Used TDK AFM 15 #9229934 for sale

URL successfully copied!

Tap to zoom

ID: 9229934

Wafer Size: 8"

Vintage: 2017

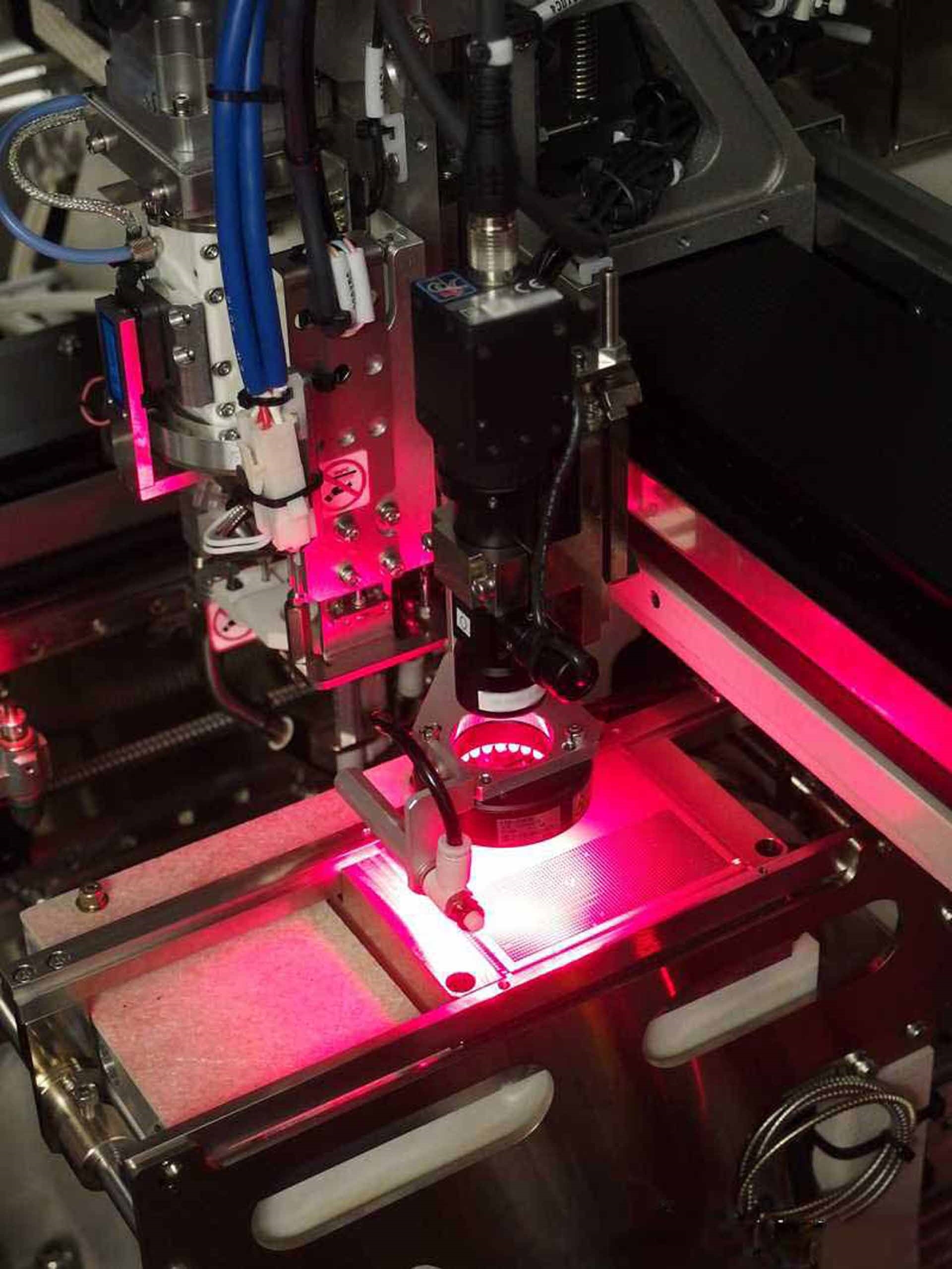

Compact ultrasonic bonder, 8"

Media handler type wafer

Power supply: 200 V, 3 Phase, 50/60 Hz, 3 Amps

2017 vintage.

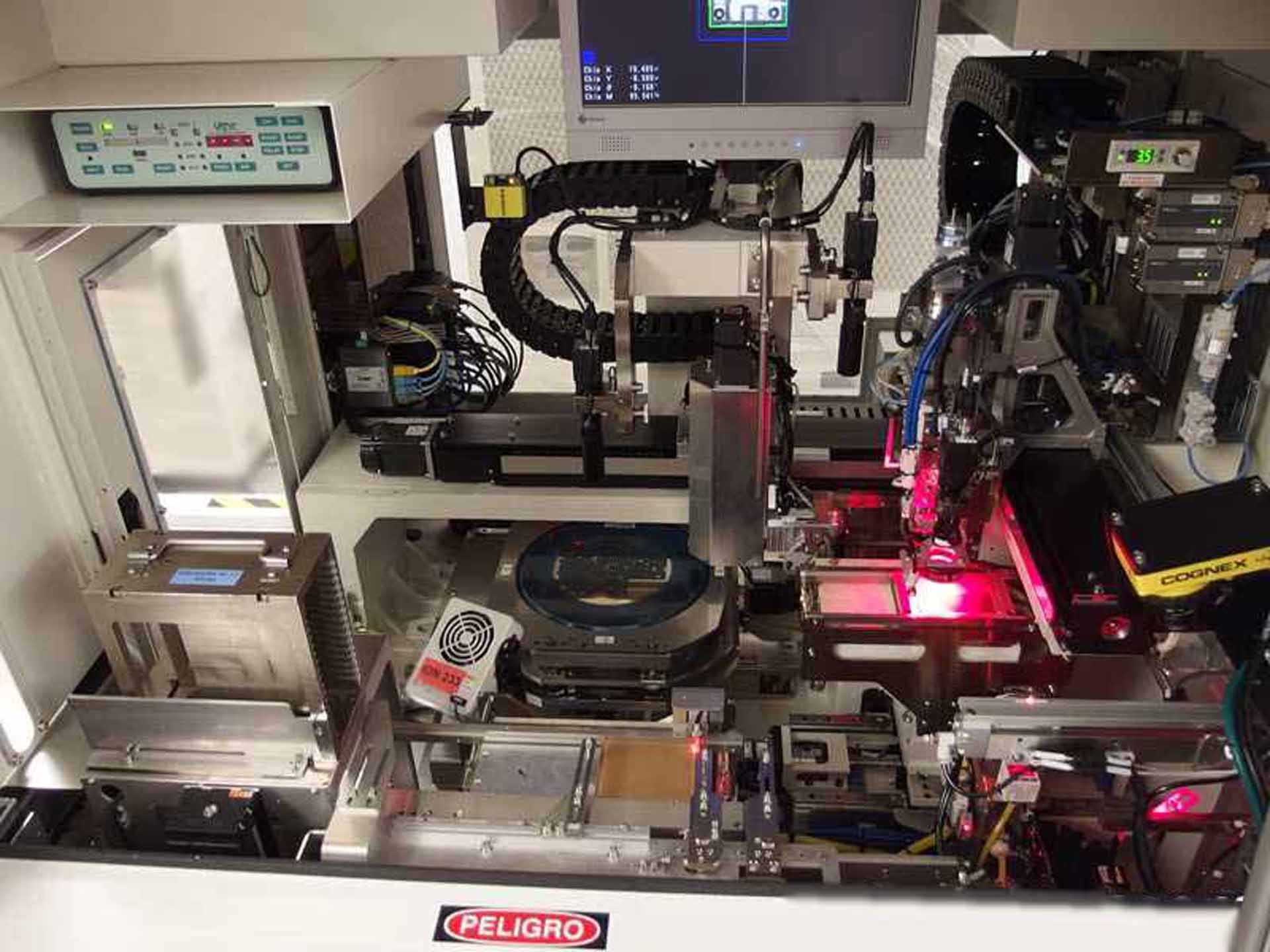

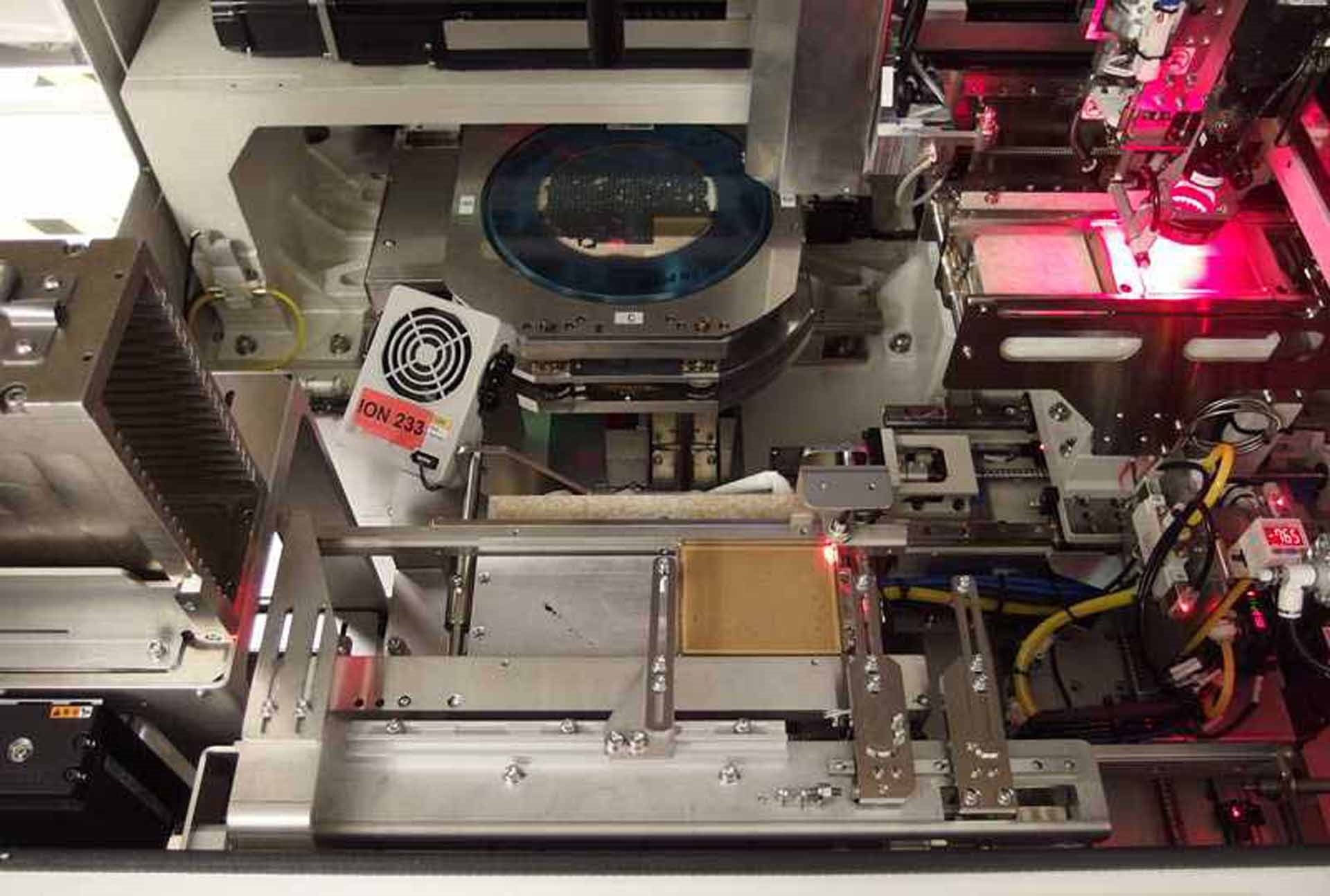

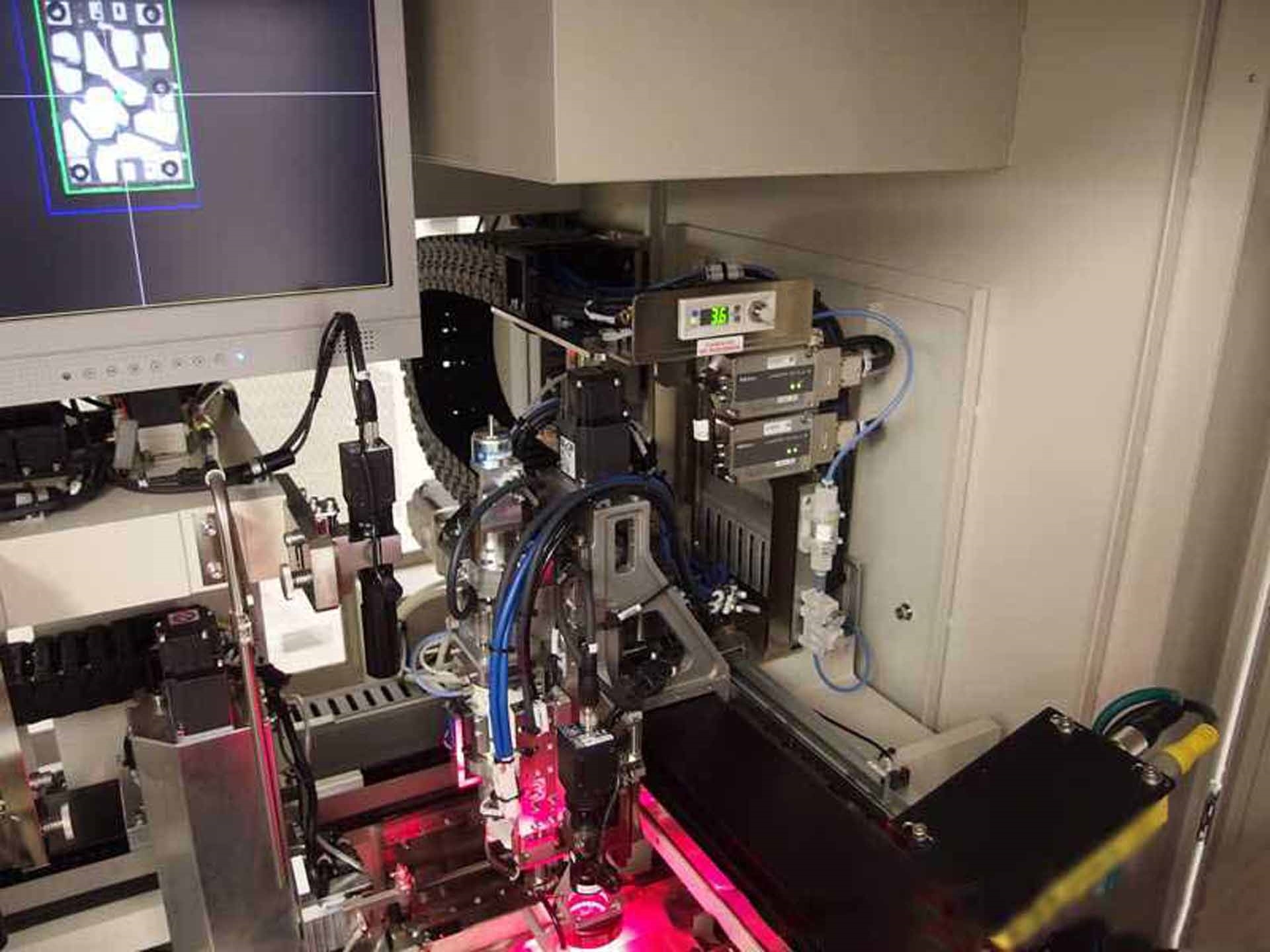

TDK AFM 15 bonder is an automated die attach platform that provides high-precision automated die-bonding. This machine is designed for assembly of chip scale packages, QFNs, and microarrays. It has a heated stage controlled by a 3-way valve, with a maximum temperature of 250°C. It has a repeatability of ±0.03mm, which ensures die-to-die placement accuracy and even distribution of the bonding force. TDK AFM-15 is also equipped with a high-powered microscope, high-resolution camera, image processing algorithms, and a vision feedback equipment for pattern recognition and alignment accuracy. It has a high-torque, dual-axis, servo-driven bond arm for controlled and precise die placement. It can accommodate multiple bond heads with a vacuum option for optimized placement. It has a two-stage process embedded in the die bonding process—die-level bond and final package-level bond—which enables the operator to perform a high-quality bond at high speeds (up to 10 packages/second). AFM 15 also has a built-in safety system, with multiple sensors and an E-stop button for emergency stoppage. It can be operated in the stand-alone or machine-to-machine mode, where it can be seamlessly integrated into existing production lines. The software accompanying the machine has a Windows-based user-friendly graphical user interface, featuring a unique spectrum of interactive icons. This allows the user to configure, monitor, and maintain the machine's operation without needing to change any commands. It also has an integrated Statistical Process Control (SPC) unit for monitoring and validating each lot. Overall, AFM-15 is an automated bonder designed for precise die-bonding at high speed, with excellent repeatability and accuracy. It provides a high-quality bond and is well suited for chip scale packages, QFNs, and microarrays. It features user-friendly software, a built-in safety machine, and a monitored SPC tool, making it an efficient and reliable choice for die-bonding in production lines.

There are no reviews yet