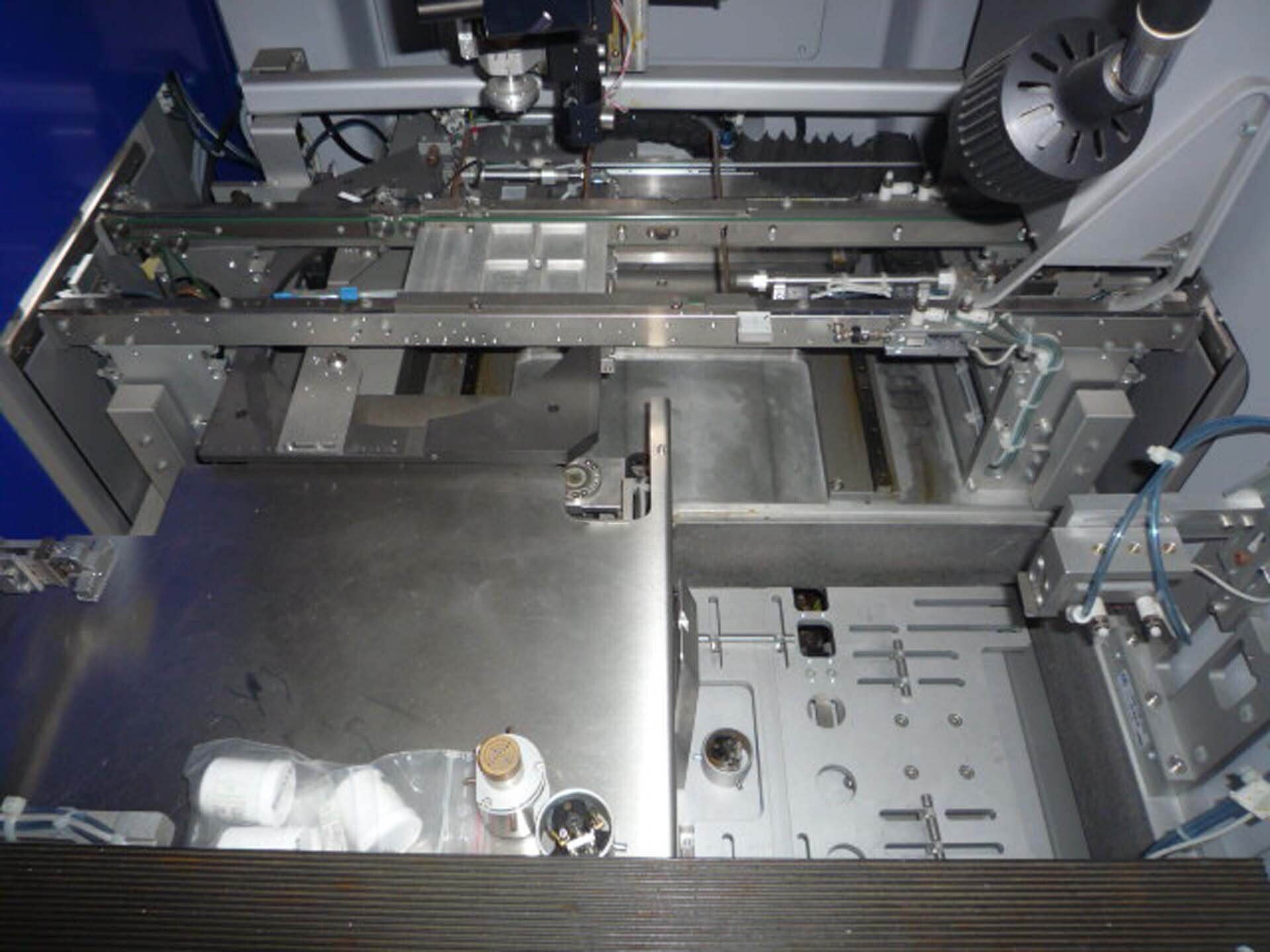

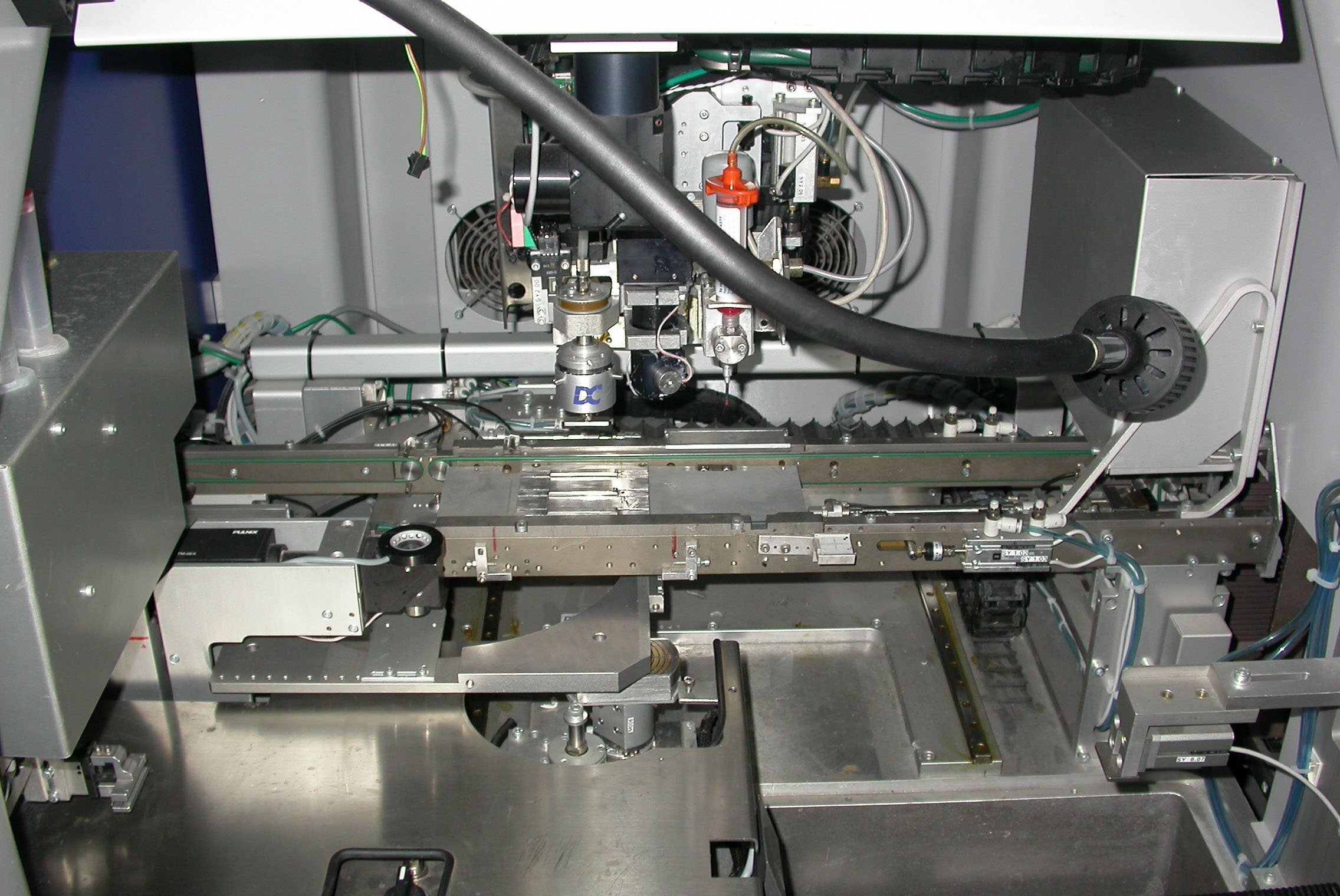

Used DATACON / BESI 2210 PPS #9299955 for sale

URL successfully copied!

Tap to zoom

ID: 9299955

Wafer Size: 8"

Vintage: 2000

Die bonder, 8"

Chip size: 0.2 to 20 mm

Chip thicknesses: >0.15 mm

Frame size up to 10"

Substrate size maximum: 255 x 203 x 30 mm

Component height maximum: 30 mm

Maximum number of bonding points / Single module: (100) Per chip type

Maximum number of single modules / Substrate: (100) With free programming

Maximum number of single substrates / Transport unit: (300) Dispensers

Data storage:

Internal hard disk, 3.5"

External disk drive, 3.5”

Missing parts:

PNP Tool bank

Tool changer

Power supply: 400 V, 50 Hz

2000 vintage.

DATACON / BESI 2210 PPS (Positive Placement Equipment) is a die attach system that is designed to deliver high accuracy and throughput for high yield die attaching applications. This unit includes both a base and a tooling head for individual die placement. BESI 2210 PPS is designed to attach different sizes of die, from a width of 12.5 to 50mm and a length of 8 to 100mm. The machine can be effectively utilized for attaching semiconductor die to substrates such as chip carriers, lead frames, flex circuitry, etc. DATACON 2210 PPS can operate up to 5,000 die per hour with an accuracy of ±15µm. Its base is designed to handle a variety of products with a maximum substrate size of 300 X 450mm. It features a high-resolution X/Y/Z axis for individual die placement and automated vision alignment. The tooling head uses positive pressure to accurately and reliably place each die in its correct position. The tool is designed to also feature attachment of multiple die to a single substrate. The media board of 2210 PPS is capable of mounting a wide variety of different die. These boards feature an adjustable spring pressure control, which ensures that the die is properly placed and adjusted before attachment. Additionally, the asset offers a wide range of die attach materials such as CSP and flip-chip die attach materials, solder paste, and epoxy die attach materials. The model also includes in-line production tools such as vision inspection and solder reflow. The vision inspection tool is capable of checking for correct placement, alignment, and die count, while the solder reflow tool enables standardized rework processes for repairing defective die. The equipment also features built-in programs for both die attach and post placement inspection. DATACON / BESI 2210 PPS is a versatile die attach system and is ideal for high-volume die pick and place applications. It is capable of handling wide varieties of substrates, as well as a wide selection of die attach materials. Its flexibility, accuracy, and high throughput make it ideal for high yield production lines.

There are no reviews yet