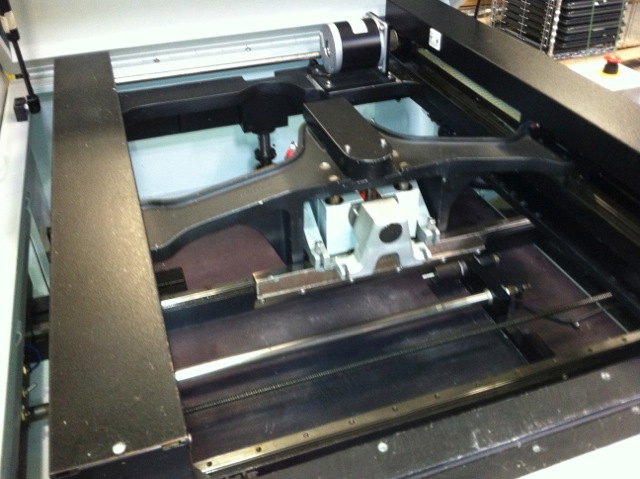

Used MPM SPM #9047159 for sale

URL successfully copied!

Tap to zoom

MPM SPM is a screen printing machine designed to facilitate quick and efficient printing on a variety of substrates. It is a versatile machine that can be used for screen printing on plastics, metals, paper, textiles, wood, glass, and even other surfaces. The basic components of the machine are a frame, a bed, a printing deck, a pallet frame, and components to lock the substrate onto the printing deck. The frame of an SPM is made from durable and robust components, ensuring that the machine can handle heavy workloads over extended periods of time. It holds the bed, which is the platform on which the substrate is placed for printing. On the bed, there is a printing deck that holds the screen or stencil for the design being printed. The print deck is connected to a pallet frame that holds the squeegee and other ancillaries of the printing process. To set up the printing process, the user must first securely locks the substrate into place on the print deck. This is done by leveraging a vacuum bedtable that clamps the substrate down firmly. Once secured, the user then fills the substrate with the chosen ink or other printing material. The squeegee is then used to press the design onto the substrate. With the rubber strap system, the user is able to control the bracing pressure of the squeegee and maintain a consistent print quality. Once the design has been printed onto the substrate, it is then dried and cured either through air or radiation. The process is then completed and the finished product is ready for finishing or assembly. MPM SPM is an efficient and versatile take on standard screen printing machines. Its robust construction and adjustable components lend its use to a range of surfaces and materials. This allows users to conveniently produce high-quality prints, regardless of what product they are working on.

There are no reviews yet