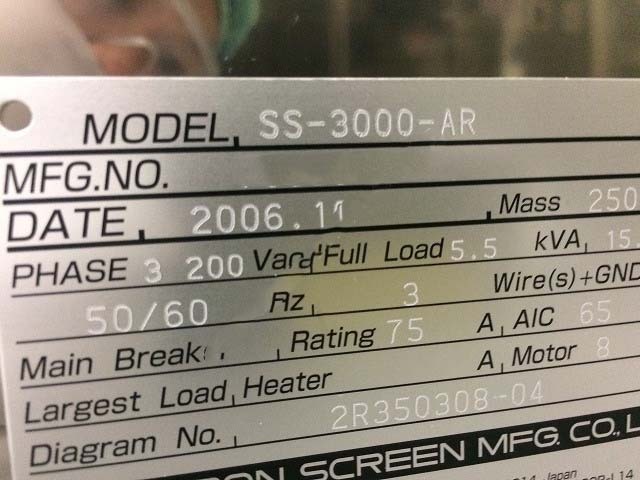

Used DNS / DAINIPPON SS-3000-AR #293627542 for sale

URL successfully copied!

Tap to zoom

ID: 293627542

Wafer Size: 12"

Vintage: 2006

Wafer scrubber, 12"

(3) Load ports

Controller

(3) MFC / Pressure unit

Drive mechanism

Chamber A and B:

Process: Wafer surface clean

Chuck: Vacuum chuck

Spray: Soft spray N2 10~100NL/min

Rinse: DIW/CO2 Injection, resistivity <1MΩ

Spin dry: 3,000 rpm

Chamber C and D:

Process: Wafer backside clean

Chuck: Mechanical chuck

Brush: PVA Brush

Rinse: DIW/CO2 Injection, resistivity <1MΩ

Spin dry: 2,400 rpm

Multi-chambers system:

Unit position 1 / U03 SS (surface) / CO2water

Unit position 2 / U04 SS (surface) / CO2water

Unit position 3 / U05 SS (backside) / CO2water

Unit position 4 / U06 SSR (backside) / CO2water

Gas configuration:

Gas line 1: C4F6 200 sccm- STEC D519 / C4F6 200

Gas line 2: COS 30 sccm - STEC D519 / COS 30

Gas line 3: O2 20 sccm - STEC D519 / O2 20

Gas line 4: O2 3000 sccm - STEC D519 / O2 3000

Gas line 5: CH2F2 200sccm - STEC D519 / CH2F2 200

Gas line 6: C4F8 200 sccm - STEC D519 / C4F8 200

Gas line 7: O2 200 sccm - STEC D519 / O2 200

Gas line 8: Ar 1000 sccm - STEC D519 / AR 1000

Gas line 9: CHF3 200 sccm - STEC D519 / CHF3 200

Gas line 10: H2 300 sccm - STEC D519 / H2 300

Gas line 11: NF3 30 sccm - STEC D519 / NF3 30

Gas line 12: N2 500 sccm - STEC D519 / N2 500

Gas line 13: CF4 200 sccm - STEC D519 / CF4 200

Tuning gas 4/line 14: O2 10 sccm - STEC D519 / O2 10

Tuning gas 3/line 15: C4F6 10 sccm - STEC D519_L / C4F8 10

Tuning gas 2/line 16: O2 10 sccm - STEC D519 / O2 10

Tuning gas 1/line 17:C4F6 10 sccm- STEC D519_L / C4F6 10

ATM, EFEM: 4 Wide EFEM type

Power supply: 208 AC, 3 Phase

2006 vintage.

DNS / DAINIPPON SS-3000-AR Wafer and Mask Scrubber is a state-of-the-art, reliable, and easy to use machine designed to clean wafers and masks. This widely used equipment boasts high-precision wafer and mask cleaning operations with a low particle size. The comprehensive cleaning mechanism of this scrubber features oscillations and sloshing to remove particle contamination and residual chemicals in a quick but gentle manner. This system is engineered for superior cleaning performance through innovative technology and advanced engineering. DNS SS-3000-AR was designed with an efficient cleaning architecture that includes a wafer and mask scrubber module, a sloshing quick scrubber, a Chemical Injection Module, and a wet scrubber. The wafer and mask scrubber module consists of a bowl, sliders, and a brush. The sliders are motorized for gentle and gently washing away particles in a controlled way. The brush softly cleans away dirt and other contaminants from the wafer, taking into account its delicate composition. Additionally, the Chemical Injection Module precisely injects cleaning solution into the scrubber bowl right tracks to efficiently reduce chemical consumption. The Wet Scrubber then further removes the dirt and chemical solution after the scrubbing process is complete. Furthermore, this unit can scrub with a wide variety of cleaning solutions, including de-ionized water, isopropyl alcohols, and dilute hydrochloric acid. The actual cleaning process is derived from a combination of oscillations and sloshing motion, resulting in superior effectivity of the scrubbing operations. In addition, this scrubber enables even molecular cleaning with a particle size as low as 0.3 μm. Another great feature is the ability to set a wide range of parameters according to the cleaning purpose, including scrubbers, amplitudes, and pre-scrubbing time. This enables this scrubber to be used for various kinds of cleaning purposes with high precision and accuracy. DAINIPPON SS 3000 AR Wafer and Mask Scrubber is user-friendly as well. This machine is equipped with intuitive LCD touch displays and easy-to-understand menus, making machine operation a breeze. The LCD display provides a comprehensive understanding of the scrubbing progress and any potential errors, while quickly conveying all relevant information. In conclusion, SS-3000-AR Wafer and Mask Scrubber is an incredibly efficient and user-friendly tool designed to clean wafers and masks with high precision and accuracy. It is equipped with a wide array of features to tailor cleaning parameters with meticulousness, while also offering intuitive and easy-to-use LCD displays. With its comprehensive cleaning mechanism, this asset will be sure to provide superior cleaning results in a short amount of time.

There are no reviews yet