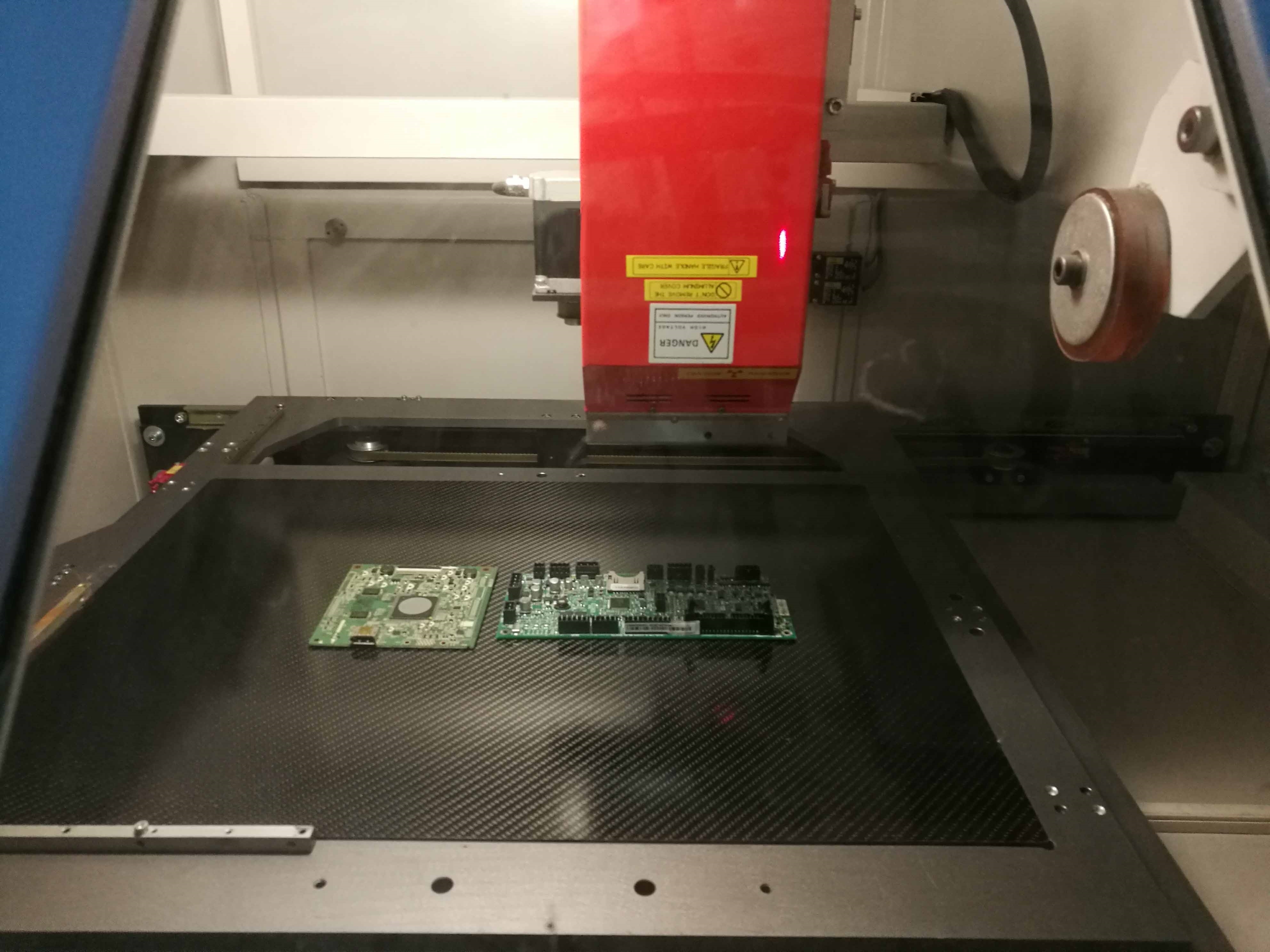

Used PHOENIX PCBA Analyser 160 #9094994 for sale

URL successfully copied!

Tap to zoom

ID: 9094994

Vintage: 2008

X-ray inspections systems

Micro focus: 1 um

Open tube

Manipulator system

System magnification and resolution:

Geometric magnification: Up to 2060x

Total magnification: Up to 12800x

Detail detect ability: Down to 200nm

Contrast resolution: Down to 0.5%

X-ray tube:

Maximum tube voltage: Up to 225kV

Maximum tube power: Up to 50W

Dose rate stability: < 0.5% / 8 h

Manipulator:

X-Y Scanning area: 610 mm x 460 mm

Maximum sample size: 710 mm x 560 mm

Ovhm- Oblique view at highest magnification view angle: Up to 61°

Control:

Joystick control (Manual mode)

CNC (Automatic mode)

Axis speed (X-Y-Z): 10 micron/s to 80 mm/s

Manipulation aids:

Sample X-ray mapping

Click'n-move-to function

Click'n-zoom-to function

Automatic isocentric manipulator movement

Laser crosshair

Anti collision system (ACS): Deactivated for maximum magnification

Image processing:

Quality assurance:

Comprehensive X-ray inspection software image enhancement function

Measuring function

CNC Inspection programming for semi-automatic inspection

Radiation safety:

Safety cabinet steel

With lead shield, lead glass, leakage radiation: < 1 μSv / h

2008 vintage.

PHOENIX PCBA Analyser 160 is a state-of-the-art X-ray imaging equipment used for non-destructive testing and validation of printed circuit board assemblies. This system's advanced technology enables it to produce extremely high-resolution 3D X-ray images of components, interconnects, and other assembly features. Using this data, it can reveal component orientation, reveal hidden or hard-to-see solder joints, inspect inner-layer connections, and detect faults such as shorts, opens, misalignments, pin-lift, and defects. PCBA Analyser 160 provides accurate, non-invasive analysis of complex Printed Circuit Board Assemblies (PCBAs). Its automated process ensures only the most reliable results. This unit utilizes an advanced X-ray source that provides an optimal imaging geometry and produces a large-sized image. The digital acquisition and display of X-ray images is achieved with its high-resolution, low-noise imaging machine. This tool also features a high-sensitivity video chain for low-contrast image enhancement, high-resolution digital imaging and automatic gain control for optimum contrast. PHOENIX PCBA Analyser 160 can quickly detect and isolate hidden faults that would otherwise be difficult or impossible to find visually. Using the X-ray data and sophisticated 3D analysis tools, it can provide detailed insight into the electrical status of the PCBA and generate error-free BOM information. This asset also allows for functional electrical testing and comparison for a complete solution to troubleshooting complex PCBA assemblies. PCBA Analyser 160 is equipped with an integrated robotics model for automated positioning and flexible imaging workflow. This equipment also supports a wide range of positioning techniques including linear, rotary, and linear-motorized motions as well as custom configurations for more powerful analysis and production throughput. PHOENIX PCBA Analyser 160 offers a range of software suites for an enhanced user experience. This system also offers a large library of skill profiles and pre-defined analyses for faster evaluation and application of necessary information. The software is available in both Windows and Mac OS versions so it can be easily used with existing operations or adapted to new environments. In conclusion, PCBA Analyser 160 is a sophisticated and reliable tool for non-destructive testing and failure analysis of printed circuit board assemblies. It enables faster and more complete inspection of the assembled components, interconnects, and other features in the most challenging applications. With its automated process, advanced imaging capabilities, and powerful analysis tools, it helps to quickly and accurately diagnose design problems and maximize PCBA assembly quality.

There are no reviews yet