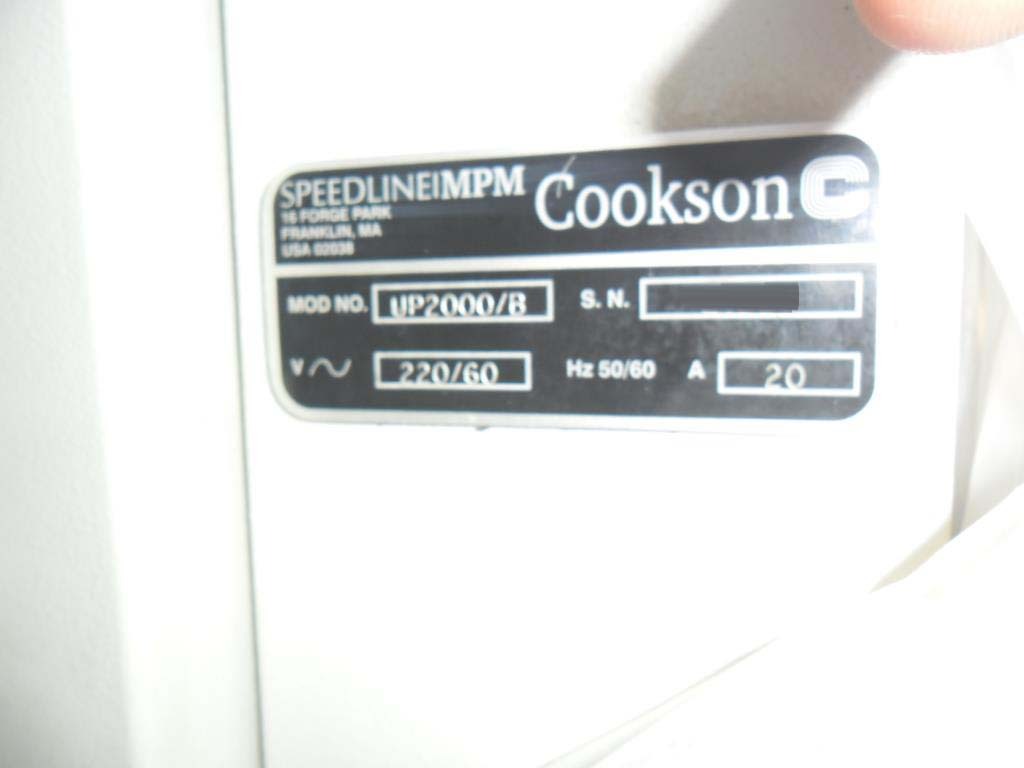

Used MPM UP 2000/B #9098429 for sale

URL successfully copied!

Tap to zoom

ID: 9098429

Screen printer

Print area: 2" x 2" to 18" x 16"

Using workholders: 2" x 2" to 20" x 16"

Board size: 2" x 2" to 20" x 16"

Frame size: 29" x 29"

X-Y Adjustment: +/- 0.5"

Total Y Axis Travel: 8"

Theta adjustment: +/- 3°

Input line voltage: 220V, 20 amp

Input line frequency: 60Hz

Air 80 to 125 psi at 4 cfm

Conveyor length standard: 51".

MPM UP 2000/B is a screen printing machine developed by MPM. It is a fully automated, high-speed printing solution designed for a wide range of production environments and production throughputs. Designed for versatility and scalability, it can handle substrates up to 400mm wide and up to 50mm thickness, making it ideal for a wide range of applications including printing circuit boards, nameplates, and membrane switches. MPM UP2000/B comes with an advanced software controller that allows for precise registration, repeatable process control, and fully automated production setups. This controller allows users to easily save and recall production recipes from the machine's memory, eliminating costly and time-consuming manual adjustments. UP 2000 B also features an integrated camera equipment that can be used to inspect and diagnose print quality, and an advanced two-zone drying system which ensures consistent curing of both UV and water-based ink over a wide range of production rates. UP2000/B's frame is constructed out of extruded aluminum channels and features a stainless steel platens that can be re-positioned as needed for printing substrates up to 400mm in width. The two-zone drying unit makes use of a pre-drying chamber and a curing chamber that can be independently programmed to reach temperatures of over 400°F (204°C). The entire machine is enclosed in a metal cabinet that is designed to provide a dust-free printing environment and protect the machine from ambient temperature variations. In addition to the two-zone drying tool, MPM UP 2000 B also features a patented feeder design that utilizes vacuum and airflow to accurately and reliably feed substrates to the print head. The print head is mounted to a linear servo motor that drives it along the x-axis and y-axis, providing precise and repeatable registration at high speeds. The nozzle is also mounted to a one-degree articulation mechanism that allows the nozzle to tilt to spread out the ink at the edges of the substrate, resulting in precise and consistent prints with no bleeds or irregularities. UP 2000/B is a robust, reliable, and high-performance screen printing solution that can handle both short and long-run production requirements. With its advanced automation, integration, and performance capabilities, MPM UP 2000/B is capable of providing high-quality, consistent prints that can meet or exceed even the most stringent customer requirements.

There are no reviews yet