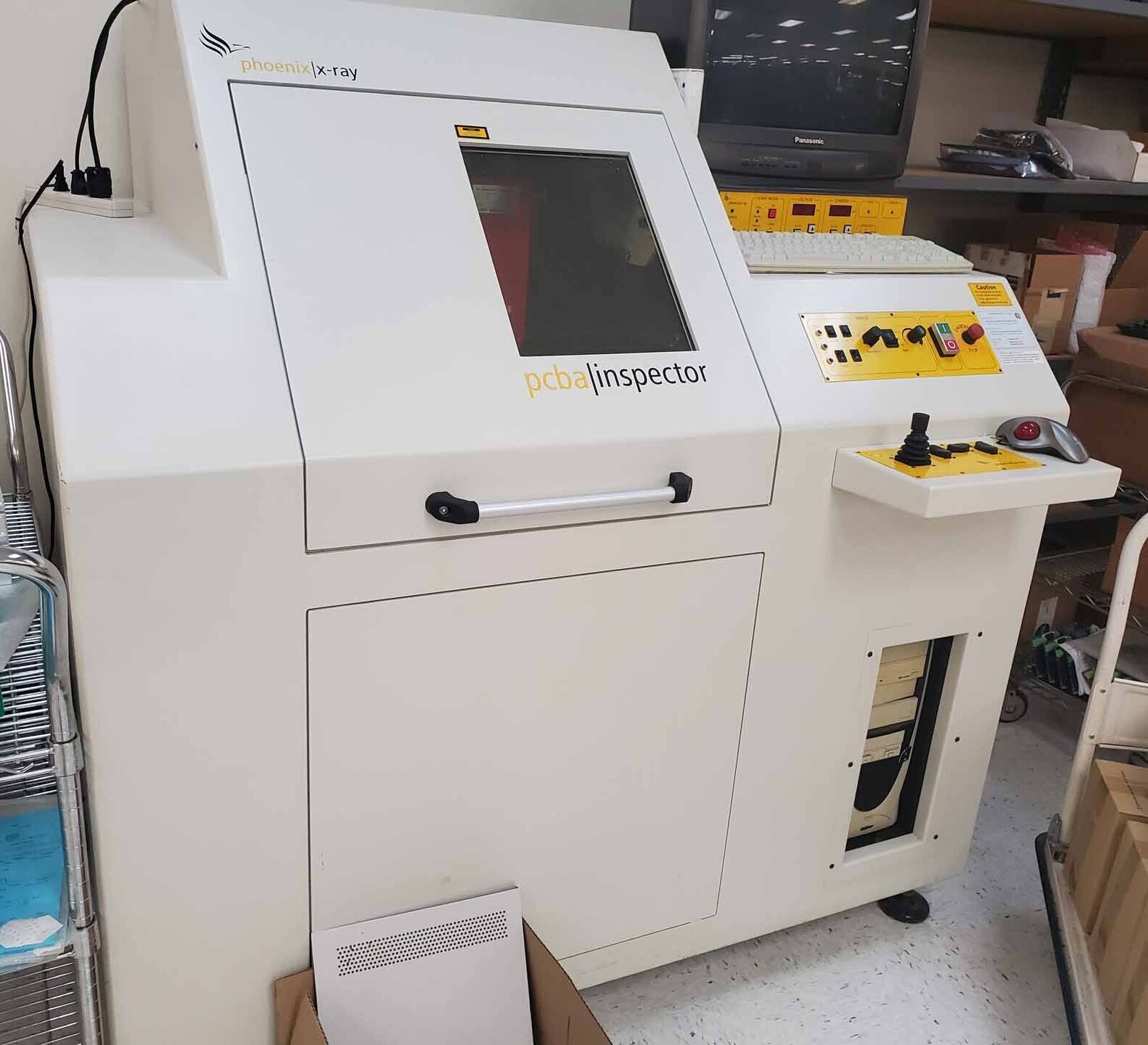

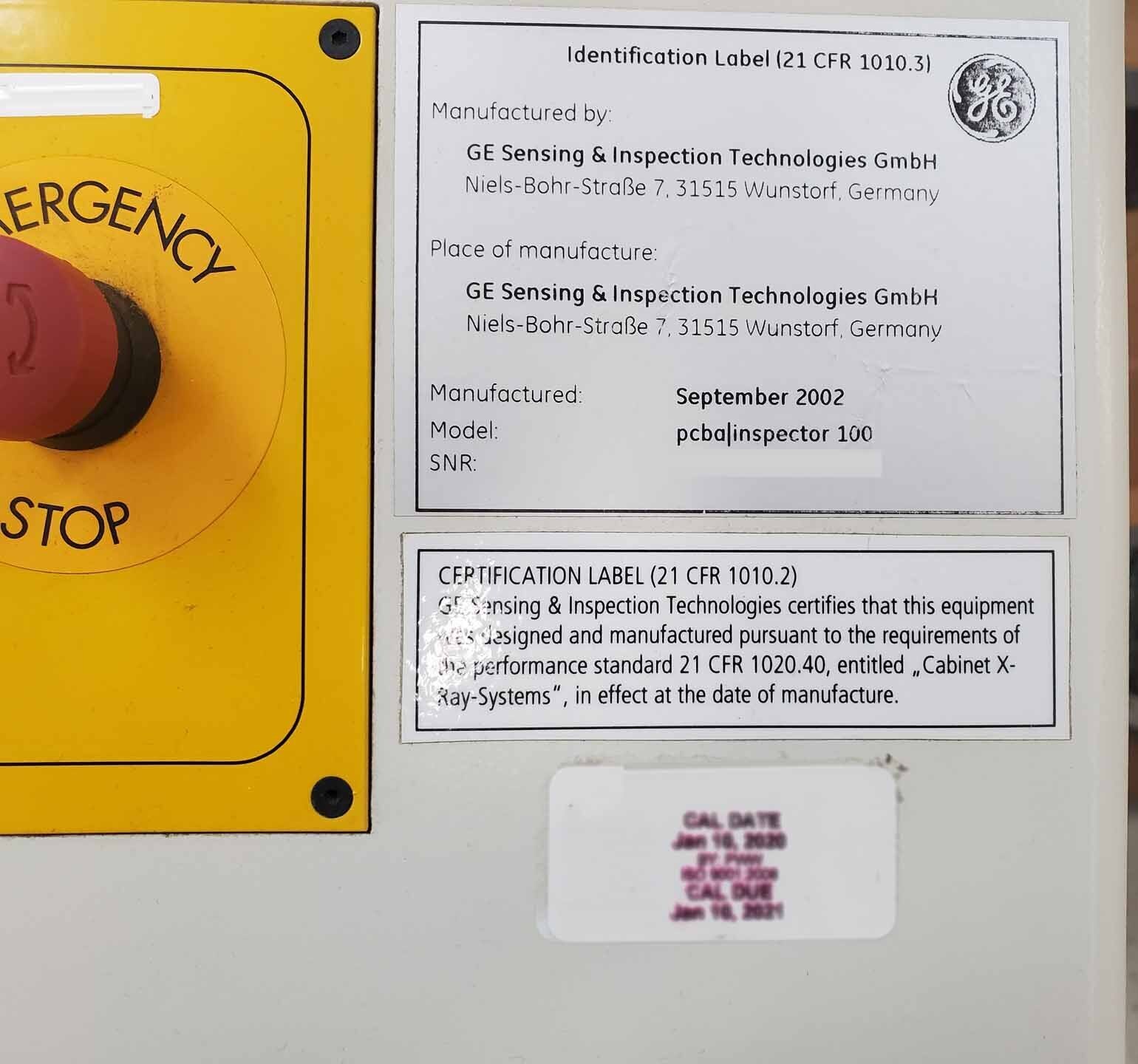

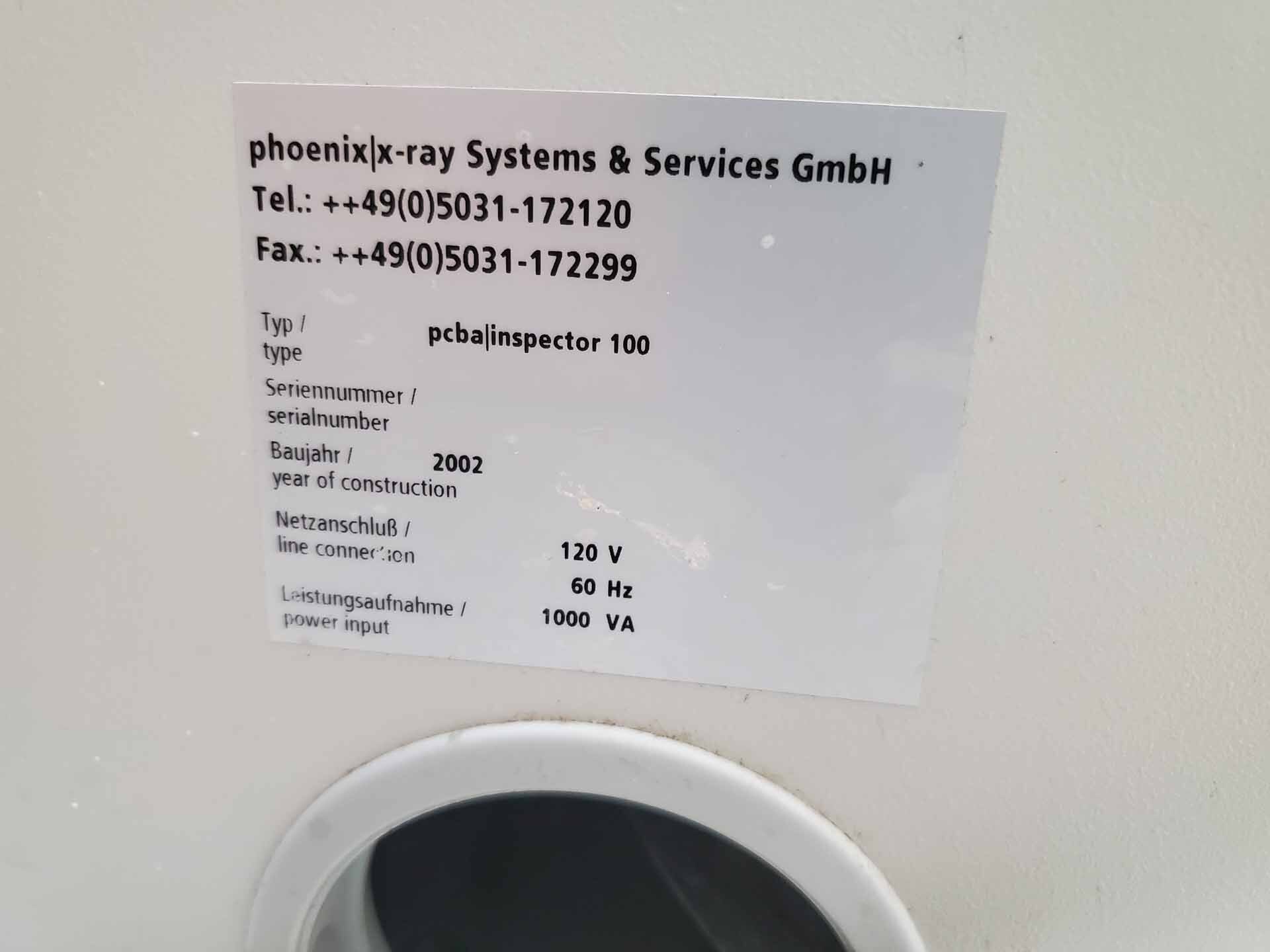

Used PHOENIX PCBA Inspector 100 #9294401 for sale

URL successfully copied!

Tap to zoom

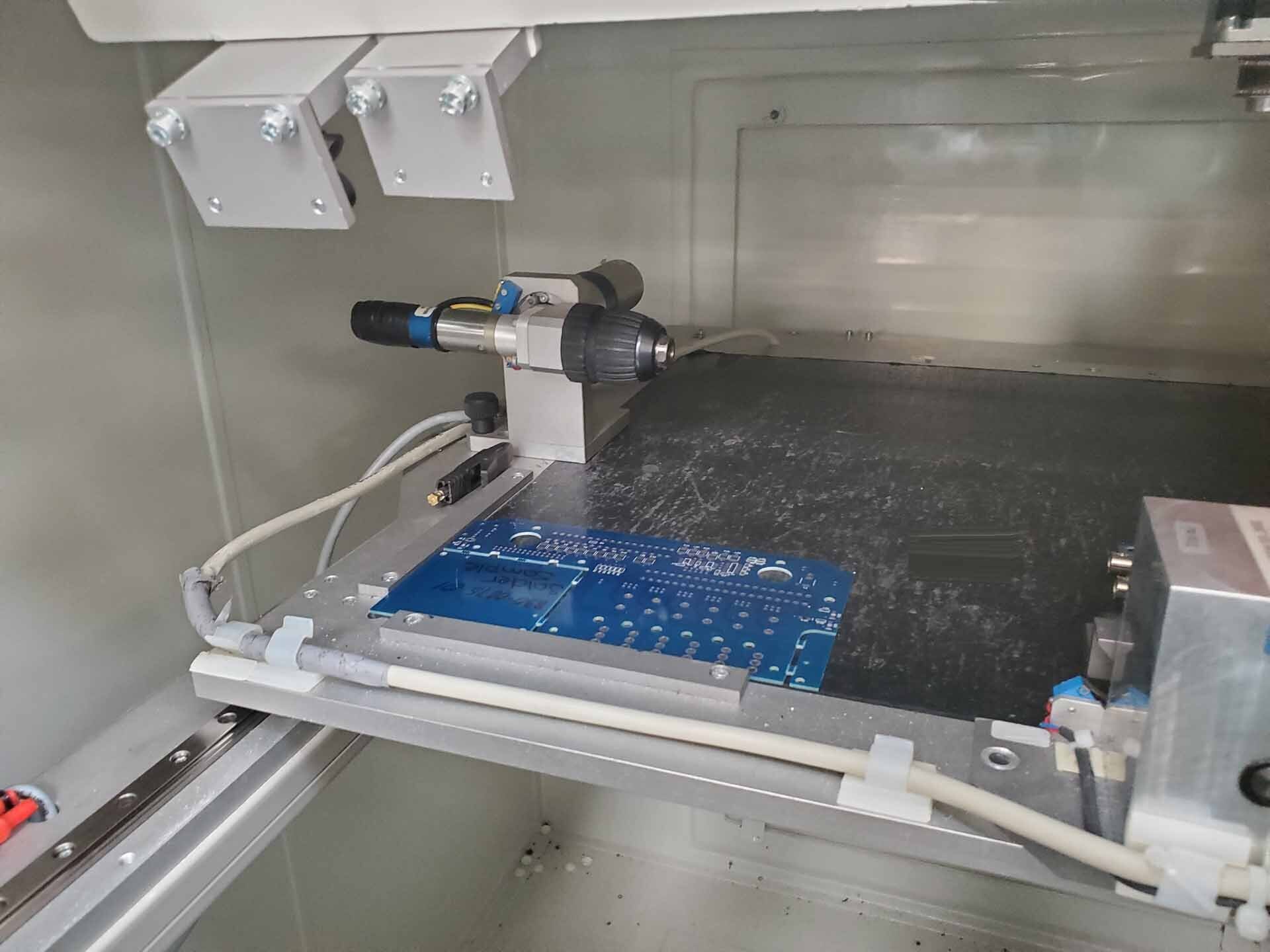

PHOENIX PCBA Inspector 100 is an advanced x-ray equipment designed to inspect Printed Circuit Board Assemblies (PCBAs) for defects. The x-ray system allows users to take direct x-ray images of entire boards with outstanding accuracy and sensitivity. This technology allows users to detect hidden defects such as poor solder joints, cracks, voids, and other material imperfections in PCBAs. PCBA Inspector 100 x-ray unit consists of an x-ray source, an array detector, a workpiece holder, and a viewing and positioning machine. The x-ray source emits x-ray photons that travel through the board and are absorbed and/or scattered by the materials in the board. The array detector measures the intensity of the x-ray photons that reach its surface and forms an image of the board that is sent to the viewing and positioning tool. The image of the board is then displayed on the monitor, and any defects can easily be identified. PHOENIX PCBA Inspector 100 is equipped with a variety of imaging modes, such as radiographic, tomographic, Isometric, dual-energy contrast, and even ultrasound imaging. These imaging modes allow users to identify and analyze a wide range of defects, provided the desired image quality and accuracy is achieved. The asset also includes a fully automated adaptive focusing model, which allows users to automatically set a focus range for each individual board being tested. This ensures that every image captured is of the highest resolution and clarity. PCBA Inspector 100 is an easy-to-use x-ray equipment that can greatly improve the quality and reliability of PCBAs manufactured. With the advanced imaging modes and automated focusing system, users can easily detect and identify hidden material imperfections and defects in PCBAs. The unit ensures that the images produced are of the highest resolution and clarity, providing users with the best possible experience in x-ray inspection.

There are no reviews yet