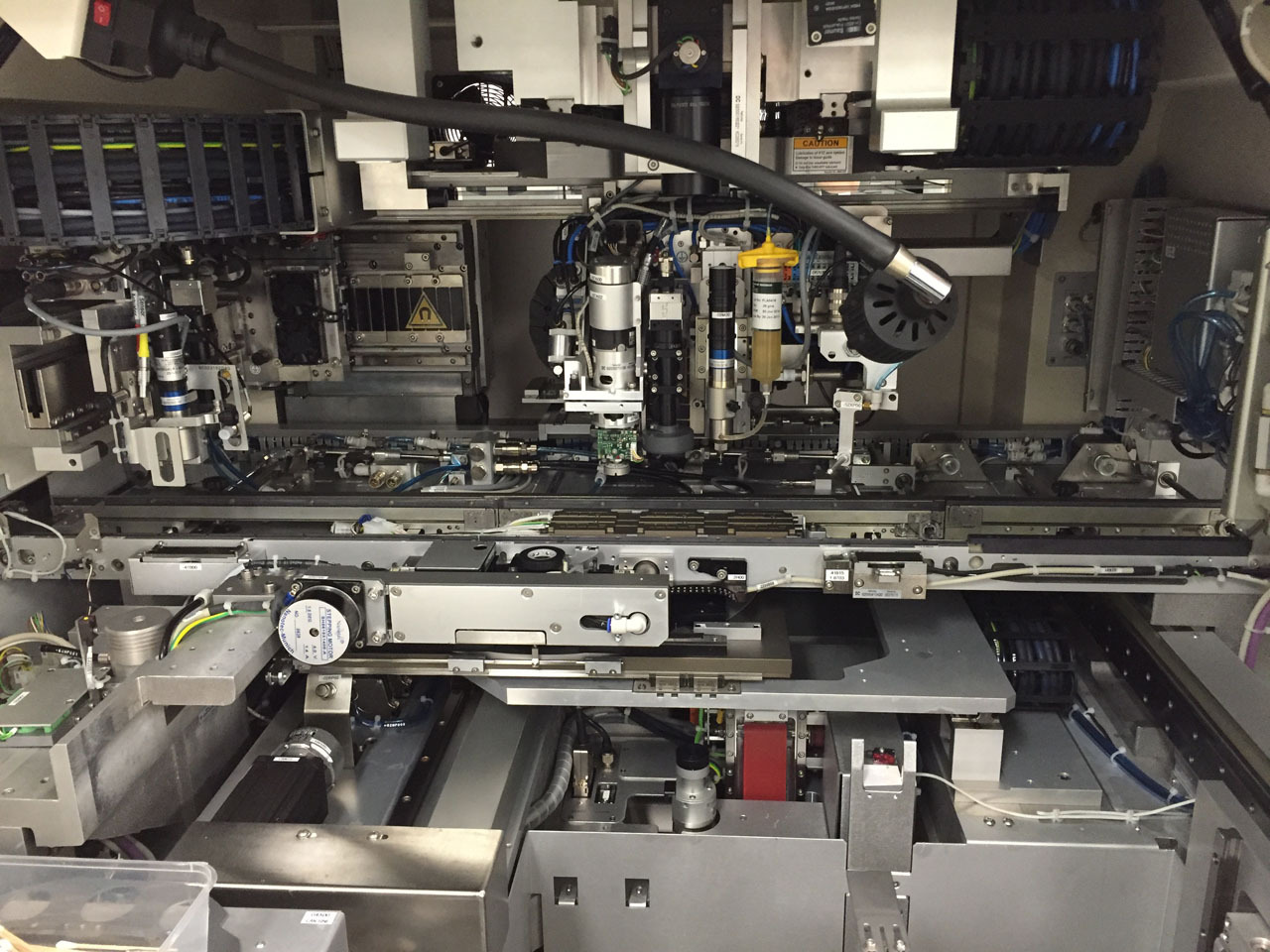

Used DATACON / BESI 2200 Evo #9115929 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9115929

Wafer Size: 8"

Vintage: 2008

Die attacher, 8"

In-line SMEMA configuration

Hard disk upgraded to SSD

Spare parts included

Equipment module:

Dynamic XYZ theta servo motors: yes

Theta axis rotary bond-head: yes

Programmable lighting systems with RGB light: yes

Datacon pattern recognition system with edge, pattern, and ink-dot recognition:

Programmable

IPU

CMOS Substrate camera/optics/illumination: Yes

Upward looking camera: Yes

Downward looking camera: Yes

Wafer camera: Yes

Programmable bond force (up to 7000 grams): Yes

Bond force sensor and mini-BMC kit: Yes

Ionizer:

Main axis: Yes

Substrate transport system:

Current transport system configuration:

Heated stage of up to 150 DC temperature

Flatboat configuration

BETS (Belt Elevation TS)

Belt classic transport system:

BETS

Component presentation system:

Wafer lifter and changer: Yes

Wafer table with stretcher: Yes

Additional frame down-holding application for 8" and 12" wafer:

Adaptor for 8"

Wafer frame adapter for automatic change: Yes

Wafer ring adapter for automatic change: Hoop ring adaptor

Waffle pack (Gel pack) holder 2":

Waffle pack adaptor

Separate gel-pack adaptor

Waffle pack (Gel pack) holder 4":

Waffle pack adaptor

Separate gel-pack adaptor

Tape and reel presentation: No

SEMS / GEMS Compliant: Capable but not activated

Input / Output system:

Magazine handler:

SMEMA Ready

I/O equipment: No

Die handling system:

Automatic tool changer unit 7-slot: Yes

Tool holders and tools:

Standard tool holder (shank and tip): Yes

Ejector system:

Single-chip ejector unit: Yes

Upgrade to multi-chip ejection carousel: Yes

Eject tool base: Yes

Needle kit: No

Epoxy application system:

Dispenser-pressure/time:

Time / Pressure

Volumetric pump

Epoxy stamping system:

Time / Pressure

Volumetric pump

Auger or positive displacement:

Configured based on solar product

Flip chip station

Automatic tool changer:

(7) Slots

Die attach

Flip chip capability

ID Axis

Jetter system: Yes

Built-in vacuum pump: Disconnected, but available

Heated stage (150°C): Yes

Vision system with up and down looking cameras

Placement accuracy: 10 µm (3 sigma)

Programmable bond force (7000 grams)

Die pick from wafer, waffle pack, gel pack - Wafer up to 12” with 8" adapter

Waffle pack / Gel-Pak® 2” x 2” and 4” x 4”

Substrate working range: 8"

ID Integrated dispenser for classic transport system

Dispenser volumetric screw pump (ID Axis)

P-Part for automatic transport system (for ID axis)

Calibration tool kit: No

208V/220V Power compatibility: 3Phase - 400V

Machine software installation disk: No

Integrated dispenser

Vision alignment

Pick & place head

X / Y Placement accuracy: ± 7 μm @ 3s

Theta placement accuracy: ± 0.15° @ 3s

Die attach: Disconnected

Heated bond head and plate

Standard bond head: 0° - 360° Rotation

Equipment operating and maintenance manual or CD-ROM: Yes

CE Marked

Currently crated

2008 vintage.

DATACON / BESI 2200 Evo is a die attacher designed to offer precision placement of parts during the manufacturing process. This equipment uses an advanced laser-guided vision system and several servomotor-driven motors to accurately place each part. Its high throughput and velocity make it capable of quickly assembling large numbers of parts while maintaining the highest quality. BESI 2200 Evo is an automated die attacher designed to handle all types of components, including bare dies, MEMs devices, flip chips, and various other products in various package types. The unit is composed of several major components, including control unit, motion machine, mechanical pick-and-place unit, vision tool, and pick up systems. The control asset is responsible for controlling the motors and other actuators and also offers communication with a host computer. The motion model is composed of two servo motors that allow for fine movement and accuracy. The mechanical pick-and-place provides great precision via the precision of five motor axes. The card-picker mechanism ensures accurate placement of components from standard 13" full grids to individual components. The vision equipment uses a machine vision camera to detect the presence of components, determine positions, and perform precision alignment. Lastly, the pick-up system is composed of electromagnets that allow for picking of components with either force fields or vacuum cups. The high throughput of DATACON 2200 Evo is greatly increased by the integrated micro-teaching module. Operators can quickly teach the machine exact paths and location coordinates, utilizing the coordinate unit and teaching rig of the laser-guided vision machine. These paths can then be reproduced within extremely tight tolerances when the machine is given a go signal based on the coordination tool. In order to ensure the highest quality standards, 2200 Evo features multiple sensors that keep track of every step taken in the assembly process. This includes things like temperature and vibration, allowing for complete monitoring of the asset. Quality control systems also check for product consistency upon completion of assembly. Overall, DATACON / BESI 2200 Evo is an effective and efficient die attacher designed to offer the highest level of precision and speed in parts placement. By utilizing advanced laser-guided vision systems and various automation components, BESI 2200 Evo is able to quickly and accurately produce high volumes of parts with the utmost care and consistency.

There are no reviews yet