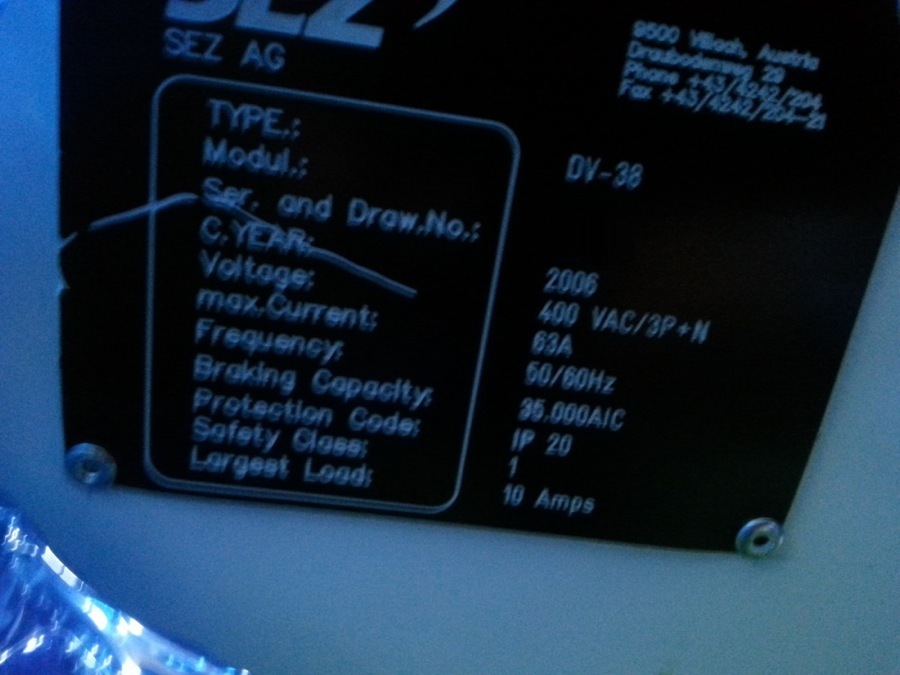

Used SEZ / LAM RESEARCH DV-38DS #9040754 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9040754

Wafer Size: 12"

Vintage: 2006

Wet station, 12"

Frontside handling

(8) Chambers

Number of chemistry: 1

Operator cassette loading

Overhead transport system (OHT)

Through the wall

Front machine section:

Robot & controller

Main PC condition

Hard drive for IC/TC

Front FFU

Buffer station

(3) Load ports

Load port access: Light curtain

Asyst ISO port

Carrier ID reader

Asyst Advan-Tag

E 84 Parallel I/O

Front handling system: ECO end-effector, ceramic

Rear machine section:

ECO

FFU

Control cabinet

Left process section

(3) PSL: Process chamber, Chuck, Spindle unit, Dispenser motors

(1) PSL: Process chamber, Chuck, Spindle unit, Dispenser motors, Regulators, MFCs, Pump valve and chemistry lines

Right process section

(3) PSR: Process chamber, Chuck, Spindle unit, Dispenser motors

(1) PSR: Process chamber, Chuck, Spindle unit, Dispenser motors, Regulators, MFCs, Pump valve and chemistry lines

Components included

ATMI

AC Rack

DVR

Exhaust line kit

IPA module

Liquid Chemistry cabinet 1:

Media 1 supply: Filtration system and sampling port

Buffer option A1: Medium, PZ10 spiking pump

Buffer option B1: No medium

Paddle wheel

DI water

Inline cooler for temperature control

Flowmeter

Liquid Chemistry cabinet 2:

Media 2 supply: Medium / Temperature

Buffer option A2: Medium, PZ10 spiking pump

Buffer option B2: No medium

Paddle wheel

Horiba CM-210 chemical analyzer: (2) Process loop, (2) Preparation loop

Flowmeter for DI water

Gas supply

CO2 Injection: No

Overall features:

White light

Transparent windows

Transformer 208V/400V CE

Frame

Leak sensor box

Submodules:

Process chamber display

Digital video recording

Currently de-installed

2006 vintage.

SEZ / LAM RESEARCH DV-38DS is an etcher/asher equipment specifically designed for etching and ashing photoresist and other residues on a variety of substrates. SEZ DV-38DS system offers fast, high-precision etching and ashing, with low-temperature processes and short processing times. LAM RESEARCH DV-38DS unit uses the latest semiconductor technologies such as chemical reactive ions for etching, and lamps and laser sources for ashing. It is capable of processing over a wide range of wafer sizes, from 4" to 12". The machine is designed to provide uniform, high-quality coverage for various substrates including silicon, oxides, metals, and ceramics. DV-38DS tool consists of two parts - the tool itself and the associated control asset. The tool is a compact, fully automated model that is designed for ease of use and efficient operation. It includes a high-performance feeder for loading and unloading wafers, a high-performance etching chamber for etching photoresist and other residues, and an ashing chamber for fusing layers. The etching chamber and the ashing chamber are both equipped with advanced thermal control systems to ensure optimal processing results and uniform coverage. The control equipment is designed to provide the user with precise control over SEZ / LAM RESEARCH DV-38DS system. The unit is equipped with an intuitive user interface, which allows users to make changes to their processes in a few clicks. The user interface enables users to set up the machine and to check on the tool's status in real-time. In addition, the control asset can be linked to a remote computer, allowing for easy remote access to the model's diagnostic data. SEZ DV-38DS equipment is designed for both low volume and high volume operations. Its advanced control system can be easily modified to fit a variety of processing tasks. In addition, the unit is designed with various safety features, such as emergency shut off, to ensure the safety of its operators and equipment. Overall, LAM RESEARCH DV-38DS is an advanced etcher/asher machine specifically designed for etching and ashing photoresist and other residues on a variety of substrates. Its advanced control tool allows for precise control and its intuitive user interface makes it easy to set up and operate. The asset's safety features ensure the safety of its operators and equipment, and its high-performance feeder enables efficient loading and unloading of wafers, making DV-38DS a great choice for a variety of etching and ashing processes.

There are no reviews yet