Used RIGAKU Wafer X-300 #9014460 for sale

URL successfully copied!

Tap to zoom

ID: 9014460

Wafer Size: 6"-12"

Vintage: 2005

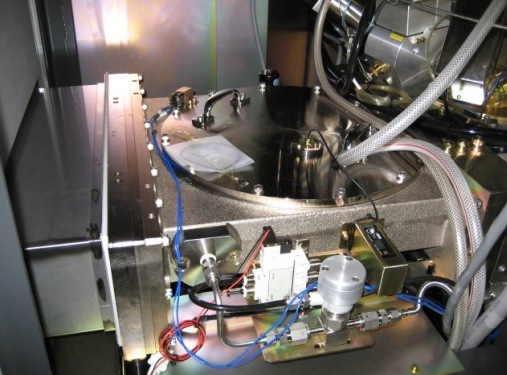

X-ray fluorescence spectrometer, 6"-12"

Currently configured for 12"

Cassette Interface: (1) Hirata KWF-12B 300mm FOUP

Installed Channels: Al, Si, P, B, F

Capable of measuring up to 16 elements simultaneously

Automatic Pressure Controller (APC)

Wafer Positioning mechanism

Computer controlled 3-Position Collimator

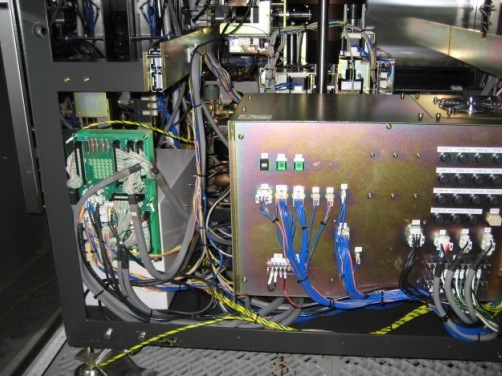

OptiPlex GX260 Computer & SW Package

Status Lamp (R, Y, G)

Supporting Equipment:

(1) Rigaku Heat Exchanger

(1) Edwards IGX100L Dry Pump

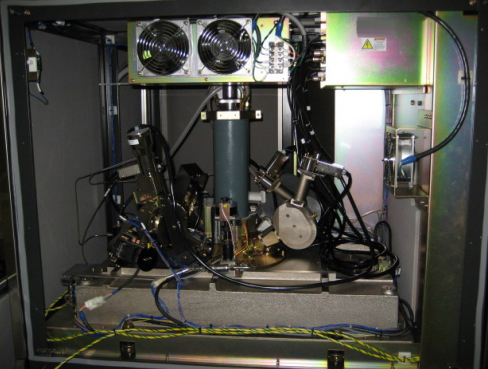

(1) XG Unit (HV Transformer)

(1) AC Box (wall-mount)

Power Requirements: 208V, 50A, 3-Phase, Freq 50/60Hz

Pre-Aligner:

Handling Robot: Tazmo S4003, Single Blade

4kW Constant Potential Ground Cathode

4.0kW Ultra-Thin, High Frequency End-Window, Rh Target X-Ray Tube

(11) Port Spectrometer Chamber

2005 vintage.

RIGAKU Wafer X-300 is a X-ray equipment developed by RIGAKU for wafer characterisation applications. This system is used to acquire 3D imaging data from single die or multiple die at the same time. It is a multi-beam x-ray inspection unit that provides an efficient and reliable way to characterize the internal structure of complicated integrated circuit (IC) structures. It is powered by a high-resolution digital X-ray detector, allowing the user to accurately image the IC component without damaging them. The main features of the machine include an advanced imaging software, expansion capabilities, and high utilization rates. The imaging software is designed to acquire precise imaging data and analyse the images quickly. It also allows the user to adjust the imaging parameters to produce better results. Additionally, RIGAKU WAFERX 300 tool can be easily expanded with additional modules such as an XYZ stage and an automated sample changer. This makes it possible to inspect a larger number of wafers in a single time, increasing sample throughput and data accuracy. Wafer X-300 is capable of capturing 3D images of various types of ICs, which is a critical factor in determining their performance. With its high resolution and fast data acquisition rate, it can image even the smallest components for accurate characterisation. It also offers high utilization rates, allowing users to perform multiple inspections in one process. The asset is equipped with a high-resolution digital X-ray detector for imaging a wide array of components and materials. This combined with its innovative imaging software allow the user to accurately capture the internal structure of integrated circuits with precise results. Furthermore, the model is compatible with a variety of industry standard automation protocols, enabling users to easily integrate it with their existing production line. In sum, WAFERX 300 is a reliable and highly-accurate X-ray equipment that enables users to efficiently characterise and analyse the internal structure of integrated circuits. It offers high resolution imaging, fast data acquisition rates, and compatibility with multiple automation protocols. All of these features make it an ideal choice for any type of wafer or IC inspection.

There are no reviews yet