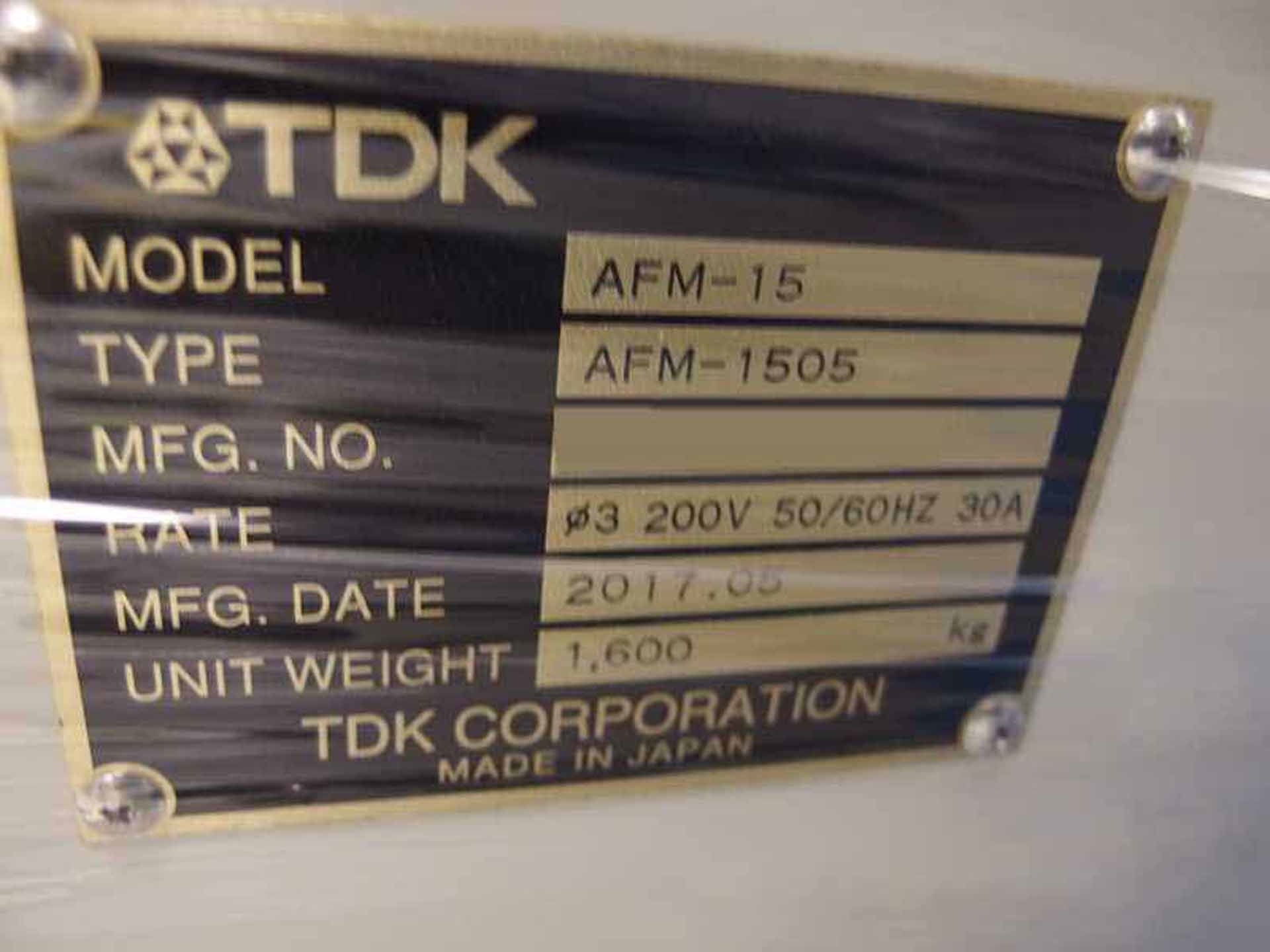

Used TDK AFM 15 #9229902 for sale

URL successfully copied!

Tap to zoom

ID: 9229902

Wafer Size: 8"

Vintage: 2017

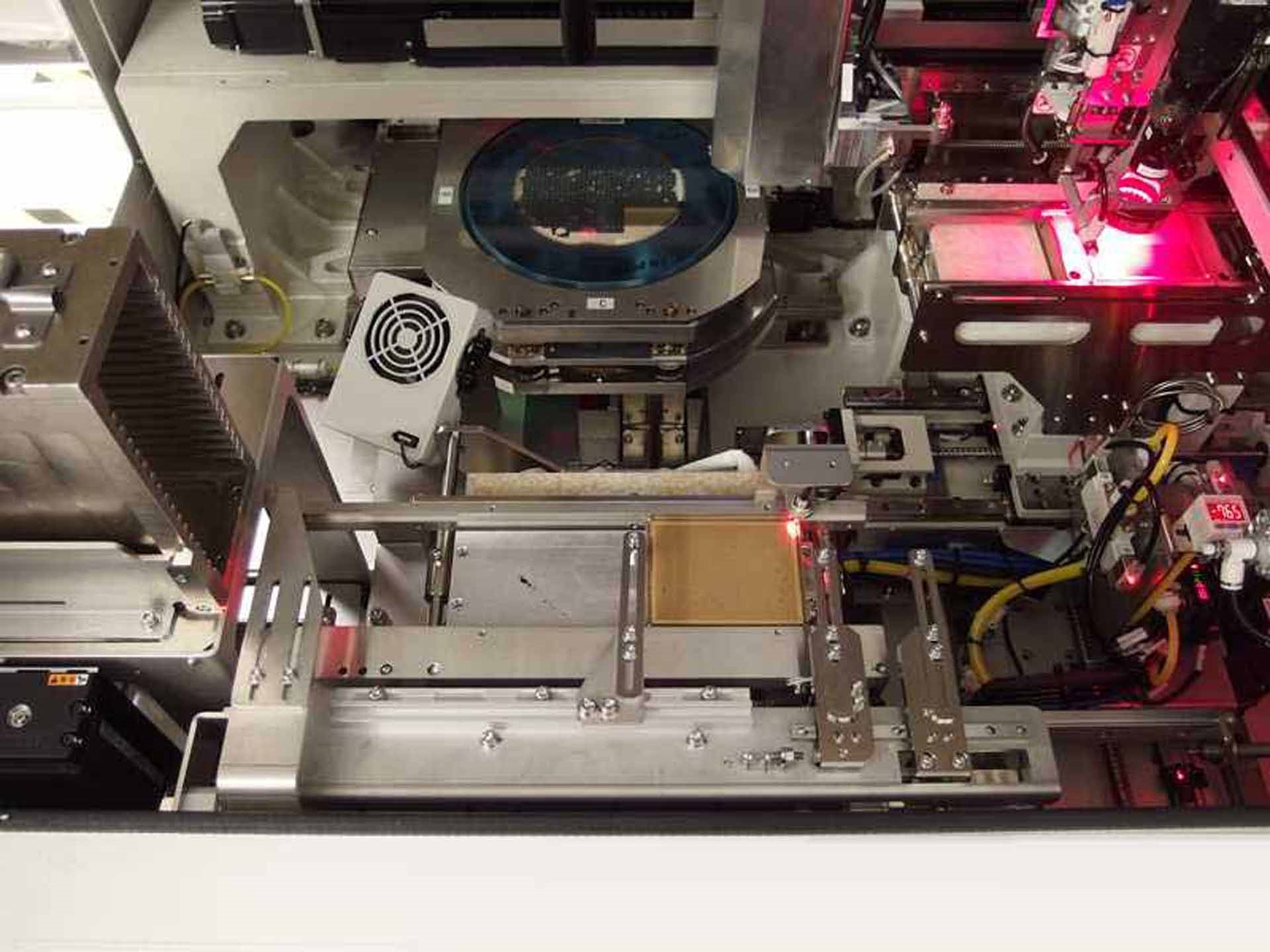

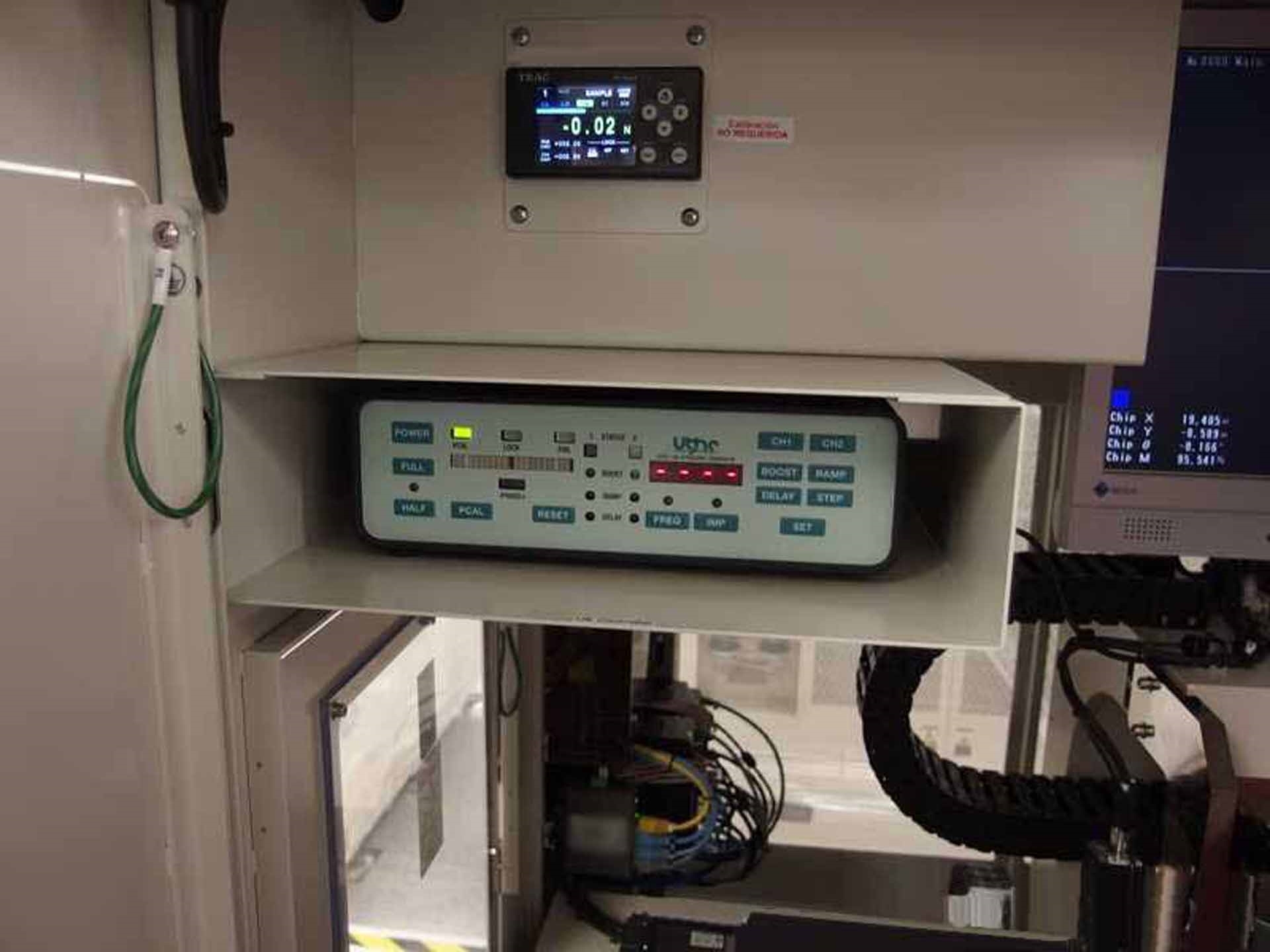

Compact ultrasonic bonder, 8"

Media handler type wafer

Power supply:

Voltage: 200 V

Frequency: 50 / 60 Hz

3 Phase

Current: 30 Amps

2017 vintage.

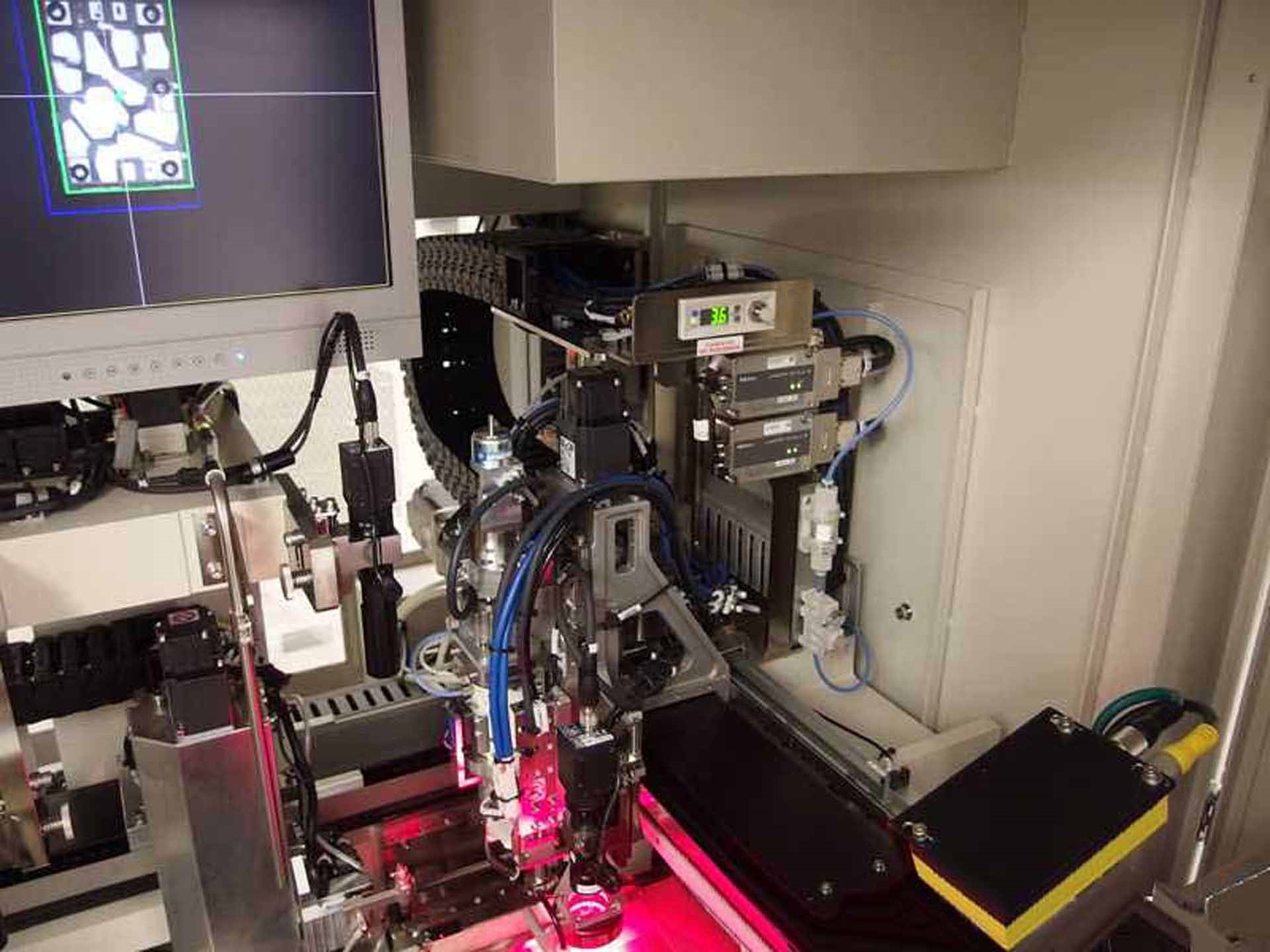

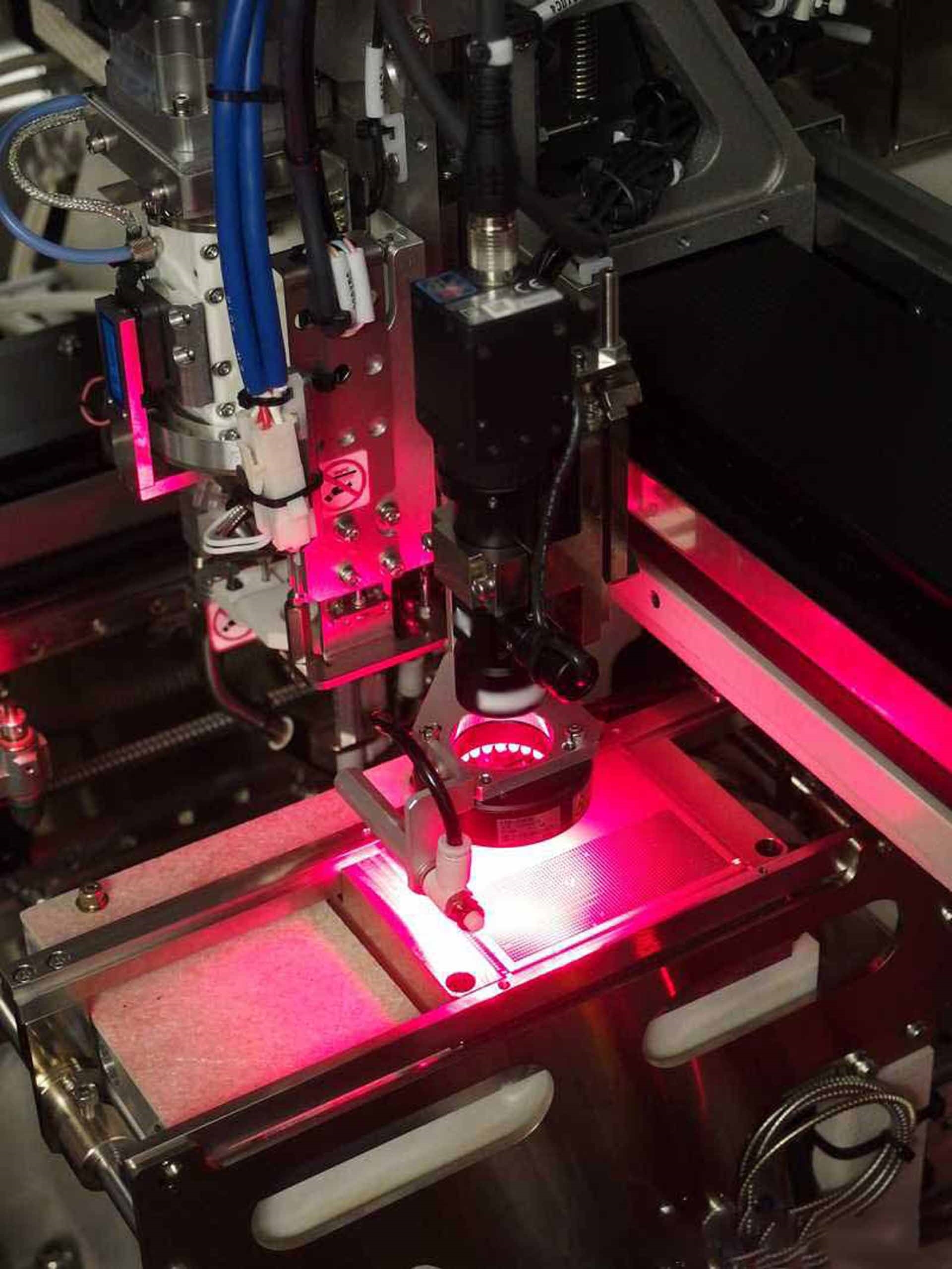

TDK AFM 15 is an advanced ceramic flip chip lead forming and bonding equipment for the automated assembly of advanced packages such as small outline packages and CSPs. It features a simple and efficient design to ensure fast and accurate bond formation and connection. The system comes with a wide range of features designed to make the assembly process faster and more reliable. First off, the unit has an easy to use GUI-based user interface that allows the user to quickly program and monitor the process. There are multiple language options, and a built-in help machine to assist with initial setup and troubleshooting. The tool also includes a built-in camera for the precise alignment of components. In terms of performance, the asset is capable of forming bond wires on a range of substrates including silicon, copper and ceramic. The model can handle work pieces up to 10 mm thick and 25 mm in size. It can also handle substrates as thin as 0.2 mm. It can bond bonds as small as 0.2mm and as thick as 1mm. The temperature range goes up to 400 °C for both ends of the metal base. The equipment also features a high precision placement system, which guarantees accurate, repeatable, and accurate placement of parts. It uses a unique vacuum chuck unit for accurate positioning of parts while the bonding jig secures them in place. The machine also comes with advanced features such as top and backside heating chairs, and advanced process control that automatically adjusts the temperature and time parameters to ensure that all bond wires are of good quality. Additionally, the tool comes with an attached servo-driven gripper to accurately pick and place components. Lastly, TDK AFM-15 features an easy-to-use asset maintenance kit and a software development kit for troubleshooting and upgrading of the model. This ensures that the equipment is running optimally and can be easily and cost-effectively maintained.

There are no reviews yet