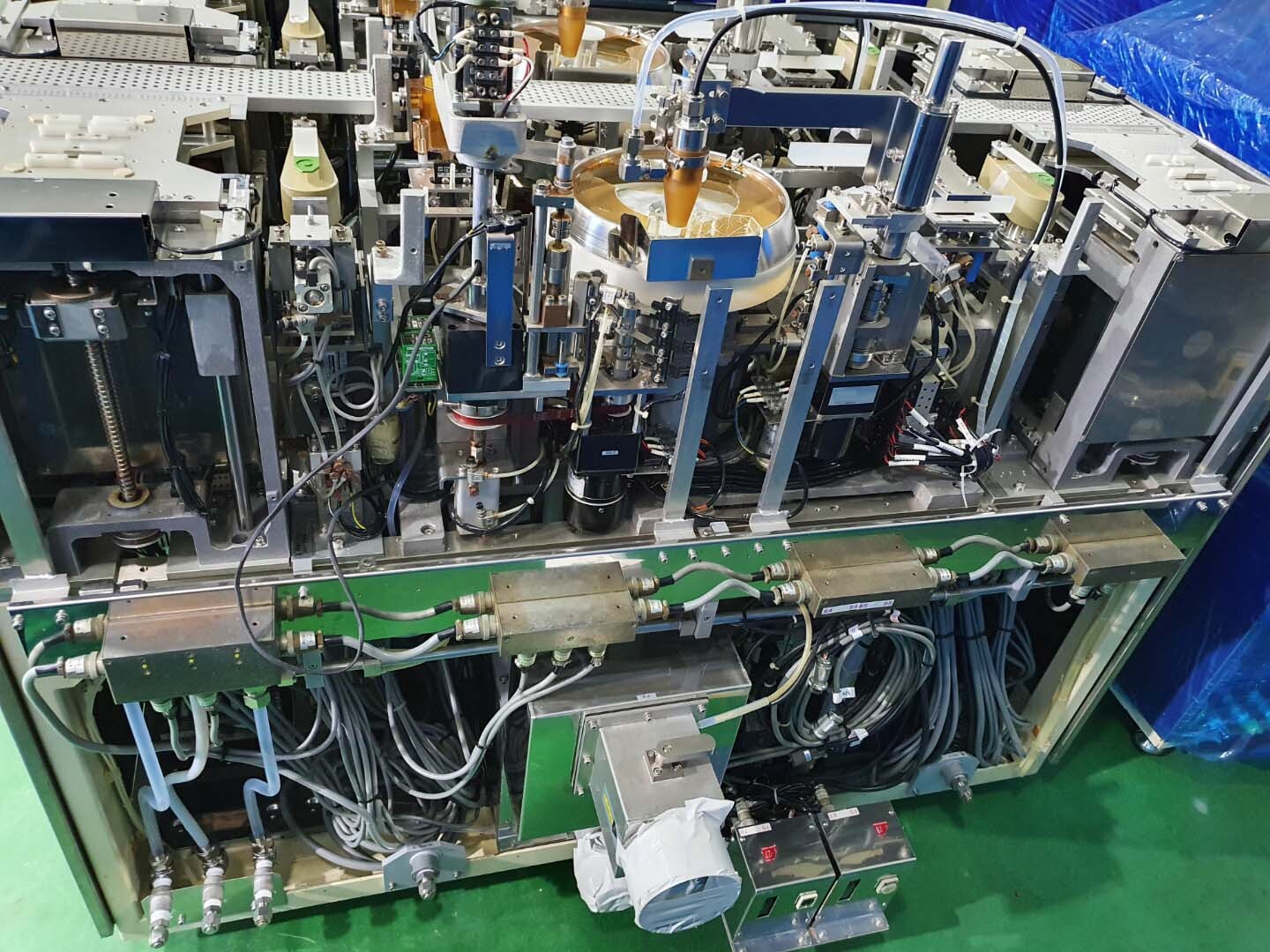

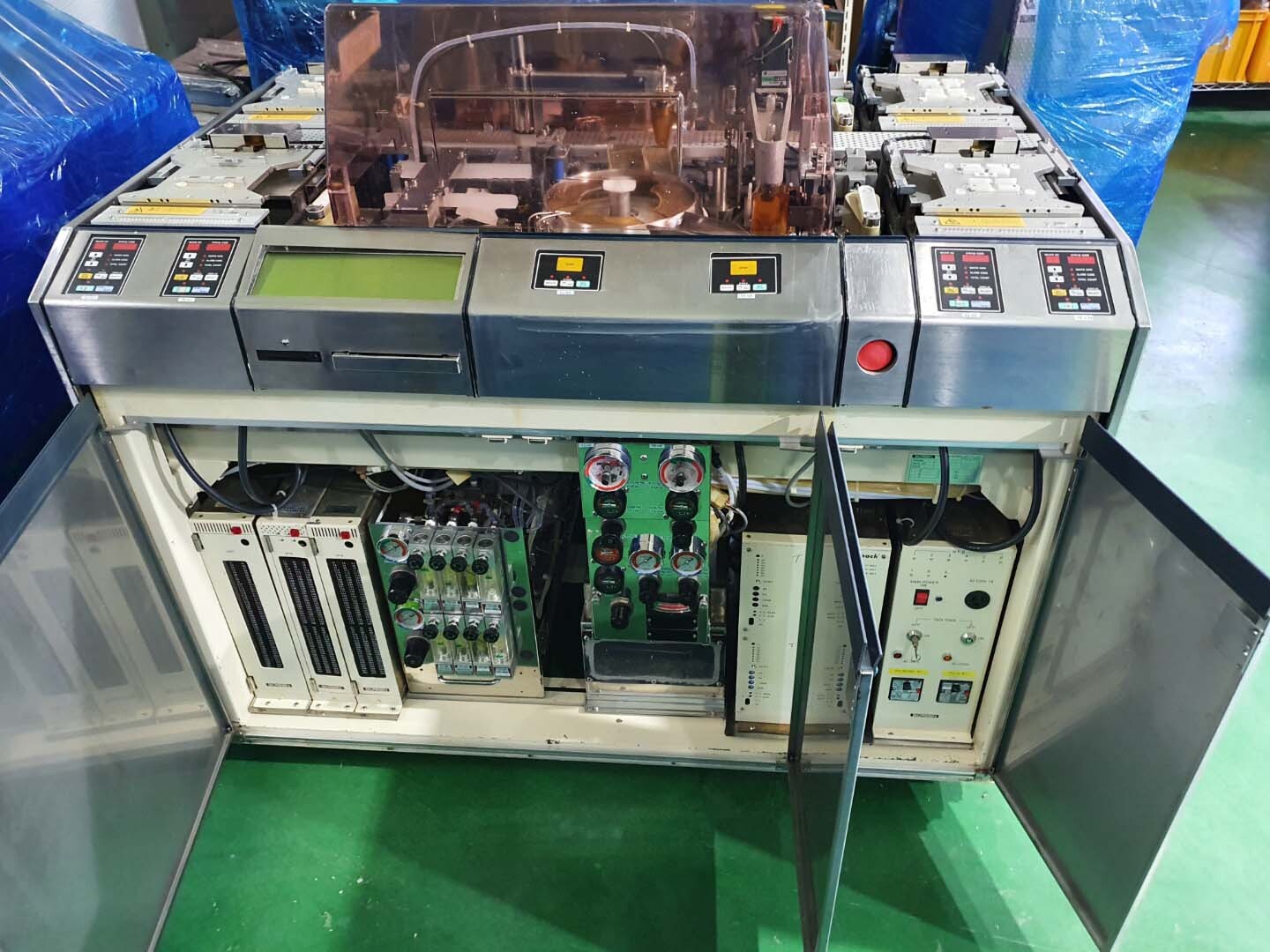

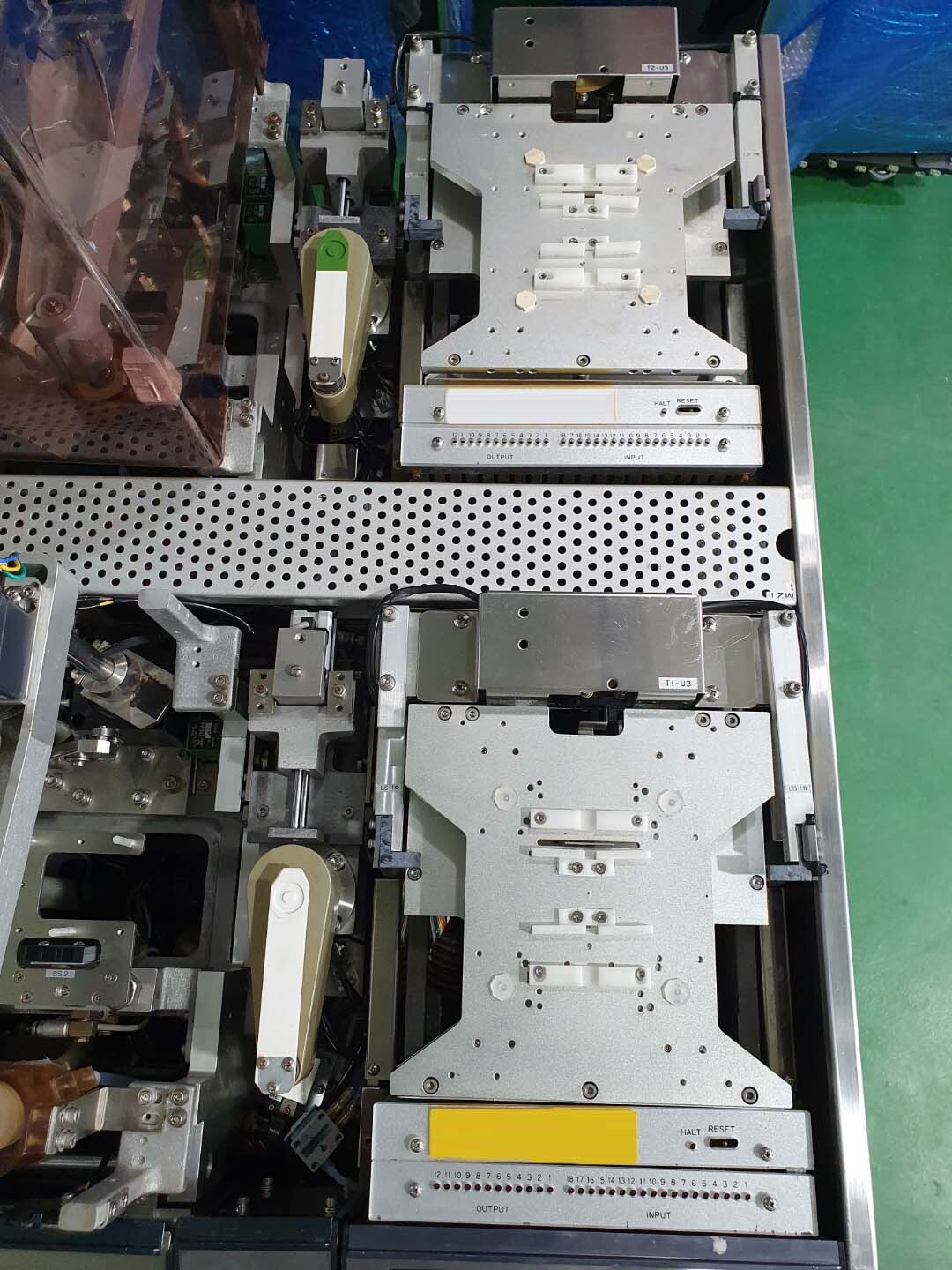

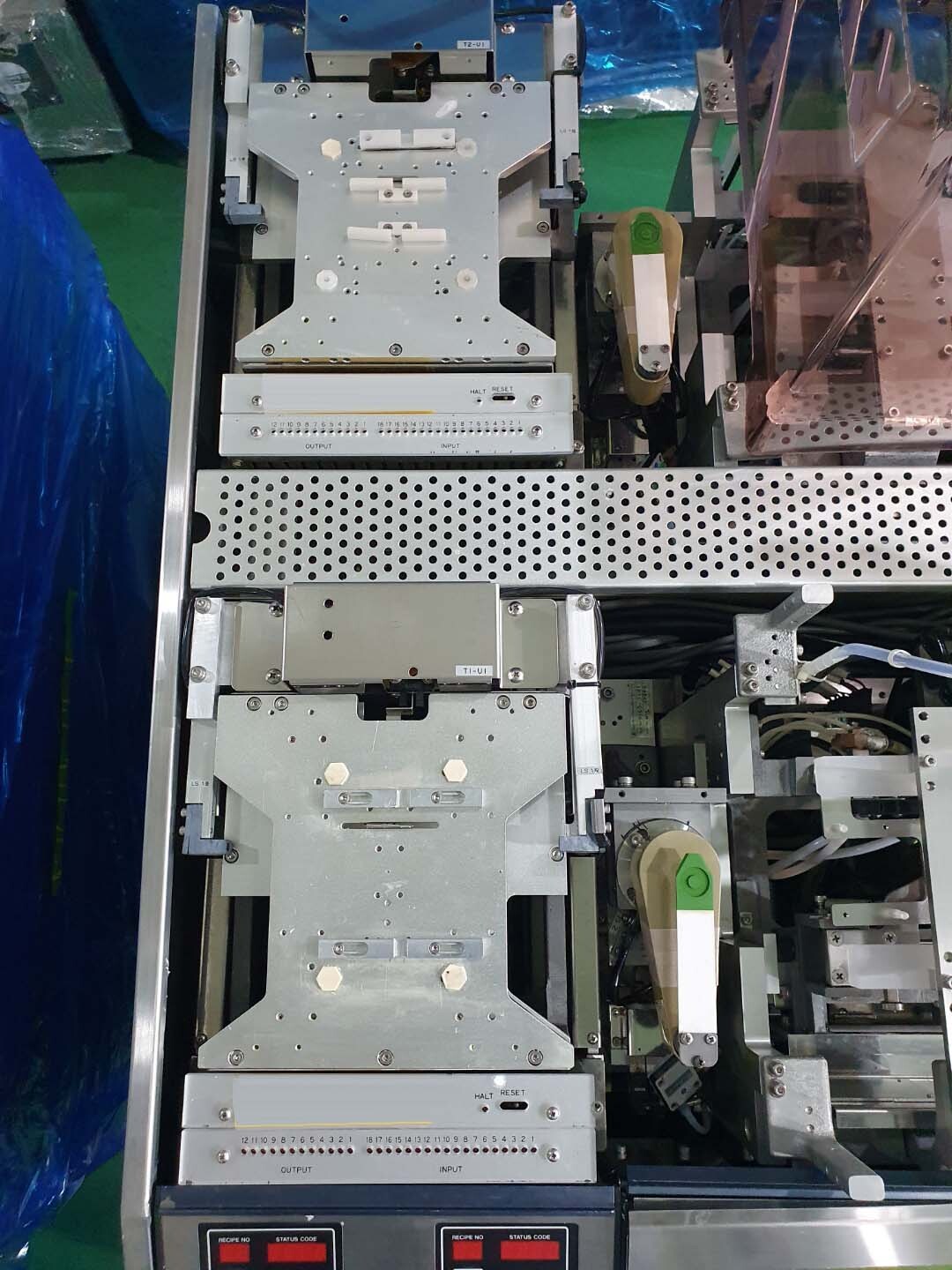

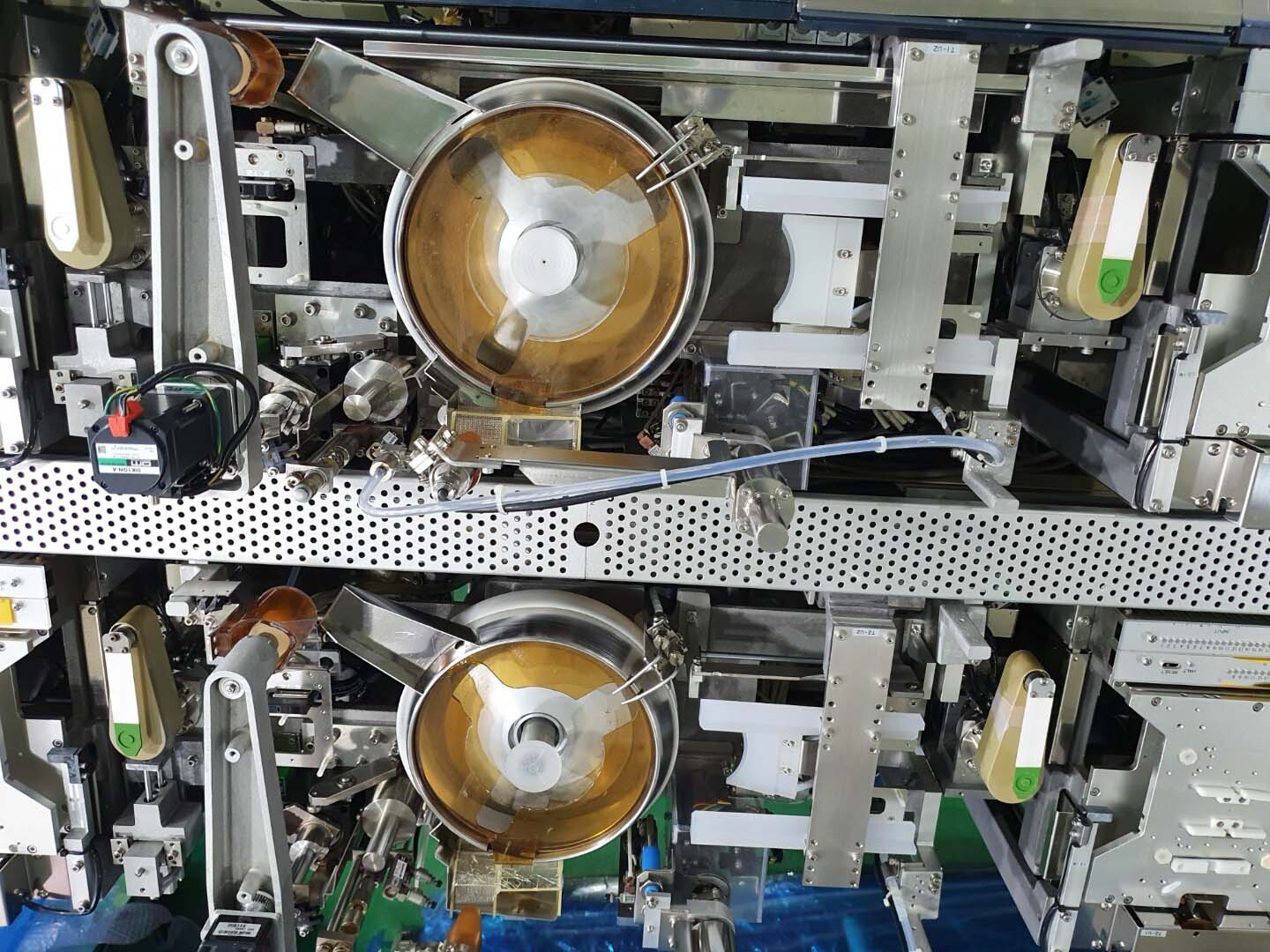

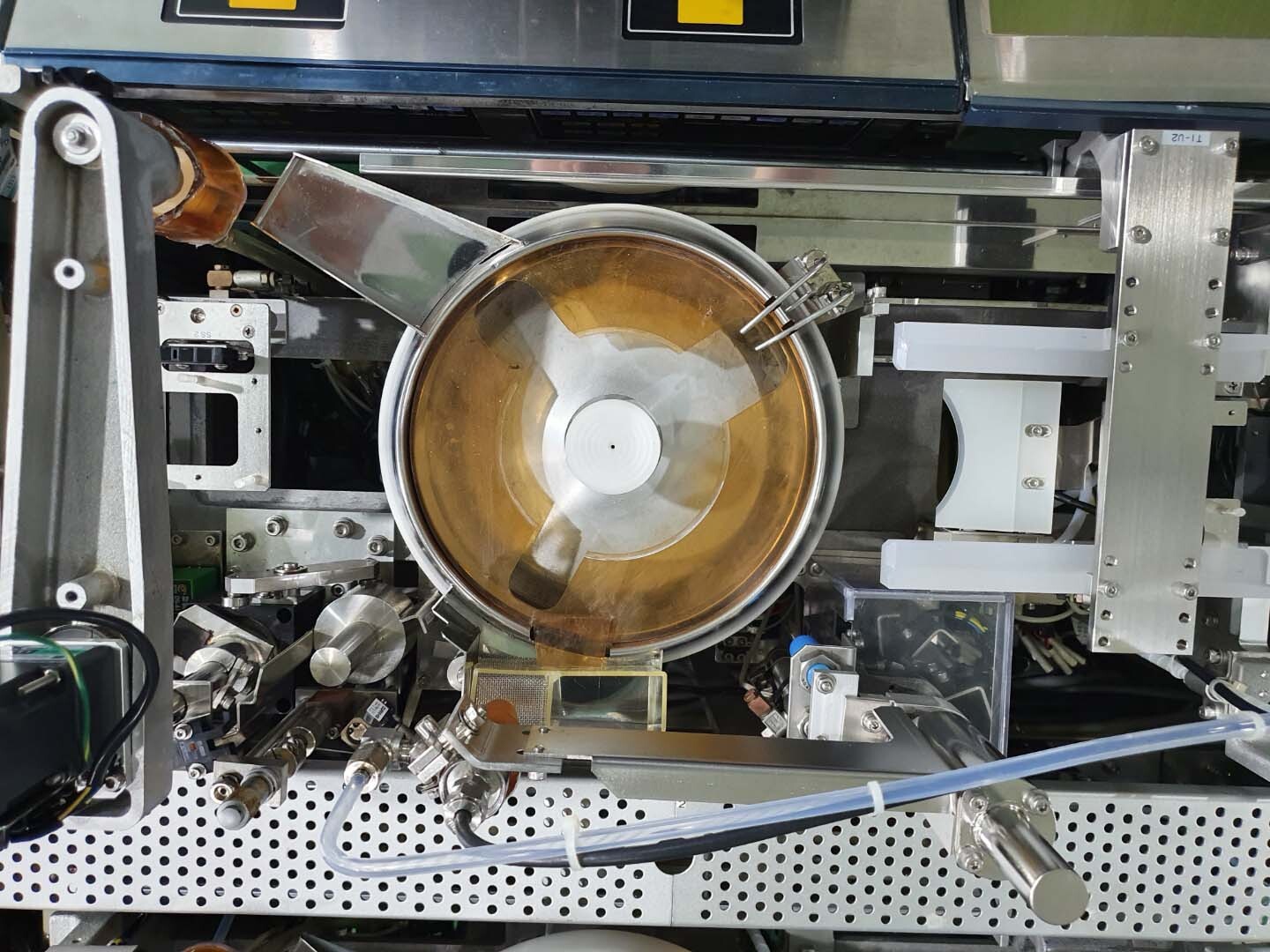

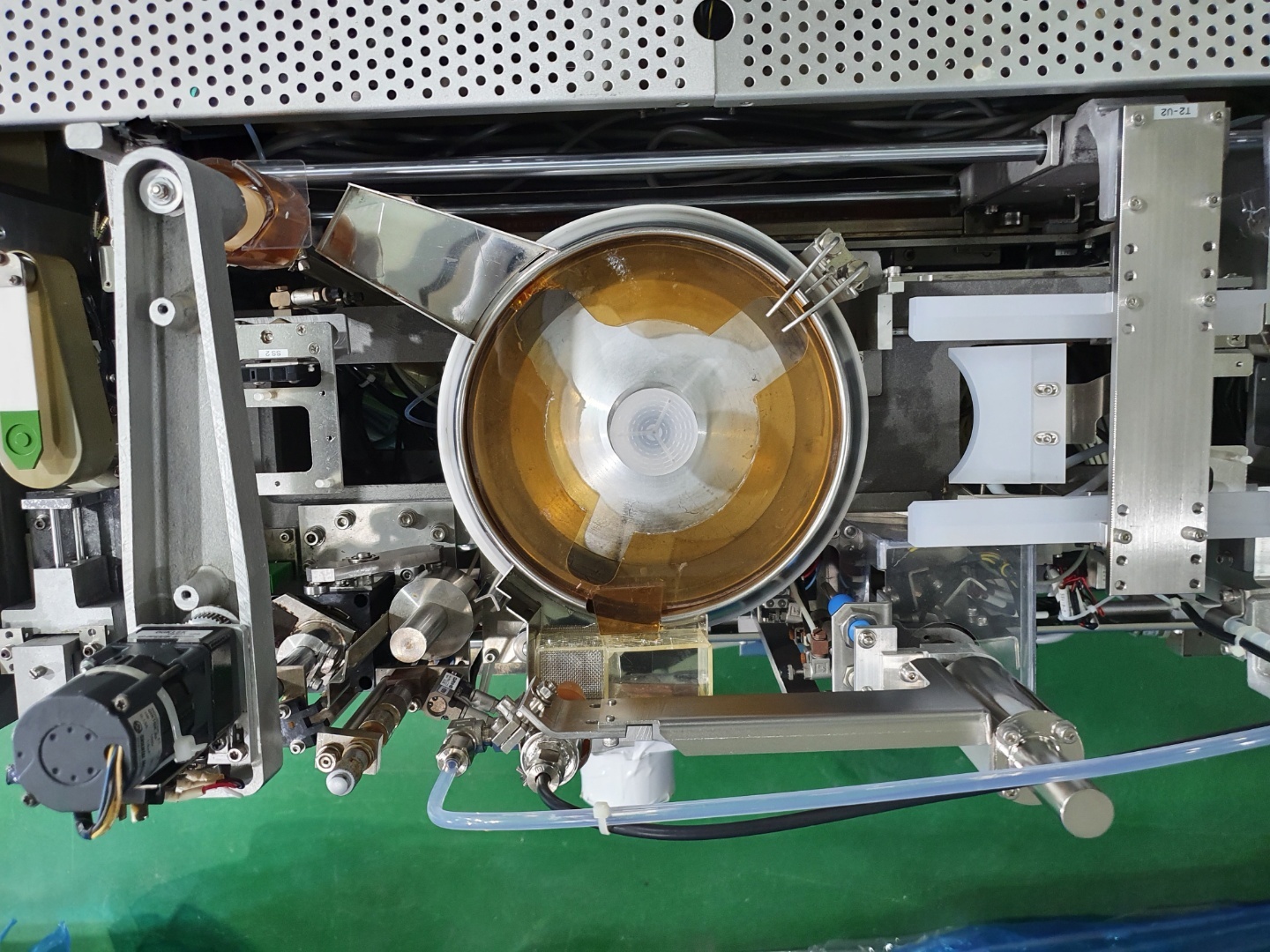

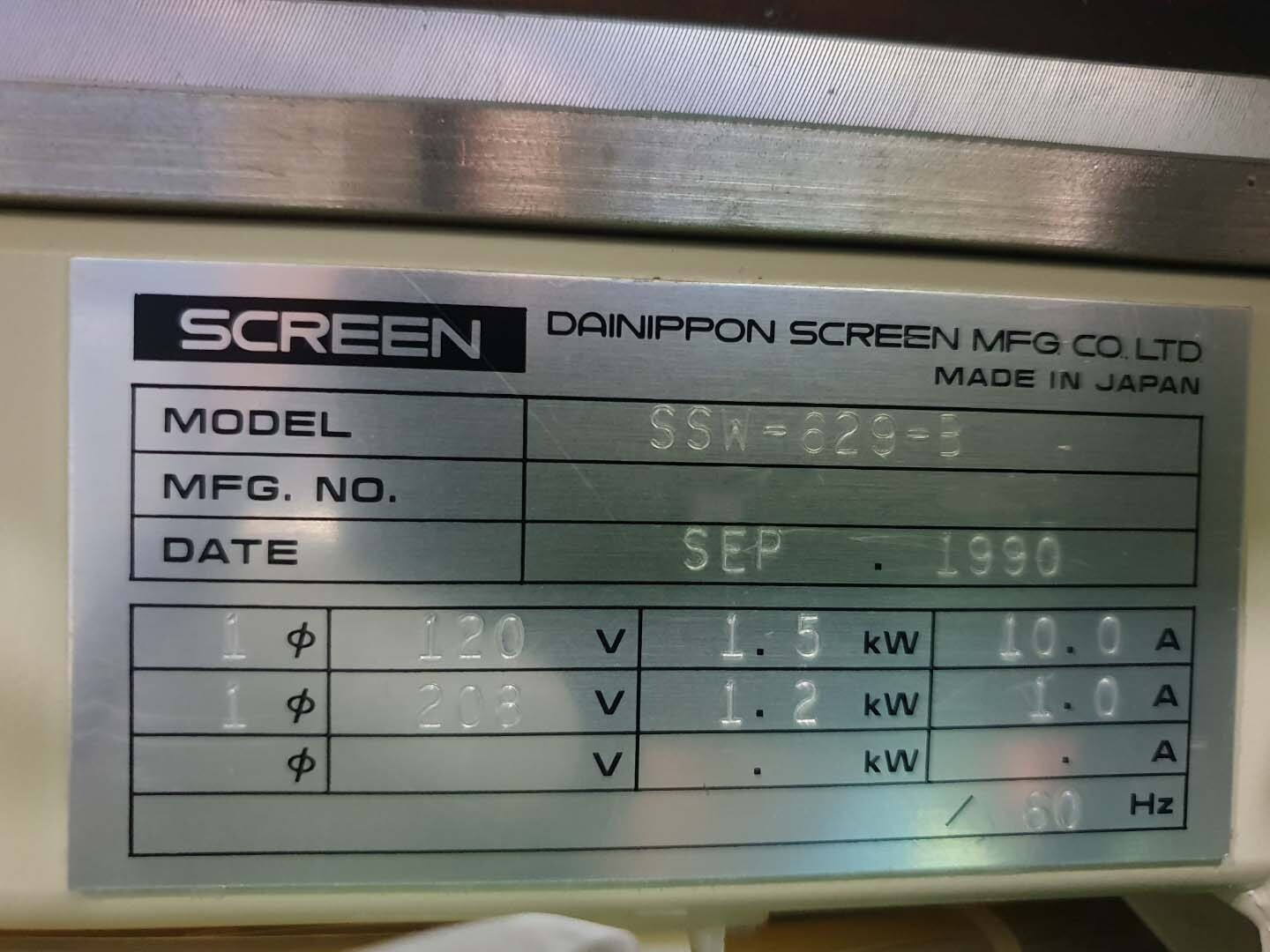

Used DNS / DAINIPPON SSW-629-B #293610239 for sale

URL successfully copied!

Tap to zoom

ID: 293610239

Vintage: 1990

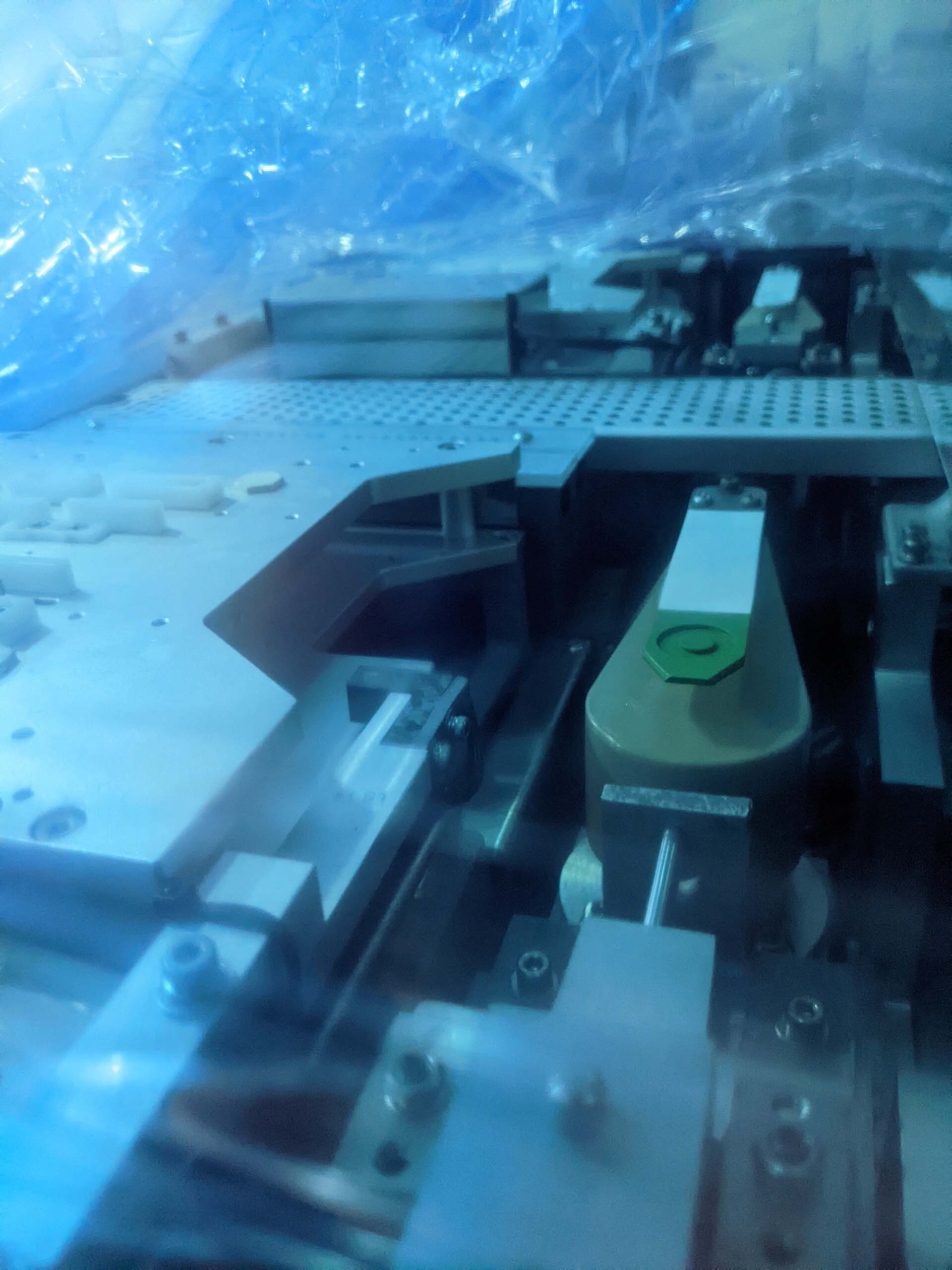

Coater

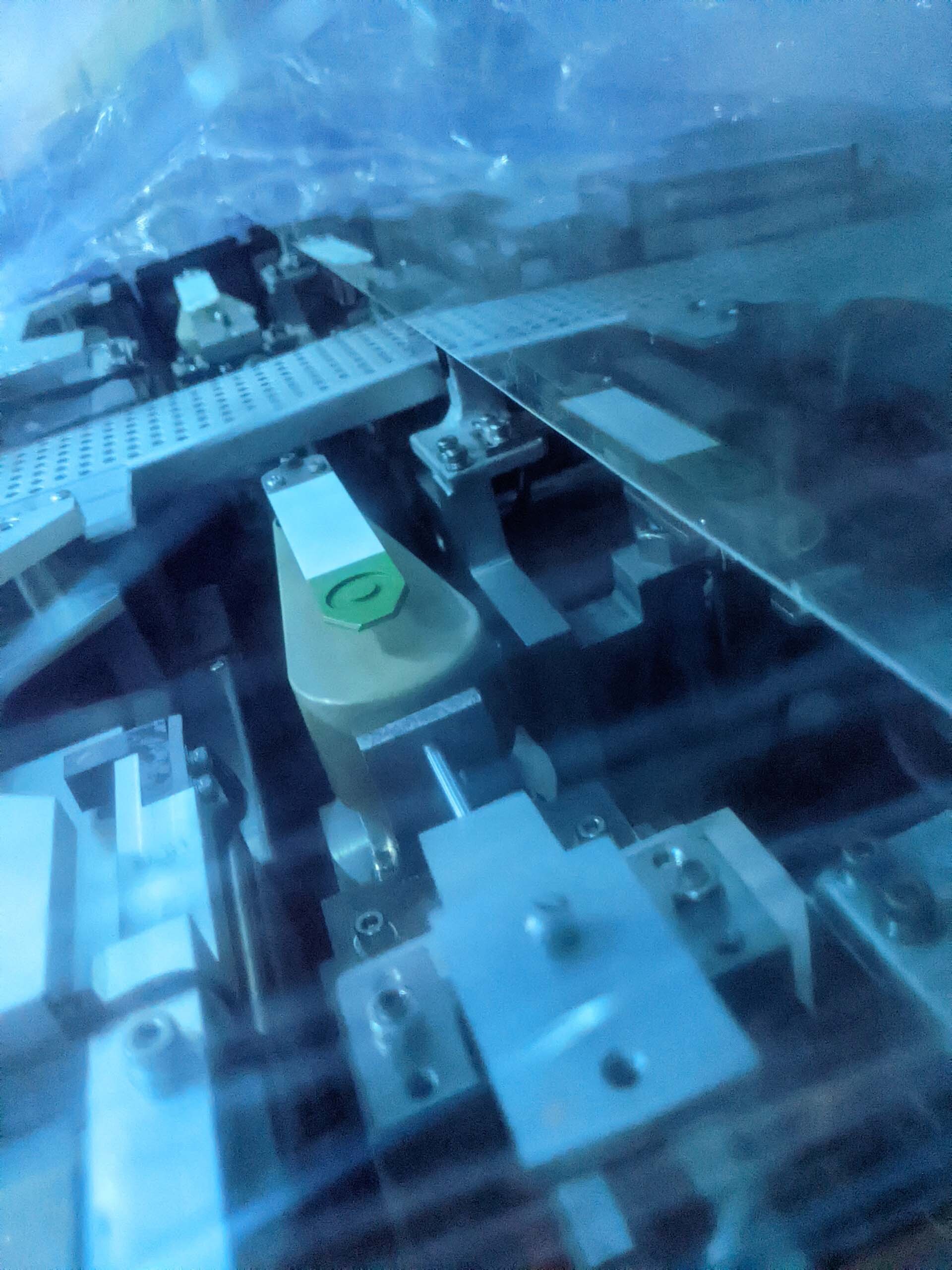

D-Sonic nozzle

Brush nozzle

DI Rinse

1990 vintage.

DNS / DAINIPPON SSW-629-B is a wafer and mask scrubber that provides effective removal of particles, dust and stains to ensure clean wafer and mask surfaces. A special mechanical and chemical process is used to remove particles and other contaminants from the surface of the wafer or mask. The wafer and mask scrubber is designed for fully automatic operation and is capable of handling any size and type of wafer, mask and substrate up to 300 mm diameter. DNS SSW-629B starts with a pre-wash stage, using a high pressure micro-jets to flush substances from the substrate surface. This is followed by a brushing or chemical scrubbing stage. A special brushing unit, with a built-in special bristle offering high water throwing effect, rotates and brushes the substrate surface at high pressure. This removes particles and dirt, achieving a high-quality clean surface. A high-density detergent is used during this step to remove stubborn particles and grease. The next stage of the process is a secondary chemical scrubbing stage. This further removes particles and other contaminants using a high-density surfactant. This cleans the surface to a high-level, removing any contaminant residue after the pre-wash and brushing stages. The last stage of the process is a vacuum drying stage. This uses high-powered vacuum drying equipment to rapidly dry the wafer or mask, resulting in a high-quality clean surface. This stage also helps to further remove particles and contaminants on the surface. DAINIPPON SSW 629B also works on both flat and curved substrates, allowing for a wide range of applications. Overall, SSW-629 B wafer and mask scrubber is an effective and efficient device for removing particles and other contaminants from the surface of wafers and masks. It provides clean, high-quality surfaces that are ideal for use in a range of applications. It is capable of handling any size and type of wafer and mask, up to 300 mm diameter, and is fully automated.

There are no reviews yet