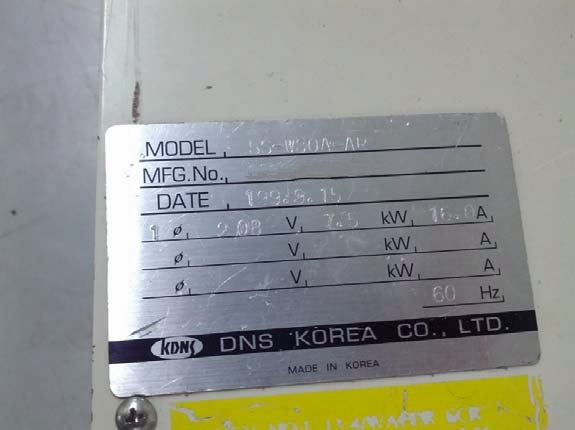

Used DNS / DAINIPPON SS-W80A-AR #9149126 for sale

URL successfully copied!

Tap to zoom

ID: 9149126

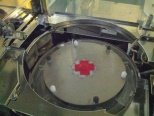

Wafer Size: 8"

Vintage: 1998

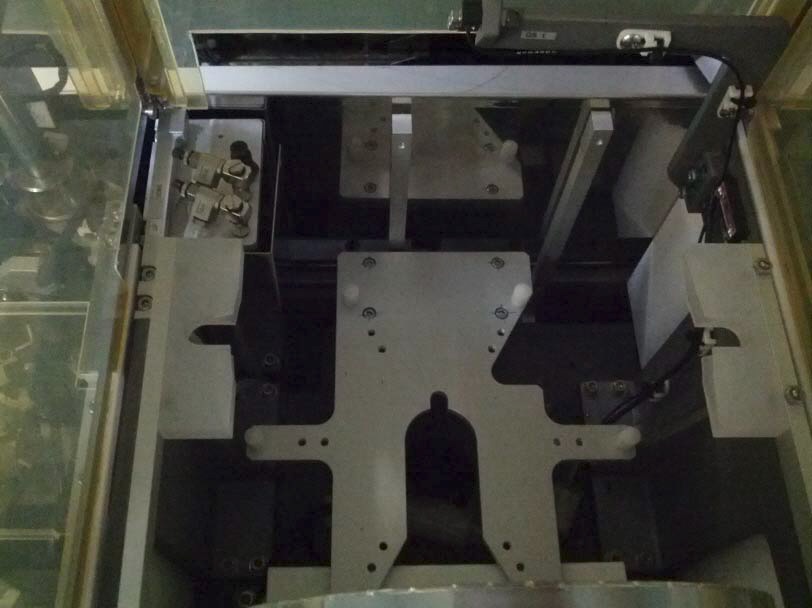

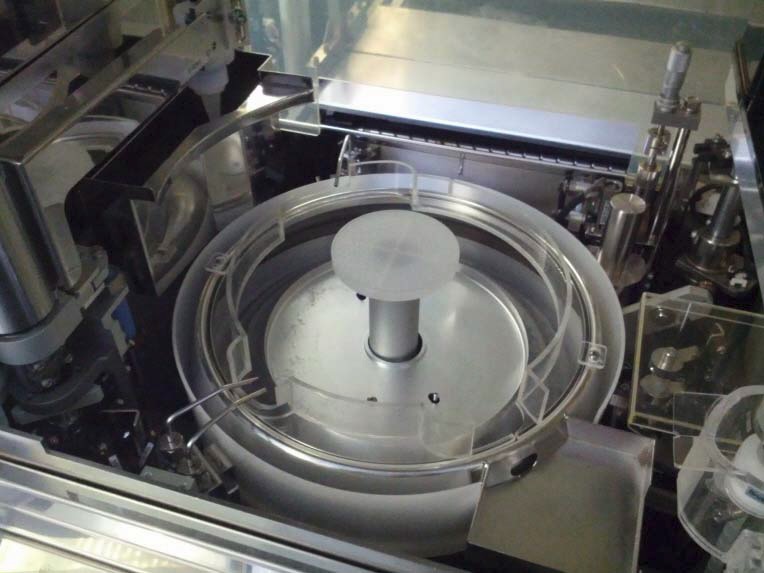

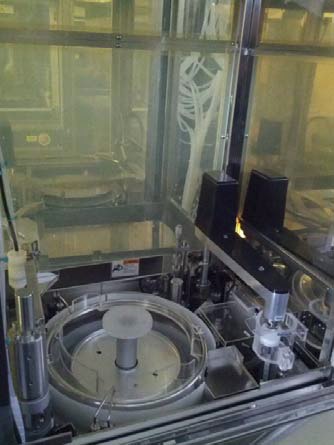

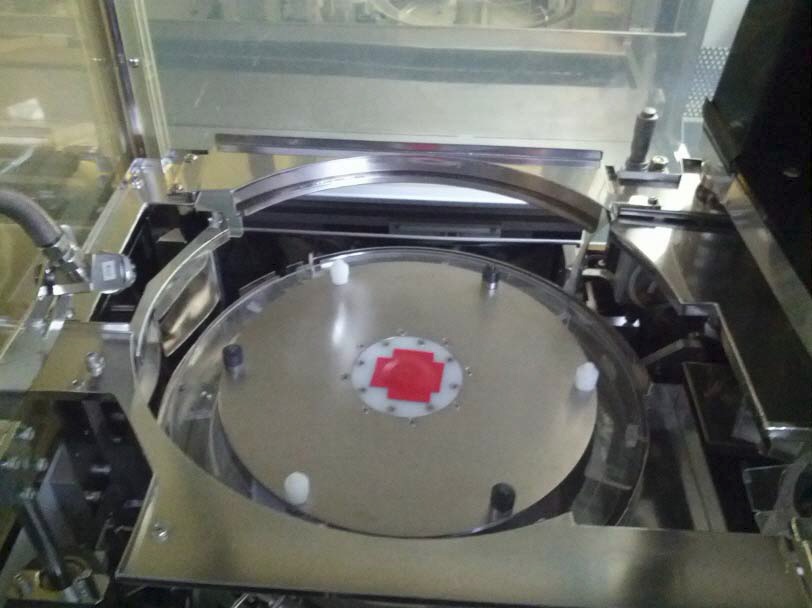

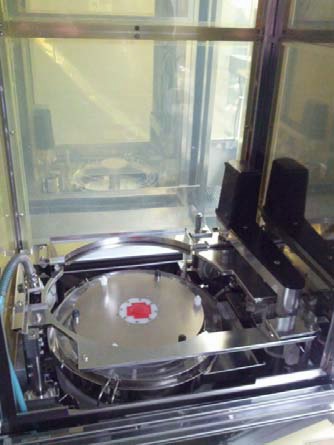

Scrubber, 8"

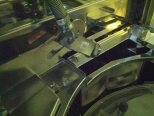

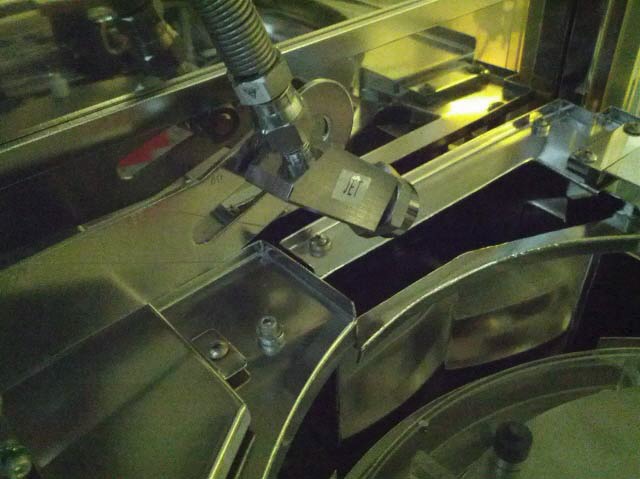

(2) Front side scrubbing units

(2) Back side scrubbing units

Reverse unit

Transformer

1998 vintage.

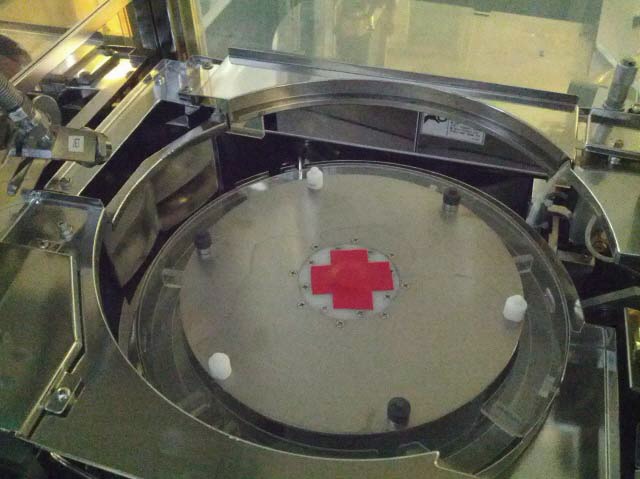

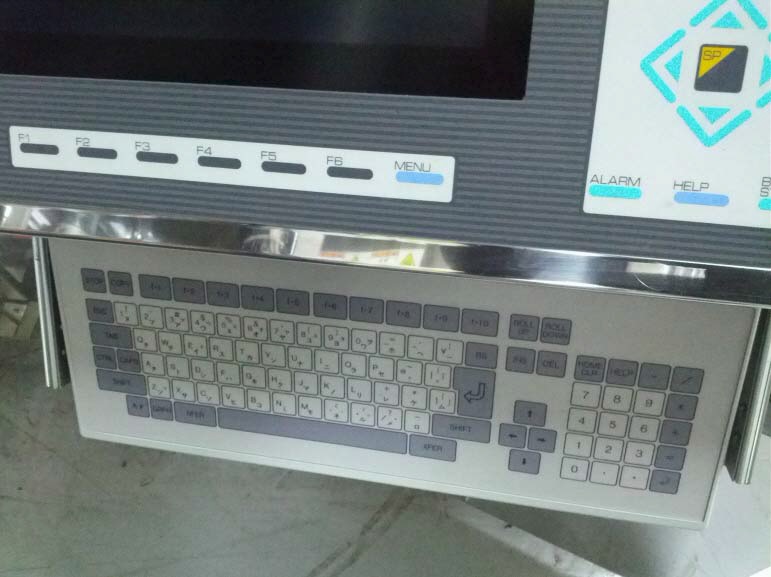

DNS / DAINIPPON SS-W80A-AR is a wafer & mask scrubber that offers automatic quality assurance in a wide range of semiconductor and LCD semiconductor fabrication processes. DNS SSW80A-AR is designed to minimize astigmatism, contamination, and deep scratches. The scrubber offers a reservoir capacity of 80 liters, up to 6 stages of brush control, temperature range of 25°C to 90°C, and scrubbing speed up to 3,000 rpm. The scrubber also features a scrubbing process monitor and alarm functions for over-temperature, over-current, and over-load capacity of the brush motor. Its advanced and user-friendly software manages various scrubbing solutions such as deionized water, spin-rinse-dry cleaning solution and Teflon cleaning solution. Moreover, this scrubber has a quenching plate, a cleaning tray, and a bubble detector to facilitate operations. Additionally, its ergonomic design ensures easy handling. The dust and chip removal unit consists of an air-suctioning unit equipped with diffusion papers to prevent dust scattering. This system also uses an oil-separator filter to separate oil mist from the scrubbing solution. Furthermore, the scrubber is made of stainless steel with an anti-corrosion coating to maintain its high performance even in harsh environments. It can be easily installed and operated. Moreover, its wafer & mask scrubbing process is supported by operating quality assurance, operation data storage, and a sharing function. Furthermore, its chip-collecting system is designed for user-friendly operation with easy-to-replace filters for periodic maintenance. Overall, the DNIDAINIPPON SSW-80A-AR offers an effective solution for managing various semiconductor and LCD fabrication processes. It offers advanced user-friendly features such as a dust and chip removal unit, wafer & mask scrubbing software, and a chip-collecting system. Additionally, its operation is further supported by quality assurance and data storage. This scrubber is essential for operators to ensure efficient production with minimum contamination and deep scratches.

There are no reviews yet