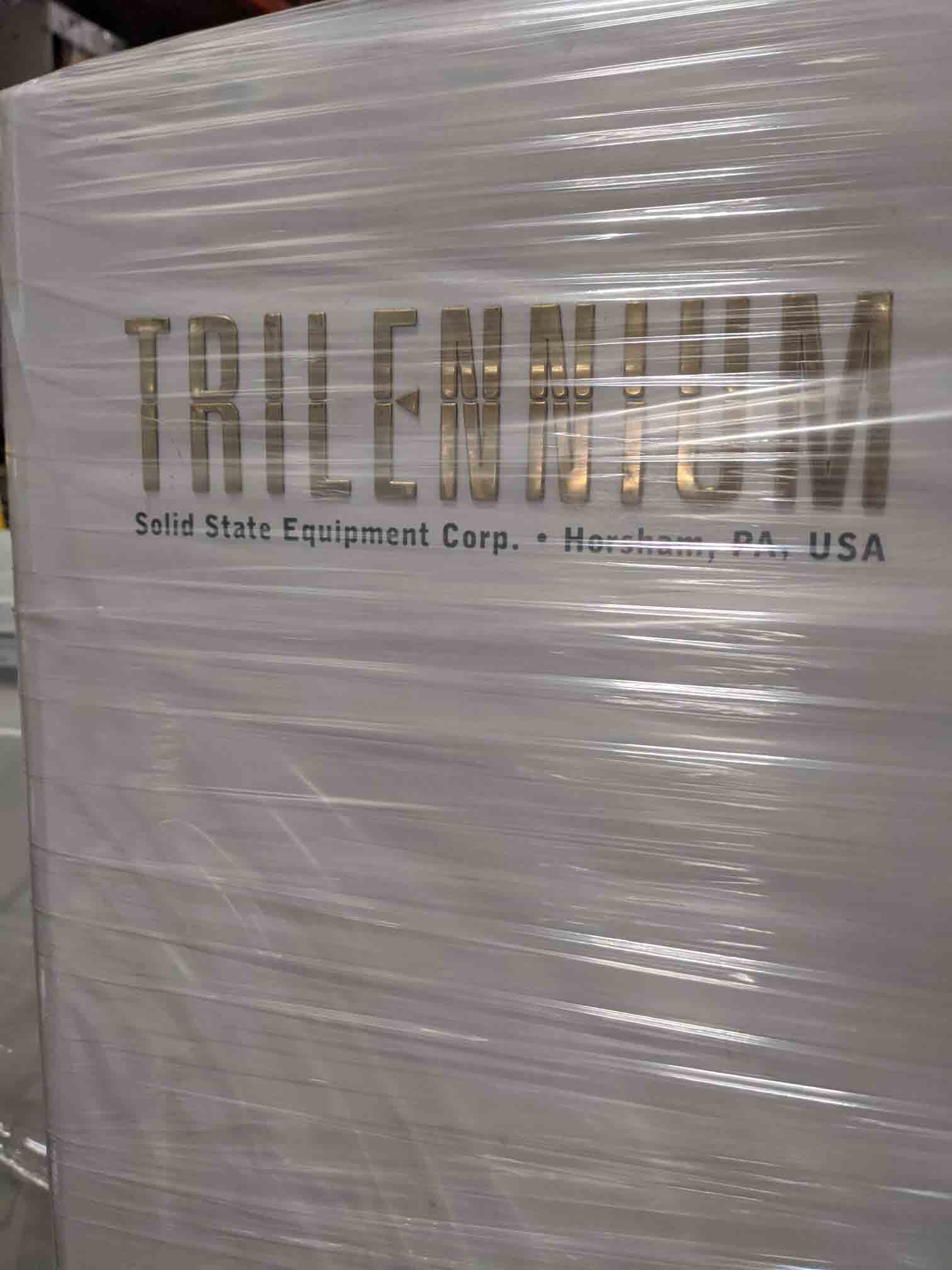

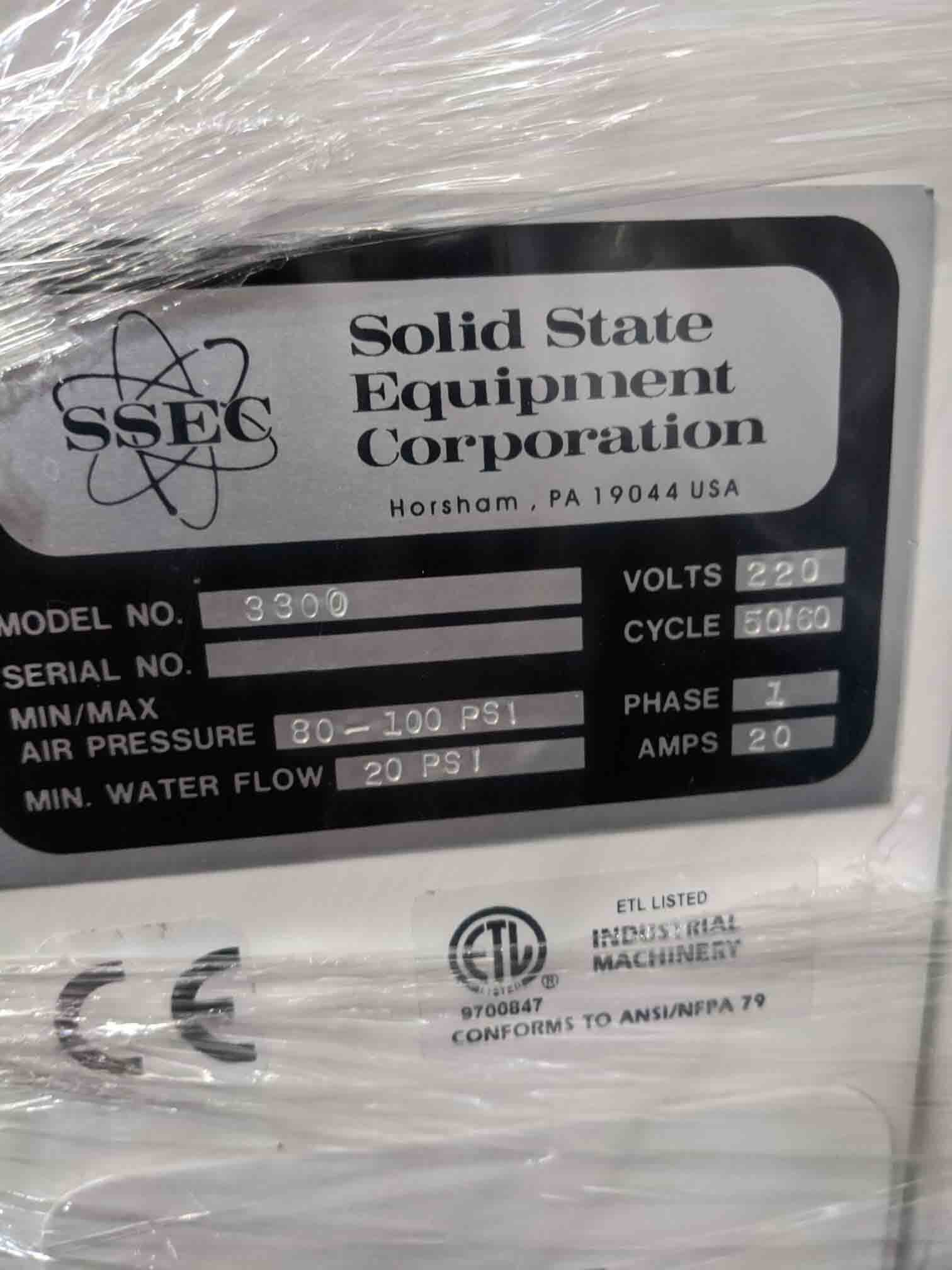

Used SSEC 3300 #293593176 for sale

URL successfully copied!

Tap to zoom

SSEC 3300 wafer & mask scrubber is a high-precision, automated cleaning equipment used to remove particle contamination from delicate semiconductor wafers and photomask blanks. The system is engineered with advanced robotics, PLC controllers and a PC interface to virtually guarantee cleaning consistency and accuracy. 3300 utilizes one of two scrubbing technologies: contact scrubbing or localized scrubbing. The contact scrubbing process utilizes multiple robotic arms controlled by pre-programmed CNC software that are designed to move along a specified path. As each arm moves along the desired route, the scrubbing head, mounted at the end of the robot arm, uses a roller squeegee to remove particulates from the wafer. Localized scrubbing is a more precise, point-source scrubbing process typically utilized for mechanical cleaning of extremely delicate substrates, such as photomask blanks. In localized scrubbing the scrubbing action is generated from a stationary-mounted scrubbing head that is equipped with an array of multiple small cleaning micro-washlets. Additionally, localized scrubbing offers an ice-cooling feature that allows the process to occur at a very low-temperature, typically just above freezing, to further minimize the chance of damaging the substrate. In both processes, a liquid cleaning solution is delivered to the scrubbing head via a recirculation unit that introduces fresh liquid and removes spent liquid and particle debris. The used liquid is cleaned via the built-in filtration machine before being reintroduced back into the scrubbing process. SSEC 3300 provides full flexibility in wafer size, geometry, chemical compatibility, tooling changes and chemical concentration. The tool can also be easily adjusted to meet individual user specifications. When combined with comprehensive communication and operator notification systems, 3300 offers both a high-degree of reliability and cleaning accuracy. The patented design of SSEC 3300 greatly reduces the user-generated error often associated with manual systems. The automated cleaning process also greatly reduces the overall operator time needed to perform a cleaning cycle, saving valuable resources. Furthermore, optimizing the chemical concentration and scrubbling action results in cleaner wafers, longer part life, and extended tooling life. As a result, 3300 is favored and preferred by many users due to its reliability, flexibility, and superior results.

There are no reviews yet