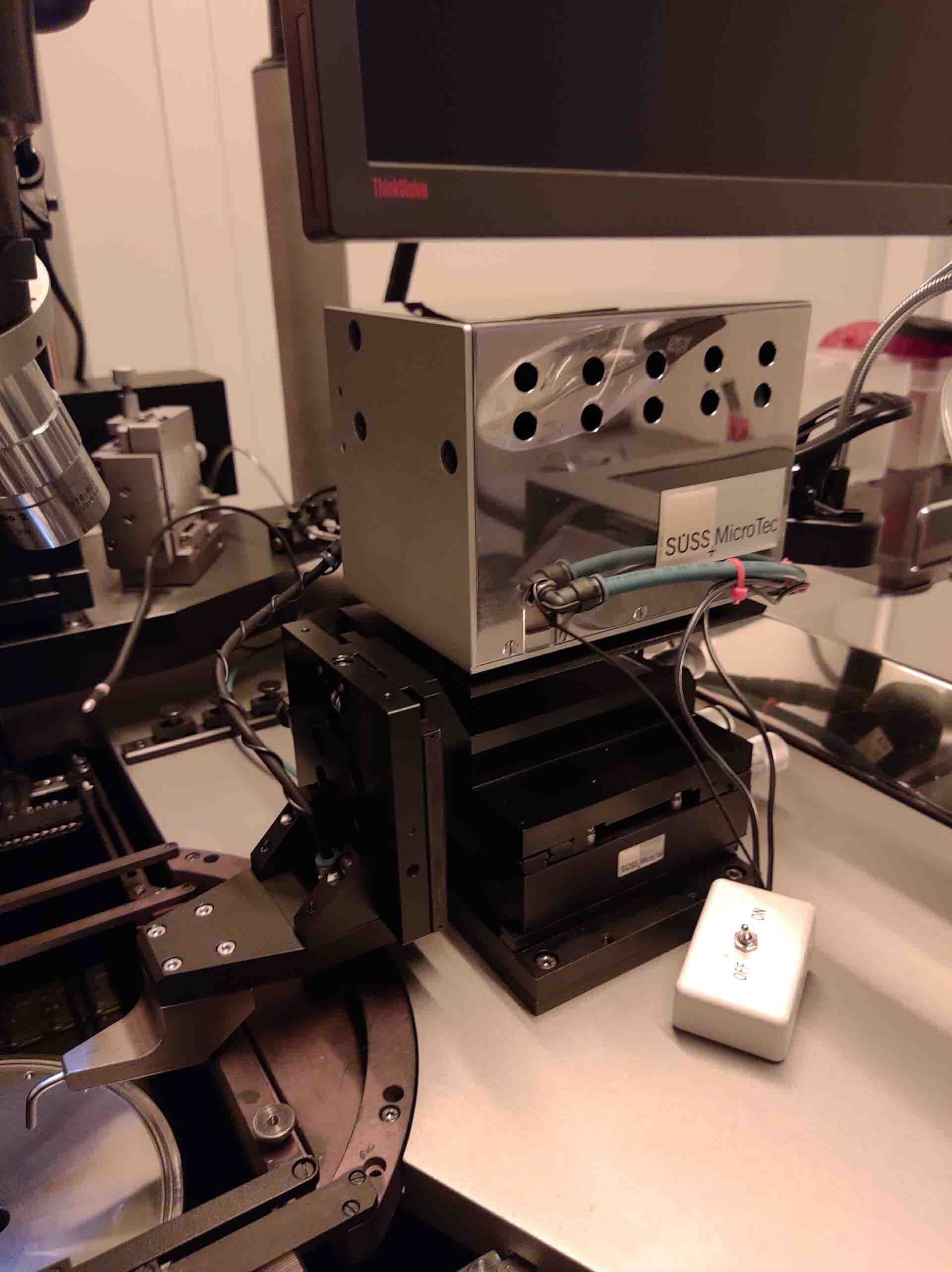

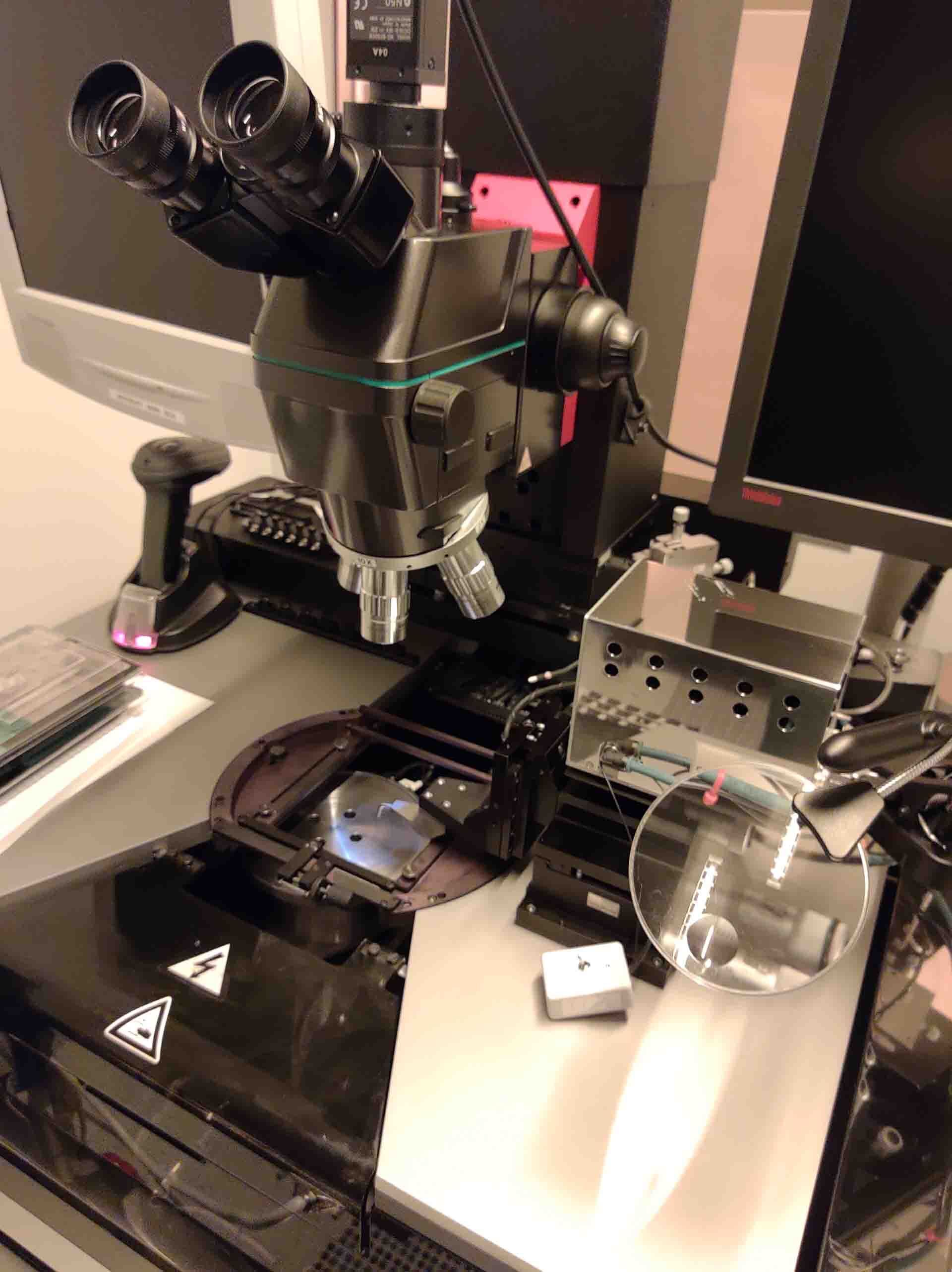

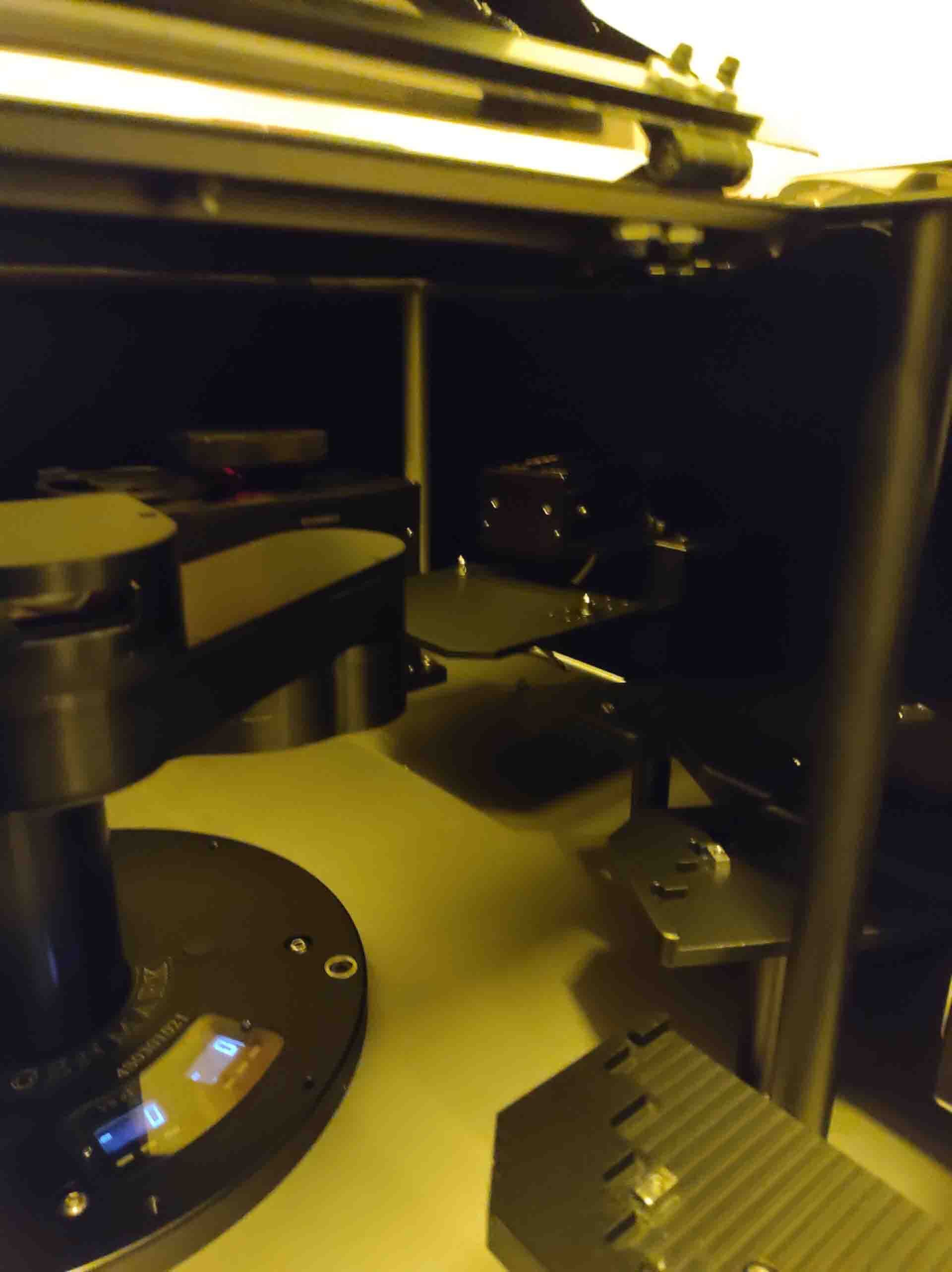

KARL SUSS / MICROTEC AP 200 is an automated precision screen printing equipment designed for the production of a wide variety of components. It is capable of printing on substrates up to 200 millimeters in width, making it ideal for printing larger circuit boards and components. MICROTEC AP 200 is equipped with a precision servo-assist Y-axis drive system and a frequency-controlled exposure unit that allow for repeatable and accurate screen printing. The conveyer machine provides quick and accurate indexing of the printed part. The tooling tool combined with the exposure asset ensures that the optimum alignment is maintained during printing. KARL SUSS AP 200 boasts a wide array of features that enable it to meet the electronic assembly needs of many industries. Its modular design and unique film-lock feature allow for rapid tool exchange and the ability to accommodate a wide range of film thicknesses. The machine is also equipped with an optional off-contact control model that allows for more accurate placement of parts onto the substrate. AP 200 features dual-squeegee systems for maximum transfer efficiency and accuracy. The position of the inner/outer squeegees can be adjusted to accommodate substrates of different sizes and thicknesses. The dual-squeegee equipment also provides improved accuracy of ink release during the printing process. The degree of squeegee pressure can be adjusted to suit the requirements of different substrates. KARL SUSS / MICROTEC AP 200 is equipped with a vision system that allows for easy and accurate placement of parts on to the substrate. This unit is capable of targeting any area of the substrate and providing absolute positional feedback. In addition, this vision machine can be used to monitor and detect any printing defects or mismatches that may occur. To optimize production and reduce down time, MICROTEC AP 200 is equipped with a user-friendly interface that guides users through the setup, calibration and maintenance processes. This interface displays a wide range of options, including printing speed and pressure settings and job recipe details, allowing users to quickly customize settings for specific applications. KARL SUSS AP 200 is a reliable, efficient, and user-friendly tool that ensures accurate and repeatable results. It is ideal for the production of a wide variety of electronic and semiconductor components.

There are no reviews yet