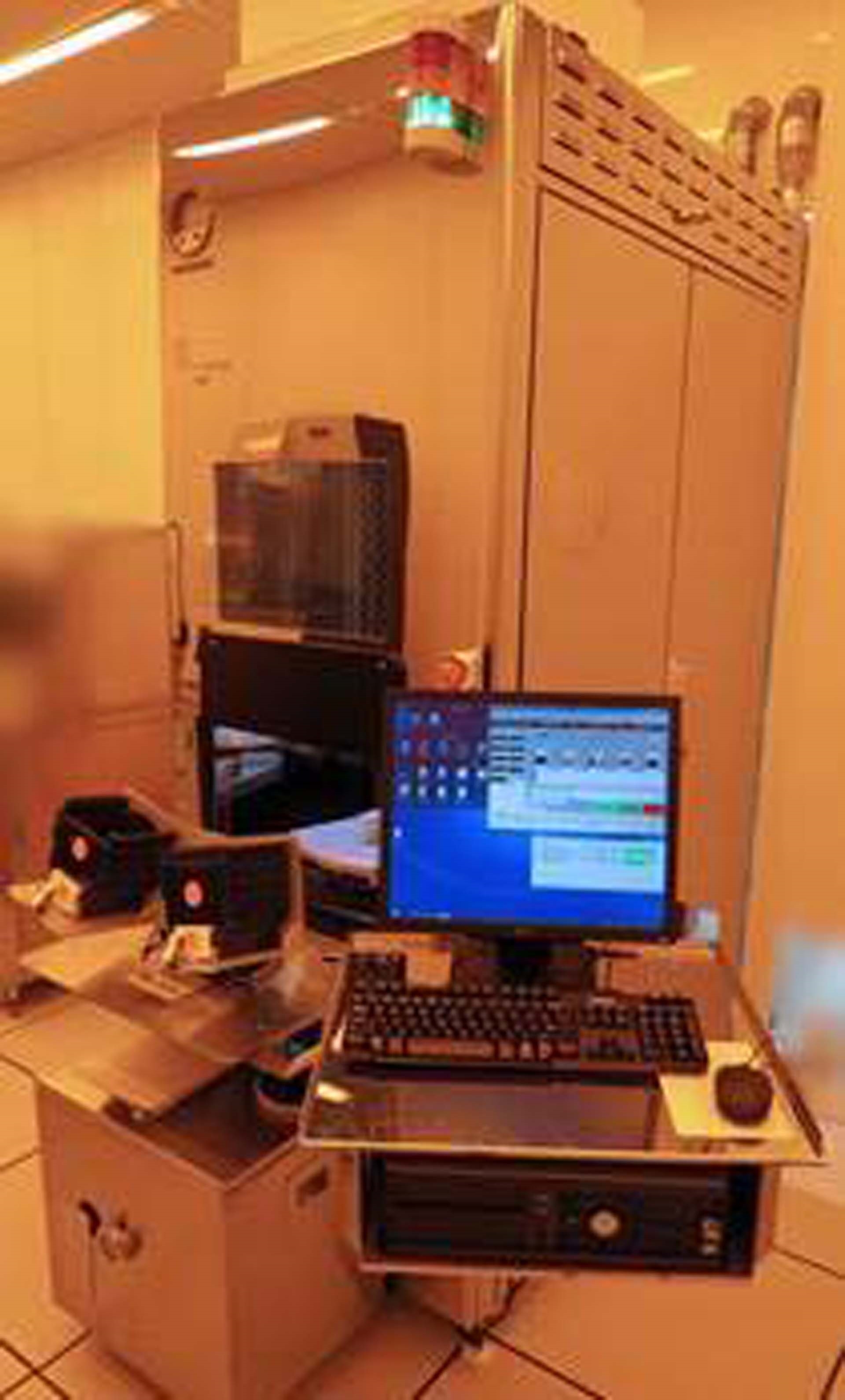

Used SSEC M3302 #9229623 for sale

URL successfully copied!

Tap to zoom

ID: 9229623

Wafer Size: 6"

Vintage: 2011

Wafer cleaning system, 6"

Designed for isopropyl alcohol (IPA)

N-Methylpyrrolidone (NMP)

Pipes: Ammonia and hydrogen peroxide

Modules:

Loading module

Unloading module

Processing module

Drying module

Processing plates in 3-stages:

Processing in an alkaline solution of caustic potassium

Processing in stream of deionized water

Drying in stream of nitrogen

Time of one cycle of processing a plate: 45-60s

Centrifuge rotor speed:

Treatment in alkali + washing deionized water: 30-300 RPM

Drying: 2500-3500 rpm

Accessories:

ACER Monitor

Processor block

Fastening for monitor and keyboard

Mouse

Keyboard

Power consumption: 208 V, 6.0 kVA, 3-Phase, 60 Hz

2011 vintage.

SSEC M3302 is a high-performance wafer and mask scrubber. This machine is designed to accurately and efficiently remove surface particulate from semiconductor wafers and photomask substrates. SSEC M 3302 is able to provide superior cleaning by utilizing a combination of high-pressure jets and vacuum extraction. The machines tank is made entirely of stainless steel in order to resist chemicals, and to allow for easy cleaning and maintenance. M3302 is equipped with a variable-speed conveyor that can easily adjust to accommodate different types of wafers and photomask substrates. This allows for a consistent cleaning process regardless of material type. Within the cleaning process, M 3302 utilizes a combination of brush scrubbing and high-pressure jets of water or chemical agents to irradiate surface particulates. Using this method, SSEC M3302 is able to provide thorough cleaning for even the most difficult cleanroom applications. SSEC M 3302 is equipped with an adjustable flow rate valve for precise control over the concentration of cleaning media used within the process. To ensure an optimal quality result, the flow rate is adjustable to maintain a consistent ratio of cleaning media to wafer surface area being cleaned. Additionally, for operators that wish to switch between harsh and soft cleaning solutions, M3302 comes with pre-programmable settings. This allows for quick, easy, and safechange from one cleaning solution to another without needing to manually adjust settings. To further ensure a high-quality result, M 3302 features a dynamic vibration detection system designed to detect any abnormal vibration during cleaning. If vibration is detected, the machine will instantly shut down to prevent any damage to the wafer or photomask being cleaned. SSEC M3302 is designed to provide a fast and efficient way to clean semiconductor wafers and photomask substrates. Utilizing precise control over its cleaning solution and powerful brushing and high-pressure jet systems, SSEC M 3302 can ensure quality cleaning even for the toughest cleanroom applications. Furthermore, with its adjustable flow rate and pre-programmable settings, this machine provides a swift and simple means of cleaning multiple substrate with a variety of methods.

There are no reviews yet