Used RIGAKU Wafer X-300 #9394549 for sale

URL successfully copied!

Tap to zoom

ID: 9394549

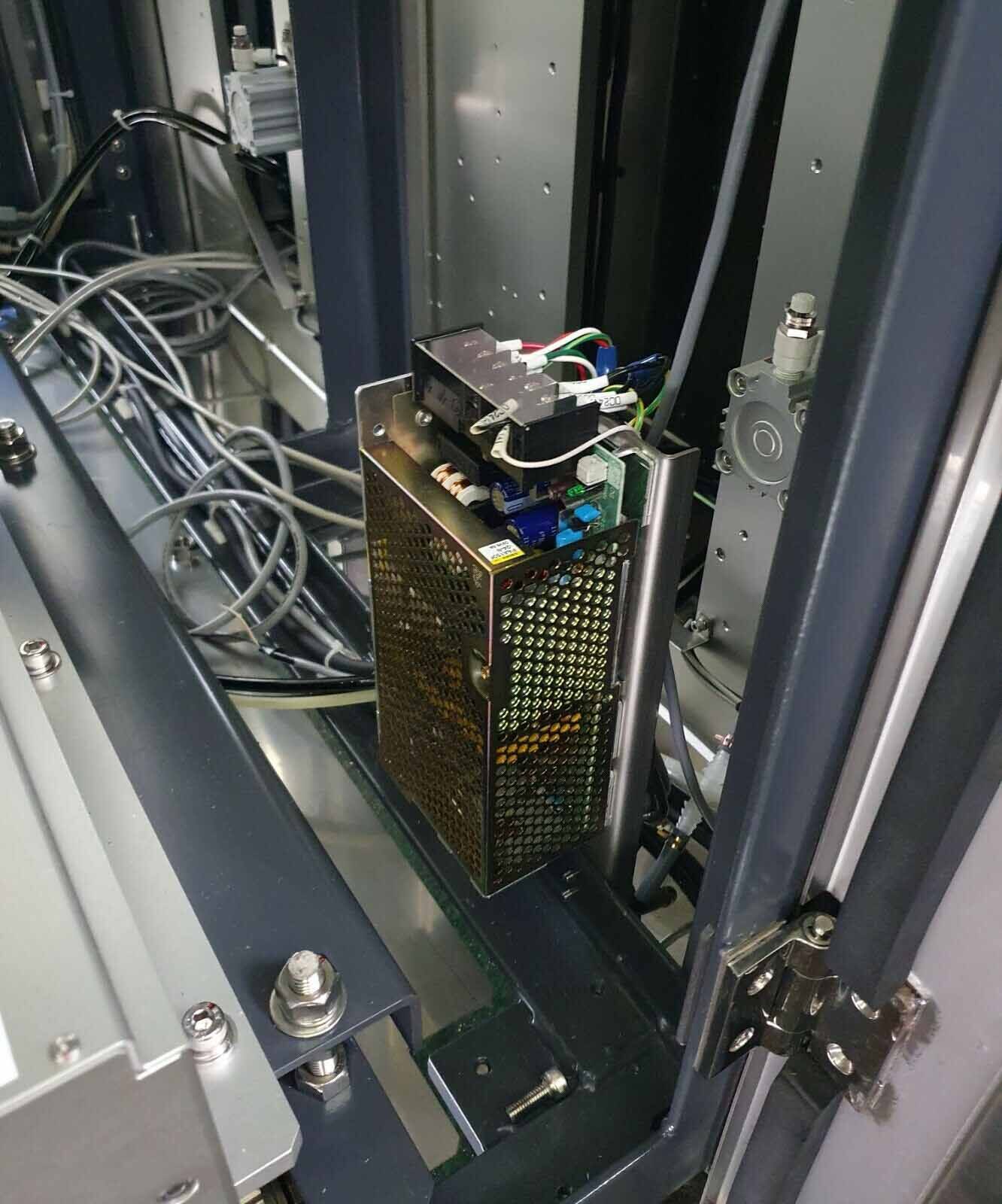

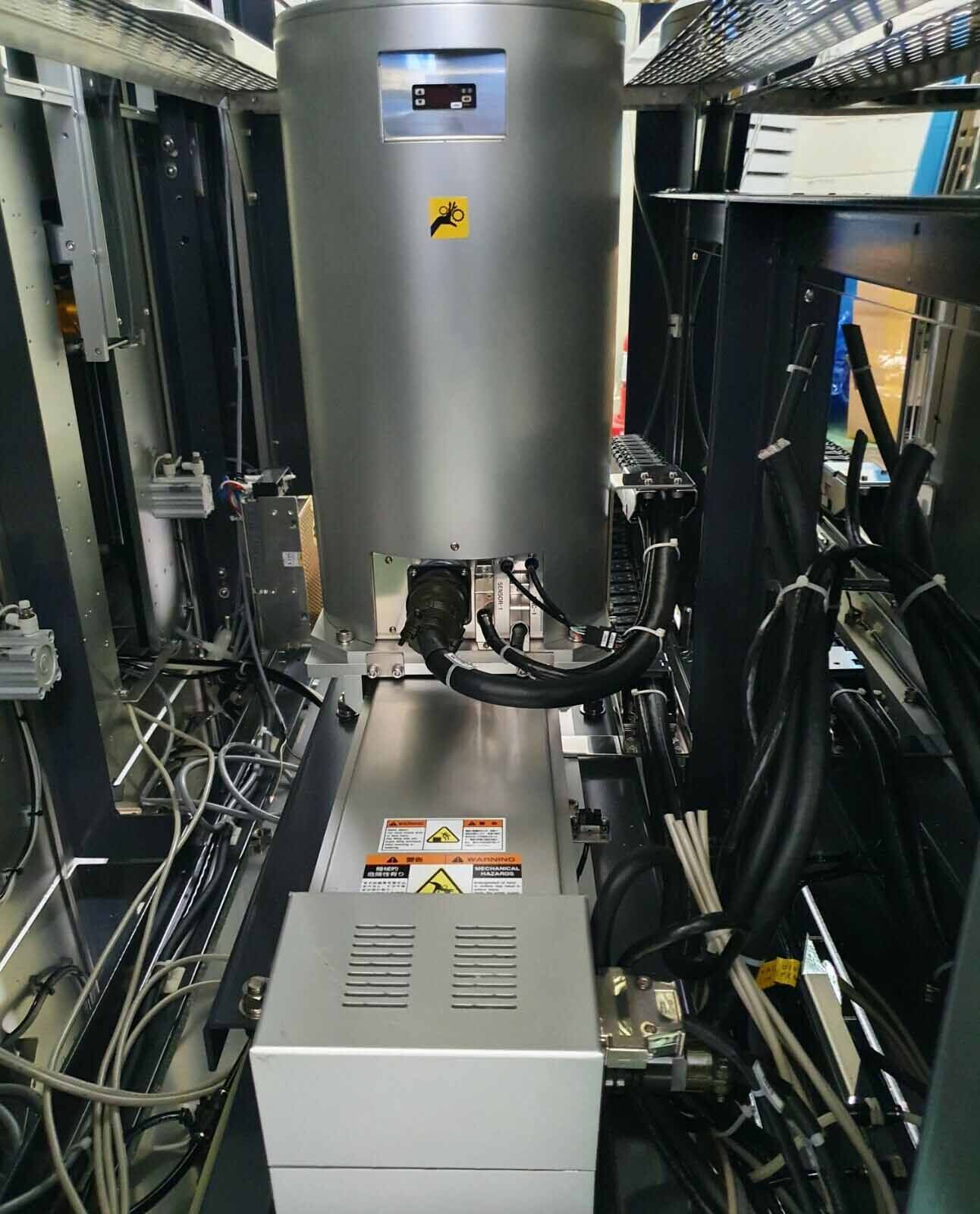

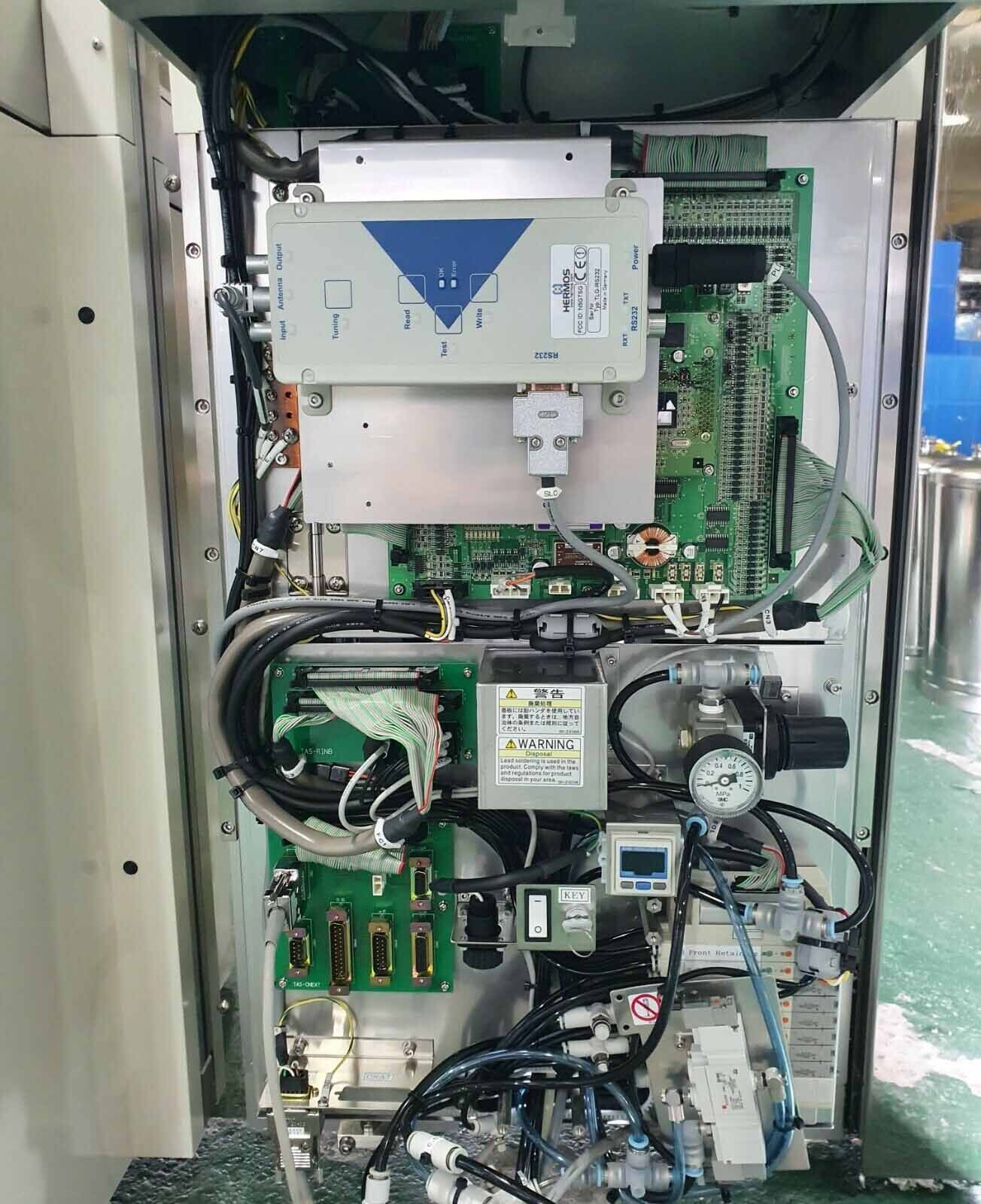

EFEM

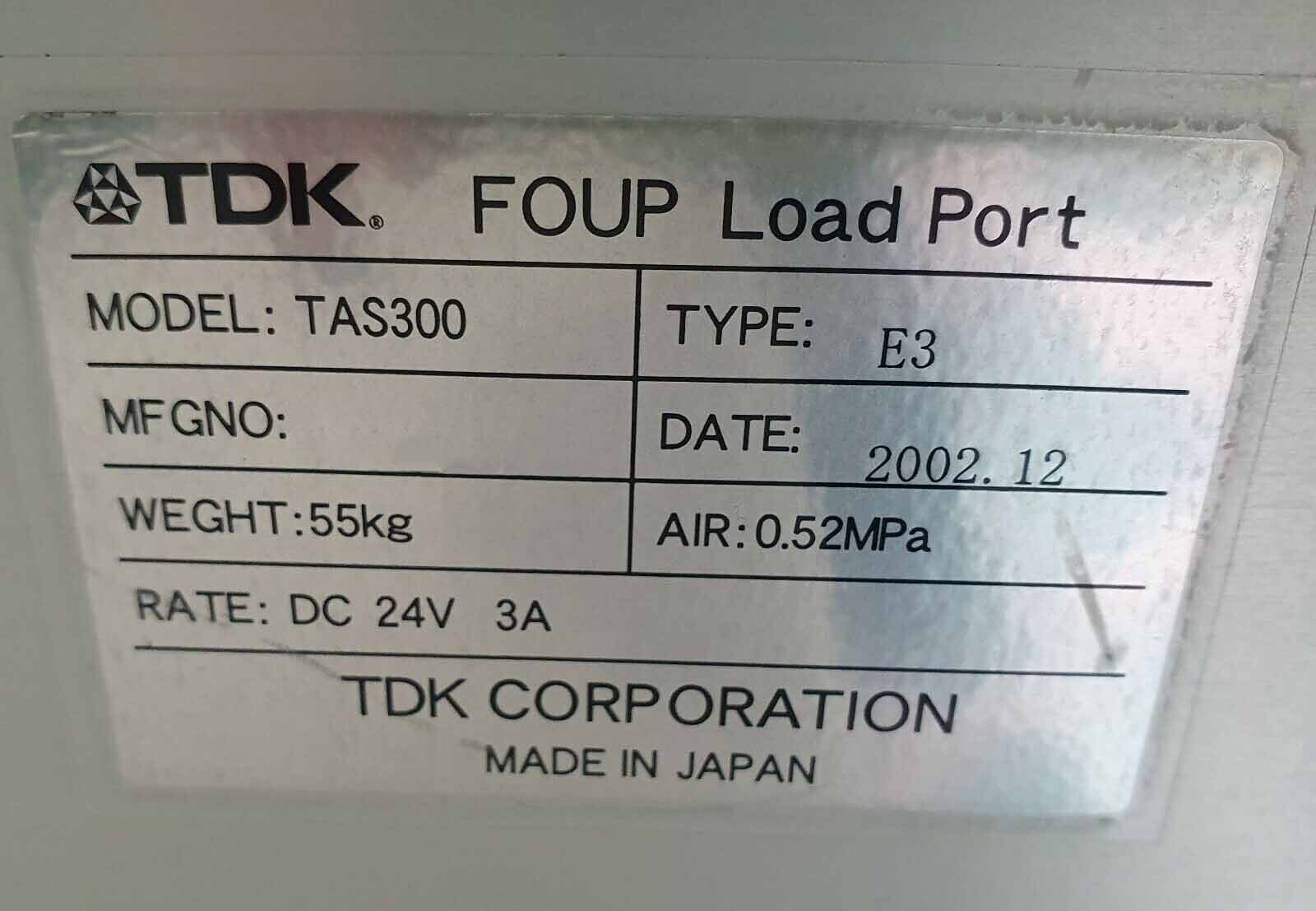

FOUP load port: TDK TAS300 E3

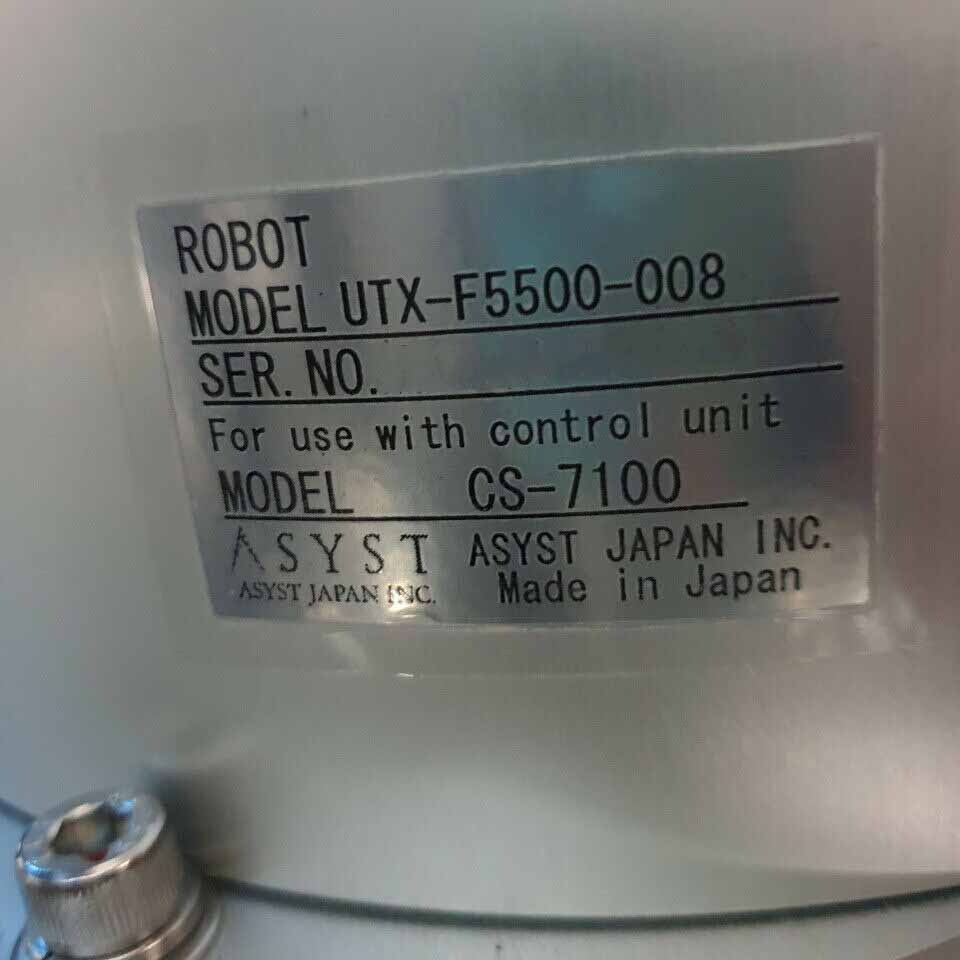

Robot: UTX-F5500-008

Control unit: CS-7100.

RIGAKU Wafer X-300 is an X-ray equipment designed to measure and inspect bulk samples with high accuracy and speed. It is a high throughput X-ray system that offers a variety of measurement capabilities, including single and dual wavelength X-ray topography, interference and diffraction, three-dimensional (3D) imaging, and digital tomography. RIGAKU WAFERX 300 employs a thin-film substage which enables accurate measurement of a variety of samples from soft materials to hard materials. Wafer X-300 is equipped with three methods of sample alignment, a 10x to 1000x magnification range, and can measure samples from 4" up to 24" in diameter. The optical unit also features a motorized control of the focus to ensure accuracy and precision. The conventional dual wavelength X- Ray topography and interference are used to detect surface microstructure, such as delamination or particle size. The 3D imaging mode provides accurate metrology of dimensional changes across a sample and can be used in a variety of applications, such as failure analysis and waste management. WAFERX 300 incorporates 16-bit digital acquisition technology to acquire and process 128-fold enlarged images. This 128x enlargement technique eliminates noise from images and provides clear image results. There is also an enhanced imaging mode option, enabling faster inspection and defect detection performance. RIGAKU Wafer X-300 can analyze both conventional and advanced substrate materials, such as gallium-nitride based wafers, MEMS mesh structures, and Germanium-on-Silicon. Its advanced X-ray topography capabilities ensure precise measurement and observation of 3D structures on a wafer, with a positional stability of up to 10nm. It also offers an automated multi-zone scanning to enhance metadata accuracy. RIGAKU WAFERX 300 is a powerful X-ray machine that offers a variety of advanced measurement and imaging capabilities. It is ideal for high precision X-ray topography, 3D imaging, diffraction, and digital tomography applications, enabling increased production efficiency and enhanced defect prevention. In conclusion, Wafer X-300 maximizes its efficiency and performance of any metrology application it is used for, making it the perfect instrument choice for any lab requiring a high throughput tool with a variety of imaging and measurement capabilities.

There are no reviews yet