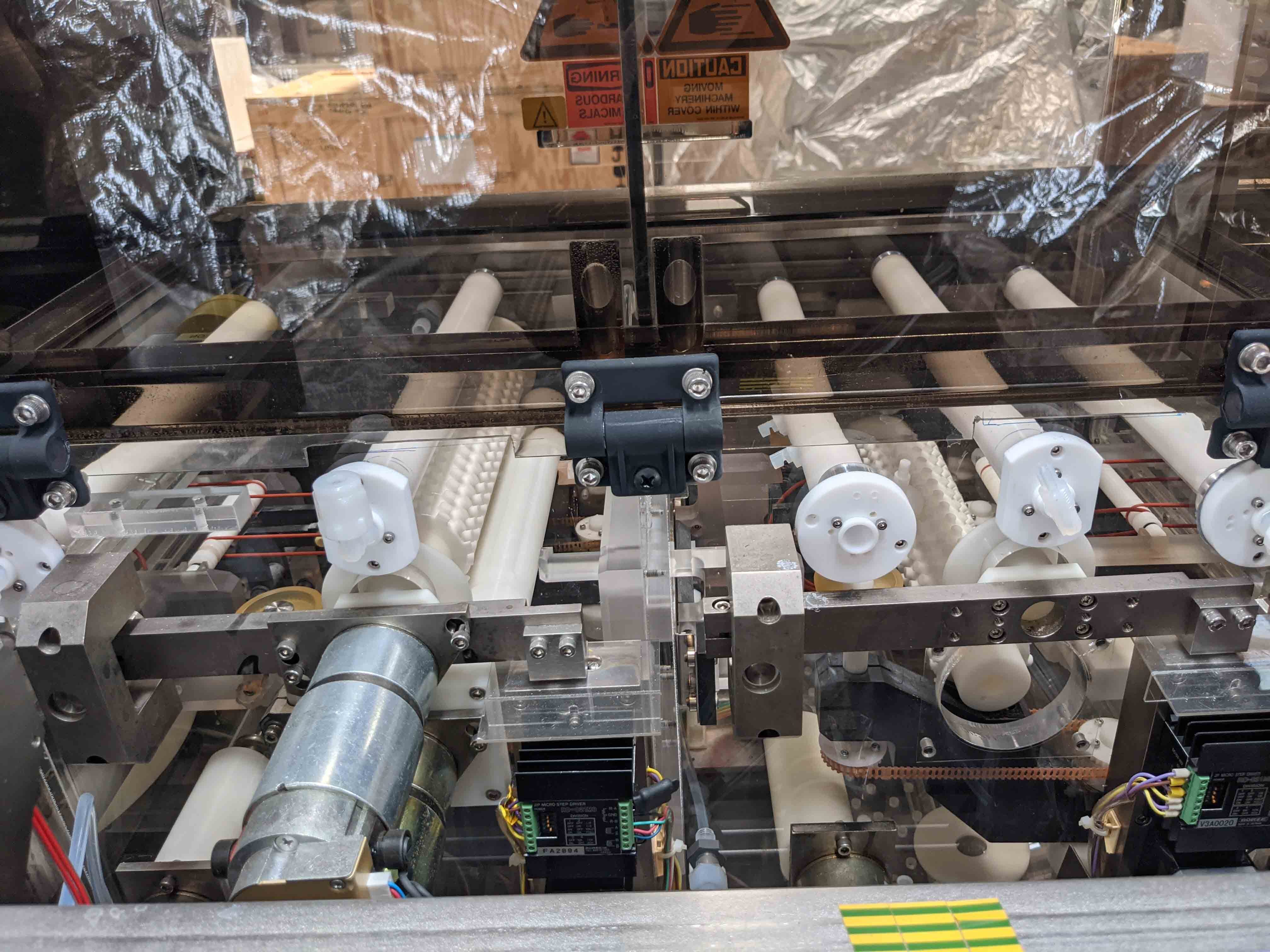

Used LAM RESEARCH DSS 200 #9392384 for sale

URL successfully copied!

Tap to zoom

LAM RESEARCH DSS 200 is an automated wafer and mask scrubber designed for semiconductor processing applications. It is used for wafer and reticle cleaning by removing surface particulate contamination from the wafers and masks. LAM RESEARCH ONTRAK DSS 200 includes a sealed scrub chamber that uses filtered air to reduce airborne contaminants. It utilizes a scrubbing system, which employs a single-stage, two-blade impeller to dissolve particulate contaminants. The wafers and masks are placed on a rotatable scrubbing spindle that is indexed sequentially for each wafer and reticle, thus ensuring a thorough cleaning. DSS 200 operates on 110V AC, consumes up to 500 watts of power, and has a load capacity of up to 40 wafers and masks. The scrub chamber measures 17" W x 21" D x 18" H, with a 2-inch scrub radius and 80 degrees of wafer suspension angle for uniform scrubbing. As an added measure of process control, the scrubbing pressure can be adjustable between 0.5 to 5 psi air pressure. Once the wafers and reticles are loaded into the scrub chamber, a programmable controller takes over the scrubbing process. The overall cleaning cycle typically includes pre-wet, scrubbing, post-wet, and drying stages. Ultrasonic energy is coupled with the scrubbing air to help dissolve contaminates. Once scrubbed, the wafers and masks are passed through a heated drying chamber, where the air is recirculated and exhausted to remove moisture. In summary, ONTRAK DSS 200 is an automated scrubbing system designed to clean wafers and masks in semiconductor processing applications. It utilizes a scrubbing system, a single-stage, two-blade impeller, a programmable controller, and a heated drying chamber, all supported by filtered air in a sealed chamber. The scrubbing pressure, cycle parameters, and air-exhaust control can all be adjusted to provide maximum process control and reliable cleaning results.

There are no reviews yet