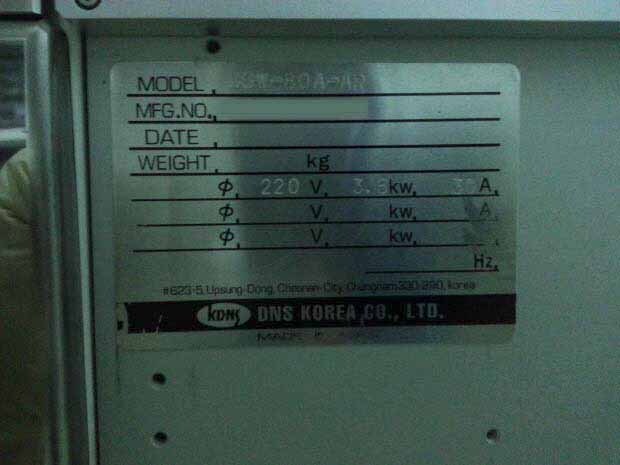

Used DNS / DAINIPPON SS-W80A-AR #9149127 for sale

URL successfully copied!

Tap to zoom

ID: 9149127

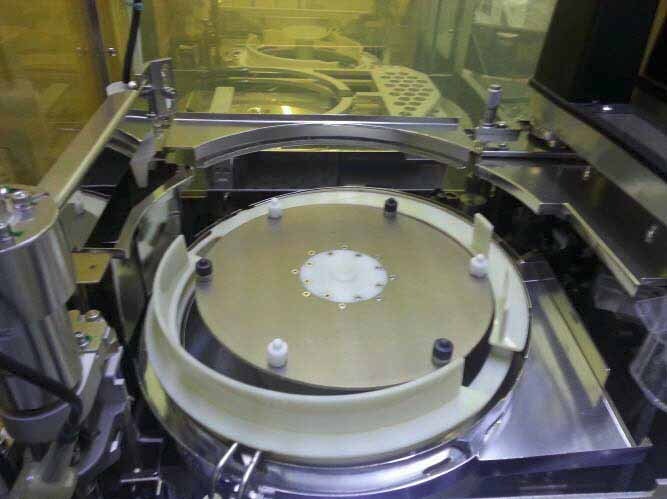

Wafer Size: 8"

Vintage: 2001

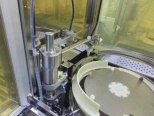

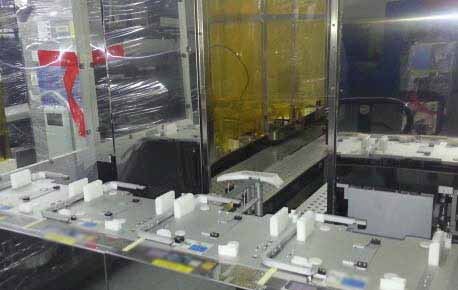

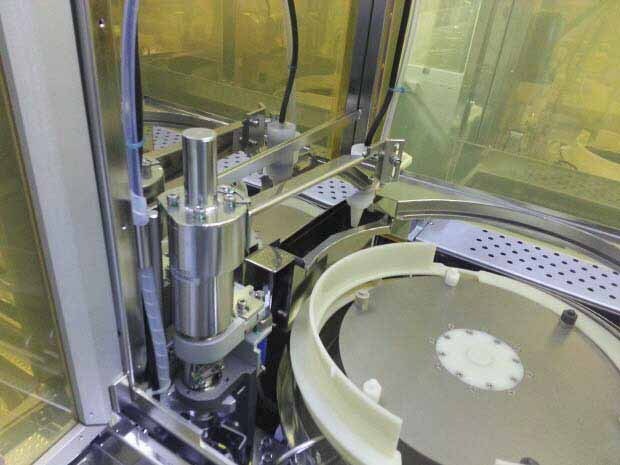

Scrubber, 8"

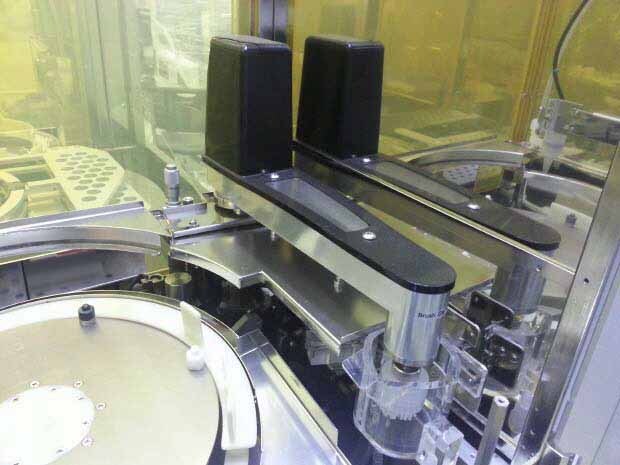

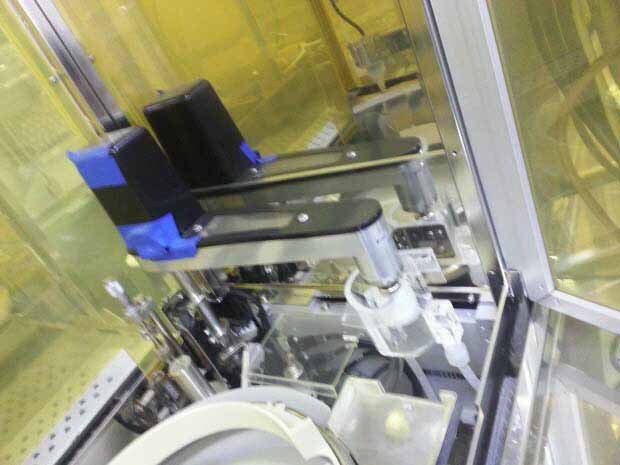

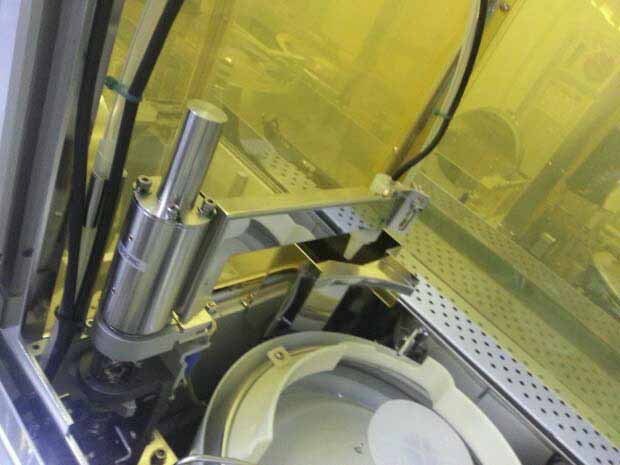

(2) Front side scrubbing units

(2) Back side scrubbing units

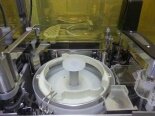

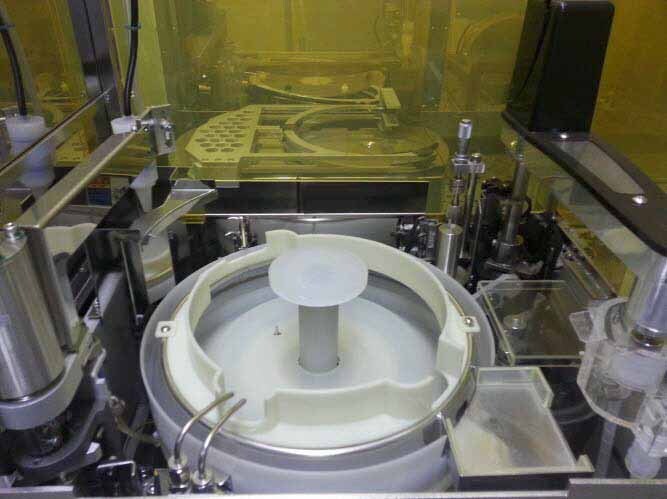

Reverse unit

Transformer

2001 vintage.

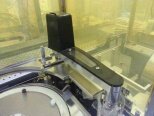

DNS / DAINIPPON SS-W80A-AR Wafer & Mask Scrubber is a highly compact automated scrubbing equipment specifically designed for the cleaning of semiconductor photomasks. This system is composed of three scrubbing modules: the wafer scrubber, the mask scrubber, and the predryer. The wafer scrubber module consists of a universal transport unit which supports up to eight 6-inch wafer cassettes. The machine is equipped with a 3-axis, high-resolution automatic wafer rotator which is capable of rotating a variety of wafer sizes including reticles up to 200mm in diameter. The wafer is then spin-sprayed and sprayed-scrubbed with a detergent solution to ensure thorough cleaning, followed by a high-pressure rinse. The mask scrubber module is designed for cleaning liquid bronzing masks and is composed of a three-axis robotic mechanical arm, which is automatically positioned to an optimal scrubbing angle. This ensures that all surface defects are effectively removed from the mask. The mask is then spin-sprayed and scrubbed with a detergent solution, followed by a high-pressure rinse. The predryer module is a hotplate drying tool which seals off any residual gas from the scrubbing of the wafer and mask due to the elevated surface temperature. The asset consists of an electric heater which is capable of reaching a maximum temperature of 800°C and a signal detection model for detecting thermal and voltage variation of the hotplate. The equipment is also fitted with two-stage temperature timers which allow for precise control of the drying cycle. DNS SSW80A-AR is designed as an effective cleaning system for semiconductor photomasks. Its modular design ensures that all three scrubbing modules can be used simultaneously, allowing for highly efficient cleaning of up to eight 6-inch wafers and up to sixty masks in one process. Additionally, its hotplate predryer ensures that no residual gas is left on the surface of the wafers and masks, allowing for highly reliable materials processing.

There are no reviews yet