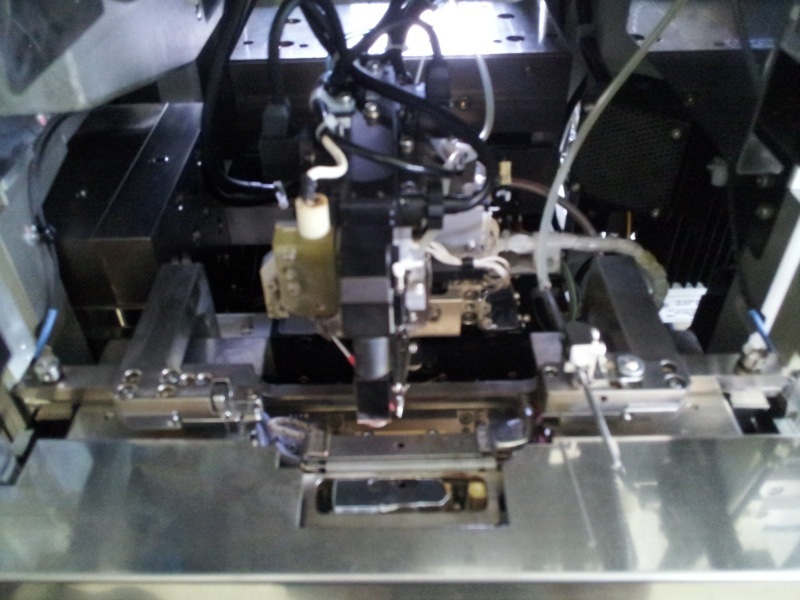

Used SHINKAWA UTC-1000 #9000828 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9000828

Wire bonders

Standard type

XY Table assy: XY-168A

Motor unit: MD-19

Bonding speed: 76ms/2mm wire

Fine pitch: 46um @ 3 sigma

Bonding wire length: max 8mm

Number of bonding wire: max 5000 wire

Machine accuracy: +-2.5um @ 3 sigma

Bondhead assy: BH-171

Transducer: UST-330B

Wire clamper: CL-49

Camera unit: CMU-31

Torch: EFU-35A

Optic type: Dual optic (6x, 1.5x)

PRS accuracy: 0.31um @ 3 sigma

Recognition speed: within 0.14s / 2 point

Workholder assy: UF7B001

RPS: MS-267

RPS body: RPS-01-01

Loader assy: SU-123-011

Unloader assy: SU-124-011

Wire feed unit: LCU-51

Switch panel: SWU-182

Power supply: JU-100

Motor drive board: MDU-87

EFO box: EFU-35A

Printed circuit board: SC2060-70A

PRS board: VPM-8100CX

FRP board: FRP-341C

ZUP board: ZUP-02

Drive board (x-axis): MDP-94

Drive board (FF): MDP-87

Lead frame dimensions:

20-80mm W

95-262mm L

0.07-0.03m thickness

Magazine dimensions:

23-90mm W

95-265mm L

79-208mm height

Can be inspected with power on

2002 - 2005 vintages.

SHINKAWA UTC-1000 is a fully automated, computer-controlled bonder specifically designed to improve the efficiency and accuracy of the bonding process across a variety of industries. This device is capable of accurately joining two items, such as a chip and a substrate, with a precision of 5 micrometers. It utilizes a robust, computer-programmable, multi-stage bonding process that eliminates the need for manual configuration and labor-intensive setup. The machine comes equipped with a high-power xenon arc lamp to ensure uniform heating across the target area. This feature is critical for achieving the level of exquisite heat control needed for reliable and repeatable bonds. The device is also designed with a sophisticated imaging system that utilizes state-of-the-art optics to capture precise two-dimensional and three-dimensional images of the bonding area. The system is capable of detecting latent defects or subtle surface inconsistencies. SHINKAWA UTC1000 is also equipped with an advanced control program that helps to ensure the accuracy of the bonding process. This program is designed to provide real-time feedback on the state of the process, resulting in greater control and regular optimization. In addition to this, the device is also equipped with a variety of programmable settings and fine-tuning options in order to meet the needs of the specific application. This bonder is perfect for use in the most exacting industries, such as the medical industry. Thanks to the precision offered by the device, it is capable of forming accurate and reliable bonding with a variety of substrates, Ultra Thin Substrates (UTS) and Wafers-on-Wafer (WoW). It is also capable of working with a variety of metallic conductive materials such as copper, gold, silver, and zinc, meaning that it can join objects with different electrical properties. The device is outfitted with a series of intuitive user interfaces and features that make it easy to operate. It is designed to be friendly to novice and experienced operators alike, offering a configuration and operation that can be quickly mastered. Additionally, performance-related data measurements can be easily accessed and interpreted, providing feedback that further improves the reliability of the bonding process. On top of all this, UTC 1000 is designed to be exceptionally energy efficient, making it highly desirable from an environmental standpoint. It is also highly reliable and aesthetically pleasing, making it suitable for a variety of industries and applications. With its robust design and intuitive controls, this bonder promises to provide reliable and repeatable bonds for years to come.

There are no reviews yet