Used MPM UP 400 #66949 for sale

URL successfully copied!

Tap to zoom

ID: 66949

Vintage: 1999

Screen Printers

PC with Windows 2000 PRO

Closed-loop dual-beam optics vision system

Full process parameters

Configurable warning beacon

Automatic paste dispense with 'low material' sensor

Power-assisted stencil load

Vacuum stencil cleaning with 'low solvent' and 'paper out' sensors

Automatic tooling management system

SPC data collection and reporting

Environmental control unit - temperature and humidity

Temperature control unit with humidity

Multi-language software support

Multiple-line interface options

Transfer height options

Variable conveyor direction, front/rear dedication, and motorized/manual option

Maximum board size 420mm x 360mm (16.5 x 14 inch)

Minimum board size 50mm x 25mm (2 x 1 inch)

Board thickness 5.0mm (0.2 inch) including warp age

Maximum underside clearance 8mm (0.31 inch)

Maximum board weight 0.5kg (1 Ib)

Registration repeatability 25 microns at 6 Sigma at CpK '1.33

Print area 420mm x 350mm (16.5 x 14 inch)

Maximum print stroke 360mm (14 inch)

Operation modes Print/print, print/flood, flood/print, 1 or 2 deposits

Standard stencil frame size 508mm x 508mm x 25mm (20 x 20 x1 inch)

X/Y stencil alignment range +-10mm (+-0.393 inch)

Radial stencil alignment range +-3 degrees

Squeegee pressure 0 - 15.0 Kg (33 Ibs)

Squeegees Metal or Polyurethane

Print speed 5 - 170mm sec (0.2 - 6.7 inch / sec)

Snap off speed 1 - 20mm sec (0.04 - 0.748 inch / sec)

Transfer height 915mm - 965mm (36 - 38 inch)

PCB Support Magnetic pin + vacuum support

Throughput time 20 seconds per cycle (20 sec per board) excluding print time

Conveyor 3mm 'O' ring Front / rear dedicated Right / left feed

Min board edge clearance 5 mm (0.19 inch)

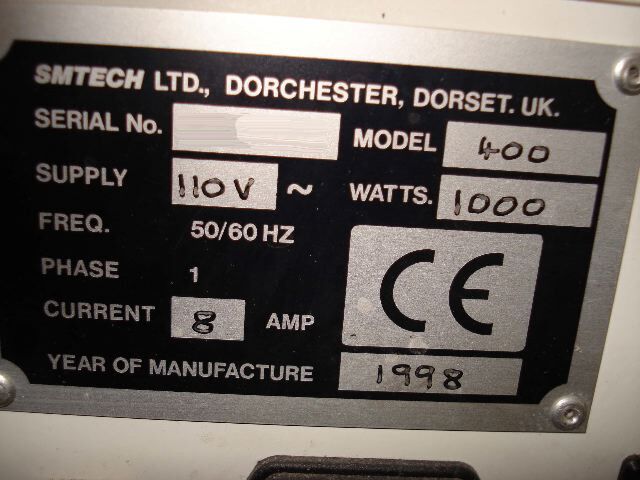

Power supply 110-240V, 60/50Hz +/-10%

Internal power supply 24V

Power consumption 400W

Air supply 5 cfm at 5 Bar clean air supply

Weight 250 kg

Height 1118mm

Depth 1070mm (42.13 inch)

Width 797mm (31.4 Inch)

User interface Microsoft Windows 95 with SigmaPro v6.3 machine control

software

Interface control Monitor with light pen

Product file storage Disk-constrained

Camera field of view 10mm x 10mm (0.0393inch x 0.0393inch)

Teach window Up to 10mm x 10mm

Viewing capability 508mm x 584mm (20 x 23 inch)

Camera system Roving camera module with dual beam optics

Fiducials Standard shape fiducials. See SMEMA standards

Processing speed (typical) Less than 500 milliseconds per fiducial (for a 1.0mm fiducial within +/-

2.5mm of trained location)

Vision processing methods Normalized gray scale correlation and binary boundary tracking

Gray scale resolution 256 shades of gray per pixel

Image storage capacity 512 x 512 pixels

Frame store Matrox

Pixel to mm ratio ~ 0.019mm/pixel (Assumes 10mm horizontal field of view)

Crated

1999 vintage.

MPM UP 400 is a screen printing machine designed for the mass production of screen printed components. It is one of the latest models from MPM, a leading manufacturer in screen printing equipment. UP 400 has a generous working area of 420mm x 420mm, allowing for larger printed parts to be created. It is also equipped with a vertical lift mechanism, which helps increase production speeds and reduce wastage in the process. The machine is supported by a dual-servo equipment, with an integrated vision system to help ensure accuracy and precision over the entire print cycle. MPM UP 400 is also fitted with an advanced, automatic film loading and unloading unit, which supports films of various thicknesses. This machine speeds up the production process and helps to reduce operator fatigue. Additionally, UP 400 is equipped with environment-friendly safety devices and high-speed pick and place mechanisms, which increase production rates even more. MPM UP 400 is powered by an inverter-driven direct current (DC) motor, which delivers smooth, precise and reliable operation even during large runs. The entire machine is PLC-controlled, allowing for various parameters to be adjusted quickly and accurately via the colour touch screen. Furthermore, UP 400 is designed to be low maintenance, with many of the machine's components being accessible from the outside enabling easy access and simplified upkeep. All in all, MPM UP 400 is an ideal choice for anyone looking for a reliable, precise, and high-speed screen printer with a great capacity to work around large components. The compact design, low maintenance requirements and user-friendly features make UP 400 an attractive choice for any professional looking to improve production efficiency and cycle times whilst maintaining a safe and clean working environment.

There are no reviews yet