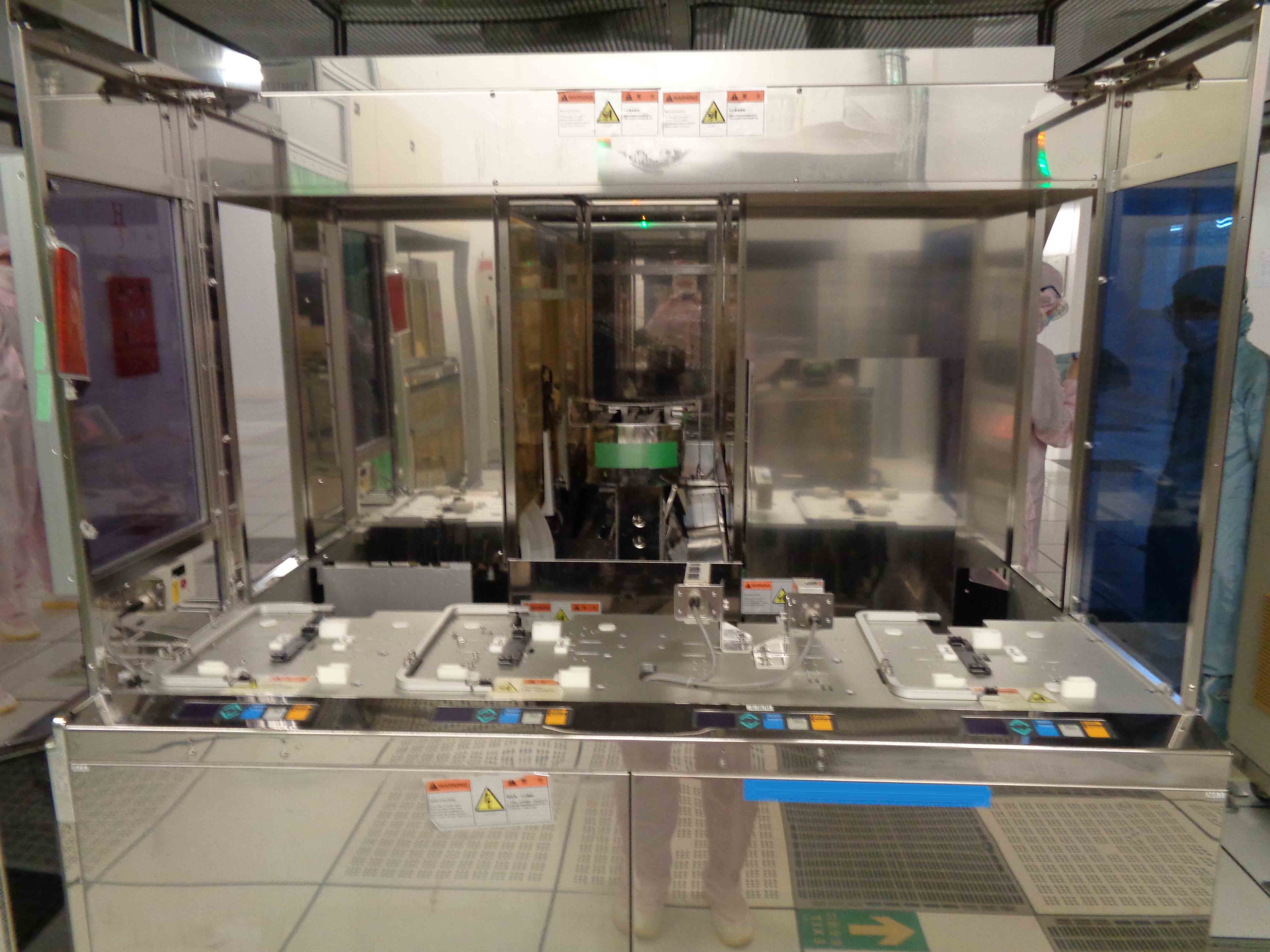

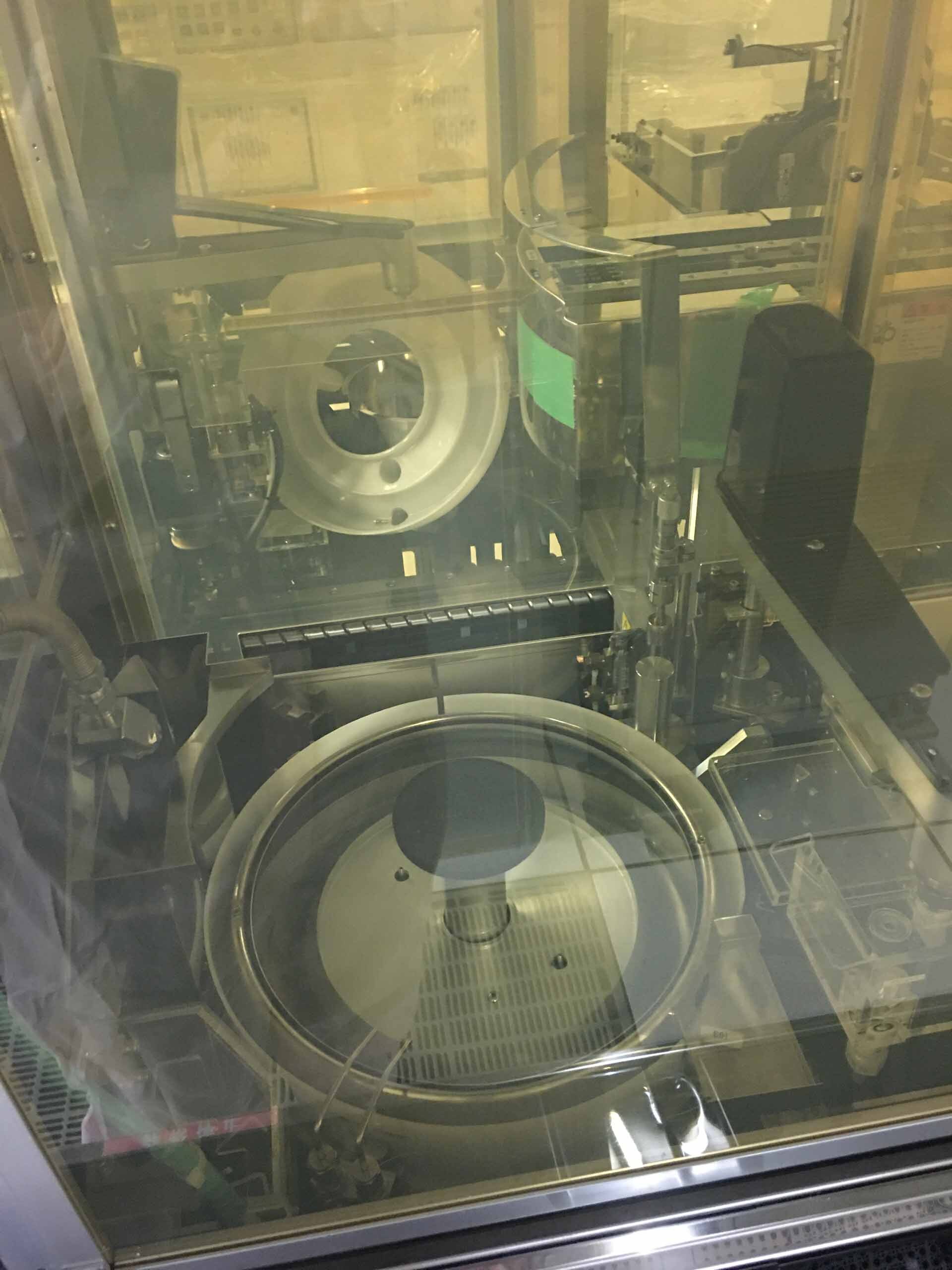

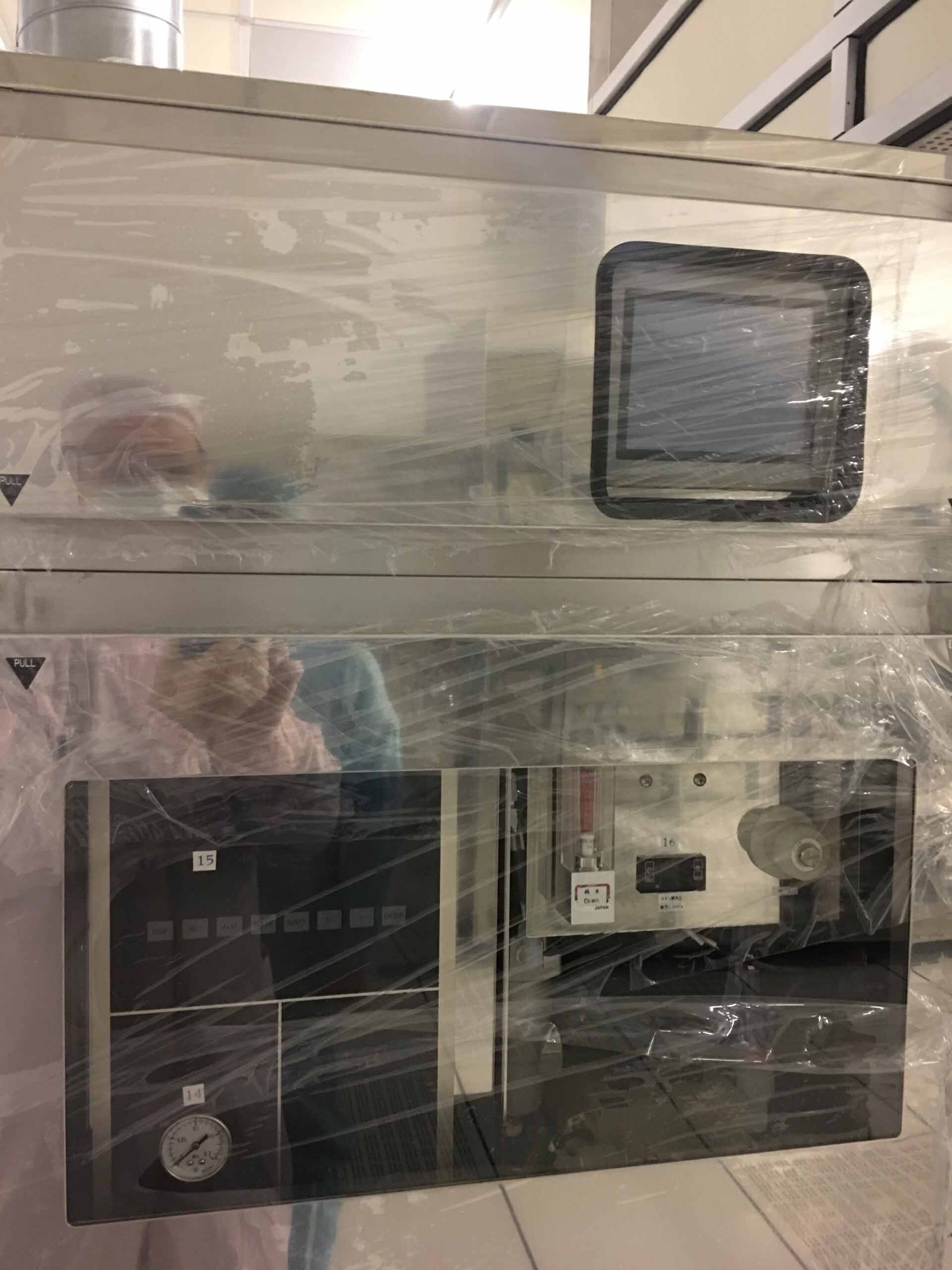

Used DNS / DAINIPPON SS-W80A-AR #9364251 for sale

URL successfully copied!

Tap to zoom

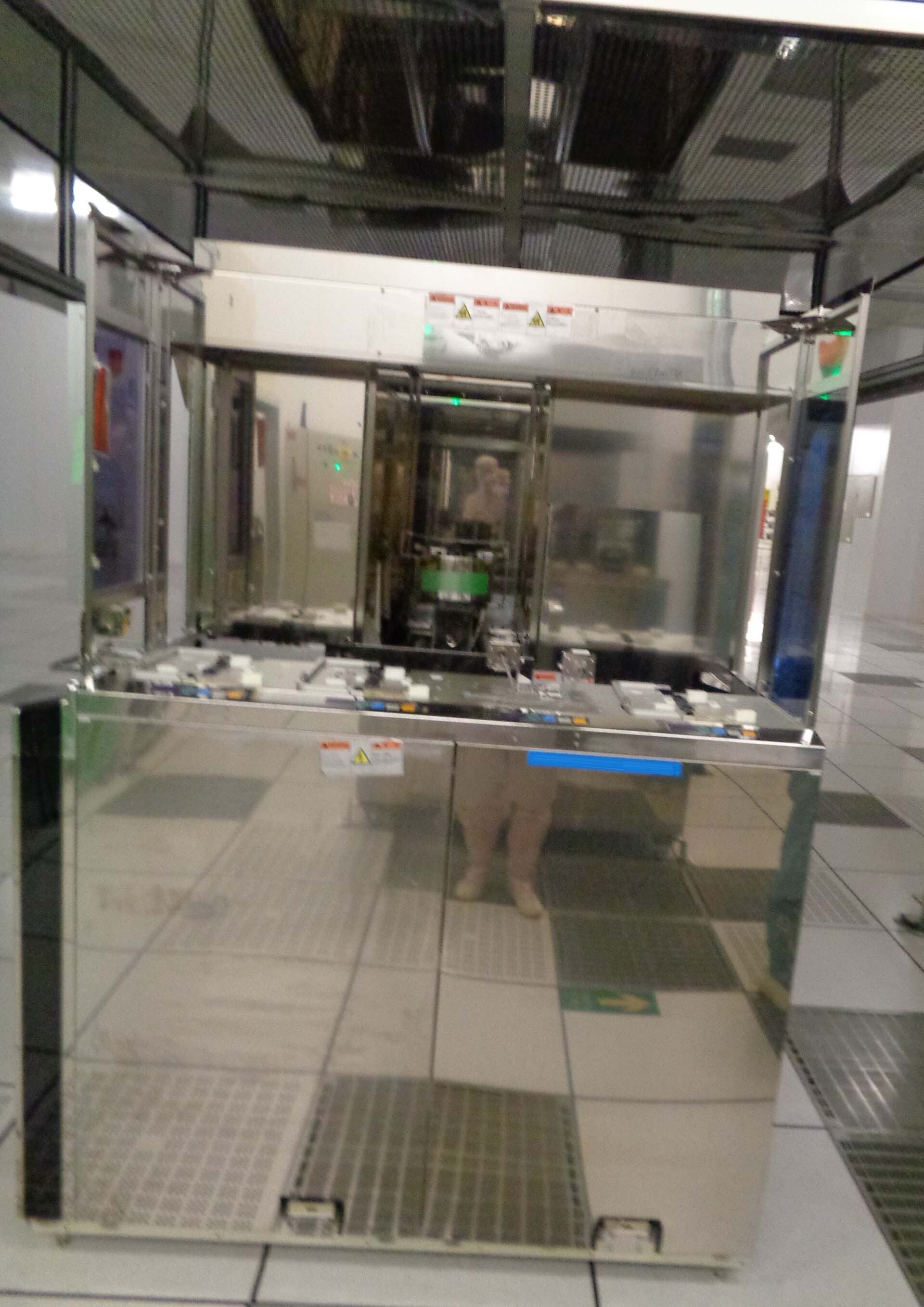

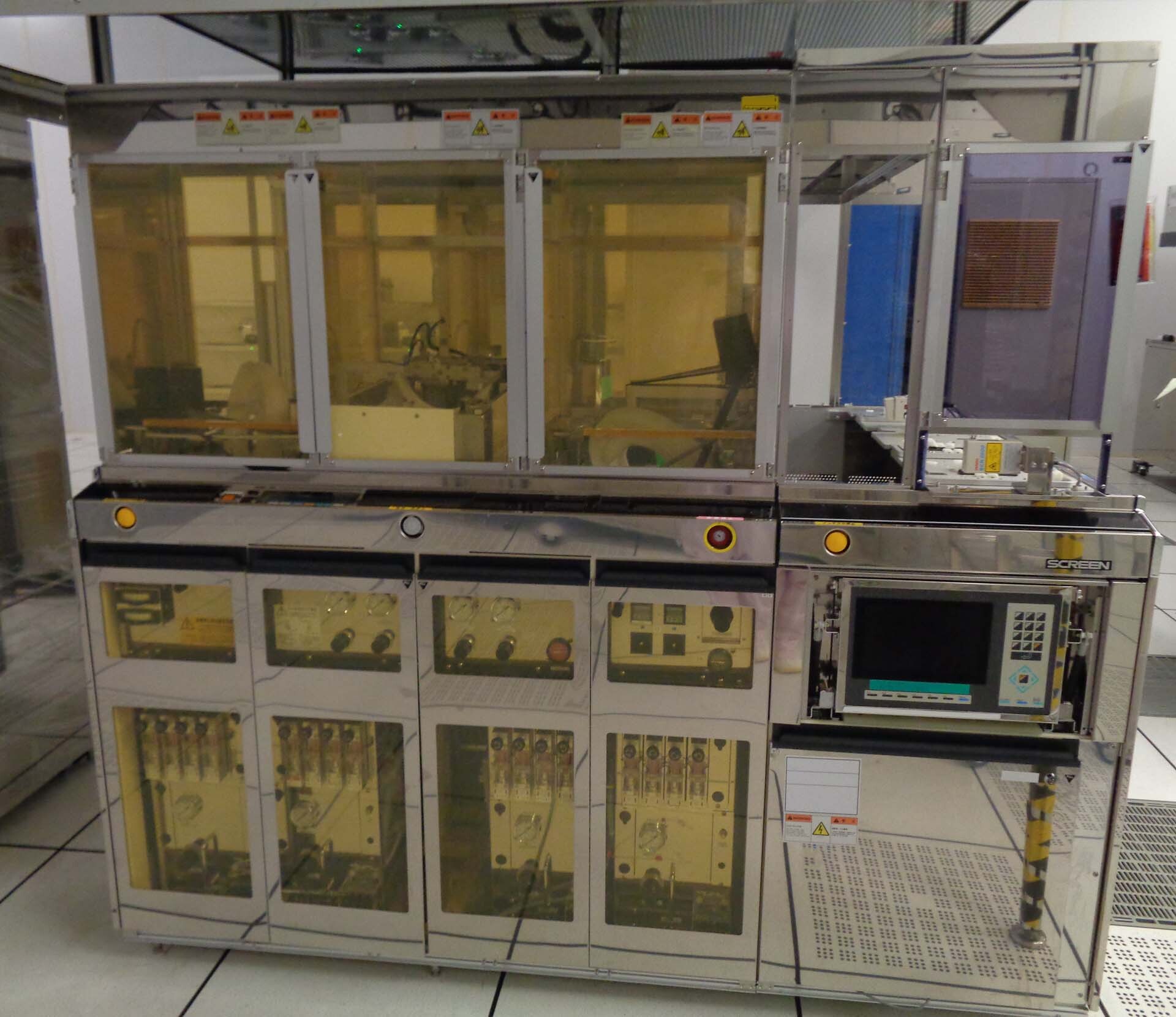

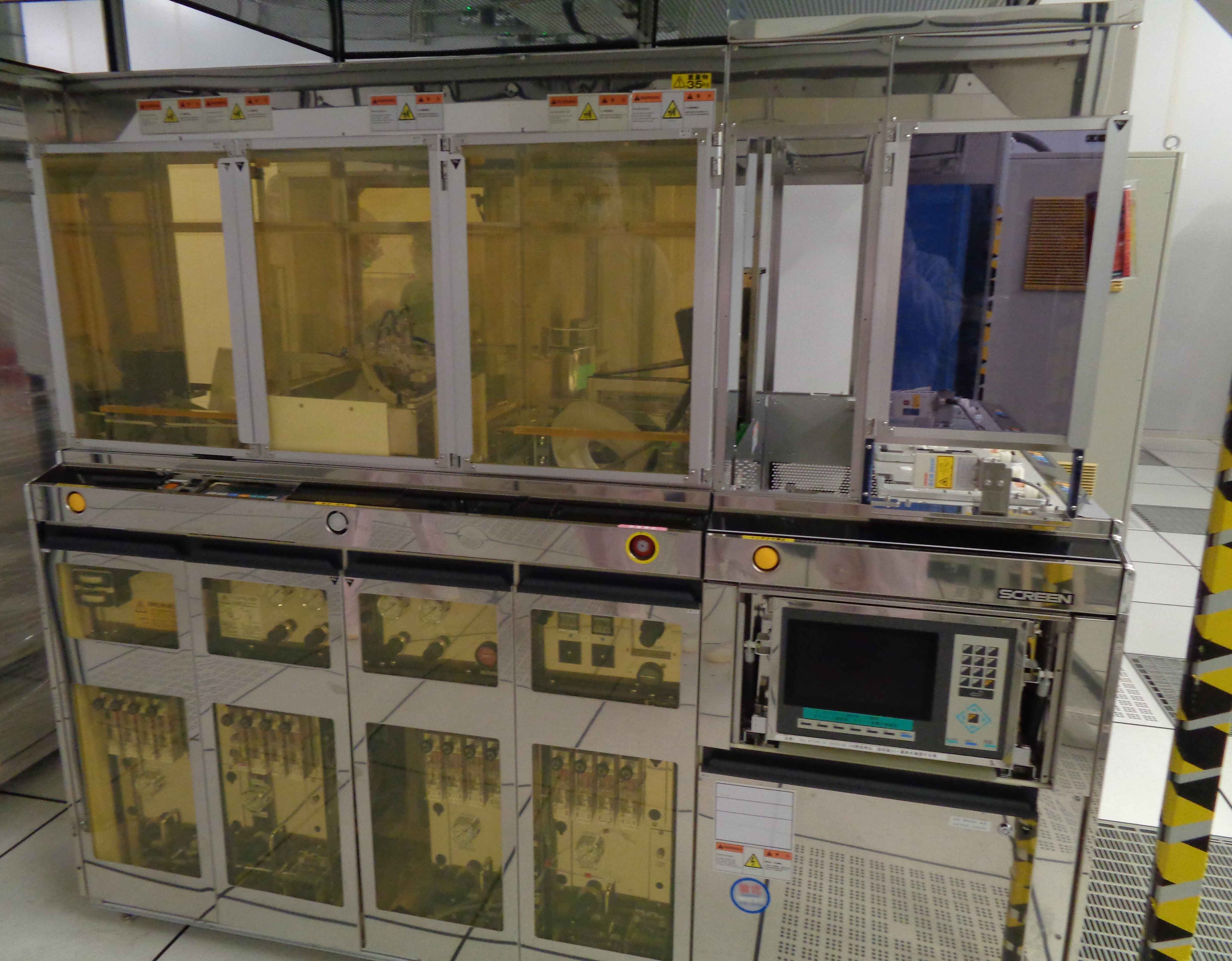

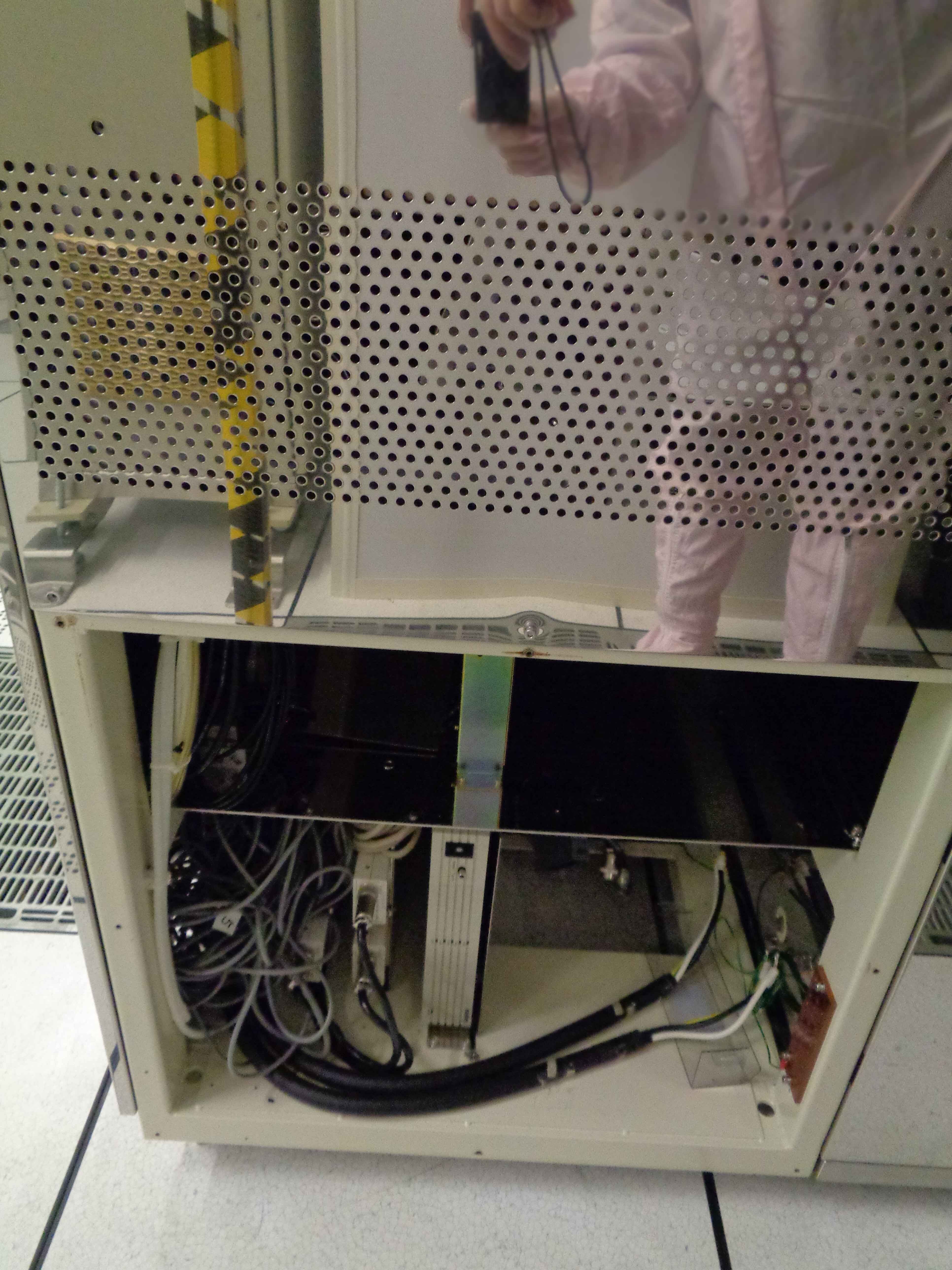

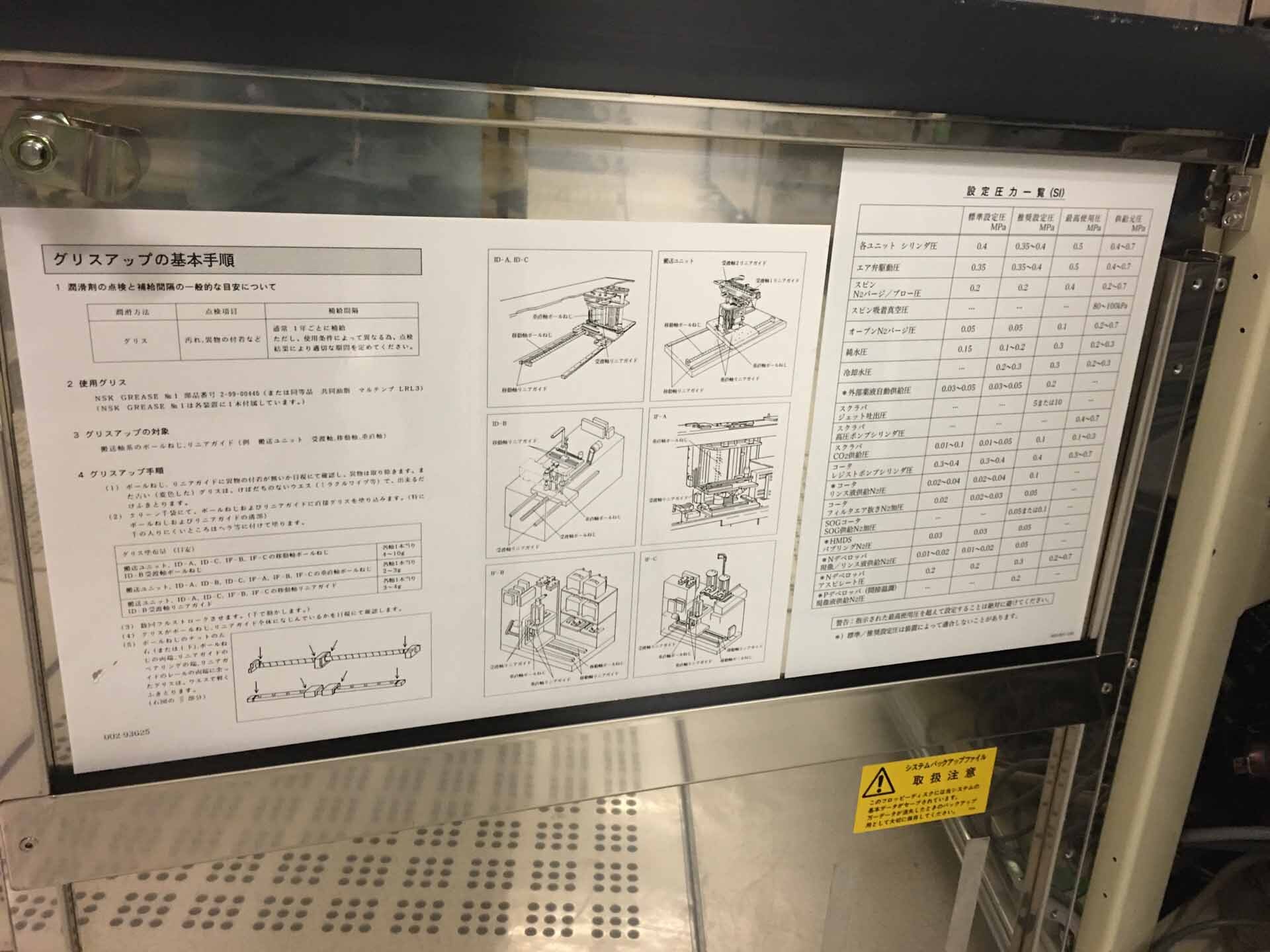

DNS / DAINIPPON SS-W80A-AR is a wafer and mask scrubber machine that is designed to automate the cleaning of wafers and masks used in semiconductor manufacturing. It uses a unique air scrubbing process to gently remove contaminants from the wafer surface and to clean any residues from the mask surfaces or optically transparent layers such as photoresists. The air scrubber enables better, faster, and more precise cleaning than manual techniques and is an essential tool in the production line of semiconductor devices. DNS SSW80A-AR wafer scrubber is designed with a five-axis flexible arm that allows it to access the top, bottom, and side of the wafer to ensure complete coverage of the wafer surface during the scrubbing process. This allows the scrubber to remove debris from hard-to-reach areas which can create contamination on the wafer surface during the lapping and polishing process. Additionally, the scrubbing arm can be customised to accommodate different wafer sizes and materials. Once the wafer is loaded into the scrubber, the scrubber uses a high-velocity air stream to remove the particles. The air stream is created from a series of nozzles that look like a circular fan. The scrubbing process is done in four stages - pre-cleaning, scrubbing, rinsing, and final cleansing. The air scrubbing process also uses proprietary detergents with weak surfactant properties to help further reduce the contamination on the wafer. In terms of safety, the scrubber protects the process environment from any blow-out particles or dust that is generated from the abrasive scrubbing process. This is achieved by using inbuilt HEPA (High Efficiency Particulate Air) filters that trap any particles or dust from entering the process environment. This helps to create a clean and safe working environment for the wafer scrubbing process. Finally, DAINIPPON SSW-80A-AR has an automated control system which makes it easy to operate and monitor the scrubbing process from a centralised control station. The system also provides feedback on the detected level of contamination on the wafer and will notify the operators in case of any abnormal conditions. This helps to ensure that the production process is running smoothly with minimal risk of contamination. Overall, DAINIPPON SSW80A-AR is an efficient tool that assists in cleaning the wafers and masks used in semiconductor production. Its automated control system makes it easier to monitor and operate, and its advanced air scrubbing technology ensures better and faster cleaning with minimal risk of contamination while providing a safe working environment.

There are no reviews yet