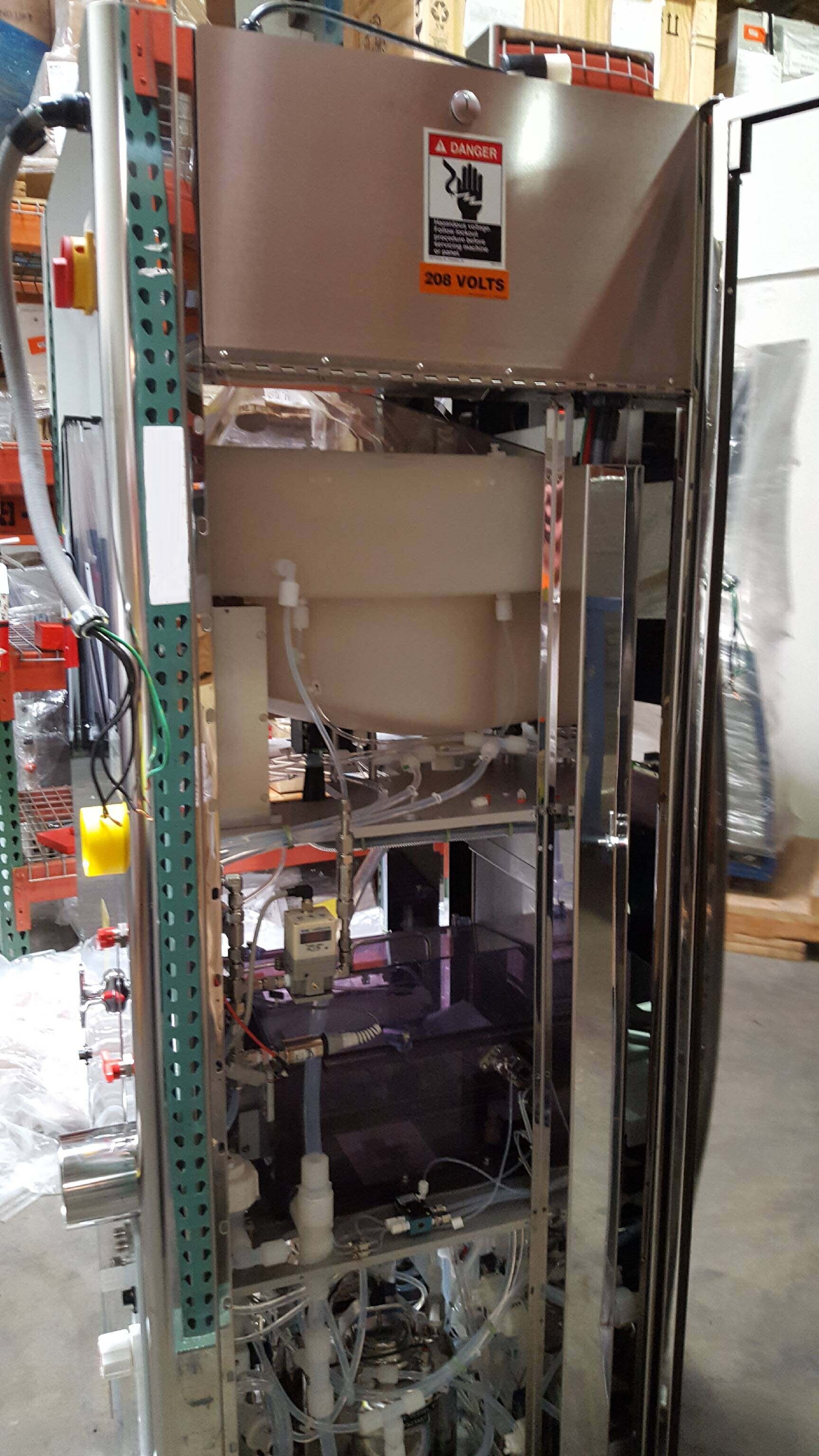

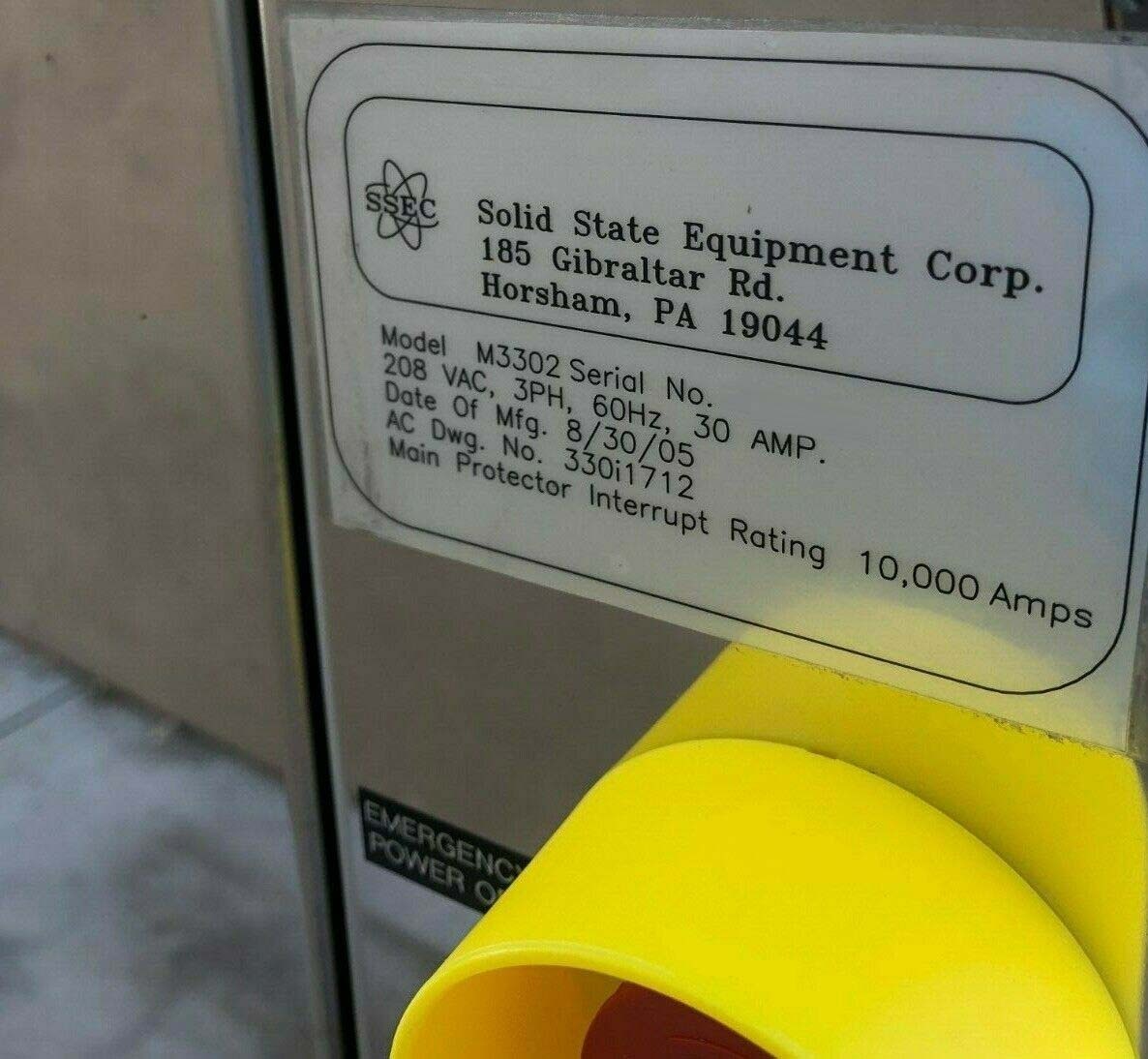

Used SSEC M3302 #9236399 for sale

URL successfully copied!

Tap to zoom

ID: 9236399

Vintage: 2005

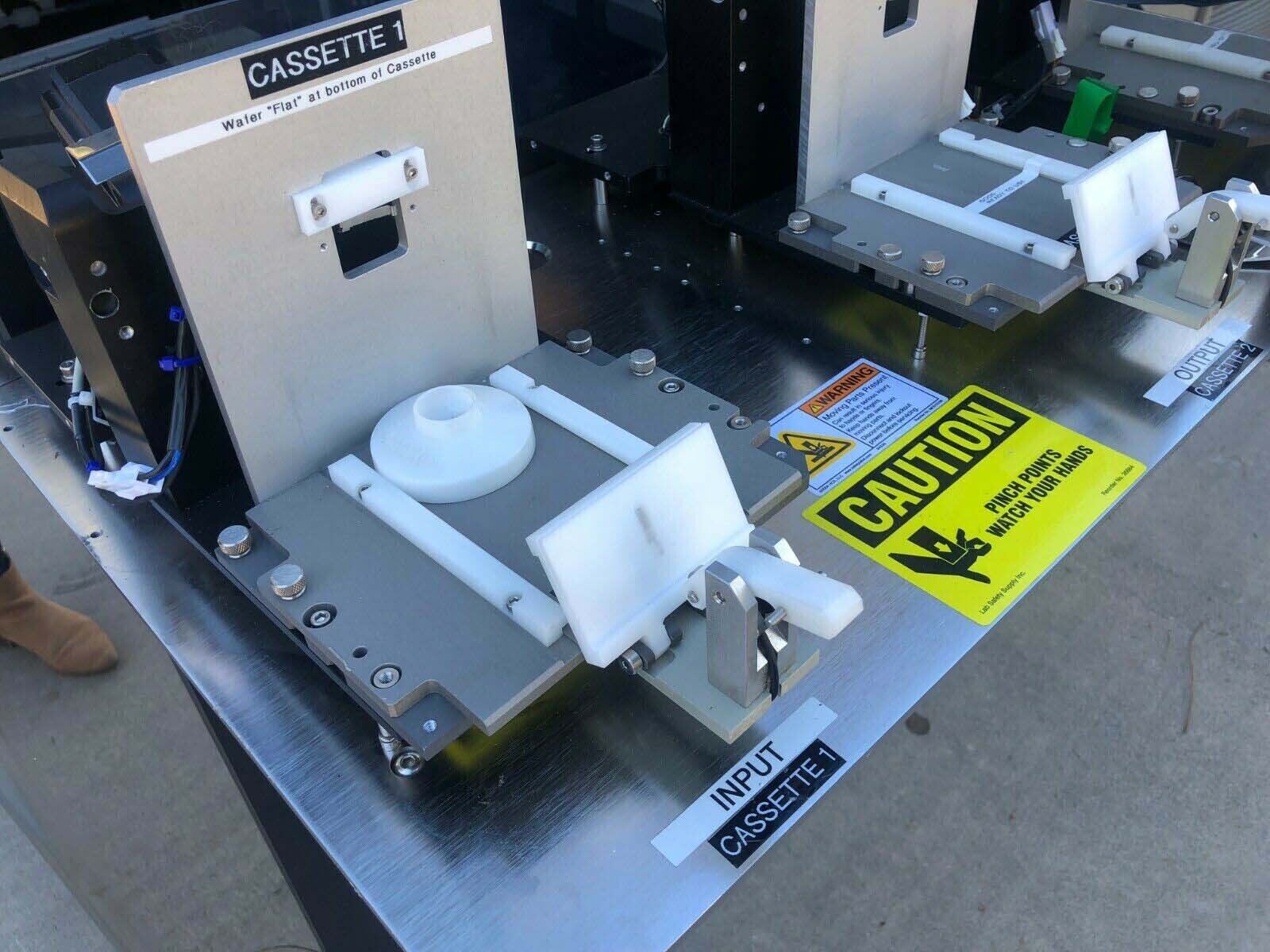

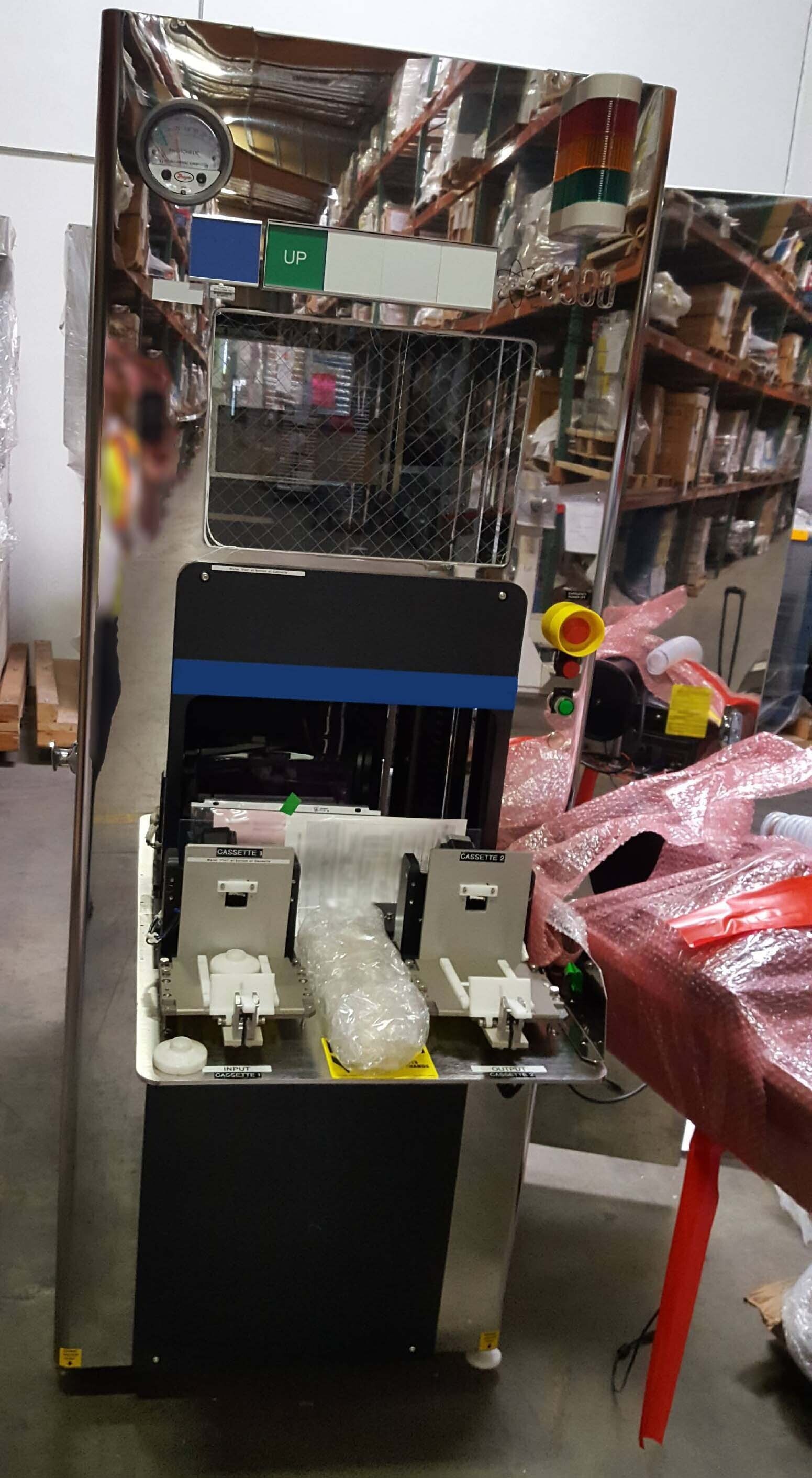

Single wafer etcher

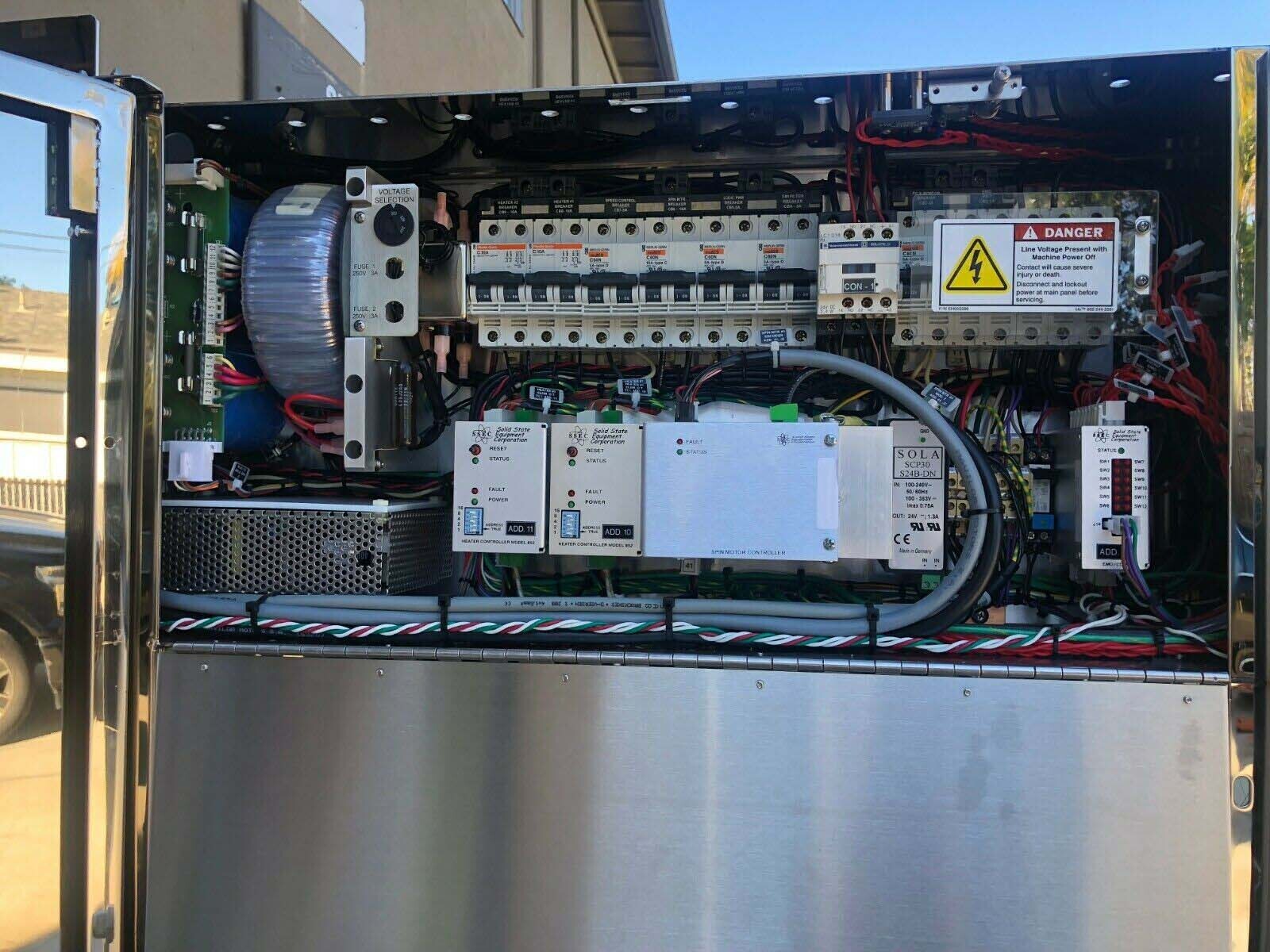

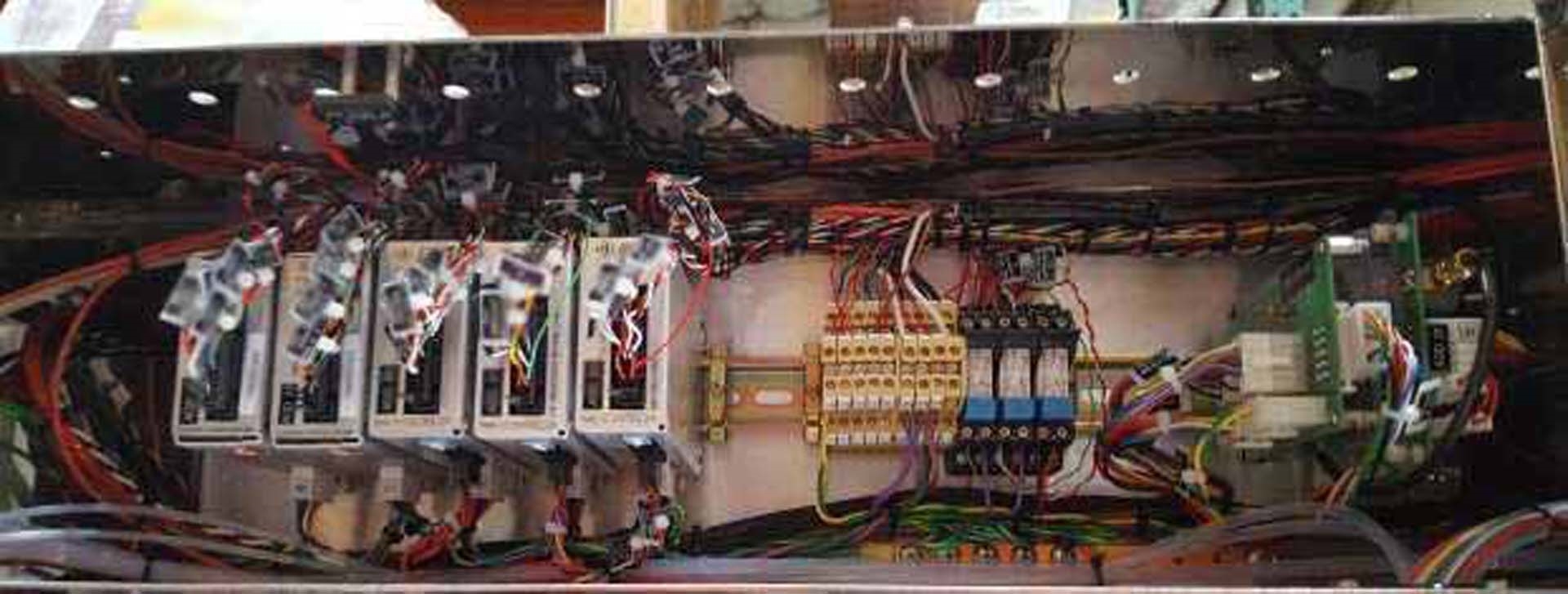

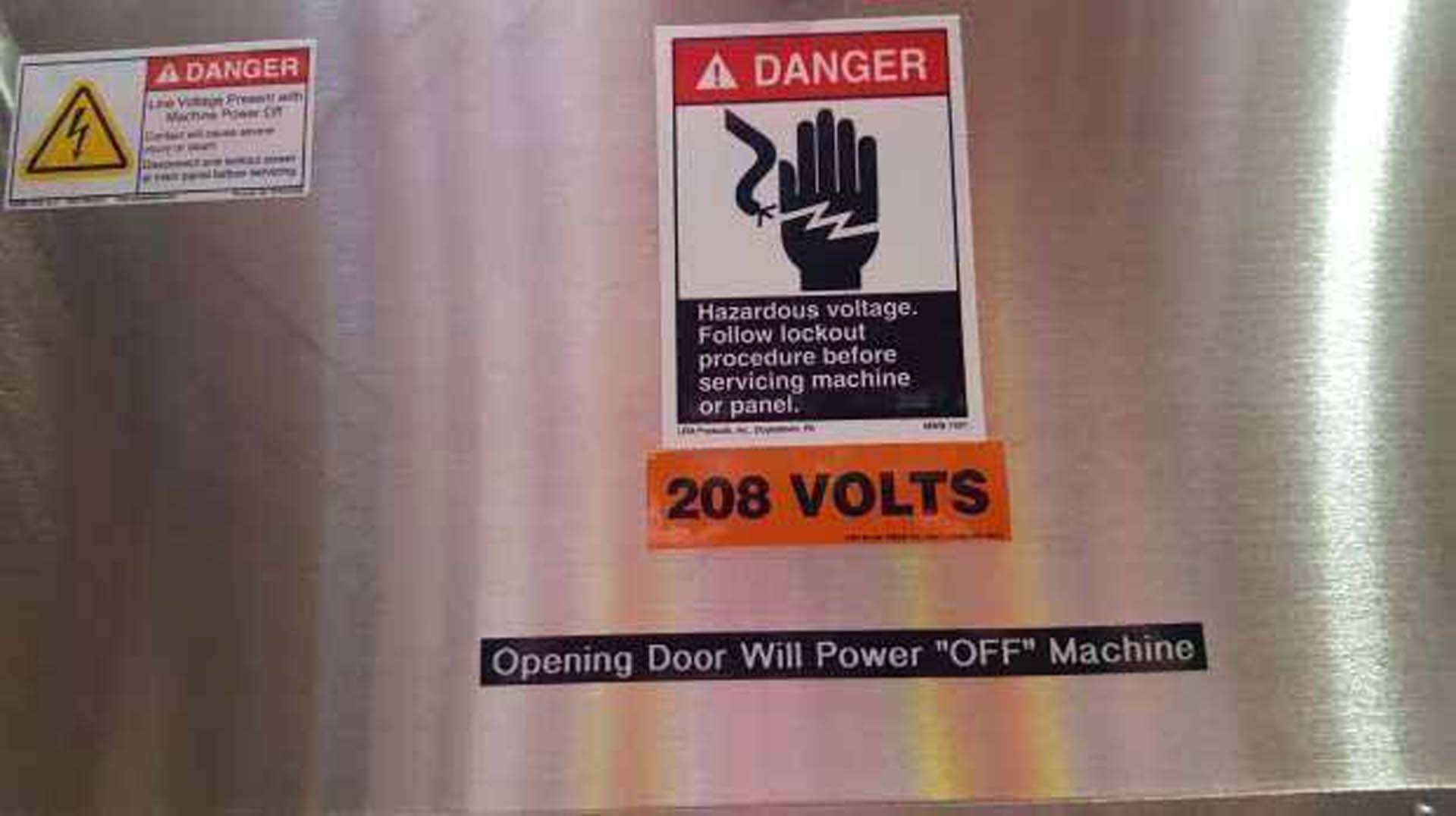

Main protector interrupt rating: 10,000 Amps

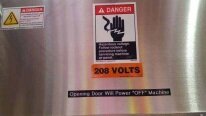

Power supply: 208 VAC, 3 Phase, 60 Hz, 30 A

2005 vintage.

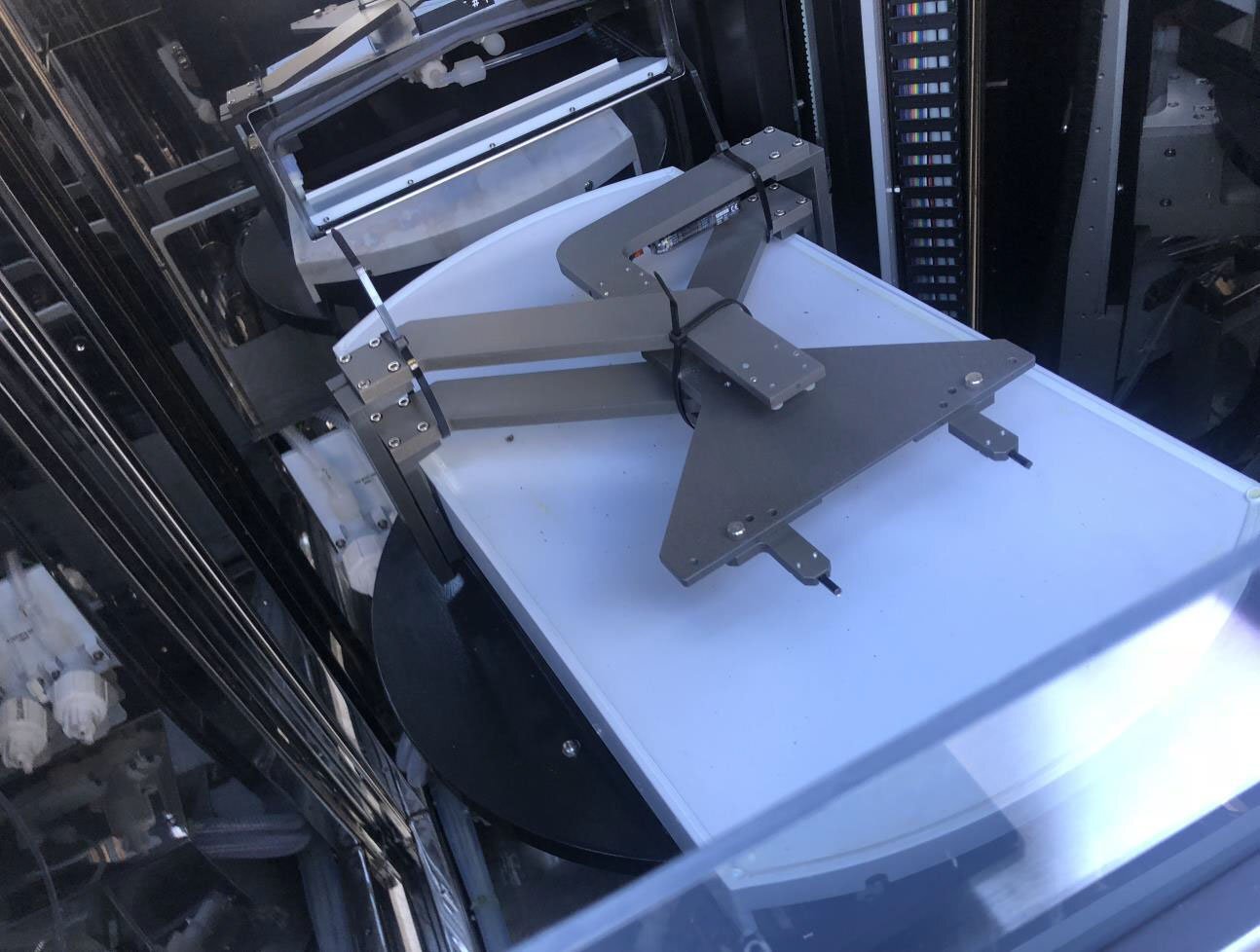

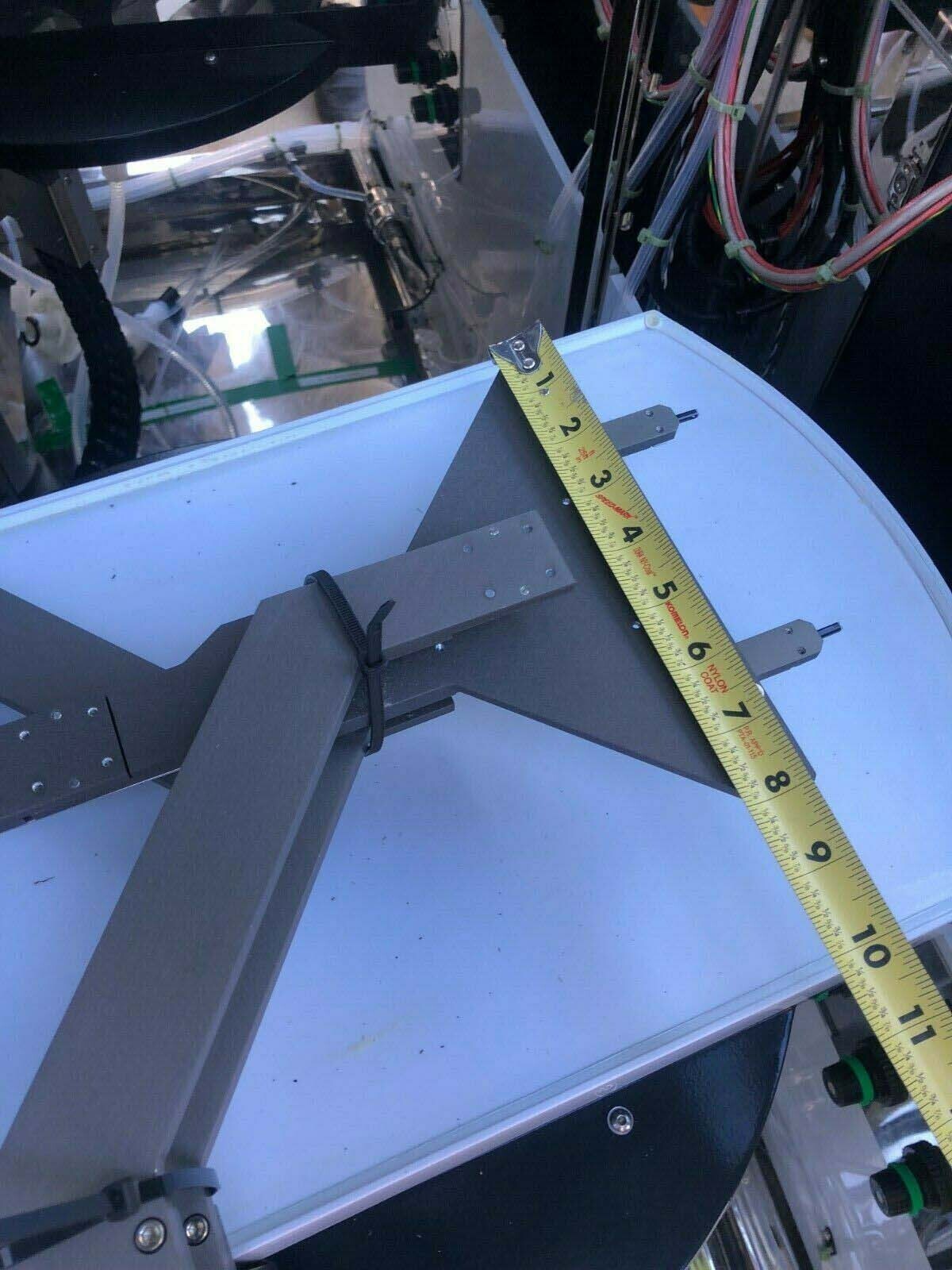

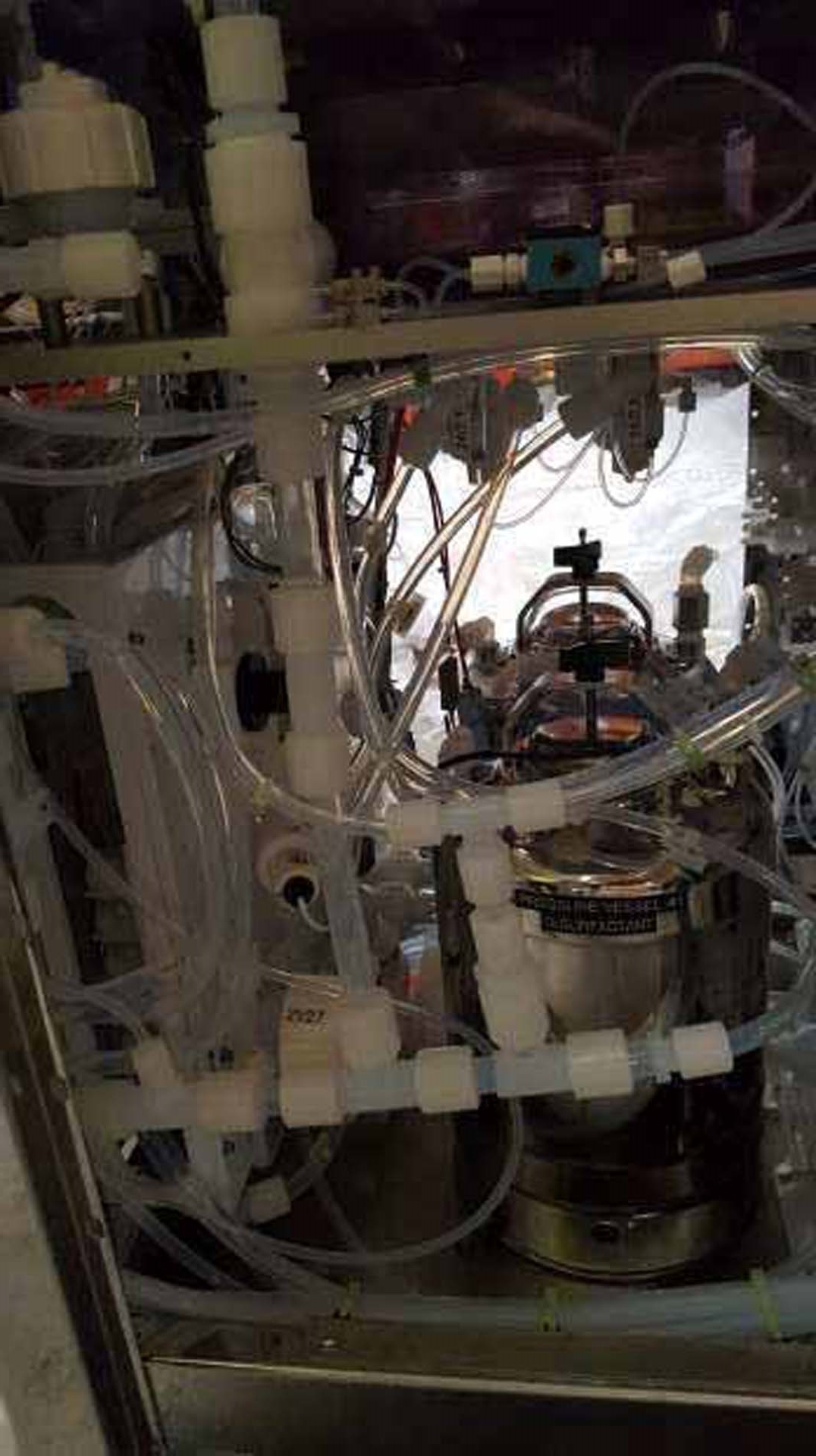

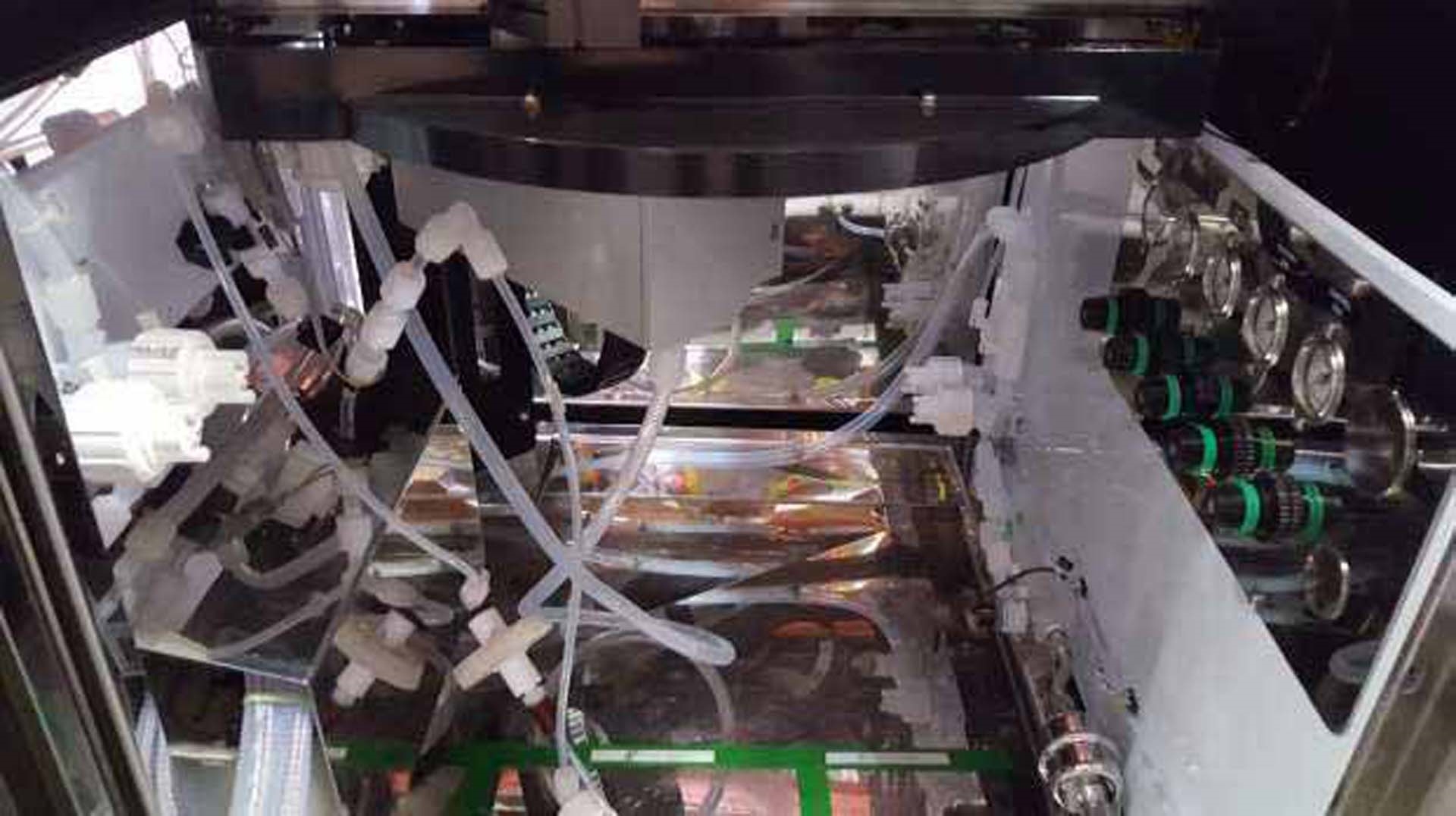

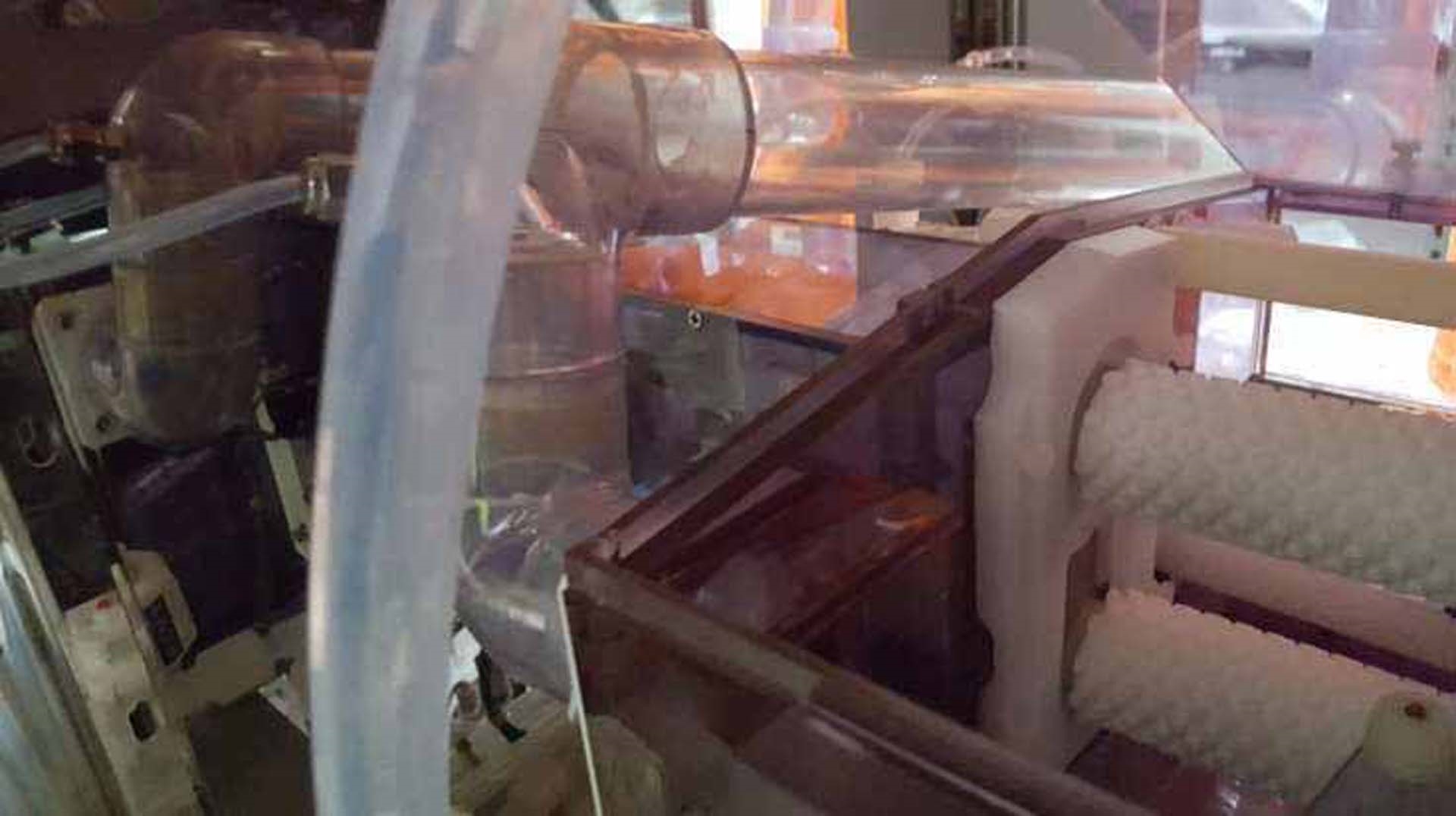

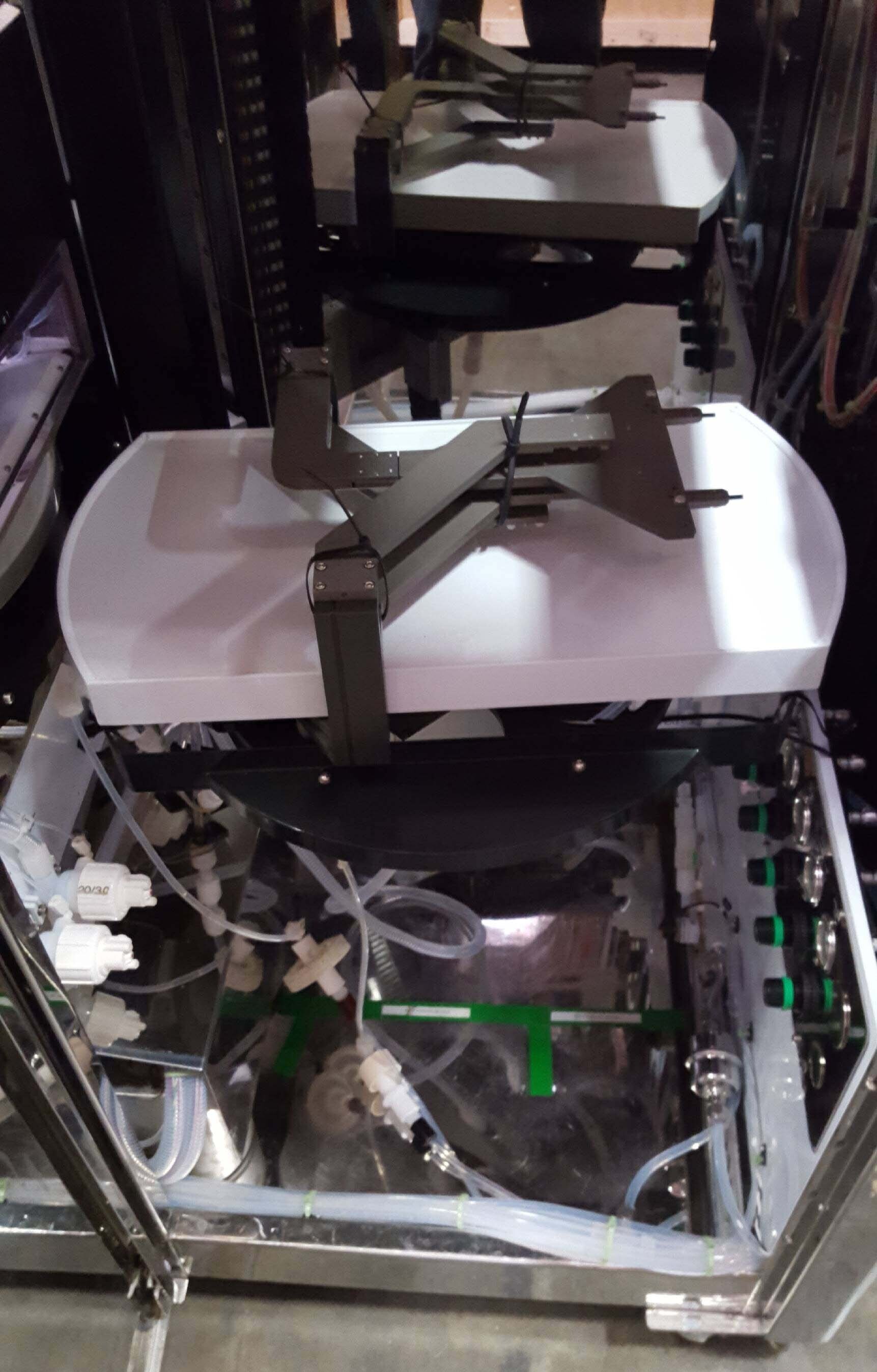

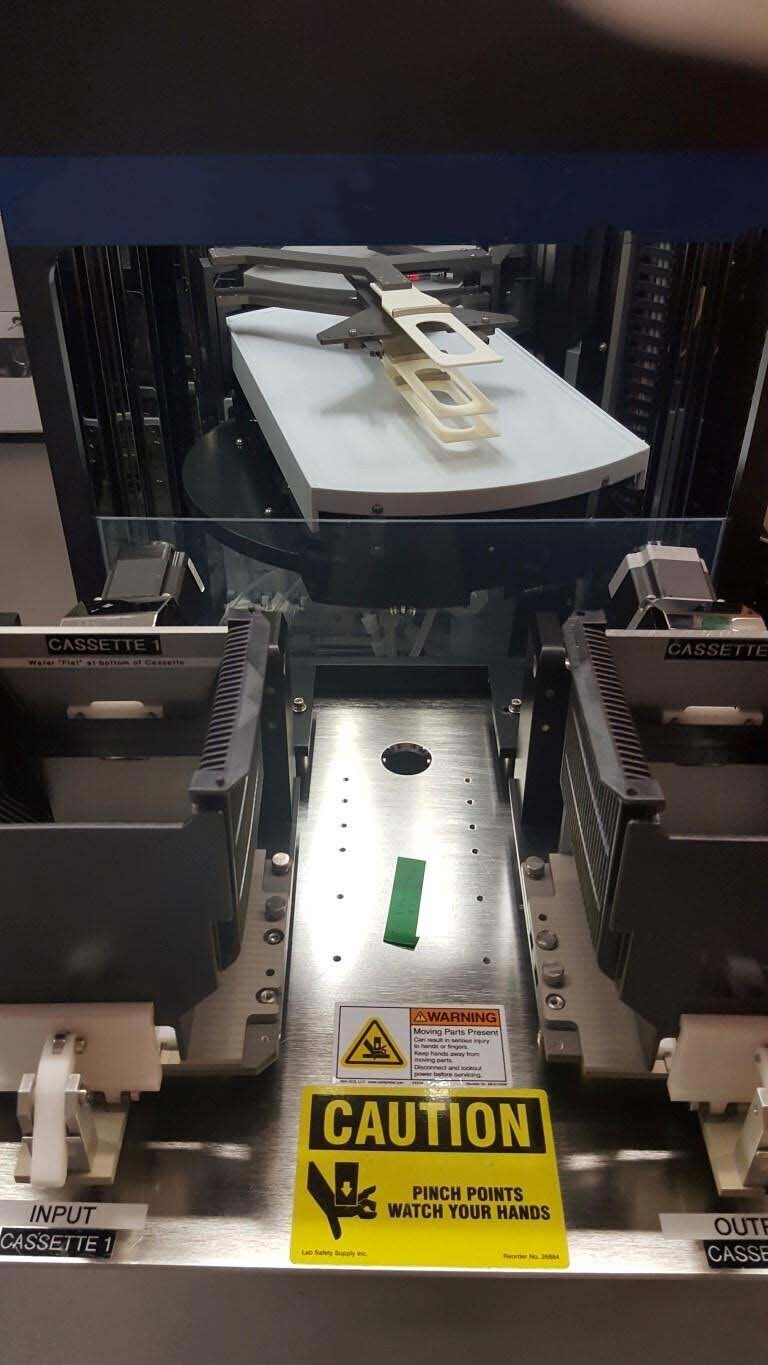

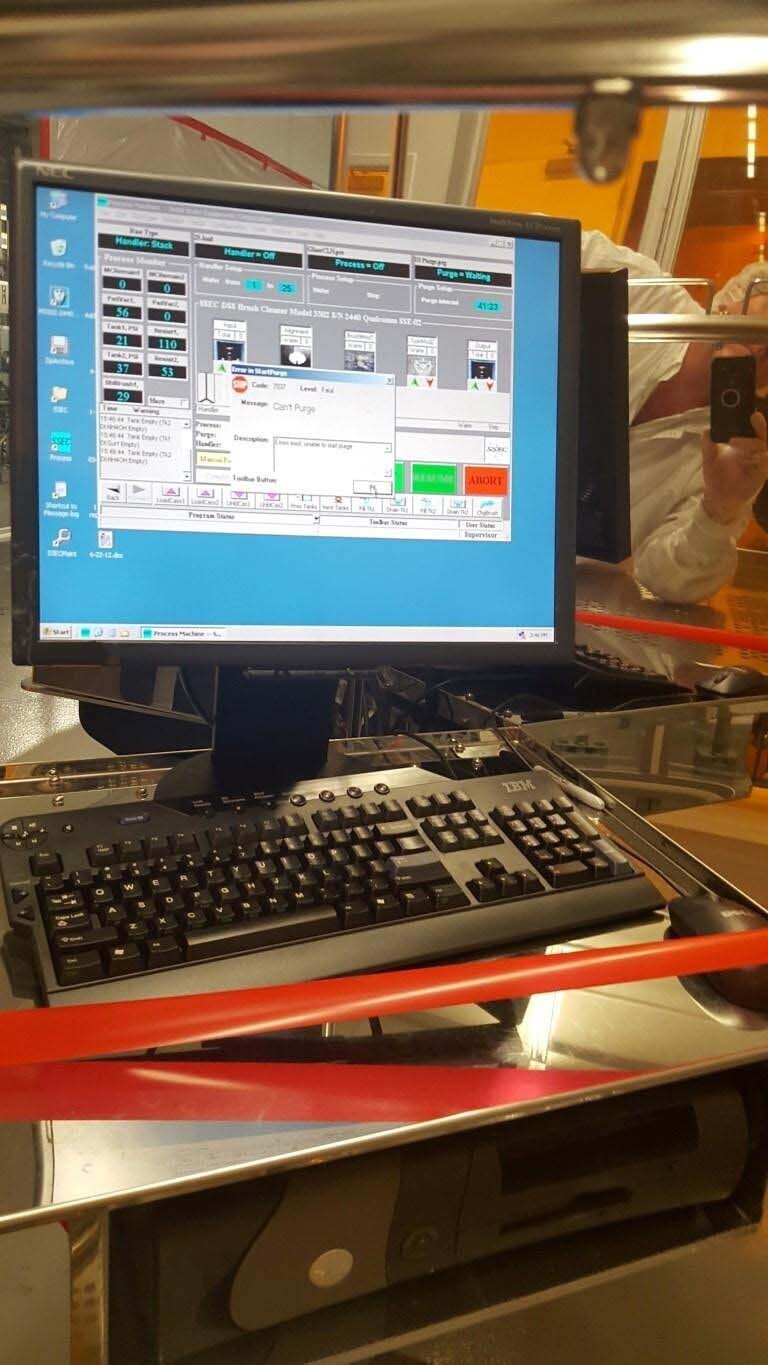

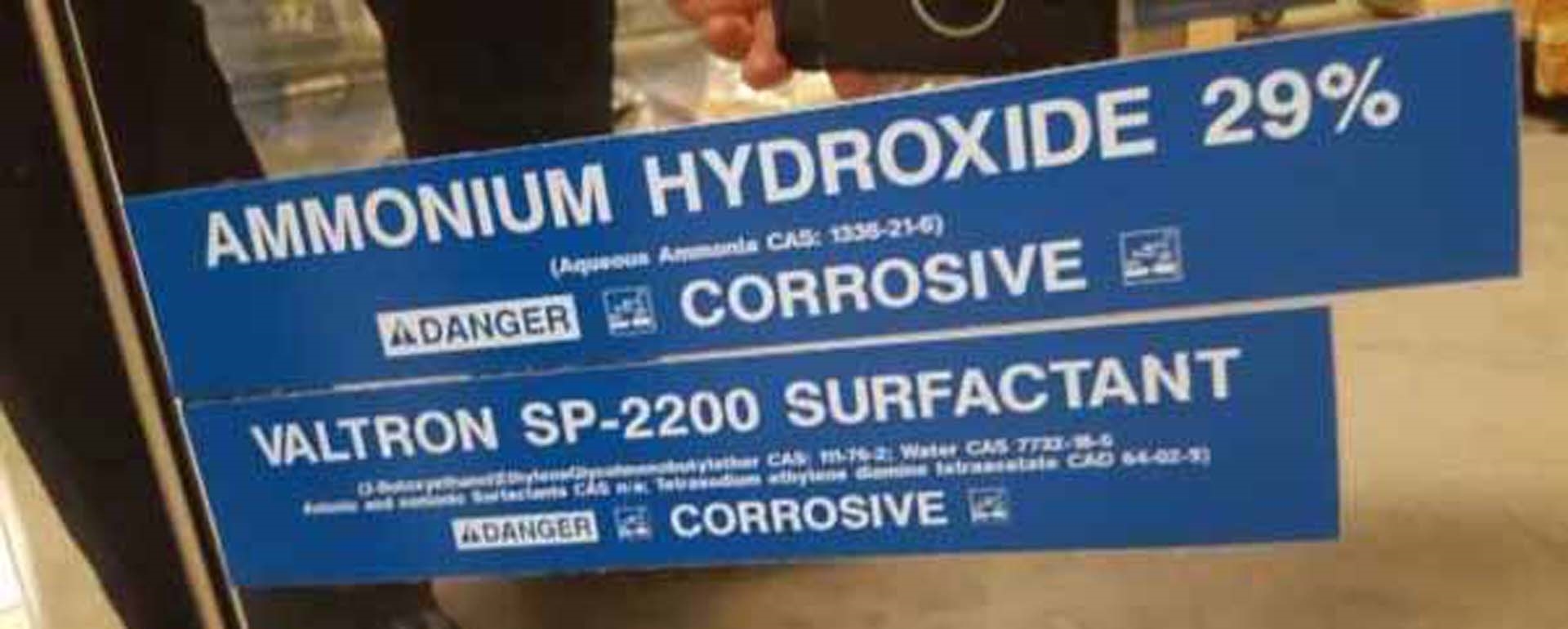

SSEC M3302 wafer and mask scrubber is a precision equipment for the cleaning and scrubbing of wafers and photomasks used in semiconductor manufacturing. It is designed to provide high scrubbing performance at the same time as increased throughputs and minimized abrasion losses. SSEC M 3302 wafer and mask scrubber features an industrial grade, all-in-one design with cutting edge technology that is designed to keep up with the demands of today's semiconductor market. It is equipped with four scrubbing modules, each featuring three scrubbers with adjustable velocities and functions that allow a wide range of scrubbing speeds and pattern. It also features a programmable scrubbing cassette core, that allows for quick set-up time, precise control, and high scrubbing efficiency. The main components of M3302 wafer and mask scrubber include a dust and particle removal unit, scrubbing station, concentrate delivery equipment, concentrate management system, photo mask protection unit, and automatic wafer handling machine. The dust and particle removal unit offers filtering of particles down to 0.003 micron in size, to ensure all unwanted debris is removed prior to scrubbing. The scrubbing station consists of three scrubbing heads that can scrub up to 35 wafers at any given time. Additionally, the brush pressure can be adjusted to ensure a consistent level of scrubbing consistency. The concentrate delivery tool is designed to be both accurate and reliable. It is equipped with a asset of ultra sonic concentrates that provide superior cleaning performance, regardless of wafer or photomask material, without waste or contamination of the substrate. Additionally, the concentrate management model ensures that the correct amount of concentrate is delivered for each individual application. The photomask protection equipment ensures that any foreign substance or rod particles are avoided during the scrubbing process by using an electromagnetic shielding process that helps protect the photomask during scrubbing. Finally, the automated wafer handling system offers increased throughput and reliability, minimizing the risk of wafer scratches that can occur during manual handling. It is important to note that M 3302 wafer and mask scrubber must be handled in a clean room environment to ensure the utmost cleanliness and contamination prevention. Additionally, the unit must also be maintained regularly, as improper cleaning can lead to a reduction in scrubbing efficiency.

There are no reviews yet