Used DATACON / BESI 2200 Evo #9316015 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9316015

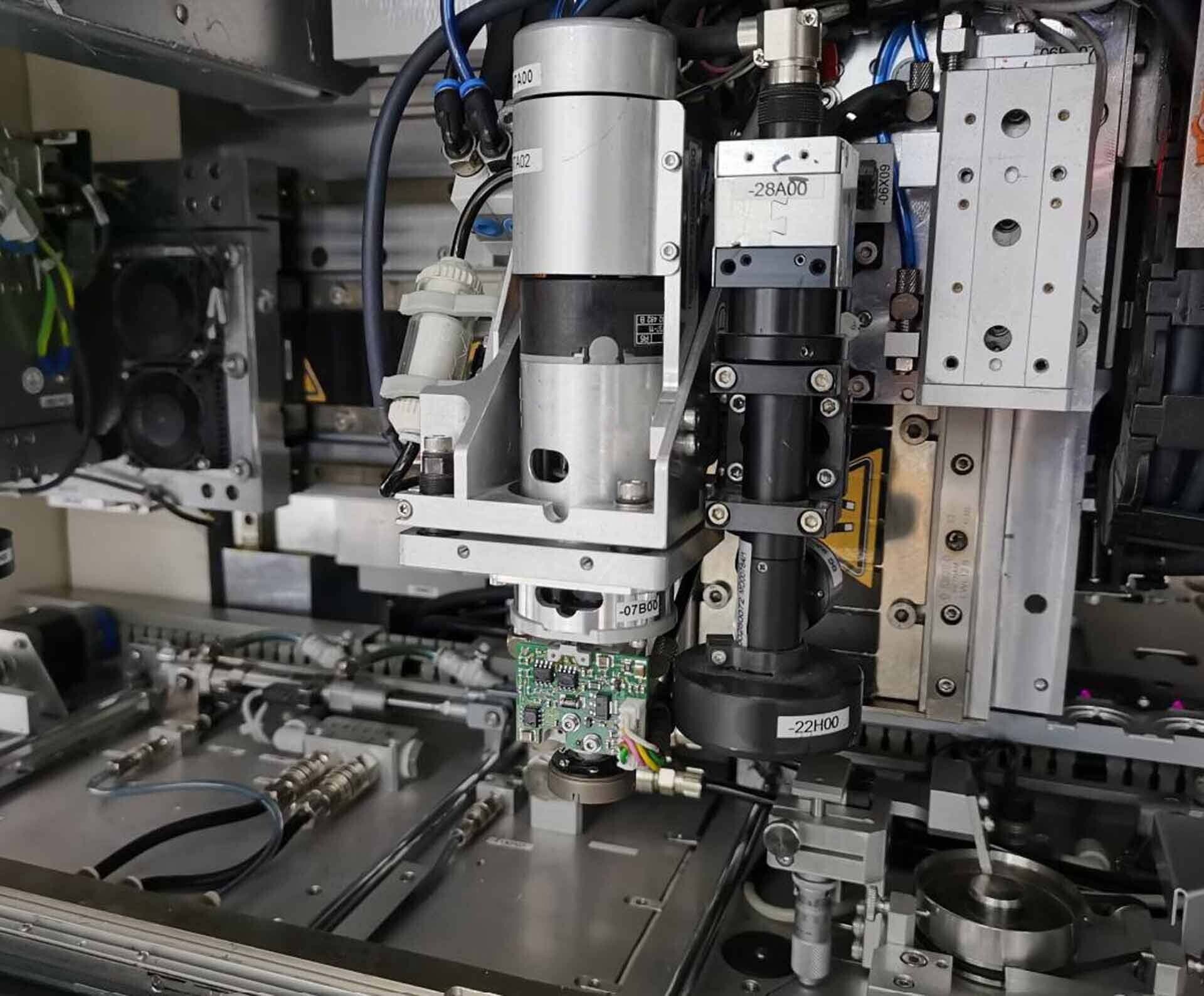

Multi-chip die bonder

With high accuracy and high productivity

Dynamic XYZ theta servo motors

Pattern recognition system

With edge, pattern, ink-dot recognition

Programmable lighting systems with RGB light

Capability: 10 µm at 3s

CMOS Substrate camera / Optics / Illumination

Camera

Wafer camera

Transport system

Bond force sensor and Mini-BMC kit

CD-ROM

Theta axis rotary bond head

Theta range: 0°-360°

Resolution: 0.0045°

Options:

DC1278 / Input buffer

DC1528 / Output buffer

DC2008 / Wafer table without stretcher

DC2308 / Wafer lift include wafer changer

DC4308 / Automatic tool changer unit, (7) slots, 7-nozzle position

DC6008 / Integrated dispenser for classic transportation system

DC1188 / MUSASHI Dispenser super sigma CMII for ID-Axis

DC5008 / Single chip ejector unit

DC5108 / Upgrade to multi-chip ejection carousel

DC7708 / Ionizer (Main axis) ion fan

DC7918 / Connection kit (Tubes, fittings, cables)

DC7948 / Calibration kit

DC8008 / SECS / GEM Capability communication protocol

- / Stamping squeegee unit (Main slider behind)

- / IPT Unit (Main slider front).

DATACON / BESI 2200 Evo die attacher is an advanced and versatile machine used for attaching dies to circuit boards in the electrical engineering industry. This type of die attaching machine was developed as an improvement on past methods. It is used to embed a wafer or die onto a substrate using a mix of localized heat and pressure. It is this combination of heat and pressure that allows for reliable and accurate die attachment. BESI 2200 Evo has a modular design, allowing for its customization and versatility. The platform is constructed with a vacuum-manipulated pallet system that can be tailored to specific attachment processes. This allows the machine to quickly and safely place dies and components onto boards with precise accuracy. It also enables the user to quickly change between different die and wafer sizes, allowing for a wide range of applications. The technical components of the attacher are designed for ease of use and maintenance. The heated head is thermally-integrated into the housing for quick warm-up and cool down times. The temperature can also be closely monitored and controlled. Additionally, the joystick controls and LED readouts allow users to quickly manipulate the platform and accurately monitor the process. This ensures a reliable and safe die-attaching process. Furthermore, DATACON 2200 Evo has both pneumatic and electrical implementation options. Its modern design includes capabilities for both pre- and post-fire feedback control systems. These systems allow for instantaneous adjustments to yield a highly accurate and reliable attachment process. The pneumatic system controls the air pressure and volume of the attachment, while the electrical system encompasses components such as the feeder, encoder, and the die head. Finally, the attacher has its own software that is designed to help the user customize and modify the attachment process to their needs. The software allows them to program the machine's positioning and firing parameters. It offers a robust user interface and comprehensive trouble-shooting capabilities. The software is also capable of creating detailed machine logs that provide a comprehensive record of the attacher's operation and performance. Overall, 2200 Evo is a highly advanced and versatile die attacher that allows electrical engineers to quickly and reliably attach dies to circuit boards. Its modular design, thermal-integrated head, customizable software and feedback control systems make it a superior choice for the electrical engineering industry.

There are no reviews yet