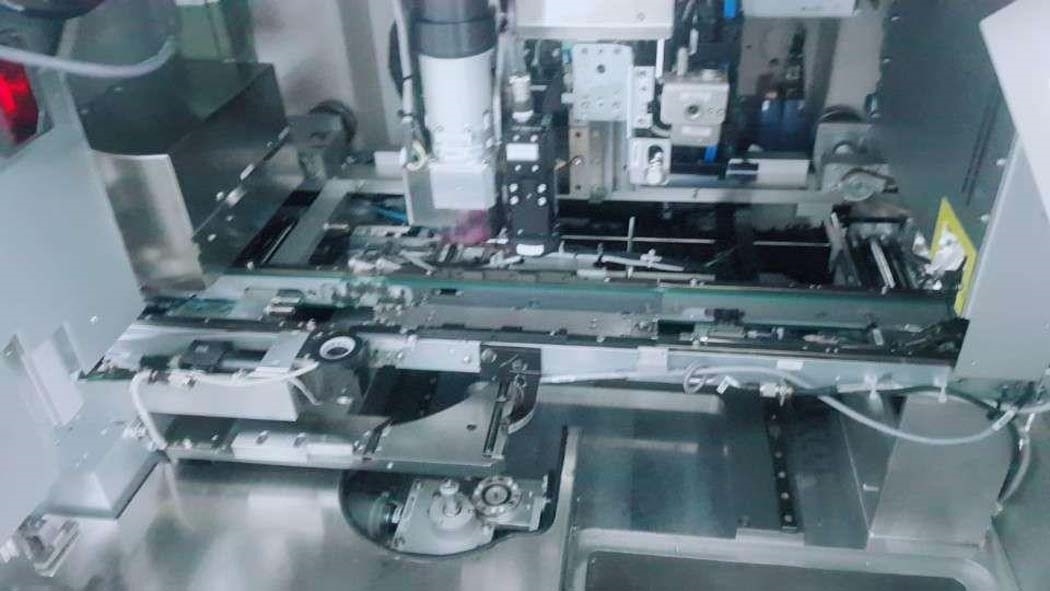

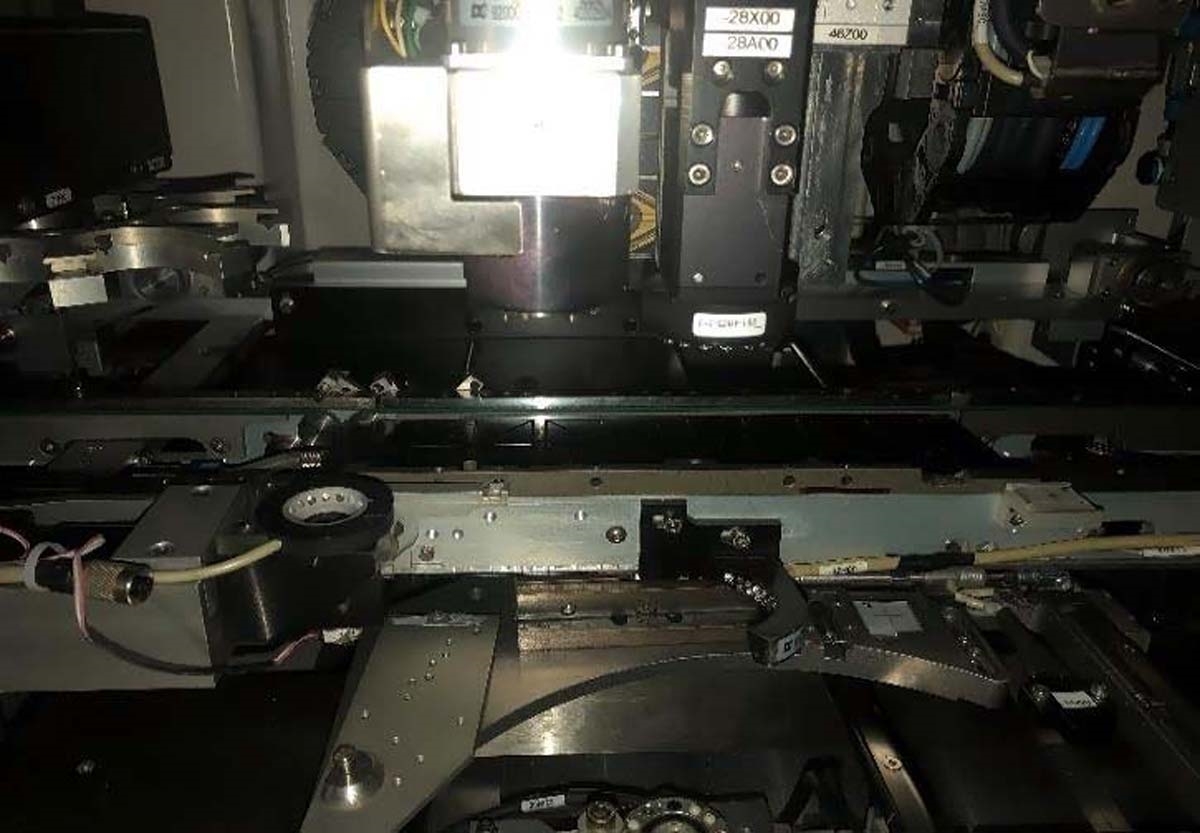

Used DATACON / BESI 2200 APM #9258775 for sale

URL successfully copied!

Tap to zoom

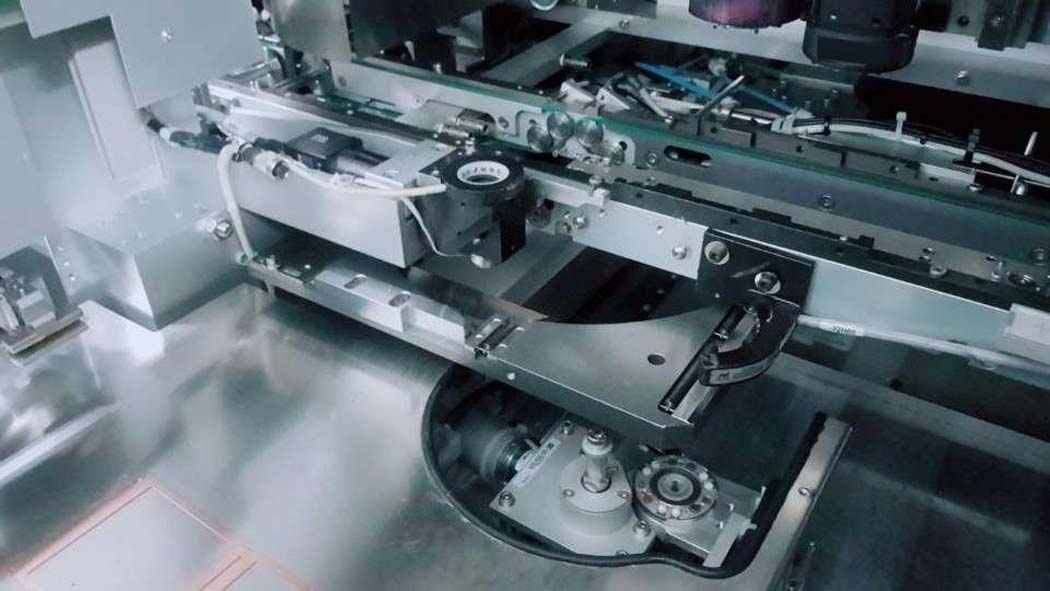

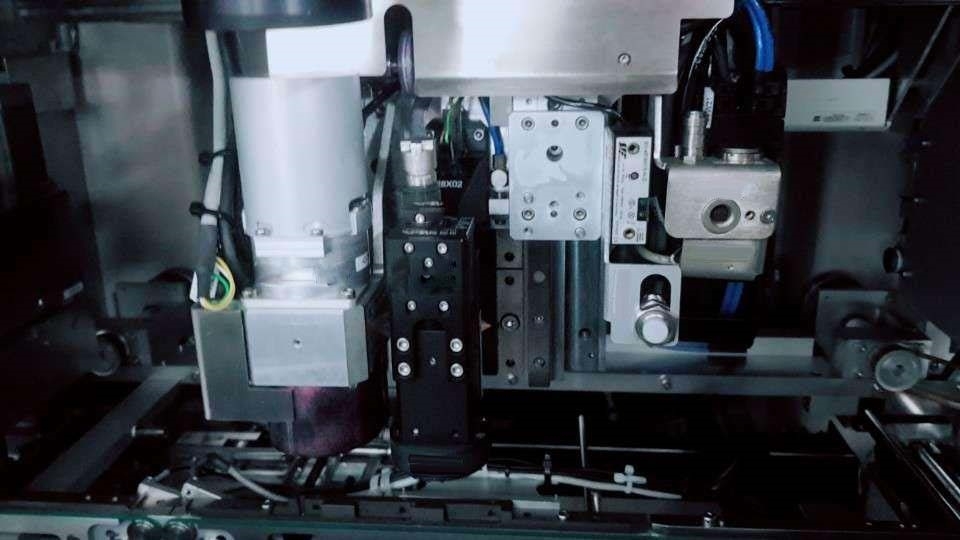

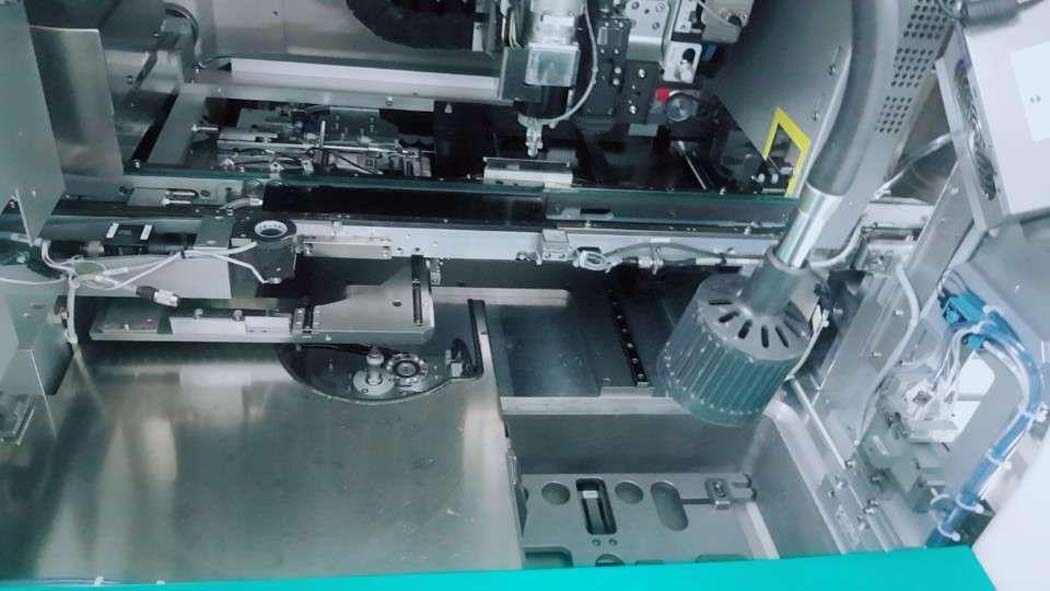

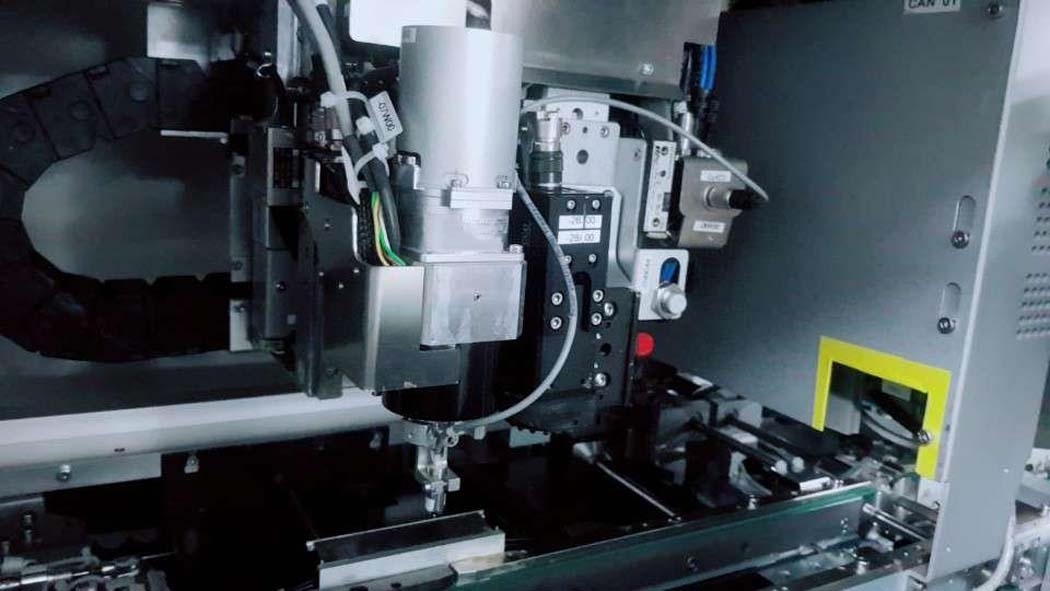

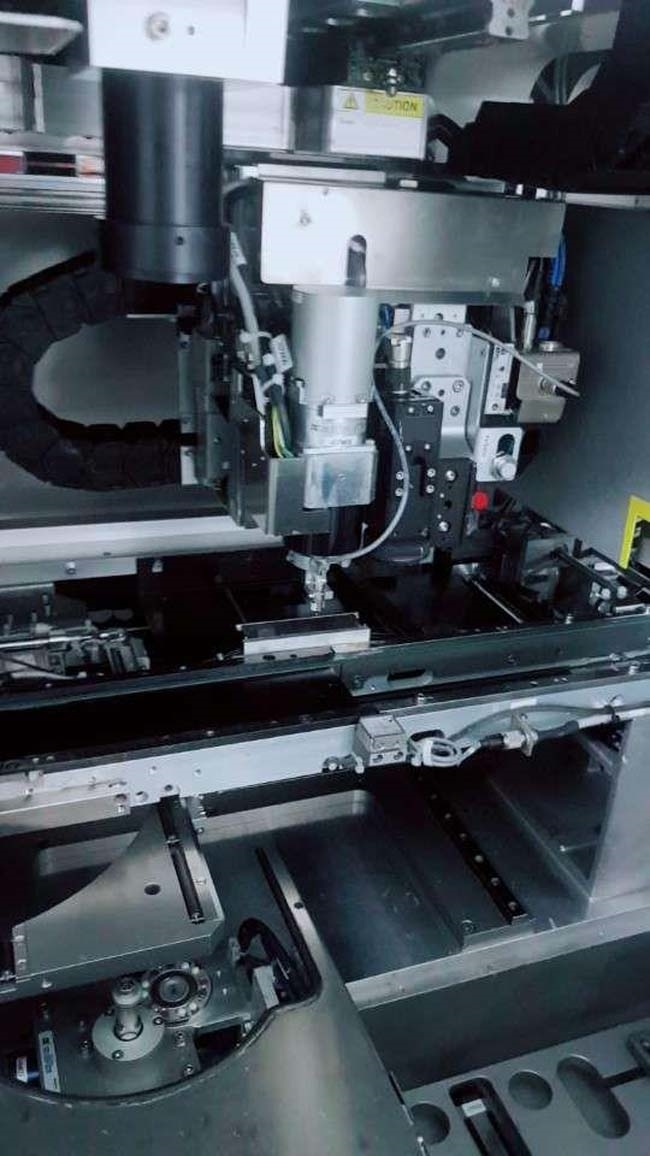

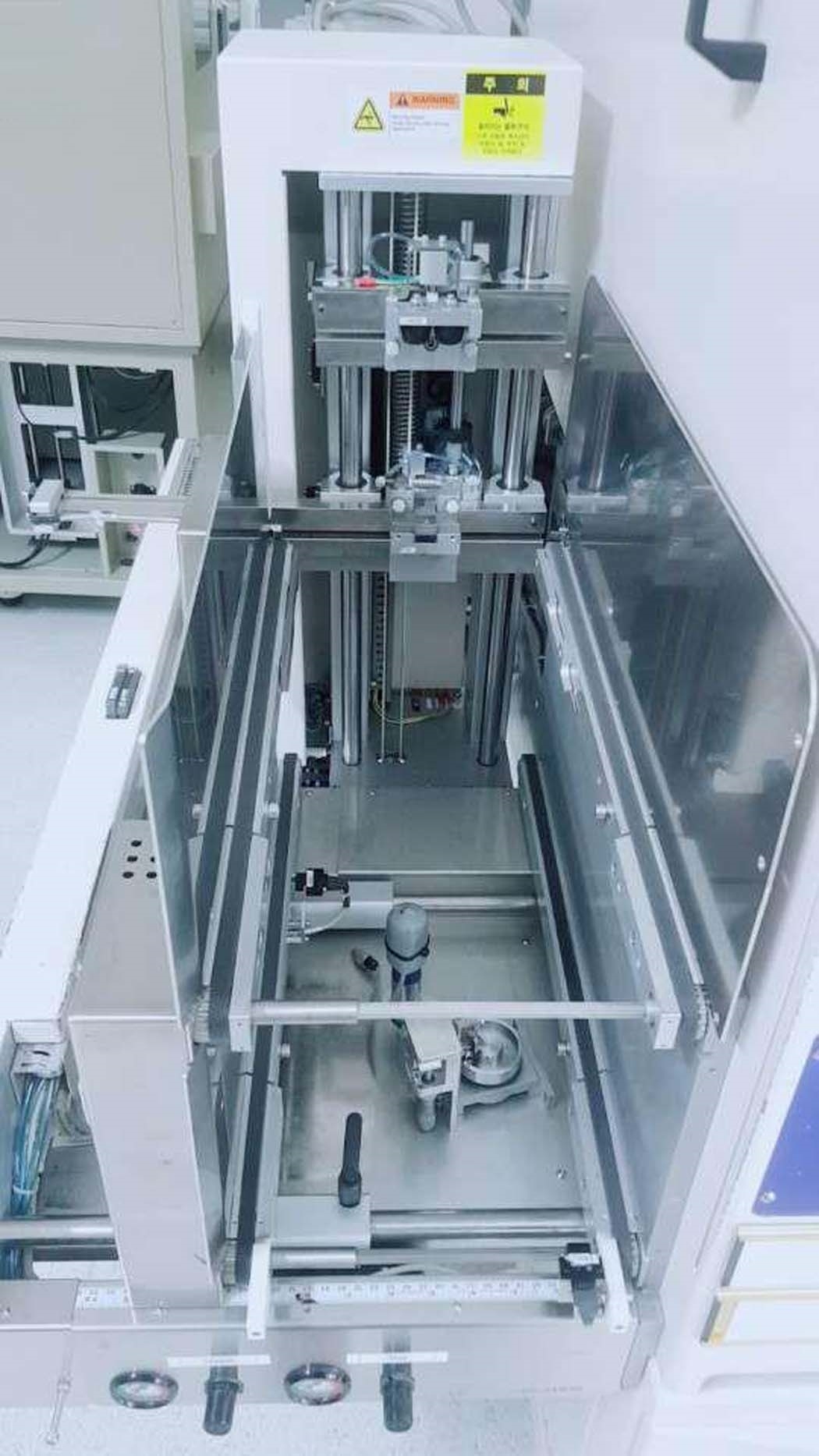

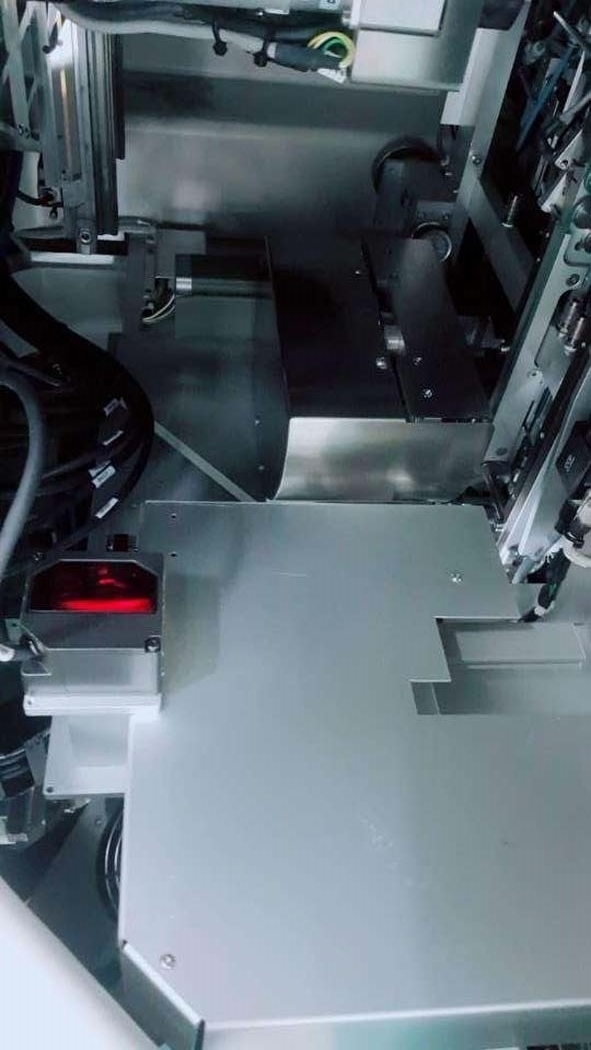

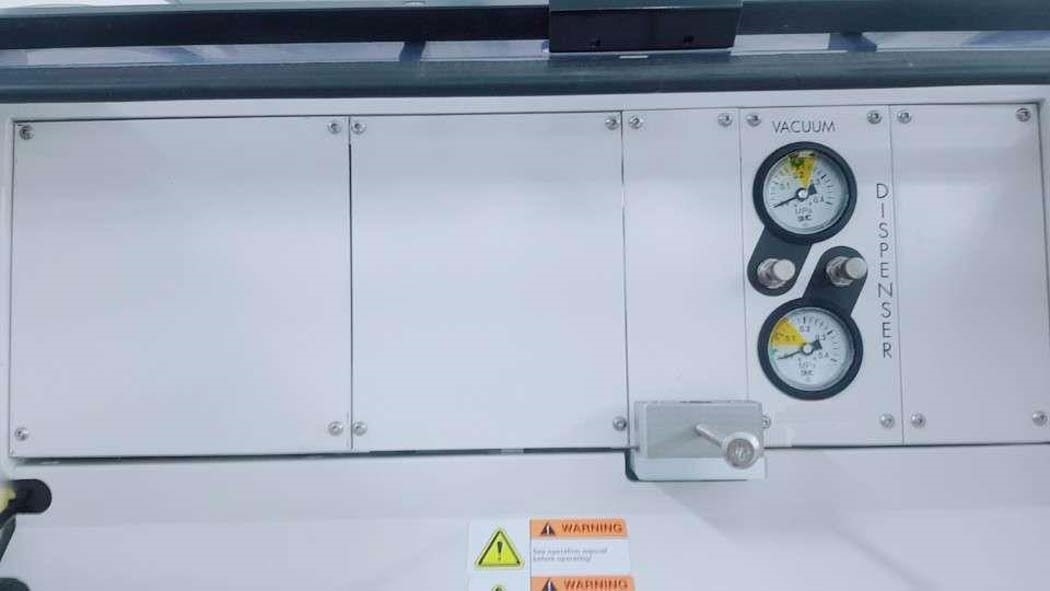

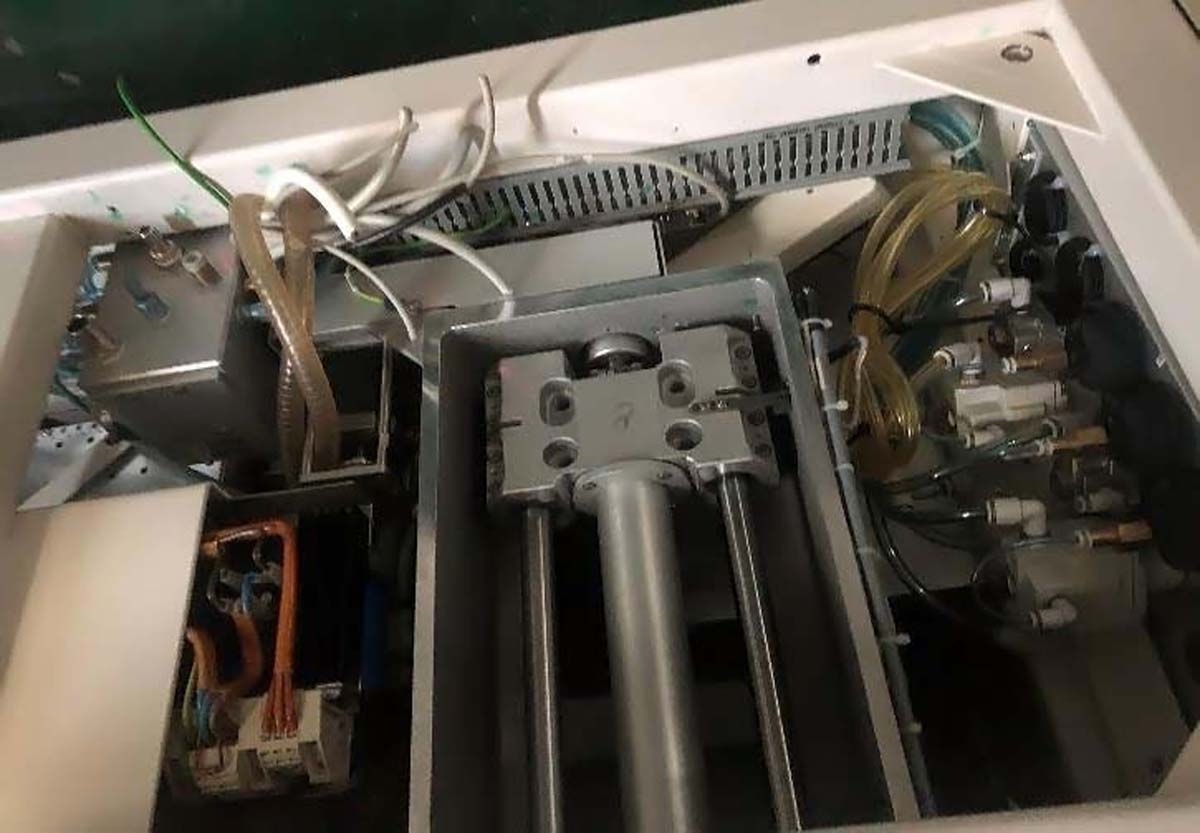

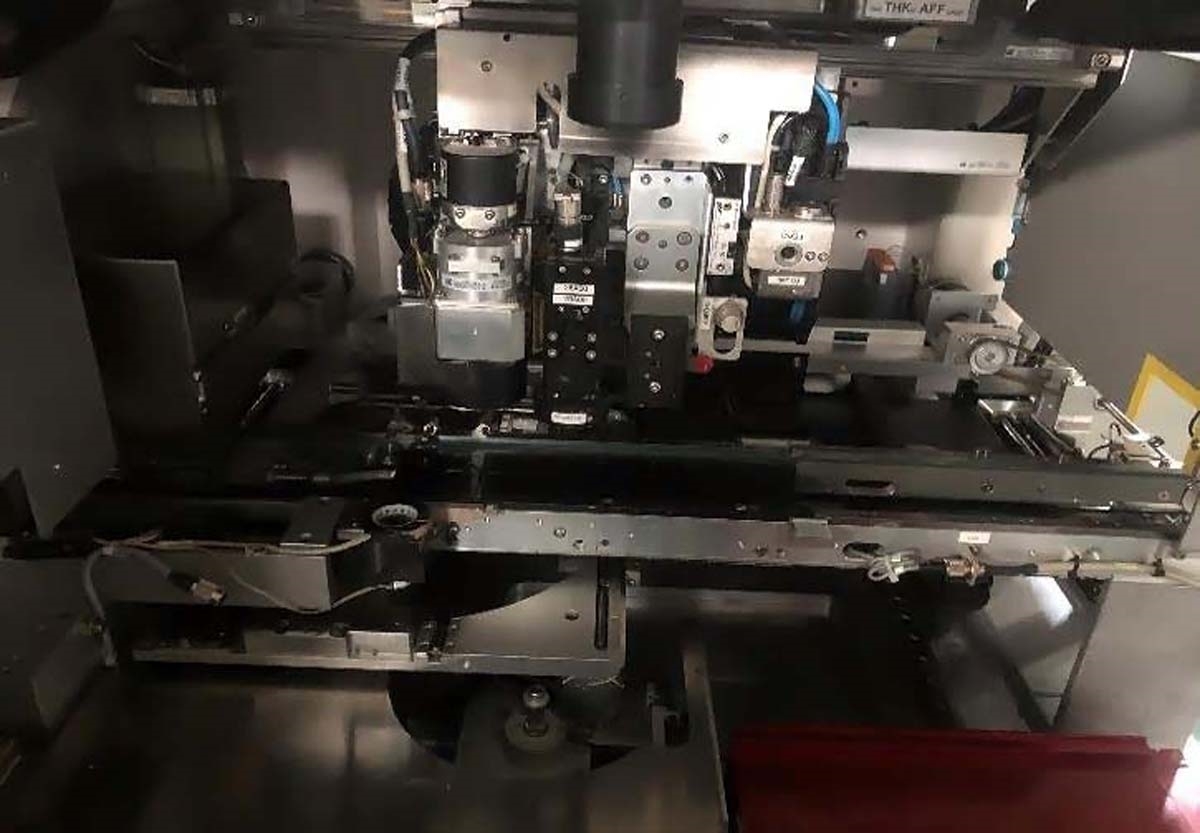

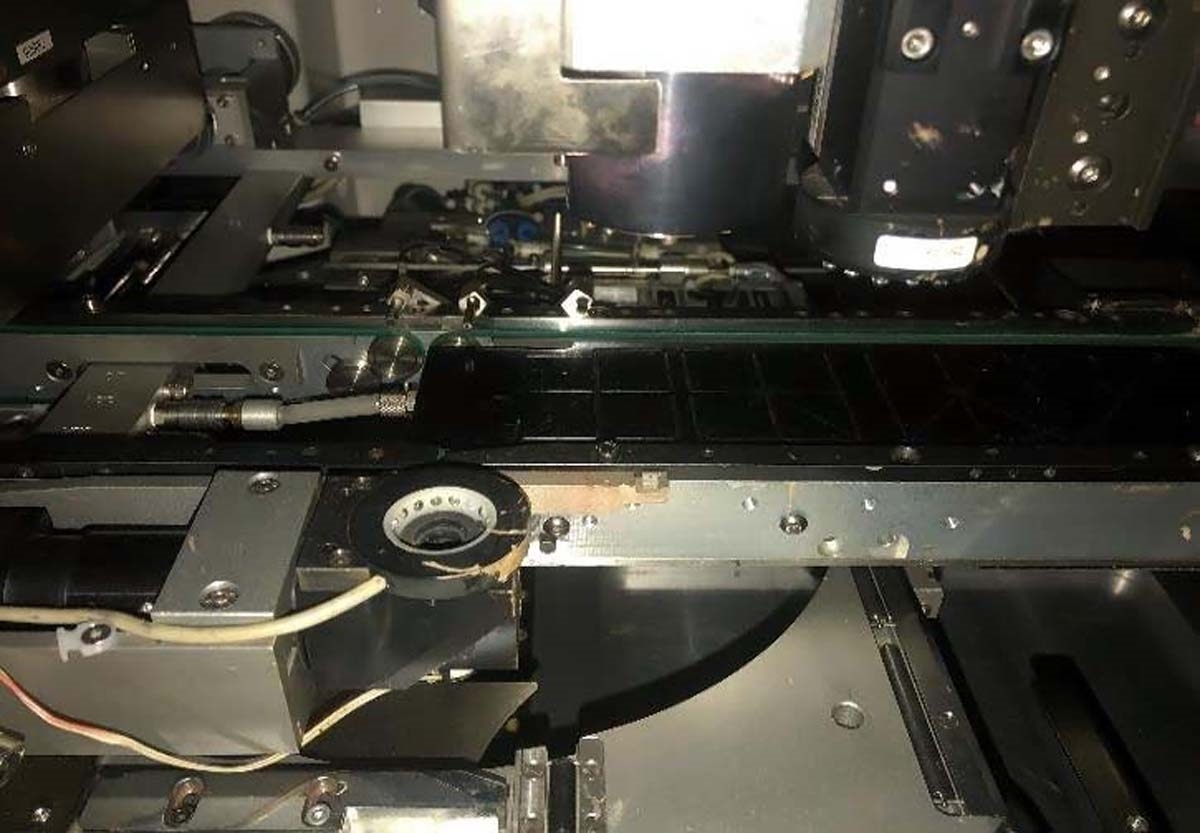

DATACON / BESI 2200 APM is a die attach machine designed for use in the electronics industry. It is an automated process machine (APM) used for attaching die or chips to substrates. The unit is equipped with an efficient pick and place equipment that allows for accurate placement of dies on substrates, and is capable of operating with a variety of die types. It also includes multiple nozzles for larger die applications and has a large work surface for working with multiple substrates. BESI 2200 APM has precise automated control for all die bonding parameters such as voltage, current, and frequency. The machine also has a number of programmable parameters, such as temperature, pressure, and time, for controlling the attachment of die to substrates. This ensures accuracy in the process and allows for high levels of repeatability and quality. The machine has two main components. The first is the processor, which is in charge of controlling the machine and processing user commands. The second is the system, which contains all the sensors and automation mechanisms for the processing and bonding functions. This unit is divided into three sections: a die picker, a dispenser, and a bonder. The picker is responsible for picking and placing the die on the substrate. The dispenser is used to dispense the flux that will help the die attach to the substrate. Lastly, the bonder is used to bond the die and the substrate together using heat and pressure. In addition to these components, DATACON 2200 APM includes a number of other components that are used to enhance and improve the performance of the machine. These include a board rotator for easy and accurate die placement, an enhanced vision machine that helps to detect and correct any misalignments, and a monitor for observing the die attacher's progress. The machine also comes with several safety features, including automatic shutoff if any problems occur, and a number of automatic calibration routines to ensure accuracy and reliability. 2200 APM is an efficient and cost-effective way to attach die and chips to substrates. Its automated process control and safety features make it an ideal solution for die attach applications in the electronics industry.

There are no reviews yet