Used CONVAC DSS 200 #9053125 for sale

URL successfully copied!

Tap to zoom

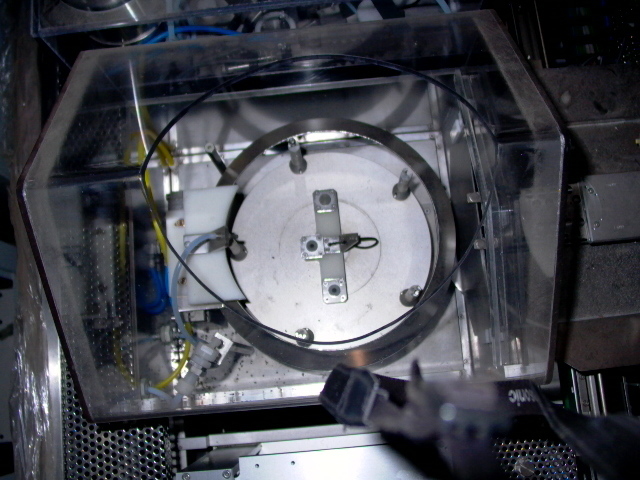

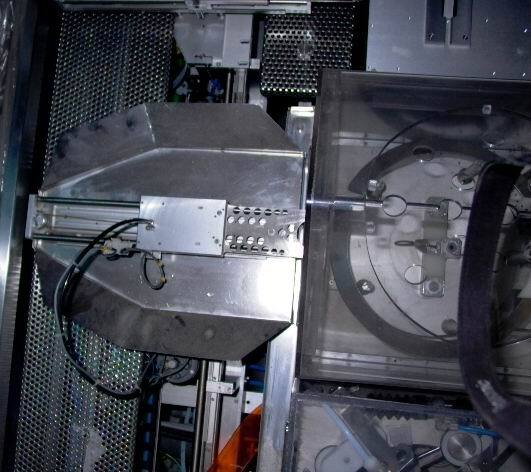

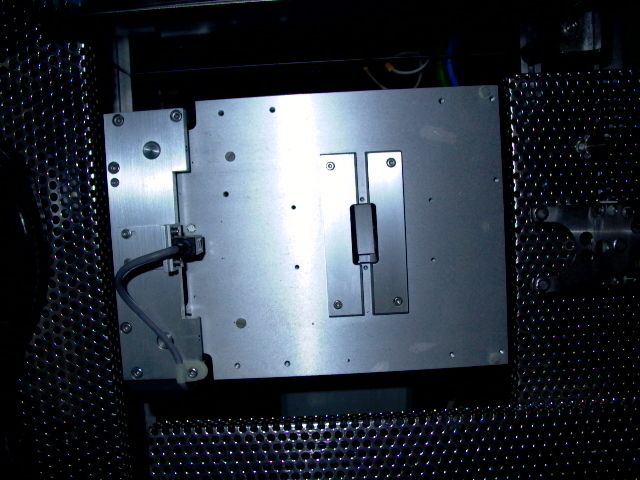

CONVAC DSS 200 is a wafer and mask scrubber designed for use in semiconductor device fabrication facilities. It is a self-contained unit which is typically placed directly in front of the clean room entrance or in the clean room itself. DSS 200 utilizes a dual stage scrubbing process which effectively cleans wafers and masks (stencils, films, frames, discs, and strips) prior to their entrance into the clean room. The first stage of the scrubbing process utilizes chemical tablets loaded into the unit which are stored in a removable drawer. The chemical tablets are slowly released into the internal chamber which causes a simulated rain shower onto the components within. This shower removes dust, dirt, and other contaminants from the wafer or mask which can cause contamination within the clean room environment. The second stage of the scrubbing process utilizes a dual sided scrubbing block. The block is treated with a special cleaning compound which allows it to easily remove any contaminants or residues which were not removed in the chemical misters of the first stage. The block is rotated over the wafer or mask while air jets create a vacuum which lifts the debris off the surface and causes it to enter the collection bin. Once the scrubbing cycles are complete, CONVAC DSS 200 is deactivated and the door opened to allow the cleaned components to be retrieved. The unit can then be vacated and allowed to dry for use in the next cleaning cycle. DSS 200 is a reliable, efficient, and cost-effective way to improve clean room environment in semiconductor device fabrication facilities. In addition to providing superior cleaning, CONVAC DSS 200 also helps control costs by reducing time spent by staff on additional cleaning and maintenance.

There are no reviews yet