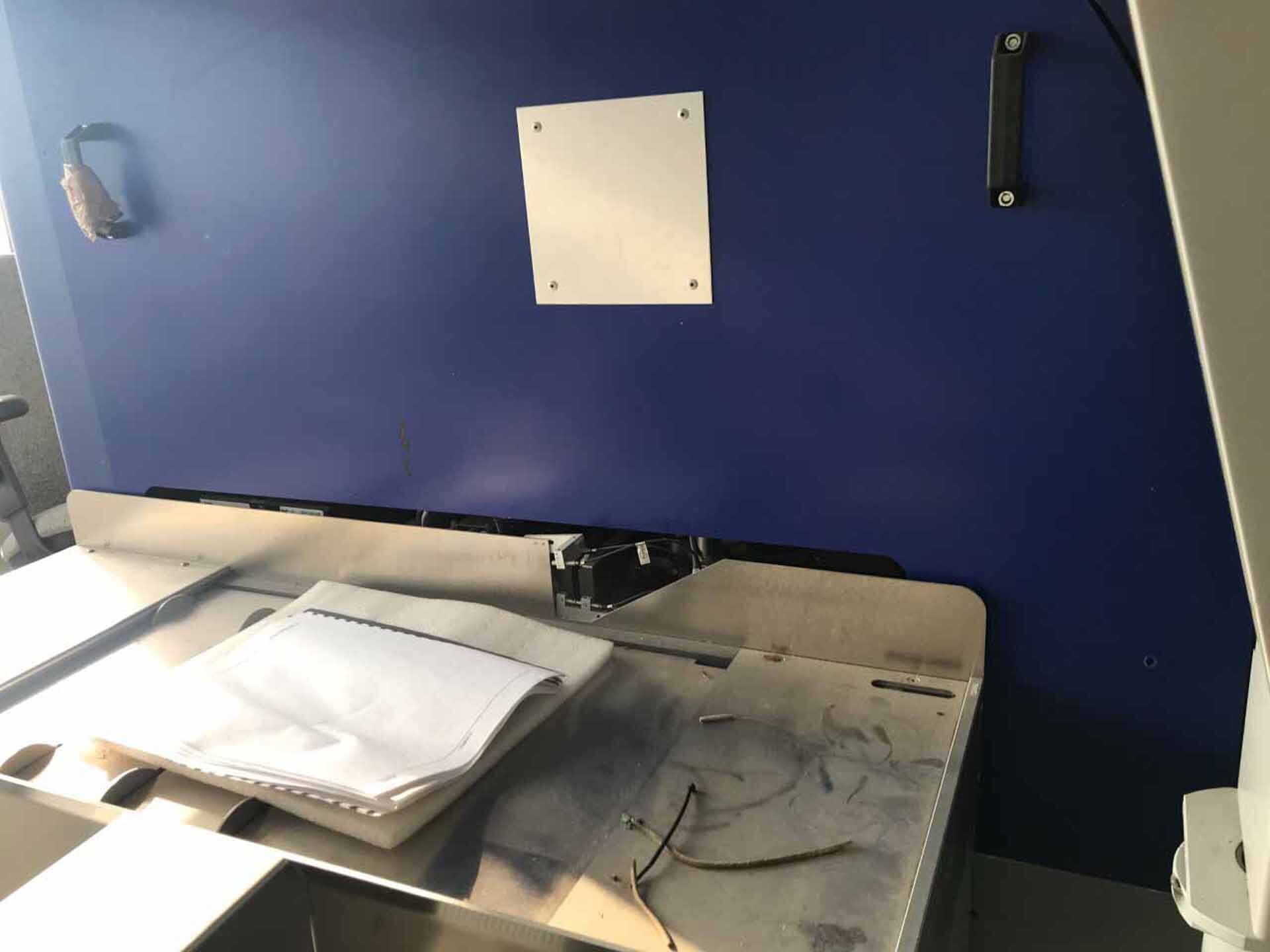

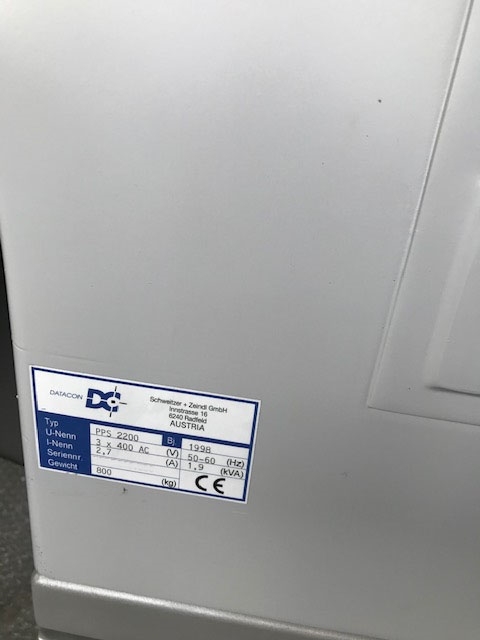

Used DATACON / BESI 2200 PPS #9285090 for sale

URL successfully copied!

Tap to zoom

DATACON / BESI 2200 PPS is a die attach process equipment designed for packaging electronic components onto printed circuit boards. It uses a ceramic paste that is melted and applied to the substrate material, followed by the controlled application of a precise amount of die over the paste. This process results in a more reliable and uniform bond that is less prone to cracking, delamination, and other issues that can affect the quality of the final product. The system features a base station and a controller that are both PC-based with optional network compatibility. The unit is configurable with programmable refill systems and various controlled thermal profiles. This allows the operator to customize each process step and ensure optimum performance. The controller of BESI 2200 PPS has a graphical user interface (GUI) that is both intuitive and easy to use. The GUI allows the operator to program parameters into the machine and monitor its performance. In addition, the user-friendly touch screen ensures that even a novice operator can quickly gain the necessary knowledge to use the tool with accuracy and speed. DATACON 2200 PPS offers enhanced process control to ensure consistent results. It gives the operator access to a range of self-adjusting parameters to troubleshoot problems if needed. It also features a diagnostic asset with alarm notification for easier maintenance. The model is also equipped with an automated vision equipment that utilizes a digital camera to detect and compensate for component orientation errors. This system allows the user to quickly and easily make corrections in real-time, ensuring that every die and component is placed correctly in the process. 2200 PPS is designed to be a flexible and cost-effective solution for the assembly of electronic components on circuit boards. It features efficient setup, operation, and maintenance with its intuitive controls and user-friendly design. This unit is suitable for any PCB assembly process and offers the user a reliable and consistent result.

There are no reviews yet