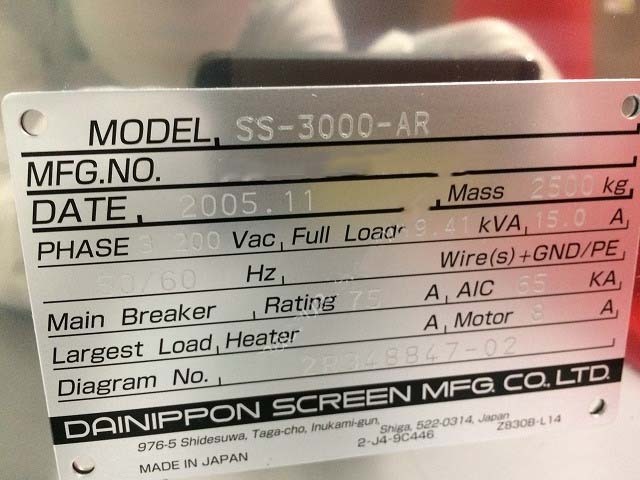

Used DNS / DAINIPPON SS-3000-AR #293627543 for sale

URL successfully copied!

Tap to zoom

ID: 293627543

Wafer Size: 12"

Vintage: 2005

Wafer scrubber, 12"

(3) Load ports

Controller

(3) MFC / Pressure unit

Drive mechanism

Chamber A and B:

Process: Wafer surface clean

Chuck: Vacuum chuck

Spray: Soft spray N2 10~100NL/min

Rinse: DIW/ CO2 Injection, resistivity <1MΩ

Spin dry: 3,000 rpm

Chamber C and D:

Process: Wafer backside clean

Chuck: Mechanical chuck

Spray: Soft spray N2 10~100NL/min

Brush: PVA Brush

Rinse: DIW/CO2 Injection, resistivity <1MΩ

Spin dry: 2,400 rpm

Multi-chambers system:

Unit position 1 / U03 SS (surface) / CO2water

Unit position 2 / U04 SS (surface) / CO2water

Unit position 3 / U05 SS (backside) / CO2water

Unit position 4 / U06 SSR (backside) / CO2water

Gas configuration:

Gas line 1: C4F6 200 sccm- STEC D519 / C4F6 200

Gas line 2: COS 30 sccm - STEC D519 / COS 30

Gas line 3: O2 20 sccm - STEC D519 / O2 20

Gas line 4: O2 3000 sccm - STEC D519 / O2 3000

Gas line 5: CH2F2 200sccm - STEC D519 / CH2F2 200

Gas line 6: C4F8 200 sccm - STEC D519 / C4F8 200

Gas line 7: O2 200 sccm - STEC D519 / O2 200

Gas line 8: Ar 1000 sccm - STEC D519 / AR 1000

Gas line 9: CHF3 200 sccm - STEC D519 / CHF3 200

Gas line 10: H2 300 sccm - STEC D519 / H2 300

Gas line 11: NF3 30 sccm - STEC D519 / NF3 30

Gas line 12: N2 500 sccm - STEC D519 / N2 500

Gas line 13: CF4 200 sccm - STEC D519 / CF4 200

Tuning gas 4/line 14: O2 10 sccm - STEC D519 / O2 10

Tuning gas 3/line 15: C4F6 10 sccm - STEC D519_L / C4F8 10

Tuning gas 2/line 16: O2 10 sccm - STEC D519 / O2 10

Tuning gas 1/line 17:C4F6 10 sccm- STEC D519_L / C4F6 10

ATM, EFEM: 4 wide EFEM type

Power supply: 208 AC, 3 Phase

2005 vintage.

DNS / DAINIPPON SS-3000-AR Wafer & Mask Scrubber is a highly reliable, efficient, and precise tool designed to clean wafer and mask surfaces with fully-automated, multiple operation modes. This scrubber was created as a part of an advanced semiconductor manufacturing process. The scrubber uses pressurized, hot water with detergents, and low-vacuum suction to effectively scrub the surface area of the wafer and mask. This process creates a perfectly flat and smooth surface, allowing a perfect etch pattern during the next step of physical vapor deposition. The scrubber also includes a fine purification equipment to make sure that any small particles dislodged from the surface during cleaning are removed. The scrubber boasts a wide range of features, including a powerful and energy-efficient pump that uses only about two to three pascals of pressure for cleaning, and a separate low-vacuum suction for particle removal. The pump also features an adjustable flow rate for better control over the cleaning process. Additionally, the scrubber has an ultra-high precision mode so that the device can accurately target and scrub minute areas in the wafer or mask. The scrubber is also equipped with a motion control system that is easily adjustable and programmable. This feature allows the operator to customize the scrubber to the task at hand. The motion control unit also ensures that the scrubber is used in a safe and reliable manner. For added convenience and accuracy, DNS SS-3000-AR Wafer & Mask Scrubber comes with digital image processing software that works with the scrubber's motion control machine. This software is able to analyze and recognize any imperfections in a wafer or mask's surface, allowing it to make adjustments to the scrubber's settings to quickly and effectively clean the surface. Overall, DAINIPPON SS 3000 AR Wafer & Mask Scrubber is a reliable and efficiently designed tool that can create high-quality, even surfaces for any wafer or mask being prepared for the semiconductor manufacturing industry. With its high-precision asset, efficient energy-saving features, and digital image processing software, the DS-3000-AR can ensure that the surfaces being prepared for the manufacturing process are properly cleaned, even and ready for etching.

There are no reviews yet