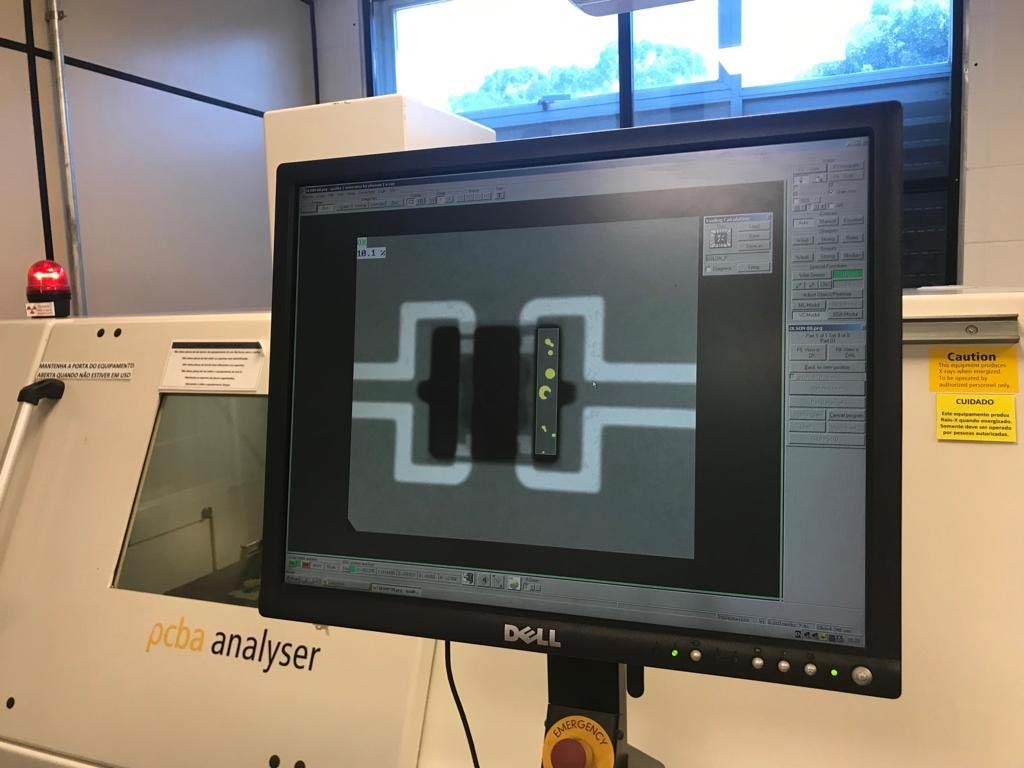

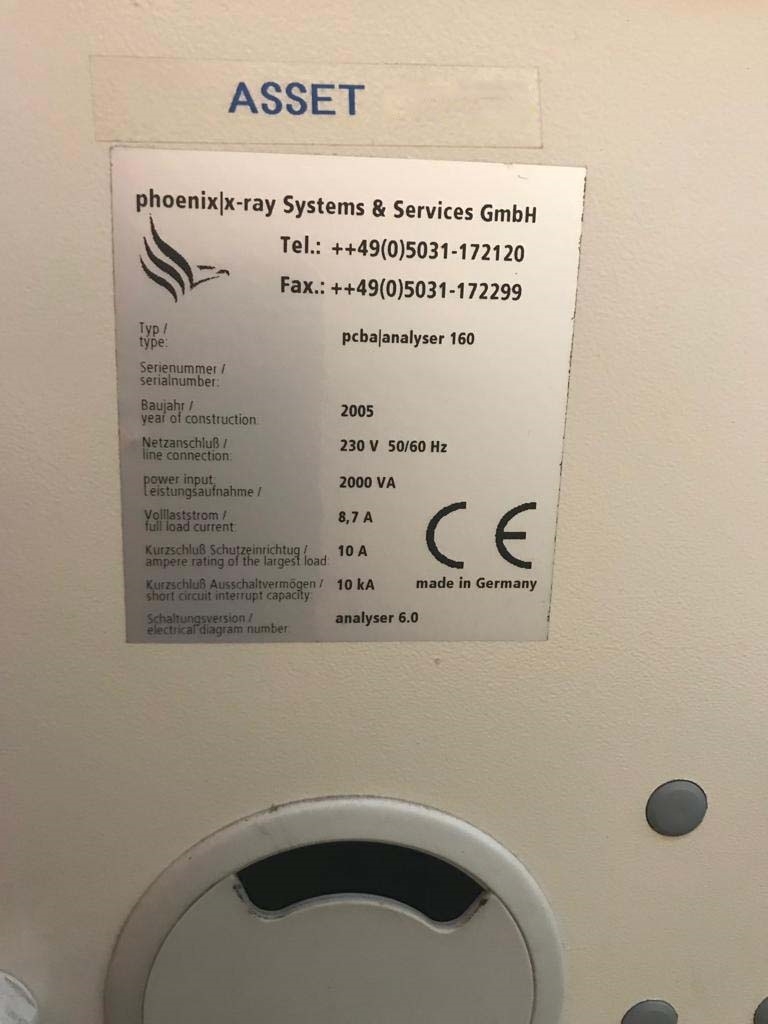

Used PHOENIX PCBA Analyser 160 #9255333 for sale

URL successfully copied!

Tap to zoom

PHOENIX PCBA Analyser 160 is an x-ray equipment designed for the inspection of Printed Circuit Board Assemblies (PCBA). It is one of the top-of-the-line in its class, featuring a 160kV/600 W generator and an up to 750x800x240mm working envelope. It enables the detection of multiple types of defects without manual intervention, regardless of their location on the board. This system is characterised by its focus on a high level of automation, with quick setup time and thorough analysis of the board assemblies. The automated analysis algorithms identify several types of defects including opens, shorts, missing components, delamination, misroutes and more, and can identify both macro defects and micro defects. The analysis is done with both 2D images and 3D volume images, which are then correlated in one view. PCBA Analyser 160 is equipped with a built in rotary stage and high resolution imaging, which can capture even the smallest of defects. The digitally stored 2D and 3D images can also be easily accessed later, allowing easy access to troubleshooting data. The unit also includes an intuitive and customisable user interface, allowing operators to adjust machine settings and make image upgrades over time, with the flexibility to easily adapt the tool to meet changing requirements. In addition, PHOENIX PCBA Analyser 160 is compliant with IPC-A-610 standard, and the large colour LCD shows the data in a very clear way. PCBA Analyser 160 is a useful tool for both small businesses and big corporations. It helps them analyse the board assemblies quickly and accurately, finding any hidden glitches or errors. It allows them to keep their production line efficient and reduce the time spent on troubleshooting. Additionally, its intuitive user interface is designed to give fast and accurate results and is backed by comprehensive customer service.

There are no reviews yet