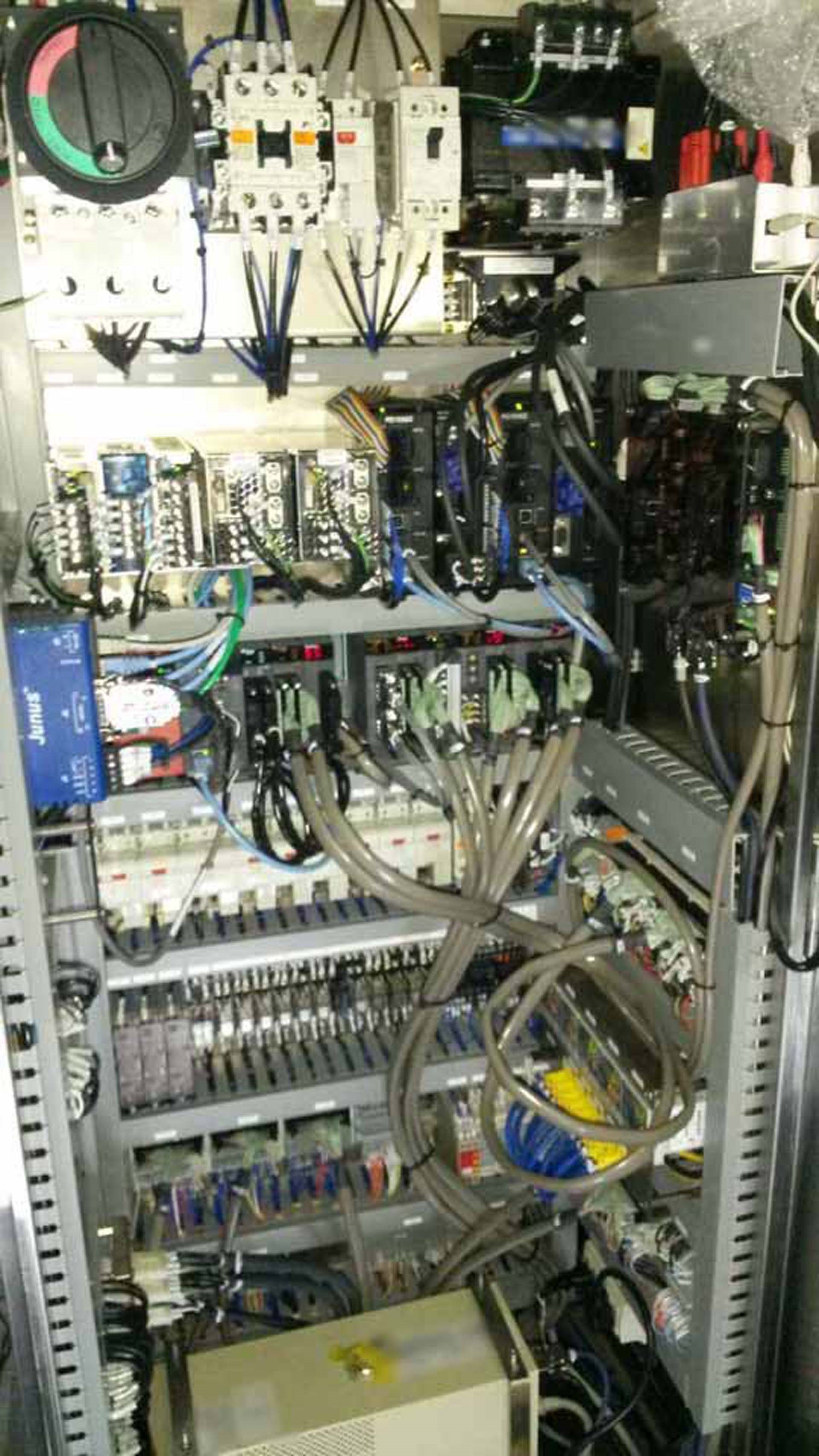

Used TDK AFM 15 #9199915 for sale

URL successfully copied!

Tap to zoom

ID: 9199915

Vintage: 2012

Flip chip bonders, 8"-12"

Chip size range: 300um ~ 5000um

Bonding process: Gold-to-gold interconnection (Ultra sonic)

Products:

TCXO

SAW

OPTO

High frequency

IC:

Maximum: 5.0W X 5.0D X 1.0T mm

Minimum: 0.3W x 0.3D x 0.1T mm

Board:

Maximum: 180W x 120D x 3.2T mm

Minimum: 50W x 50D x 0.3T mm

Cycle time: 0.8sec/IC (Excluding bonding process time)

Accuracy: ±8nm/3σ

Maximum load: 20N (Special 100N)

IC Supply: 5/6 Inch wafer

Standard features:

Pre / Mounting heater table

Nozzle auto cleaning & monitoring

US Checking

IC Height measurement

Bump detection

Wafer expand

Wafer θ axis correction

Hot blow

Production management data

Option and features:

Magazine loader / Unloader

Ionizer

Carrier handling

Hepa-tilter

Plasma cleaning unit

Load / US Sampling

Nozzle surface monitoring

Map data

High accuracy mode

2012 vintage.

TDK AFM 15 is a high-quality bonding instrument that is a perfect choice for a wide variety of adhesive bonding needs. This precision bonding equipment is designed to help users confidently and accurately bond different substrates in a fast and efficient manner. TDK AFM-15 system features an innovative design which includes a stepper motor drive unit as well as an interface panel which makes operation and adjustment of the unit simple and intuitive. The closed-loop pressure machine gives users precise control, allowing them to set the ideal level of pressure required for perfect results. The tunable frequency range of AFM 15 reaches up to 5kHz, allowing it to easily bond a wide range of substrates, including plastics, metals, glass, and ceramics. The machine also features both face and pin bonding capabilities, making it suitable for use with a wide range of materials. The simple setup process of AFM-15 helps users quickly move from fixture to fixture and job to job. This user-friendly machine gives users precision control for accurate results, making it a valuable tool for any adhesive bonding process. It also features a small footprint, so it doesn't take up too much space on the workbench or in the lab. TDK AFM 15 is built with a precision design that is ideal for high-accuracy adhesive bonding processes. Its powerful frequency capabilities allow users to work with different materials, while its clean interface makes operation and adjustment a breeze. Its closed-loop pressure tool gives users full control over the bonding process, while its small footprint helps users of every size. For accurate large-scale adhesive bonding, TDK AFM-15 is the perfect choice.

There are no reviews yet