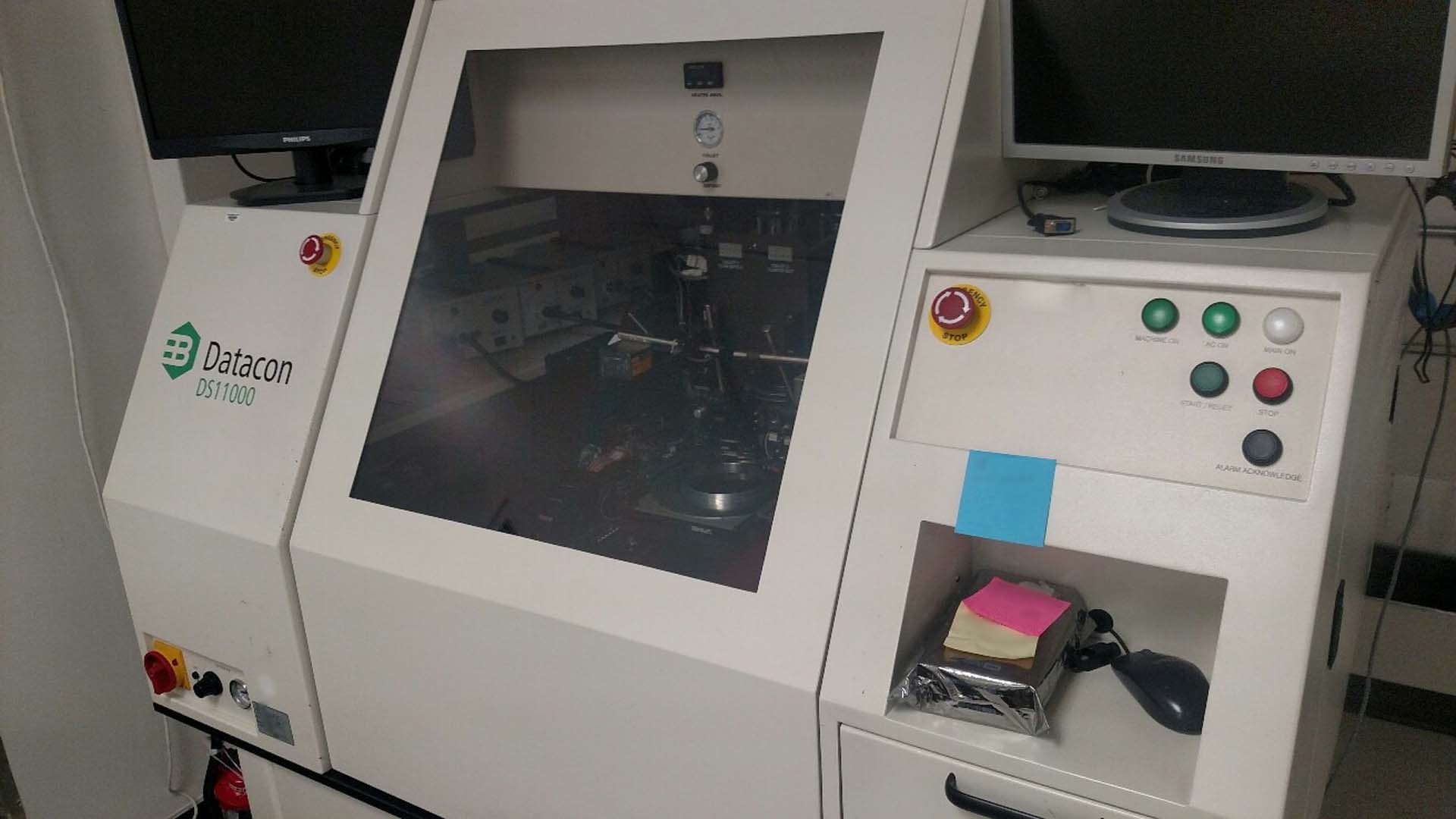

Used DATACON / BESI DS 11000 #9240933 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9240933

Die sorter

Power cord without plug included

Tape frame / Hoop ring

Dicing tape head

With servo amplifier

Input table for wafer, 6"

With motorized rotation and wafer expansion

Furnace:

Double layer steel case

With (2) cooling fans

Low surface temperature

Fibrous alumina liner and insulation

AI2O3 Coating

Wafer:

Table tooling

Stage camera and optics

Frame barcode reader

Cassette elevator and loader

Digital vacuum detection

Product specific tools:

(5) Needles and vacuum anvil assemblies

(5) Pairs of vacuum pickup tool

Adaptive map correlation

Pick & place: 11000 UPH

Placement accuracy: ±37μ @ 3s

Sort up to (37) Bins with single cassette / (148) Bins with multi cassette

Wafers up to input & output, 8"

LED Size: 0.2 mm - 1 mm

Servo Z motors for independant pick and place motion

Digital vacuum detection

Air ionizer mounted over the input table

Vision system for wafer alignment

Die pick

Die placement and inspection

Wafer cassette elevator and loader

Wafer frame barcode reader

Wafer stage camera and optics

Wafer table tooling for one size wafer frame

Output:

Film frame elevator and loader

Table camera and optics

Frame barcode reader

Internet network interface: TCP / IP

Electronic map import

Operating system: Windows XP

With PC controller

Temperature range:

100°C~1100°C (Continuous)

1200°C (<1 Hour)

Heating rate: ≤ 20°C /min

Temperature accuracy: ±1°C

Heating element: FeCrAl Alloy doped by Mo

Heating zone length:

(2) Zones, 8" (200 mm)

Total heating zone length: 16" (400 mm)

Tube accessories:

Fused QUARTZ tube: 1000 mm L

(2) Fibrous ceramic tube blocks

Power: 3 KW (20 A Breaker)

Power supply: AC 208-240 V, Single Phase, 50/60 Hz.

DATACON / BESI DS 11000 is a die attacher that ensures accurate accuracy and repeatability when attaching semiconductor dice to substrates in a variety of forms, including glass, silicon, and flexible circuits. The equipment is designed for delicate process steps and can handle a variety of die sizes, up to 28 mm x 28 mm. The die attach process is carried out with a pick-and-place head and the heat source for bonding the die is provided by an integrated heater plate fitted to the head. The system is optimized for large-scale production processes, with an advanced motion control unit that allows multiple dispensing programs to run simultaneously to ensure fast throughput. The digital amplifier and laminar gap control technology help to ensure precise placement and repeatable results, while the fine-tune and real-time monitoring features allow for a perfect match between die size and application. BESI DS 11000 also features a patented vacuum head that ensures a secure grip of the die along with an integrated laser vision machine to both inspect the die before and after attachment. An integrated surface mapping tool guarantees a flat and uniform die attach, while the force-displacement monitor verifies the process. The asset also features a single-pass vacuum and high-accuracy thermocouple metrology to ensure accurate heating control. DATACON DS 11000 is part of BESI Production Line, together with fully automated die sorters and wafer handlers. The Building Block Technology allows users to easily integrate with multiple equipment modules to reduce setup time and process stress. The user-friendly software interface makes the model easy to use and maintain, and the low maintenance requirements make it extremely cost-effective. DS 11000 is the ideal solution for mass production applications requiring precision and reliability.

There are no reviews yet