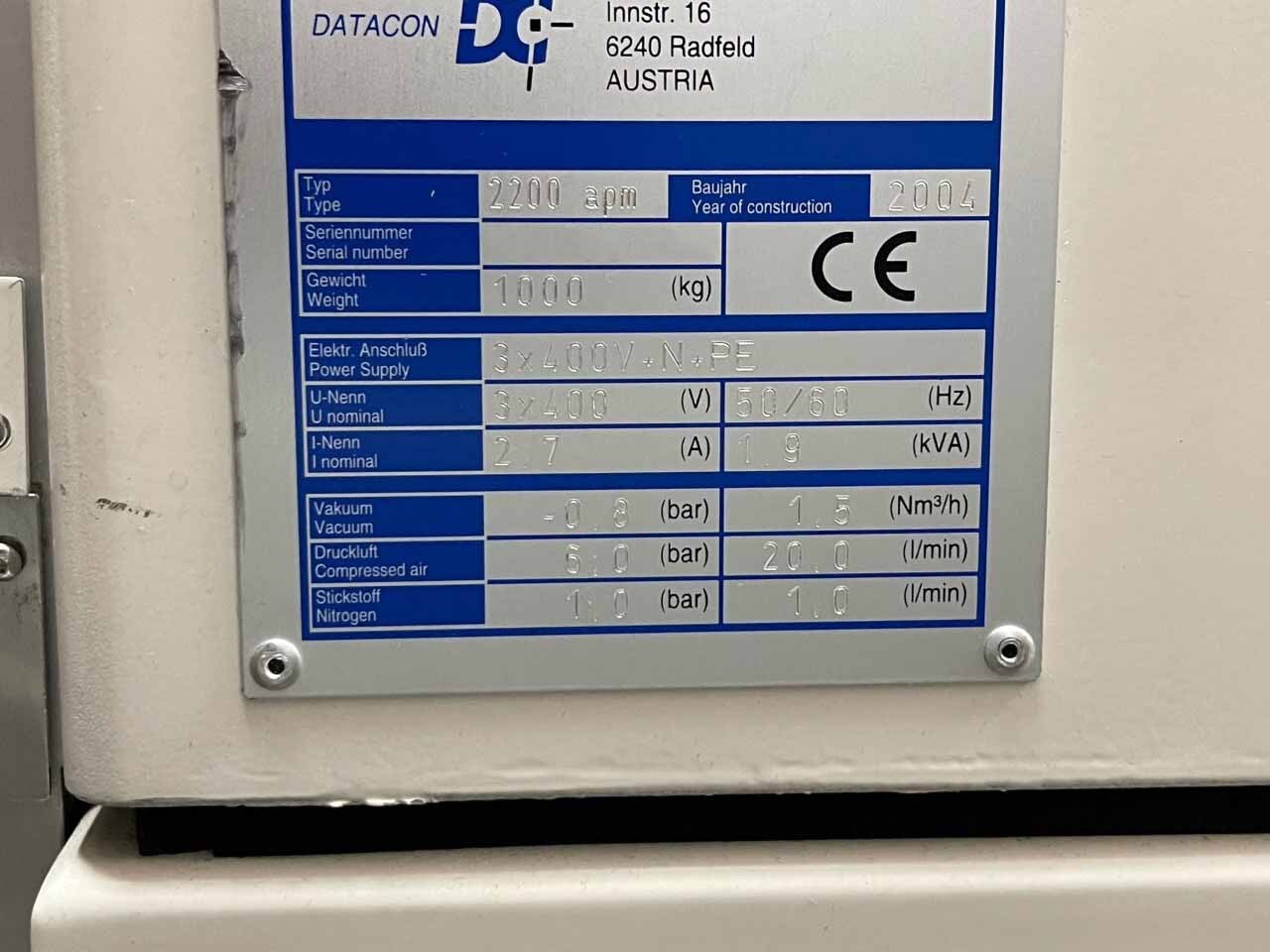

Used DATACON / BESI 2200 APM #293597151 for sale

URL successfully copied!

Tap to zoom

ID: 293597151

Wafer Size: 8"

Vintage: 2004

Die bonder, 8"

Does not include cassette

2004 vintage.

DATACON / BESI 2200 APM is an advanced die attacher designed for high precision and efficiency in assembling components on printed circuit boards. It boasts a range of advanced features, such as die prealignment, component loading, component soldering, component marking and component inspection. The main unit of this machine has a 2-axis gantry structure and can move along the X-Y axis. It is equipped with a high-tensor aluminum frame to provide maximum stability and accuracy. There are two independent vision systems consisting of a camera and a camera control module to help ensure component alignment and placement on the printed circuit board. The vision system can be used to detect component/die markers, component outlines and component recognition. The component loading process begins by placing a component into a component holder and loading it on the attaching tool. A component orientation pick up unit then picks up the component and feeds it into the attaching tool. The component is then fed into the component holding device where the component is aligned with the termination area of the printed circuit board using the vision systems. The component soldering process is done using a precision laserhead with laser spot temperature control system. A soldering temperature area is created on the component and the component is then securely soldered to the printed circuit board. The component marking process is done using a marker module that is integrated into the main unit and can mark both sides of the component accurately. The component inspection process is done using both manual and automated inspection tools. Manual inspection tools such as tweezers, magnifier and flux pens are used to check for any imperfections or defects. Automated inspection tools such as optical sensors, monitors and x-ray scanners can detect component misplacement, incorrect polarity and other errors. Overall, BESI 2200 APM is an advanced die attacher designed for high precision and efficiency in assembling components on printed circuit boards. Its range of advanced features, such as die prealignment, component loading, component soldering and component marking and inspection, offer increased reliability and accuracy in printed circuit board assembly.

There are no reviews yet